Oil & Gas Production Handbook: Introduction to Industry Processes

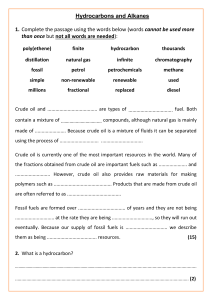

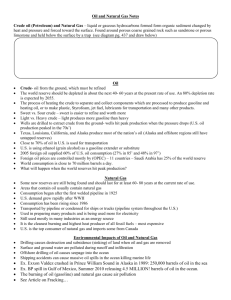

advertisement