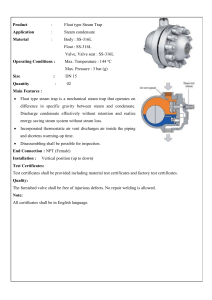

Shell - DEP 30.75.10.10 - Steam, Condensate and Boiler Feed Water Systems

advertisement