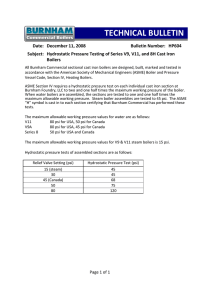

PDHonline Course M398 (3 PDH) __________________________________________________________________________ ASME Section I & Section VIII Fundamentals 2012 PDH Online | PDH Center 5272 Meadow Estates Drive Fairfax, VA 22030-6658 Phone & Fax: 703-988-0088 www.PDHonline.org www.PDHcenter.com Approved Continuing Education Provider www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Contents: 1.0 - INTRODUCTION 2.0 – ASME SECTION I & SECTION VIII – Fundamentals 3.0 – ASME SECTION I – POWER BOILERS: Types, Design, Fabrication, Inspection & Repair 4.0 – ASME SECTION VIII – Division 1, Division 2, Division 3 5.0 – ASME SECTION I: Dished Heads Formulae 6.0 – ASME SECTION VIII – DIVISION 1: Dished Head Formulae 7.0 - ASME SECTION VIII – Main Scopes 8.0 – ASME SECTION VIII – Shell Nozzles 9.0 – ASME SECTION II - Materials 10.0 – ASME SECTION VIII – DIVISION 1: Suplementary Design Formulae 11.0 – ASME SECTION VIII – DIVISION 1: Hydrostatic Pressure Tests 12.0 - ASME Section VIII - Rules for Construction of Pressure Vessels 55 ©2012 Jurandir Primo 2 de www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 1.0 - INTRODUCTION: The ASME Code design criteria consist of basic rules specifying the design method, design loads, allowable stress, acceptable materials, fabrication, testing, certification, and inspection requirements. The design method known as "design by rule" defined in ASME Section VIII - Division 1 uses design pressure, allowable stress and a design formula compatible with the geometry to calculate the minimum required thickness of pressurized tanks, vessels and pipes. The ASME - American Society of Mechanical Engineers - International Boiler and Pressure Vessel Code is made of 12 sections and contains over 15 divisions and subsections. 1.1 - Code Sections: I. Power Boilers II. Materials III. Rules for Construction of Nuclear Facility Components IV. Heating Boilers V. Nondestructive Examination VI. Recommended Rules for the Care and Operation of Heating Boilers VII. Recommended Guidelines for the Care of Power Boilers VIII. Pressure Vessels IX. Welding and Brazing Qualifications X. Fiber-Reinforced Plastic Pressure Vessels XI. Rules for In-service Inspection of Nuclear Power Plant Components XII. Rules for Construction and Continued Service of Transport Tanks SECTION I - Power Boilers: This Section provides requirements for all methods of construction of power, electric, and miniature boilers; high temperature water boilers used in stationary service; and power boilers used in locomotive, portable, and traction service. SECTION II – Materials: Part A - Ferrous Material Specifications Part B - Nonferrous Material Specifications Part C - Specifications for Welding Rods, Electrodes, and Filler Metals Part D - Properties SECTION III - Rules for Construction of Nuclear Facility Components: This Subsection contains appendices, both mandatory and non-mandatory for Section III, Division 1 (Subsection NCA through NG) and Division 2, including a listing of design and design analysis methods and information, and Data Report Forms. Includes the “NV” (Nuclear Safety and Pressure Relief Valves), Section II, Part A, Ferrous Materials, Part B, Nonferrous Materials, Part D, Properties, Customary or Metric and “N3” (N-Type Certificates of Authorization and Certificates of Accreditation). Subsection NCA - General Requirements for Divisions 1 and 2 DIVISION 1 Subsection NB- Class 1 Components Subsection NC- Class 2 Components ©2012 Jurandir Primo 3 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Subsection ND- Class 3 Components Subsection NE- Class MC Components Subsection NF - Supports Subsection NG - Core Support Structures Subsection NH - Class 1 Components in Elevated Temperature Service DIVISION 2 Code for Concrete Containments DIVISION 3 Containments for Transportation and Storage SECTION IV - Heating Boilers: Requirements for design, fabrication, installation and inspection of steam generating boilers, and hot w ater boilers intended for low pressure service that are directly fired by oil, gas, electricity, or coal. It contains appendices which cover approval of new material, methods of checking safety valve, safety relief valve capacity, definitions relating to boiler design and welding and quality control systems. SECTION V - Nondestructive Examination: Requirements and methods for nondestructive examination which are referenced and required by other code Sections. It also includes manufacturer's examination responsibilities, duties of authorized inspectors and requirements for qualification of personnel, inspection and examination. SECTION VI - Recommended Rules for the Care and Operation of Heating Boilers: It defines general descriptions, terminology and guidelines applicable to steel and cast iron boilers limited to the operating ranges of Section IV Heating Boilers. It includes guidelines for associated controls and automatic fuel burning equipment. SECTION VII - Recommended Guidelines for the Care of Power Boilers: Guidelines to promote safety in the use of stationary, portable, and traction type heating boilers. The section provides guidelines to assist operators of power boilers in maintaining their plants as safely as possible. These guidelines contains fuels for routine operation; operating and maintaining boiler appliances; Inspection and prevention of boiler failure; design of installation; operation of boiler auxiliaries; control of internal chemical conditions. SECTION VIII - Pressure Vessels: Division 1 - Provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Division 2 - Alternative rules, provides requirements to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Division 3 - Alternative rules for Construction of High Pressure Vessels, provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures generally above 10,000 psi. ©2012 Jurandir Primo 4 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org SECTION IX - Welding and Brazing Qualifications: Rules relating to the qualification of welding and brazing procedures as required by other Code Sections for component manufacture. Covers rules are related to the qualification and re-qualification of welders and welding and brazing operators in order that they may perform welding or brazing as required by other Code Sections in the manufacture of components. SECTION X - Fiber-Reinforced Plastic Pressure Vessels: Requirements for construction of FRP (Fiber-Reinforced Plastic) pressure vessels in conformance with a manufacturer's design report. It includes production, processing, fabrication, inspection and testing methods required. SECTION XI - Rules for In-service Inspection of Nuclear Power Plant Components: Requirements for the examination, in-service testing and inspection, and repair and replacement of components and systems in light-water cooled and liquid-metal cooled nuclear power plants. SECTION XII - Rules for Construction and Continued Service of Transport Tanks: Requirements for construction and continued service of pressure vessels for the transportation of dangerous goods via highway, rail, air or water at pressures from full vacuum to 3,000 psig and volumes greater than 120 gallons. 1.2 - The ASME-ANSI B31 Codes: ASME B31 was earlier known as ANSI B31. The B31 Code for Pressure Piping, covers Power Piping, Fuel Gas Piping, Process Piping, Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids, Refrigeration Piping and Heat Transfer Components and Building Services Piping. Piping consists of pipe, flanges, bolting, gaskets, valves, relief devices, fittings and the pressure containing parts of other piping components. It also includes hangers and supports, and other equipment items necessary to prevent overstressing the pressure containing parts. It does not include support structures such as frames of buildings, buildings stanchions or foundations. B31.1 - 2001 - Power Piping: Required piping for industrial plants and marine applications. This code prescribes requirements for the design, materials, fabrication, erection, test, and inspection of power and auxiliary service piping systems for electric generation stations, industrial institutional plants, central and district heating plants. The code covers boiler external piping for power boilers and high temperature, high pressure water boilers in which steam or vapor is generated at a pressure of more than 15 PSIG; and high temperature water is generated at pressures exceeding 160 PSIG and/or temperatures exceeding 250 degrees F. B31.2 - 1968 - Fuel Gas Piping: Withdrawn as a National Standard and replaced by ANSI/NFPA Z223.1, but B31.2 is still available from ASME and is a good reference for the design of gas piping systems (from the meter to the appliance). B31.3 - 2002 - Process Piping: Code rules for design of chemical, petroleum plants, refineries, hydrocarbons, water and steam. This Code contains rules for piping typically found in petroleum refineries; chemical, pharmaceutical, textile, paper, semiconductor, and cryogenic plants; and related processing plants and terminals. ©2012 Jurandir Primo 5 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org It prescribes requirements for materials and components, design, fabrication, assembly, erection, exam ination, inspection, and testing of piping. Also included is piping which interconnects pieces or stages within a packaged equipment assembly. B31.4 - 2002 - Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids: This Code prescribes requirements for the design, materials, construction, assembly, inspection, and testing of piping transporting liquids such as crude oil, condensate, natural gasoline, natural gas liquids, liquefied petroleum gas, carbon dioxide, liquid alcohol, liquid anhydrous ammonia and liquid petroleum products between producers' lease facilities, tank farms, natural gas processing plants, refineries, st ations, ammonia plants, terminals (marine, rail and truck) and other delivery and receiving points. The requirements for offshore pipelines are found in Chapter IX, and included within this scope are: Primary and associated auxiliary liquid petroleum and liquid anhydrous ammonia piping at pipeline terminals (marine, rail and truck), tank farms, pump stations, pressure reducing stations and m etering stations, including scraper traps, strainers, and proper loops; Storage and working tanks including pipe-type storage fabricated from pipe and fittings, and piping interconnecting these facilities; Liquid petroleum and liquid anhydrous ammonia piping located on property which has been set aside for such piping within petroleum refinery, natural gasoline, gas processing, ammonia, and bulk plants; Those aspects of operation and maintenance of liquid pipeline systems relating to the safety and protection of the general public, operating company personnel, environment, property and the piping systems. B31.5 - 2001 - Refrigeration Piping and Heat Transfer Components: This Code prescribes requirements for the materials, design, fabrication, assembly, erection, test, and inspection of refrigerant, heat transfer components, and secondary coolant piping for temperatures as low as -320 °F (-196 °C), whether erected on the premises or factory assembled, except as specifically excluded in the following paragraphs. Users are advised that other piping Code Sections may provide requirements for refrigeration piping in their respective jurisdictions. This Code shall not apply to: Any self-contained or unit systems subject to the requirements of Underwriters Laboratories or other nationally recognized testing laboratory: Water piping and piping designed for external or internal gage pressure not exceeding 15 psi (105 kPa) regardless of size; or Pressure vessels, compressors, or pumps, but does include all connecting refrigerant and secondary coolant piping starting at the first joint adjacent to such apparatus. B31.8 - 2003 - Gas Transmission and Distribution Piping Systems: This Code covers the design, fabrication, installation, inspection, and testing of pipeline facilities used for the transportation of gas. This Code also covers safety aspects of the operation and maintenance of those facilities. It includes gas transmission, appurtenances for transporting gas; gas storage equipment fabricated from pipe and fittings; and gas storage lines. B31.8S-2001 - 2002 - Managing System Integrity of Gas Pipelines: This Standard applies to on-shore pipeline systems constructed with ferrous materials and that transport gas. Pipeline system means all parts of physical facilities through which gas is transported, including ©2012 Jurandir Primo 6 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org pipe, valves, appurtenances attached to pipe, compressor units, metering stations, regulator stations, delivery stations, holders and fabricated assemblies. The principles and processes are applicable to all pipeline systems. This Standard is specifically designed to provide the operator (as defined in section 13) with the information necessary to develop and implement an effective integrity management program utilizing proven industry practices and processes. The processes and approaches within this Standard are applicable to the entire pipeline system. B31.9 - 1996 - Building Services Piping: This Section has rules for the piping in industrial, institutional, commercial and public buildings, and multiunit residences, which does not require range of sizes, pressures, and temperatures covered in B31.1. This Code prescribes requirements for the design, materials, fabrication, installation, inspection, exam ination and testing of piping systems for building services. It includes piping systems in the building or within the property limits. B31.11 - 2002 - Slurry Transportation Piping Systems: Rule for design, construction, inspection and security requirements of slurry piping systems. This code covers piping systems that transport aqueous slurries of no hazardous materials, such as coal, mineral ores and other solids between a slurry processing plant and the receiving plant. It also covers piping transporting liquids, tank farms, natural gas processing plants, refineries, pump stations, ammonia plants, terminals (marine, rail, and truck), and other delivery and receiving points. B31G - 1991 - Manual for Determining Remaining Strength of Corroded Pipelines: The scope of this Manual includes all pipelines within the scope of the pipeline codes that are part of ASME B31 Code for Pressure Piping, ASME B31.4, Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum Gas, Anhydrous Ammonia, and Alcohols; ASME B31.8, Gas Transmission and Distribution Piping Systems; and ASME B31.11, Slurry Transportation Piping Systems. Parts 2, 3, and 4 are based on material in ASME Guide for Gas Transmission and Distribution Piping Systems, 1983 Edition. 1.3 - ASME Certification and Inspection Procedures: The symbols "A", "S", "U", "PP" and "H" Stamps covers the fabrication and alteration of high pressure boilers, unfired pressure vessels, power piping and heating boilers. Once an ASME Stamped Pressure Vessel is manufactured, it is checked, tested and approved by the ASME Authorized Inspector, who review all the procedures and all documentation and sign the Data Report Form before the procedure to stamp the name plate with the “U” or “UM” symbols, which means that the Pressure Vessel fully complies with the ASME Code rules for construction of Pressure Vessels. The National Board of Boiler & Pressure Vessel Inspectors uses the “NB” Symbol as well the “R” Symbol to repair or to alter any previous Stamped Pressure Vessel. All material used in manufacture must be documented. All welders must be certified. Manufacturers have an Authorized Inspector, who is the judge of code acceptability. The quality of weld is then checked for lack of weld penetration, slag inclusion, overlap and excessive reinforcement. At the final inspection the units are hydrostatically tested at 1.5 times working pressure and observed for leaks. 1.4 – Imperial and Metric Values: Professionals and students should be well versed in conversion practice. Many US customary unit values presented in the ASME codes do not convert directly into metric values in the ASME editions. ©2012 Jurandir Primo 7 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 2.0 – ASME SECTION I & SECTION VIII – Fundamentals: The formulae in ASME Section I and Section VIII are used to determine the minimum required thickness and design pressure of piping, tubes, drums and headers using the Maximum Allowable Working Pressure (MAWP). However, Paragraph UG-31 states, that these formulae may be also used for calculating wall thickness of tubes and pipes under internal pressure. 2.1 – Design: The ASME Boiler Code Section I, as well as Section VIII, requires longitudinal and circumferential butt joints to be examined by full radiograph. When the vessel design is required fully radiographed longitudinal butt-welded joint, the cylindrical shell will have a joint efficiency factor (E = 1.0). This factor corresponds to a safety factor (or material quality factor) of 3.5 in the parent metal. When the vessel design is required non-radiographed longitudinal butt-welded joints the vessel will have a joint efficiency factor (E = 0.7, which corresponds to a safety factor of 0.5 in., resulting in an increase of 43% in the thickness of the plates. 2.2 – Pressure Vessels Maximum Allowable Stress Values: The maximum allowable stress values to be used in the calculation of the vessel’s wall thickness are given in the ASME Code for many different materials. These stress values are a function of temperature. Maximum Allowable Stress Value for Common Steels Material Carbon Steel Plates and Sheets High Alloy Steel Plates DIVISION 1 -20°F to 650°F 13,800 15,000 16,300 17,500 DIVISION 2 -20°F to 650°F 18,300 20,000 21,700 23,300 SA - 203 Grade A Grade B Grade D Grade E 11,300 12,500 13,800 12,700 16,300 17,500 16,300 17,500 15,000 16,700 18,300 16,900 21,700 23,300 21,700 23,300 SA - 240 Grade 304 Grade 304L Grade 316 Grade 316L 11,200 12,300 10,200 20,000 16,700 20,000 16,700 Spec. Nbr Grade SA - 516 Grade 55 Grade 60 Grade 65 Grade 70 SA - 285 Grade A Grade B Grade C SA - 36 Division 1: Governs the design by “Rules”, is less stringent from the standpoint of certain design details and inspection procedures, and thus incorporates a higher safety factor of 4. For example, if a 60,000 psi tensile strength material is used, the Maximum Allowable Stress Value is 15,000 psi. Division 2: Governs the design by “Analysis" and incorporates a lower safety factor of 3. Thus, the maximum allowable stress value for a 60,000 psi tensile strength material will become 20,000 psi. ©2012 Jurandir Primo 8 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Many companies require that all their pressure vessels be constructed in accordance with Division 2 because of the more exacting standards. Others find that they can purchase less expensive vessels by allowing manufacturers the choice of either Division 1 or Division 2. Normally, manufacturers will choose Division 1 for low-pressure vessels and Division 2 for highpressure vessels. The maximum allowable stress values at normal temperature range for the steel plates most commonly used in the fabrication of pressure vessels are given in Table above. 3.0 – ASME SECTION I - POWER BOILERS: Types, Design, Fabrication, Inspection & Repair: Provides requirements for construction of power, electric, and miniature boilers; high temperature water boilers used in stationary service; and power boilers used in locomotive, portable, and traction service. Rules allow the use of the V, A, M, PP, S and E symbol stamps. The rules are applicable to boilers in which the steam is generated at pressures exceeding 15 psig, and high temperature water boilers for operation at pressures exceeding 160 psig and/or temperatures exceeding 250 °F. This code covers Power Boiler Superheaters, Economizers, and other pressure parts connected directly to the boiler without intervening valves are considered as part of the scope of Section 1. 3.1 – ASME SECTION I – Boiler Tubes up to and including 5 inches O.D. (125 mm): a) The minimum required thickness, according to ASME paragraph PG-27.2.1, use equation below: b) To calculate the Maximum Allowable Working Pressure (MAWP): Where: t = Minimum Design Wall Thickness (in); P = Design Pressure (psi); D = Tube Outside Diameter (in); e = Thickness Factor (0.04 for expanded tubes; 0 = for strength welded tubes); S = Maximum Allowable Stress According to ASME Section II, Table 1A. Example 1 - Boiler Tube: Calculate the minimum required wall thickness of a water tube boiler 2.75 in O.D., strength welded (E, or, e = 0) into place in a boiler. The tube has an average wall temperature of 650°F. The Maximum Allowable Working Pressure (MAWP) is 580 psi gauge. Material is carbon steel SA-192. Note: Before starting calculations check the correct stress table in ASME Section II, Table 1A: Consider SA-192 = 11,800 psi – allowable stress – Div. 1. ©2012 Jurandir Primo 9 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Solution: For tubing up to and including 5 in O.D., use equation 1.1 above. P = [580 psi] D = [2.75 in] e = 0 (strength welded) S = [11,800 psi] at [650°F]) t= 2.75 x 580 2 (11,800) + 580 + 0.005 (2.75) + 0 t = 0.079 in. Note: Where the manufacturing processes produce only standard plate thickness, so should be used 1/8 in (3.2 mm) minimum. 3.2 – ASME SECTION I – Piping, Drums, and Headers: The following formulae are found in ASME Section I, paragraph PG-27.2.2. The information for piping, drums, or headers may be given with either the inside I or outside D measurements. a) Using the outside diameter: b) Using the inside radius: Where: t = Minimum Design Wall Thickness (in); P = Design Pressure (psi); D = Tube Outside Diameter (in); R = Tube Radius (in); E = Tube Welding Factor (1.0 for seamless pipe; 0.85 = for welded pipe); y = Wall Thickness Welding Factor (0.4 for 900°F & lower; 0.7 for 950°F & up); C = Corrosion Allowance (0 for no corrosion; 0.0625 in. commonly used; 0.125 in. maximum); S = Maximum Allowable Stress According to ASME Section II, Table 1A. ©2012 Jurandir Primo 10 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 2 – Steam Piping: Calculate the required minimum thickness of a seamless steam piping at a pressure of 900 psi gauge and a temperature of 700°F. The piping is 10.77 in O.D., (10 inches nominal) plain end; the material is SA-335 – P1, alloy steel. Allow a manufacturer’s tolerance allowance of 12.5%. Note: Before starting calculations check the material stress table in ASME Section II, Table 1A: SA-335 – P1 = 13,800 psi – allowable stress – Div.1. Use equation 2.1: P = [900 psi] D = [10.77 in] C=0 S = [13,800] – (SA-335 – P1 alloy steel at 700°F) E = 1.0 y = 0.4 (Ferritic steel less than 900°F) t= 900 x 10.77………. + 0 = t = 0.34 in. 2(13,800) (1.0) + 2(0.4) (900) Therefore, including a manufacturer’s allowance of 12.5%; 0.34 × 1.125 = 0.38 in. Example 3 – Maximum Allowable Working Pressure (MAWP): Calculate the Maximum Allowable Working Pressure (MAWP) for a seamless steel pipe of material SA209-T1. The outside pipe diameter is 12.75 in. (nominal diam. 12 in.) with a wall thickness of 0.46 in. The operating temperature is 850°F. The pipe is plain ended. D = 12.75 in (outside diameter); t = 0.46 in; C = 0 (3 to 4 inches nominal and larger); S = 13,100 psi (Section II, Table 1A, Div.1, SA-209-T1 at 850°F); E = 1.0 (seamless pipe as per PG-9.1); y = 0.4 (austenitic steel at 850°F). Use equation 2.2: P= 2SE (t – C) = D – (2y) (t – C) P = 2 (13,100) (1.0) x (0.46 – 0) = 12.75 – (2 x 0.4) (0.46 – 0) P = 26,200 x 0.46 = 12.75 – 0.368 P = 973 psi ©2012 Jurandir Primo 11 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 4 – Welded Tube Boiler Drum: A welded water tube boiler drum of SA-515-60 material is fabricated to an inside radius of 18.70 in. on the tube sheet and 19.68 in on the drum. The plate thickness of the tube sheet and drum are 2.34 in. and 1.49 in., respectively. The longitudinal joint efficiency is 100%, and the ligament efficiencies are 56% horizontal and 30% circumferential. The operating temperature is not to exceed 500°F. Determine the Maximum Allowable Working Pressure (MAWP) based on: Welded Water Tube Boiler Drum: DRUM & TUBESHEET Note: This is a common example of a water tube drum fabricated from two plates of different thickness. Thicker material is required where the boiler tubes enter the drum than is required for a plain drum. This example has two parts: c) The drum – consider the drum to be plain with no penetrations. d) The tube sheet – consider the drum to have penetrations for boiler tubes. (a) Drum. Use equation 2.4 (inside radius R): Where: S = 15,000 psi (Section II, Table 1A, Div.1, SA-515-60 at 500°F); E = 1.0; t = 1.49 in; C = 0; R = 19.68 in; y = 0.4 (ferritic steel less than 900°F). Drum – P = (15,000) (1.0) (1.49 – 0).. = 19.68 + (1 – 0.4) (1.49 – 0) Drum – P = 15,000 x 1.49 19.68 + 0.894 Drum – P = 1,086 psi (b) Tube Sheet. Use equation 2.4 (inside radius R): ©2012 Jurandir Primo 12 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org S = 15,000 psi; E = 0.56 (circumferential stress = 30% and longitudinal stress = 56%; therefore = 0.56 < 2 x 0.30); t = 2.34 in; C = 0 (3 to 4 inches nominal and larger); R = 18.70 in; y = 0.4 (Ferritic steel less than 900°F). Tube Sheet – P = (15,000) (1.0) (2.34 – 0)… = 18.70 + (1 – 0.4) (2.34 – 0) Tube Sheet – P = 15,000 x 2.34 18.70 + 1.404 Tube Sheet – P = 1,746 psi Note: Consider the Maximum Allowable Working Pressure (MAWP) = 1,086 psi (lowest number). 4.0 – ASME SECTION VIII – Division 1, Division 2, Division 3: The ASME Section VIII, rules for fired or unfired pressure vessels, is divided into three divisions to provide requirements applicable to the design, fabrication, inspection, testing, and certification. The formulae and allowable stresses presented in this sketch are only for Division 1, the main code. It contains mandatory and non-mandatory appendices detailing supplementary design criteria, nondestructive examination and inspection acceptance standards. Rules pertaining to the use of the U, UM and UV Code symbol stamps are also included. 4.1 – SECTION VIII - Thin Cylindrical Shells: The formulae in ASME Section VIII, Division 1, paragraph UG-27, used for calculating the wall thickness and design pressure of pressure vessels, are: a) Circumferential Stress (longitudinal welds): When, P < 0.385SE: (R = Internal Radius) b) Longitudinal Stress (circumferential welds): When, P < 1.25SE (R = Internal Radius) ©2012 Jurandir Primo 13 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 5 – Thin Cylindrical Shells: A vertical boiler is constructed of SA-515-60 according to Section VIII-1. It has an internal diameter of 96 in. and an internal design pressure of 1,000 psi at 450 F°. The corrosion allowance is 0.125 in., and joint efficiency is E = 0.85. Calculate the required thickness of the shell. (Consider SA-515-60 = 15,000 psi – allowable stress, ASME Section II, Table 1A, Div.1). Since P < 0.385SE = P < 6,545 psi. Thus, as 1,000 psi < 6,545 psi, use equation 1.3: t= PR… + C SE – 0.6P Considering the internal radius = (48 in.) and corrosion allowance = 0.125 in. t= 1,000 x 48 …………. + 0.125 = 2(15,000)(0.85) – 0.6(1,000) t = 2.052 in. 4.2 – SECTION VIII - Thick Cylindrical Shells: For internal pressures higher than 3,000 psi, special considerations as specified in paragraph U-1 (d). As the ratio of t/R increases beyond 0.5, an accurate equation is required to determine the thickness. The formulae in ASME Appendix 1, Supplementary Design Formulas used for calculating thick wall and design pressure, are: a) For longitudinal welds: When, P > 0.385SE: And: b) For circumferential welds: When, P > 1.25SE: And: ©2012 Jurandir Primo 14 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Where: R = Design Radius (in.): Z = Dimensionless Factor. Example 6 – Thick Cylindrical Shells: a) When P > 0.385SE: Calculate the required shell thickness of an accumulator with a design pressure of P = 10,000 psi, R = 18 in., S = 20,000 psi, and E = 1.0. Assume a corrosion allowance of 0.125 in. Since P > 0.385SE = P > 7,700 psi. Thus, as 10,000 psi > 7,700 psi, use equation 1.7: t = R (Z ½ - 1) = Z = (20,000)(1.0) + 10,000 = 30,000 = 3 (20,000)(1.0) – 10,000 10,000 ½ t = (18) (3 – 1) + 0.125 = 8.08 in. Example 7 – Thick Cylindrical Shells: b) When P < 0.385SE: Calculate the required shell thickness of an accumulator with a design pressure of P = 7,650 psi, R = 18 in., S = 20,000 psi, and E = 1.0. Assume corrosion allowance = 0. Since P< 0.385SE = P < 7,700 psi. Thus, as 7,650 psi < 7,700 psi, use equation 1.3: t= PR… + C SE – 0.6P t= 7,650 x 18………… + 0 (20,000)(1.0) – 0.6(7,650) t = 8.9 in. Example 8 – Comparison between Equation 1.3 and Equation 1.7: Calculate the shell thickness, comparing the equation 1.3 with another answer using equation 1.7. t = R (Z ½ - 1) = Z = (20,000)(1.0) + 7,650 = 27,650 = 2.24 (20,000)(1.0) – 7,650 12,350 t = (18 + 0) (2.24 ½ - 1) = 8.9 in. This shows that the “simple use” of equation (1.3) is accurate over a wide range of R/t ratios. ©2012 Jurandir Primo 15 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 4.3 – ASME I and ASME-ANSI B31 – Pressure Piping - Minimum Wall Thickness: According to ASME Section I and ANSI B31, the minimum thickness of piping under pressure is: Where: t (min)= Minimum wall thickness required (in); P = Design pressure (psig); D = Outside diameter of pipe (in); S = Allowable stress in pipe material (psi); E = Longitudinal joint factor - E = 1.0 for seamless pipe, E = 0.85 for ERW pipe; C = Corrosion allowance, typically 0.05 in. y = Wall thickness coefficient in ASME Table 304.1.1 for ferritic steels, where: y = 0.4 for T<= 900 ºF; y = 0.5 for 900< T <= 950 ºF; y = 0.7 for 950 < T <= 1000 ºF. 4.4 – ASME SECTION VIII – Reinforcement Wall Thickness Plate: The standard design method uses an increased wall thickness plate at the equator line of the vessel to support the additional stresses caused by the attachment of the legs. The formula for calculation the wall thickness of a segmented plate of to be welded in a vessel or spherical shell is: t= PL…… + C 2SE – 0.2P L = Di/2 Where: t = Minimum Design Wall Thickness (in); P = Design Pressure (psi); Di = Inside Diameter of Sphere (in); L = Sphere Radius (in); E = Tube Welding Factor (1.0 for seamless pipe; 0.85 = for welded pipe); C = Corrosion Allowance (0 for no corrosion; 0.0625 in. commonly used; 0.125 in. maximum); S = Maximum Allowable Stress According to ASME Section II, Table 1A. 5.0 – ASME SECTION I: Dished Heads Formulae: Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the knuckle is created under the flanging method. Flanged and dished heads can be formed in a size range from 4 in to 300 in diameter and in thickness range of 14 Gauge to 1-1/2” thick. Pressure vessel heads and dished ends are essentially the same – the end caps of a pressure vessel tank or an industrial boiler, supplied with a flanged edge to make it easier for the fabricator to weld the head to the main body of the tank. ©2012 Jurandir Primo 16 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 5.1 – Blank, Unstayed Dished Heads: Paragraph PG-29.1 states that the thickness of a blank, unstayed dished head with the pressure on the concave side, when it is a segment of a sphere, shall be calculated by the following formula: Where: t = Minimum thickness of head (in); P = maximum allowable working pressure (psi); L = Concave side radius (in); S = Maximum Allowable Working Stress (psi). Paragraph PG-29.2 states: “The radius to which the head is dished shall be not greater than the outside diameter of the flanged portion of the head. Where two radii are used, the longer shall be taken as the value of L in the formula.” Example 9 – Segment of a Spherical Dished Head: Calculate the thickness of a seamless, blank unstayed dished head having pressure on the concave side. The head has an inside diameter of 42.7 in. with a dish radius of 36.0 in. The Maximum Allowable Working Pressure (MAWP) is 360 psi and the material is SA-285 A. The temperature does not exceed 480°F. State if this thickness meets Code. (Solution: Use equation 1.11) P = 360 psi; L = 36.0 in; S = 11,300 psi – SA-285 A at 480°F. t = 5 (360 x 36) = 4.8 (11,300) t = 1.19 in. PG-29.6 states: “No head, except a full-hemispherical head, shall be of a lesser thickness than that required for a seamless pipe of the same diameter.” Then, the minimum thickness of piping is: y = 0.4 - ferritic steel < 900°F; E = 1.0 - (See Section I) t= 360 x 42.7 = 2(11,300)(1.0) + 2 (0.4)(360) t = 0.67 in. The calculated head thickness meets the code requirements, since 1.19 > 0.67. ©2012 Jurandir Primo 17 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 10 - Segment of a Spherical Dished Head with a Flanged-in Manhole: Calculate the thickness of a seamless, unstayed dished head with pressure on the concave side, having a flanged-in manhole 6.0 in x 16 in. Diameter head is 47.5 in with a dish radius of 45 in. The MAWP is 225 psi, the material is SA-285-C, and temperature does not exceed 428°F. First thing to check: is the radius of the dish is at least 80% of the diameter of the shell? Dish Radius = 45 = 0.947 > 0.8 – The radius of the dish meets the criteria, use equation 1.11: Shell Diameter 47.5 P = 225 psi; L = 45 in; S = 13,800 psi (450°F - use the next higher temperature). t = 5 (225 x 45) = 4.8 (13,800) t = 0.764 in. This thickness is for a blank head. According to ASME - PG-29.3 requires this thickness to be increased by 15% or 0.125 in., whichever is greater. As 0.764 × 0.15 = 0.114 in., that is less than 0.125 in., then, the thickness must be increased by 0.125 in. Then, the required head thickness is, t = 0.764 + 0.125 = ~0.90 in. 5.2 - Seamless or Full-Hemispherical Head: The thickness of a blank, unstayed, full-hemispherical head with the pressure on the concave side shall be calculated by the following formula: t = Minimum thickness of head (in) P = Maximum Allowable Working Pressure (psi) L = Radius to which the head was formed (in) S = Maximum Allowable Working Stress (psi) Note: The above formula shall not be used when the required thickness of the head given by the formula exceeds 35.6% of the inside radius. Instead, use the following formula: ©2012 Jurandir Primo 18 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 11 - Seamless or Full-Hemispherical Head: Calculate the minimum required thickness for a blank, unstayed, full-hemispherical head. The radius to which the head is dished is 7.5 in. The MAWP is 900 psi and the head material is SA 285-C. The average temperature of the header is 570°F. Solution: Use equation 1.13. P = 900 psi; L = 7.5 in.; S = 13,800 psi - (SA 285-C at 600°F). t= 900 x 7.5 = 0.24 in. 2 (13,800) – 0.2 (900) Check if this thickness exceeds 35.6% of the inside radius = 7.5 x 0.356 = 2.67 in. It does not exceed 35.6%, therefore the calculated thickness of the head meets the code requirements. 6.0 – ASME SECTION VIII – DIVISION 1: Dished Head Formulae: The ASME Section VIII – Division 1 determines the rules for dished heads. The most common configurations are spherical, hemispherical, elliptical (or ellipsoidal) and torispherical shapes. How the shapes are, make some confusion for beginners and even professionals users of ASME Section VIII. To cast a little light on these subjects see the resume below: Semi-Elliptical Heads (2:1) Torispherical Heads Elliptical or Ellipsoidal Heads (1.9:1) Flanged and Dished Heads Dished Discs Toriconical Heads Spherical or Hemispherical Heads Flat Dished Heads Non Standard 80-10 Dished Heads ©2012 Jurandir Primo 19 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 6.1 - Spherical or Hemispherical Heads: a) When t < 0.356R or P < 0.665SE - (Thin Spherical or Hemispherical Heads): And, Example 12 - Thin Spherical or Hemispherical Head: A pressure vessel is built of SA-516-70 material and has an inside diameter of 96 in. The internal design pressure is 100 psi at 450°F. Corrosion allowance is 0.125 in. and joint efficiency is E = 0.85. Calculate the required spherical head thickness of the pressure vessel if “S” is 20,000 psi? Since P > 0.665SE = P > 11,305 psi. Thus, as 11,305 > 100 psi, use equation 2.1. The inside radius in a corroded condition is equal to, R = 48 + 0.125 = 48.125 in. t= t= PR = 2SE – 0.2P 100 x 48.125 = 2(20,000) (0.85) – 0.2(100) t = 0.14 in. Example 12.1 - Thin Spherical or Hemispherical Head: A spherical pressure vessel with an internal diameter of 120 in has a head thickness of 1 in. Determine the design pressure if the allowable stress is 16,300 psi. Assume joint efficiency E = 0.85. No corrosion allowance is stated to the design pressure. Using t = 1.0 in., then t < 0.356R = 1.0 in. < 21.3 in., use equation 2.2. P= 2SEt = R + 0.2t P = 2(16,300)(0.85)(1) = 60 + 0.2(1) P = 460 psi The calculated pressure 460 psi is < 0.665SE (9213 psi); therefore, equation 2.2 is acceptable. a) When t > 0.356R or P > 0.665SE – (Thick Spherical or Hemispherical Heads): ©2012 Jurandir Primo 20 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org And, Example 13 - Thick Hemispherical Head: Calculate the required hemispherical head thickness of an accumulator with a design pressure of P = 10,000 psi, R = 18.0 in, S = 15,000 psi, and E = 1.0. Corrosion allowance is 0.125 in. Since P > 0.665SE = P > 9975 psi. Thus, as 9975 psi < 10,000 psi, use equation 2.3. Y = 2 [(15,000)(1.0) + 10,000] = 2 [(15,000)(1.0)] – 10,000 Y = 50,000 = 2.5 20,000 t = R (Y1/3 – 1) = 18.0 (2.51/3 – 1) + 0,125 = 6.5 in. 6.2 – Elliptical or Ellipsoidal Heads - Semi-Elliptical or Semi-Ellipsoidal Heads – 2:1: The commonly used semi-ellipsoidal head has a ratio of base radius to depth of 2:1 (shown below). The actual shape can be approximated by a spherical radius of 0.9D and a knuckle radius of 0.17D. The required thickness of 2:1 heads with pressure on the concave side is given below: ©2012 Jurandir Primo 21 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 14 - Elliptical or Ellipsoidal Heads, or, SemiElliptical or Semi-Ellipsoidal Heads – 2:1: Calculate a semi-elliptical head thickness considering the dimensions given below: Inside Diameter of Head (Di): 18.0 in; Inside Crown Radius (L): (18.0 x 0.9Di) in; Inside Knuckle Radius (ri): (18.0 x 0.17Di) in; Straight Skirt Length (h): 1.500 in.; Radius L - (18.0 x 0.9Di) = 16.20 in.; Radius ri - (18.0 x 0.17Di) = 3.06 in. Material and Conditions: Material: SA-202 Gr. B (Room Temperature); Internal Pressure: 200 psi; Allowable Stress: 20,000 psi; Head Longitudinal Joint Efficiency: 0.85; Corrosion Allowance: 0.010 in. Variable: L/r = L/ri = 16.20/3.06 = 5.29 in a) Required Thickness. (Formula 2.5): t= PD + corrosion allowance 2SE – 0.2P t= 200 x 18.0 + 0.010 2(20,000)(0.85) – 0.2(200) t = 0.116 in. ©2012 Jurandir Primo 22 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org b) Maximum Pressure: P = 2SEt = D + 0.2t P = 2(20,000)(0.85)(0.116) = 18 + 0.2 (0.116) P = 219 psi. Note: Ellipsoidal heads and all torispherical heads having materials with minimum tensile strength > 80,000 psi shall be designed using a value of S = 20,000 psi at room temperature (see UG-23). 6.3 - Torispherical Heads: Shallow heads, commonly referred to as flanged and dished heads (F&D heads), are according to paragraph UG-32 (e), with a spherical radius L of 1.0D and a knuckle radius r of 0.06D. a) Flanged & Dished Head (F&D heads): The dish radius of a Flanged and Dished Head is 1.0 D and the knuckle radius is 0.06% D. The required thickness of a Torispherical F&D Head with r/L = 0.06 and L = Di, is: And, Where: P = Pressure on the concave side of the head; S = Allowable stress; t = Thickness of the head; L = Inside spherical radius; E = Joint efficiency factor. Example 15 - Torispherical Heads: A drum is to operate at 500°F and 350 psi and to hold 5000 gallons of water. The inside radius of the Dished Torispherical Heads is 78 in. The material is SA 285 Grade A. Assume “S” = 11,200 psi and “E” = 0.85. Solution: Dished Torispherical Heads with L = Di and r/L = 0.06, use equation 2.7. t = 0.885 PL = SE – 0.1P t= 0.885 (350) (78) = 2.54 (11,200)(0.85) – 0.1(350) ©2012 Jurandir Primo 23 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org b) Non Standard 80-10 Flanged & Dished Head: On an 80-10 the inside radius (L) is 0.8 Di and the knuckle radius (ri) is 10% of the head diameter. For the required thickness of a Non Standard 80-10 Head, use equations 2.7 and 2.8. Designing 8010 Torispherical Heads rather than standard shapes can be achieved by lowering the material costs. The 80-10 is typically only 66% the thickness of the standard Torispherical Heads. 6.4 – Conical or Toriconical Heads: The required thickness of the Conical or Toriconical Head (knuckle radius > 6% OD) shall be determined by formula using internal diameter of shell, α ≤ 30º. t= PD 2 (SE - 0.6P) cos α 2.9 L = Di / (2 cos α); Di = Internal Diameter (conical portion) = D - 2 r (1 - cos α); r = Inside Knuckle Radius. 6.5 - Toriconical Heads Definitions: ©2012 Jurandir Primo 24 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 7.0 - ASME SECTION VIII – Main Scopes: • Objective: Minimum requirements for safe construction and operation, Division 1, 2, and 3. • Section VIII Division 1: 15 psig < P 3000 psig • Other exclusions: – Internals (except for attachment weld to vessel) – Fired process heaters – Pressure containers integral with machinery – Piping systems • Section VIII, Division 2, Alternative Rules: 15 psig < P 3000 psig - identical to Division 1, but the different requirements are: – Allowable stress – Stress calculations – Design – Quality control – Fabrication and inspection The choice between Divisions 1 and 2 is based mainly on economics of materials. • Division 3, Alternative Rules - High Pressure Vessels: Applications over 10,000 psi; Pressure from external source, process reaction, application of heat, combination of these; Maximum pressure limits for Division 1 or 2 or minimum limits for Division 3, not established. 7.1. Structure of ASME Section VIII, Division 1: Subsection A: Part UG applies to all vessels; Subsection B: Requirements based on fabrication method, Parts UW, UF, UB; Subsection C: Requirements based on material class, Parts UCS, UNF, UHA, UCI, UCL, UCD, UHT, ULW, ULT. Mandatory and Non-mandatory Appendices Determination of Material Thickness: • Yield Strength, Ultimate Tensile Strength, Creep Strength, Rupture Strength and Corrosion Resistance. Resistance to Hydrogen Attack: -Temperature at 300 - 400°F, monatomic hydrogen forms molecular hydrogen in voids; - Pressure build-up can cause steel to crack; - Above 600°F, hydrogen attack causes irreparable damage through component thickness. Brittle Fracture and Fracture Toughness: ©2012 Jurandir Primo 25 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org The conditions that could cause brittle fracture are: – Typically at “low” temperature; – Can occur below design pressure; – No yielding before complete failure; – High enough stress for crack initiation and growth; – Low enough material fracture toughness at temperature; – Critical size defect to act as stress concentration. 7.2. Material Groups – The Most Common Used Materials: Curve A: SA-216 Gr. WCB & WCC, normalized and tempered; SA-217 Gr. WC6, normalized and tempered. Curve C: SA-182 Gr. 21& 22, normalized and tempered SA-302 Gr. C & D SA-336 Gr. F21 & F22, normalized and tempered S A-3 8 7 G r. 21 & 22, normalized and tempered S A-5 1 6 G r. 55 & 60, not normalized SA-533 Gr. B & C SA-662 Gr. A Curve B: SA-216 Gr. WCA, normalized and tempered or water-quenched and tempered; SA-216 Gr. WCB & WCC for maximum thickness of 2 in. (water-quenched and tempered); SA-285 Gr. A & B; SA-414 Gr. A; SA-515 Gr. 60; SA-516 Gr. 65 & 70, not normalized. Curve D: SA-203 SA-537 Cl. 1, 2 & 3 SA-508 Cl. 1 SA-612, normalized SA-516, normalized SA 662, normalized SA-524 Cl. 1 & 2 SA-738 Gr. A Bolting: See the ASME Code Section VIII, Div. 1, for impact and nuts test for specified material specifications. Additional ASME Code Impact Test Requirements: • For welded construction over 4 in. thick, or non-welded construction over 6 in. thick, if MDMT < 120°F • Not required for flanges if temperature -20°F; required if SMYS > 65 ksi unless specifically exempt. 7.3 - Weld Joint Efficiencies, E: ©2012 Jurandir Primo 26 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 7.4 – Resume of Pressure Vessels Formulae – ASME Section I & ASME Section VIII: Item Thickness - t (in) Cylindrical Shell Hemispherical Shell (or Head) Flat Flanged Head Stress - S (in) PR SEt P(R + 0.6t) SE - 0.6P R + 0.6t t PR 2.SEt P(R + 0.2t) 2SE - 0.2P R + 0.2t 2t D√0.3P/S t²S/0.3D² 0.3D² P/t² Notes t ≤ 0.25 D; P ≤ 0.385 SE t ≤ 0.178D; P ≤ 0.685 SE r/L = 0.06; L ≤ D + 2t 0.885PL SEt P(0.885L + 0.1t) SE - 0.1P 0.885L + 0.1t t PLM 2SE - 0.2P 2.SEt LM + 0.2t P(LM + 0.2t) 2t M = 3 + (L/r)1/2 / 4 PD 2.SEt P(D + 0.2t) h/D = 4 2SE - 0.2P D + 0.2t 2t PDK 2SE - 0.2P 2.SEt DK + 0.2t P(DK + 0.2t) 2Et PD 2.SEt cos α P(D + 1.2t cos α) 2(SE - 0.6P) cos α D + 1.2t cos α 2t cos α Torispherical Head (a) Torispherical Head (b) 2:1 Semi-Elliptical Head (a) Ellipsoidal Head (b) Toriconical Head Pressure - P (in) K = [2 + (D/2h)²] / 6; 2 ≤ D/h ≤ 6 α ≤ 30° OBS.: D = Shell / Head Inside Diameter, E = Weld Joint Efficiency (0.7 -1.0), L = Crown Radius, P = Internal Pressure, h = Inside Depth of Head, r = Knuckle Radius, R = Shell/Head Inside Radius, S = Allowable Stress, t = Shell / Head Thickness. 7.5 - Common Materials - Temperature Limits: ©2012 Jurandir Primo 27 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 8.0 – ASME SECTION VIII – Shell Nozzles: Vessel components are weakened when material is removed to provide openings for nozzles or access openings. To avoid failure in the opening area, compensation or reinforcement is required. The Code procedure is to relocate the removed material to an area within an effective boundary around the opening. Figure bellow shows the steps necessary to reinforce an opening in a pressure vessel. 8.1 - Definitions: Diameter of circular opening, d: d = Diameter of Opening – 2 (Tn + Corrosion Allowance) = Required wall thickness of the nozzle (min): tn = PR...... SE – 0.6P Area of required reinforcement, Ar: Ar = d.ts.F (in²) = d =Diameter of circular opening, or finished dimension of opening in plane under consideration, in. ts = Minimum required thickness of shell when E = 1.0, in. F = Correction factor, normally 1.0 ©2012 Jurandir Primo 28 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 16 – Basic Pipe Nozzle: Basic design: Design Pressure = 300 psig Design Temperature = 200° F Shell Material is SA-516 Gr. 60 Nozzle Diameter 8 in, Sch. 40 Nozzle Material is SA-53 Gr. B, Seamless Corrosion Allowance = 0.0625" Vessel is 100% Radiographed a) Wall thickness of the nozzle (min): tn = tn = PR...... = SE – 0.6P 300 x 4.312”…….. + 0.0625 (Corrosion Allowance) 12,000(1.0) – 0.6(300) tn = 0.11” + 0.0625” = 0.17 in (min) – Pipe Sch. 40 is t = 0.32 in. b) Circular opening, d: d = Diameter of Opening – 2 (Tn + Corrosion Allowance) d = 8.625 – 2(0.32 + 0.0625) = d = 8.625 – 2 (0.3825) = 7.86 in c) Area of required reinforcement, Ar: Ar = d.ts.F (in²) = Ar = 7.86 x 0.487 x 1.0 = 3.82 in² • Available reinforcement area in shell, Ar, as larger of As or An: As = Larger of: d (T s – ts) - 2 T n (T s – ts) = As = 7.86 (0.5625 – 0,487) – 2x 0,5625 (0.5625 – 0,487) = 0.50 in² An = Smaller of: 2 [2.5 (T s) (T n – tn)] An = 2 [2.5 (0.5625) (0.32 – 0.17)] = 0.42 in² Ar < (As + An) = Ar < (0.50 + 0.42) = 0.92 in² < 3.82 in² (Reqd.) OBS.: Therefore, it´s necessary to increase Ts and / or Tn to attend the premise Ar < (As + An). ©2012 Jurandir Primo 29 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Example 17 – Basic Shell & Nozzle: Shell and Nozzle Data: Design Pressure = 700 psi Design temperature = 700 °F Nozzle Diameter = 8 in. (8.625 OD) Corrosion Allowance = 0.0625" Material: Shell – SA 516 Gr.70; Head – SA 516 Gr. 70; Nozzle – SA 106 Gr. B; E = 1.0 (weld efficiency). Required Shell Thickness: ts = ts = PR… SE – 0.6P Opening Reinforcement: 700 x 30……..... = 1.30 (Use Ts = 1 1/2”) 16,600(1.0) – 0.6(700) d = Nozzle Diameter– 2 (Tn + Corrosion Allowance) d = 8.625 – 2(1 + 0.0625) = 6.5 in. Required Head Thickness: Ar (Reqd.) = d.ts = 6.5 x 1.3 = 8.45 in² th = PR…… 2SE – 0.2P As = Larger of: d (Ts – ts) - 2 Tn (Ts – ts) = th = 700 x 30…….......... = 0.64 (Use Th = 7/8”) 2(16,600)(1.0) – 0.2(700) As = 8.625 (1.5 – 1.3) – 2 (1.0) (1.5 – 1.3) = 1.325 in² An = Smaller of: 2[2.5 (Ts) (Tn – tn)] Required Nozzle Thickness: An = 2[2.5 (1.5) (1.0 – 0.21)] = 5.925 in² tn = PR… SE – 0.6P Ar < (As + An) = tn = 700 x 4.312”……..... = 0.21 (Use Tn = 1”) 14,400(1.0) – 0.6(700) Ar < (1.325 + 5.925) = 7.25 in² < 8.45 (Reqd.) OBS.: Necessary to increase Ts and / or Tn to attend the premise (As + An) > Ar. Example 18 – Nozzle Design: ©2012 Jurandir Primo 30 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 31 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 9.0 – ASME SECTION II - Materials: The following Tables indicates the most common ferrous materials used in Pressure Vessels design and fabrication, including structural plates, pipes, tubes, castings, forgings, flanges, fittings, bolts and nuts. Beyond the knowledge of the most common ferrous materials, the Tables also help the student how to search the materials MAWP (Maximum Allowable Stress Values) in ASME Section II, Table 1A. ©2012 Jurandir Primo 32 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 9.1 - Carbon Steels: ©2012 Jurandir Primo 33 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 9.2 - Low Alloy Steels: ©2012 Jurandir Primo 34 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 9.3 – MAWP – Maximum Allowable Working Pressure - Stress Values: The ASME Section II, Part D contains properties of ferrous and nonferrous materials adopted by the Code for design of boilers, pressure-vessels, and nuclear-power-plant components including tables of the Maximum Allowable Working Pressure (MAWP) - stress values and design-stress limits for the materials adopted by various Codebook sections. The tables below are an extract from ASME for the most common ferrous materials for a design purpose. ©2012 Jurandir Primo 35 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 36 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 37 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 38 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 39 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 40 de 55 www.PDHcenter.com ©2012 Jurandir Primo PDHonline Course M398 www.PDHonline.org 41 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 10.0 – ASME SECTION VIII – DIVISION 1: Suplementary Design Formulas: Thickness of Cylindrical Shells: The following formulas, in terms of the outside radius, are equivalent and may be used instead of those formulae given in UG-27(c) and (d). For cylindrical shells (circumferential stress) the formulas can be: For spherical shells the formulas may be: Where: Ro = Outside radius of the shell under consideration, in. Thick Cylindrical Shells: (Circumferential Stress & Longitudinal Joints). When the thickness of the cylindrical shells under internal design pressure exceeds one-half of the inside radius, or when P exceeds 0.385SE, the following formulas shall apply. When P is known and t is desired. P > 0.5R or P > 0.385SE: Where: or Where: Thick Cylindrical Shells: Longitudinal Stress & Circumferential Joints). When the thickness of the cylindrical shells under internal design pressure exceeds one-half of the inside radius, or when P exceeds 1.25SE, the following formulas shall apply. When P is known and t is desired. P > 0.5R or P > 1.25SE: Where: or ©2012 Jurandir Primo Where: 42 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Thick Spherical Shells: When the thickness of the shell of a wholly spherical vessel or of a hemispherical head under internal design pressure exceeds 0.356R, or when P exceeds 0.665SE, the following formulas shall apply. When P is known and t is desired. P > 0.356R or P > 0.665SE: Where: Where: Formulas for the Design of Formed Heads Under Internal Pressure: The formulas of this paragraph provide for the design of formed heads of proportions other than those given in UG-32, in terms of inside and outside diameter. t = Minimum required thickness of head after forming, in.; P = Internal design pressure (see UG-21), psi; D = Inside diameter of the head skirt; or inside length of the major axis of an ellipsoidal head; or inside diameter of a cone head at the point measured perpendicular to the longitudinal axis, in.; Do= Outside diameter of the head skirt; or outside length of the major axis of an ellipsoidal head; or outside diameter of a cone head at the point measured perpendicular to the longitudinal axis, in.; S = Maximum allowable working stress, as given in Subsection C, psi, except as limited to 1-4(c) and (d), UG-24, UG-32(e), and UW-12; E = Lowest efficiency of any Category A joint in the head (for hemispherical heads this includes head-toshell joint). For welded vessels, use the efficiency specified in UW-12; r = Inside knuckle radius, in.; L = Inside spherical or crown radius for torispherical and hemispherical heads, in.; L = K1D for ellipsoidal heads in which K1 is obtained from Table UG-37, in.; Lo = Outside spherical or crown radius, in.; L /r = Ratio of the inside crown radius to the inside knuckle radius, used in Table 1-4.2; M = A factor in the formulas for torispherical heads depending on the head proportion L /r; h = One-half of the length of the minor axis of the ellipsoidal head, or the inside depth of the ellipsoidal head measured from the tangent line (head-bend line), in.; K = A factor in the formulas for ellipsoidal heads depending on the head proportion D/ 2h; D/2h = Ratio of the major to the minor axis of ellipsoidal heads, which equals the inside diameter of the skirt of the head divided by twice the inside height of the head, and is used in Table 1-4.1; α = One-half of the included (apex) angle of the cone at the center line of t of the head. Ellipsoidal Heads: Ellipsoidal heads designed under K > 1.0 and all torispherical heads made of materials having a specified minimum tensile strength exceeding 80,000 psi shall be designed using a value of S equal to 20,000 psi at room temperature and reduced in proportion to the reduction in maximum allowable stress values at temperature for the material as shown in the appropriate table (see UG-23). ©2012 Jurandir Primo 43 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org or Where: Numerical values of the factor K are also given in ASME VIII, Table 1-4.1. Example 1: Determine the required thickness t of a seamless ellipsoidal head, exclusive of provision for corrosion for the following conditions: D = 40 in; h = 9 in; P = 200 psi; S = 13,750 psi; E = 1.00. ©2012 Jurandir Primo 44 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org From Table 1-4.1, K p 1.14. Substituting in Eq. (1), Example 2: Determine the maximum allowable working pressure P of a seamless ellipsoidal head for the following conditions: D = 30 in.; h = 7.5 in.; total thickness = 1⁄2 in., no allowance for corrosion; maximum operating temperature = 800°F; E = 1.00. (table in Subpart 1 of Section II, Part D, S = 10,200 psi.). From Table 1-4.1, K =1.0. Substituting in Eq. (1), Torispherical Heads: or Where: (Numerical values of the factor M are also given in ASME VIII, Table 1-4.2). Example 3: Determine the required thickness t, exclusive of allowance for corrosion, of a torispherical head for the following conditions: D = 40 in.; L p 40 in.; r = 4 in.; P = 200 psi; S = 13,750 psi; E = 1.00 (seamless head). ©2012 Jurandir Primo 45 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Thus, from Table 1-4.2, M p 1.54. Substituting in Eq. (3), Example 4: Determine the maximum allowable working pressure P of a torispherical head for the following conditions: D = 30 in.; L = 24 in.; r = 2.00 in.; E = 1.00 (seamless head); total thickness = 0.5 in., no allowance for corrosion; material conforms to SA-515Grade 70; maximum operating temperature = 900°F. From the table in Subpart 1 of Section II, Part D, S = 6,500 psi. From Table 1-4.2, M p 1.62. Substituting in Eq. (3), Conical Heads: or or Note: 1) Maximum ratio allowed by UG-32(j) when L equals the outside diameter of the skirt of the head. The formulas below provide for the design of reinforcement, if needed, at the cone to cylinder junctions for conical reducer sections and conical heads where all the elements have a common axis and the halfapex angle α ≤ 30º. Subparagraph (g) below provides for special analysis in the design of cone-tocylinder intersections with or without reinforcing rings where α is greater than 30º. In the design of reinforcement for a cone-to-cylinder juncture, the requirements of UG-41 shall be met. ©2012 Jurandir Primo 46 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Nomenclature: ArL = Required area of reinforcement at large end of cone, in².; Ars = Required area of reinforcement at small end of cone, in².; AeL = Effective area of reinforcement at large end intersection, in².; Aes = Effective area of reinforcement at small end intersection, in².; Es = Modulus of elasticity of cylinder material, psi; Ec = Modulus of elasticity of cone material, psi; Er = Modulus of elasticity of reinforcing ring material, psi; E1 = Efficiency of longitudinal joint in cylinder. For compression (such as at large end of cone); E1 = 1.0 for butt welds; E2 = Efficiency of longitudinal joint in cone. For compression; E2 = 1.0 for butt welds. f1 = Axial load at large end due to wind, dead load, etc., excluding pressure, lb /in.; f2 = Axial load at small end due to wind, dead load, etc., excluding pressure, lb /in.; P = Internal design pressure (see UG-21), psi; QL= Algebraically sum of PRL /2 and f1, lb/in.; Qs = Algebraically sum of PRs /2 and f2, lb/in.; Rs = Inside radius of small cylinder at small end of cone, in.; RL = Inside radius of large cylinder at large end of cone, in.; Ss= Allowable stress of cylinder material at design temperature, psi; Sc = Allowable stress of cone material at design temperature, psi; Sr = Allowable stress of reinforcing ring material at design temperature, psi; t = Minimum required thickness of cylinder at cone-to-cylinder junction, in.; tc = Nominal thickness of cone at cone-to-cylinder junction, in.; tr = Minimum required thickness of cone at cone to-cylinder junction, in.; ts = Nominal thickness of cylinder at cone-to-cylinder junction, in.; α = Half-apex angle of cone or conical section, deg.; Δ = Angle indicating need for reinforcement at cone to-cylinder junction having a half-apex angle α ≤ 30º. When Δ ≥ α, no reinforcement is required at the junction (see Tables 1-5.1 and 1-5.2), deg.; y = Cone-to-cylinder factor; = SsEs for reinforcing ring on shell. = ScEc for reinforcing ring on cone. For a cone-to-cylinder junction, the following values shall be determined at large end and again at the small end in order that both the large end and the small end can be examined: Example 19 – MAWP (Maximum Allowable Working Pressure: The fabricator elected to use 1.00 inch plate to satisfy the design requirements and used a corrosion allowance of 0.125. What was the calculated nominal thickness of the cylindrical section? Solution: t = t (nominal) – CA t = 1.00 in. – 0.125 in t = 0.875 ©2012 Jurandir Primo 47 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Considering the formula in UG-27, where P < 0.385SE, and t < R/2. Calculate the design pressure of the shell with the following data: Material = SA 285 A, Max. Allowable Stress = 11,300 – Line No. 6 (Tab 1A); Plate Thickness, t = 0.875 in. Weld Efficiency, E = 1.0 P= SEt… = 11,300 psi(1.0)(0.875 in.) = R + 0.6t 60 in. + 0.6(0.875) P = 163.5 psi Checking condition = P < 0.385SE. Thus, 163.5 psi < 4350 psi. Then, as calculated, the MAWP (4350 psi) is much greater than the design pressure (163.5 psi). Example 20 – Thickness of a Cylindrical Shell Considering Internal Pressure: The horizontal pressure vessel above is 60 inch inside diameter, to be fabricated from SA-516 Gr. 70. The design pressure at the top of the vessel is 490 psi at 600ºF. All longitudinal joints Type 1 and spot radiographed in accordance with UW-52. Circumferential joints are Type 1 with no radiography. The vessel operates full of liquid. The density of the liquid is 62.4 lb/ft³, and the distance from the center line to the uppermost part of the vessel is 5 ft. Calculate the required thickness. Solution: As stated in UG-22, the static head of the liquid must be included in P. The design pressure is less than 0.385SE (P < 0.385SE) and t < R/2. The allowable stress for SA-516 Gr. 70, shown in Table 1A considering ASME VIII, Division 1 is 17,500 psi. Weld efficiency, spot radiographed is 0.85 for Type 1. No corrosion allowance is considered. Since P is the total pressure acting on the section and must equal 490 psi plus the static head created by 8 feet (5’ + 3’ - the total height above the section) of liquid, then: P = 490 psi + (8 ft) 62.4 lb/ft³) 144 in²/ft² P = 493.5 psi The formula for calculate the shell plate thickness is: ©2012 Jurandir Primo 48 de 55 www.PDHcenter.com t= PR… SE-06P t= 493.5 psi (30 in.)............ 17,500 psi (0.85) – 0.6 (493.5 psi) PDHonline Course M398 www.PDHonline.org t = 1.01 For this calculation is also necessary to check the stress in longitudinal direction, which is the sum of the stress due internal pressure and the bending stress. The resulting formula to be used is: SL = MRo + P(R – 04t) = IE 2Et Where Ro is the outside radius. Calculation of moments at A give a bending moment of 183,900 ft-lb. The moment of inertia, I, for a thin wall cylinder is calculated by the formula π.r³.t, where r is the mean radius of the shell. For Type 1 with no radiography, welding efficiency, E, is 0.7. Thus, the stress in lingitudinal direction becomes: SL = (183,900 ft-lb) (12 in./ft) (37.2 in.) + 493.5 psi (36 in. – 0.4 (1.01 in.) (π) (36.6)³ (1.01 in.) (0.7) (2) (0.7) (1.01) SL = 753.8 psi + 17,566.6 psi = 18,320 psi Considerations: Assume the nominal thickness of the plate, 1 1/4 inch. Check post weld heat treatment (PWHT) and preheat requirements according to ASME code. Check radiography requirement. Paragraph UCS-56, Table 56 (2): PWHT or preheat is required if thickness is greater than 1 1/4 inches nominal thickness, thus PWHT or preheat are not necessary. Paragraph UCS-57, Table 57 requires that P-Number 1 Group 2 materials be fully radiographed if the butt weld thickness is greater than 1 1/4 inch. Thus, only spot radiography is sufficient. Example 21 – Design of a Standard Torispherical Head: Calculate a seamless torispherical head with an inside crown radius equal to the outside diameter of the skirt and with 6 % knuckle radius, the vessel is fabricated to have a cylinder with the same diameter. The internal design pressure is 150 psi at 800ºF, full radiography, material SA-516 Gr. 70, corrosion allowance (CA) is 0.125. Consider, example 19, shell plate thickness = 0.875, external diameter 120 inches, S = 17,500 psi (Table 1A); E = 1.0 (UW-32). ©2012 Jurandir Primo 49 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org t = 0.885 PL = SE – 0.1P The inside crown radius (L) is equal inside diameter plus 2 times thickness of the shell, then: L = 120 in. + 2 (0.875 in.) = 121.57 t= 0.885 (150 psi) (121.57 in.)... (17,500 psi) (1.0) – 0.1 (150 psi) t = 0.93 in. + 0,125 (CA) = 1.05 in. Check the minimum knuckle radius: r = 0.06 (121.57) = 7.3 in. r(min) =3.0 (1.35 in.) = 4.05 in r > r(min). Meets requirement of UG 32. t (required) = 1 1/2 in. Thus, all welds must be Type 1, fully radiographed. PWHT and preheat required. Example 22 – Design of a Non-Standard Torispherical Head: Rework example 21, considering a nonstandard torispherical head, assuming that the inside crown radius is 80% of the skirt outside diameter and the inside knuckle radius is 10% of the skirt outside diameter. L = 0.80 [120 in. + 2 (0.875 in.)] L = 97.2 in. r = 0.10 (121.57) r = 12.15 in. t= PLM…. 2SE – 0.2P Where: M may be also obtained from ASME Section VIII, Division 1, Table 1-4.2. t= PLM…. 2SE – 0.2P t= 150 psi (97.2 in.) (1.46)........ 2 (17,500) psi) (1) – 0.2 (150 psi) t = 0.60 in. ©2012 Jurandir Primo 50 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org 11.0 – ASME SECTION VIII – UG-99 – Hydrostatic Pressure Tests: As per ASME Section VIII-1, UG-99, the pressure vessels designed for internal pressure shall be subjected to a hydrostatic test pressure which at every point in the vessel is at l east equal to 1.3 times the MAWP multiplied by the lowest ratio for the materials of which the vessel is constructed of the stress value S for the test temperature on the vessel to the stress value S for the design temperature. Ph = 1.3 MAWP x (S at test temp. / S at design temp.) = Where: Ph = Hydrostatic Test Pressure; MAWP = Maximum Allowable Working Pressure. And as per UG-100, a pneumatic test (with at least equal to 1.1 times the MAWP multiplied by the lowest ratio for the materials of which the vessel is constructed of the stress value S for the test temperature on the vessel to the stress value S for the design temperature) may be used in lieu of the standard hydrostatic test prescribed in UG-99 for vessels under certain conditions: Designed and/or supported that they cannot safely be filled with water; Not readily dried, to be used in services where traces of the testing liquid cannot be tolerated and the parts of which have, where possible, been previously tested by hydrostatic pressure to the pressure required in UG-99. Pn = 1.1 MAWP x (S at test temp. / S at design temp.) = Where: Pn = Pneumatic Test Pressure. 12.0 - ASME Section VIII - Rules for Construction of Pressure Vessels The section of the ASME BPVC consists of 3 divisions. Division 1: This division covers the mandatory requirements, specific prohibitions and non-mandatory guidance for materials, design, fabrication, inspection and testing, markings and reports, overpressure protection and certification of pressure vessels having an internal or external pressure which exceeds 15 psi (100 kPa). The pressure vessel can be either fired or unfired. The pressure may be from external sources, or by the application of heating from an indirect or direct source, or any combination thereof. The Division is not numbered in the traditional method (Part 1, Part 2 etc.) but is structured with Subsections and Parts which consist of letters followed by a number. The structure is as follows: Subsection A - General Requirements: Part UG - General Requirements for All Methods of Construction and All Materials: ©2012 Jurandir Primo 51 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Materials: UG-4 through to UG-15 Design: UG-16 through to UG-35 Openings and Reinforcements: UG-36 through to UG-46 Braced and Stayed Surfaces: UG-47 through to UG-50 Fabrication: UG-75 through to UG-85 Inspection and Tests: UG-90 through to UG-103 Marking and Reports: UG-115 through to UG-120 Overpressure Protection: UG125 through to UG-140 Subsection B - Requirements Pertaining to Methods of Fabrication of Pressure Vessels: Part UW - Requirements for Pressure Vessels Fabricated by Welding: General: UW-1 through to UW-3 Materials: UW-5 Design: UW-8 through to UW-21 Fabrication: UW-26 through to UW-42 Inspection and Tests: UW-46 through to UW -54 Marking and Reports: UW -60 Pressure Relief Devices: UW-65 Part UF - Requirements for Pressure Vessels Fabricated by Forging General: UF-1 Materials: UF-5 through to UF-7 Design: UF-12 through to UF-25 Fabrication: UF-26 through to UF-43 Inspection and Tests: UF-45 through to UF-55 Marking and Reports: UF-115 Pressure Relief Devices: UF-125 Part UB - Requirements for Pressure Vessels Fabricated by Brazing General: UB-1 through to UB-3 Materials: UB-5 through to UB-7 Design: UB-9 through to UB-22 Fabrication: UB-30 through to UB-37 Inspection and Tests: UB-40 through to UB-50 Marking and Reports: UB-55 Pressure Relief Devices: UB-60 Subsection C - Requirements Pertaining to Classes of Materials: Part UCS - Requirements for Pressure Vessels Constructed of Carbon and Low Alloy Steels: General: UCS-1 Materials: UCS-5 through to UCS-12 Design: UCS-16 through to UCS-57 Low Temperature Operation: UCS-65 through to UCS-68 Fabrication: UCS-75 through to UCS-85 Inspection and Tests: UCS-90 Marking and Reports: UCS-115 Pressure Relief Devices: UCS-125 Non-mandatory Appendix CS: UCS-150 through to UCS-160 Part UNF - Requirements for Pressure Vessels Constructed of Nonferrous Materials: ©2012 Jurandir Primo 52 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org General: UNF-1 through to UNF-4 Materials: UNF-5 through to UNF-15 Design: UNF-16 through to UNF-65 Fabrication: UNF-75 through to UNF-79 Inspection and Tests: UNF-90 through to UNF-95 Marking and Reports: UNF-115 Pressure Relief Devices: UNF-125 Appendix NF: Characteristics of the Nonferrous Materials (Informative and Non-mandatory) Part UHA - Requirements for Pressure Vessels Constructed of High Alloy Steel: General: UHA-1 through to UHA-8 Materials: UHA-11 through to UHA-13 Design: UHA-20 through to UHA-34 Fabrication: UHA-40 through to UHA-44 Inspection and Tests: UHA-50 through to UHA-52 Marking and Reports: UHA-60 Pressure Relief Devices: UHA-65 Appendix HA: Suggestions on the Selection and Treatment of Austenitic Chromium –Nickel and Ferritic and Martensitic High Chromium Steels (Informative and Non-mandatory) Part UCI - Requirements for Pressure Vessels Constructed of Cast Iron: General: UCI-1 through to UCI-3 Materials: UCI-5 through to UCI-12 Design: UCI-16 through to UCI-37 Fabrication: UCI-75 through to UCI-78 Inspection and Tests: UCI-90 through to UCI-101 Marking and Reports: UCI-115 Pressure Relief Devices: UCI-125 Part UCL - Requirements for Welded Pressure Vessels Constructed of Material with Corrosion: Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied Linings General: UCL-1 through to UCL-3 Materials: UCL-10 through to UCL-12 Design: UCL-20 through to UCL-27 Fabrication: UCL-30 through to UCL-46 Inspection and Tests: UCL-50 through to UCL-52 Marking and Reports: UCL-55 Pressure Relief Devices: UCL-60 Part UCD - Requirements for Pressure Vessels Constructed of Cast Ductile Iron: General: UCD-1 through to UCD-3 Materials: UCD-5 through to UCD-12 Design: UCD-16 through to UCD-37 Fabrication: UCD-75 through to UCD-78 Inspection and Tests: UCD-90 through to UCD-101 Marking and Reports: UCD-115 Pressure Relief Devices: UCD-125 ©2012 Jurandir Primo 53 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org Part UHT - Requirements for Pressure Vessels Constructed of Ferritic Steels with Tensile Properties Enhanced by Heat Treatment: General: UHT-1 Materials: UHT-5 through to UHT-6 Design: UHT-16 through to UHT-57 Fabrication: UHT-75 through to UHT-86 Inspection and Tests: UHT-90 Marking and Reports: UHT-115 Pressure Relief Devices: UHT-125 Part ULW - Requirements for Pressure Vessels Fabricated by Layered Construction: Introduction: ULW-1 through to ULW-2 Materials: ULW-5 Design: ULW-16 through to ULW-26 Welding: ULW-31 through to ULW-33 Nondestructive Examination of Welded Joints: ULW-50 through to ULW-57 Fabrication: ULW-75 through to ULW-78 Inspection and Tests: ULW-90 Marking and Reports: ULW -115 Pressure Relief Devices: ULW-125 Part ULT - Alternative Rules for Pressure Vessels Constructed of Materials Having Higher Allowable Stresses at Low Temperature General: ULT-1 through to ULT-5 Design: ULT-16 through to ULT-57 Fabrication: ULT-76 through to ULT-86 Inspection and Tests: ULT-90 through to ULT-100 Marking and Reports: ULT-115 Pressure Relief Devices: ULT-125 Part UHX - Rules for Shell-and-Tube Heat Exchangers Part UIG - Requirements for Pressure Vessels Constructed of Impregnated Graphite General: UIG-1 through to UIG-3 Materials: UIG-5 through to UIG-8 Design: UIG-22 through to UIG-60 Fabrication: UIG-75 through to UIG-84 Inspection and Tests: UIG-90 through to UIG-112 Marking and Reports: UIG-115 through to UIG-121 Pressure Relief Devices: UIG-125 Mandatory Appendices: 1 through to 42. Nonmandatory Appendices: A through to MM. Division 2 - Alternative Rules: Covers the mandatory requirements, specific prohibitions and non-mandatory guidance for materials, design, fabrication, inspection and testing, markings and reports, overpressure protection and certification of pressure vessels having an internal or external pressure, which exceeds 15 psi (103 kPa). The pressure vessel can be either fired or unfired. The pressure may be from external sources, or by the ap©2012 Jurandir Primo 54 de 55 www.PDHcenter.com PDHonline Course M398 www.PDHonline.org plication of heating from an indirect or direct source as a result of a process, or any combination of the two. The rules contained in this section can be used as an alternative to the minimum requirements specified in Division 1. Generally the Division 2 rules are more onerous than in Division 1 with respect to materials, design and nondestructive examinations but higher design stress intensity values are allowed. Division 2 has also provisions for the use of finite element analysis to determine expected stress in pressure equipment, in addition to the traditional approach of design by formula (Part 5: "Design by Analysis requirements"). Division 3 - Alternative Rules for Construction of High Pressure Vessels: Covers the mandatory requirements, specific prohibitions and non-mandatory guidance for materials, design, fabrication, inspection and testing, markings and reports, overpressure protection and certification of pressure vessels having an internal or external pressure which exceeds 10,000 psi (70,000 kPa). The pressure vessel can be either fired or unfired. The pressure may be from external sources, by the application of heating from an indirect or direct source, process reaction or any combination thereof. The Section VIII, Division 1 presents several design procedures and methods in both the Mandatory and Nonmandatory Appendices; however, design procedures in the appendices differ from those in the body of the Code. As an example, Appendix 2 provides methods for designing multibolted flanges. Paragraph 2-1 (c) recommends that bolted flange connections, be used within the material, size, and pressure temperature ratings listed in UG-44. UCI-3 and UCD-3 also have restrictions on the pressure-temperature ratings of standard flanges. ASME Section I and Section VIII Stamps: The UG-44 lists the following standards as acceptable: ASME/ANSI B16.5, Pipe Flanges and Flanged Fittings; ASME/ANSI B16.20, Metallic Gaskets for Pipe Flanges, Ring Joints, Spiral-Wound and Jacketed; ASME/ANSI B16.24, Cast Copper Pipe Flanges and Fittings, Classes 150 to 900, 1500 and 2500; ASME/ANSI B16.42, Ductile Iron Pipe Flanges and Flanged Fittings, Class 150 and 300; ASME/ANSI B16.47, Large Diameter Steel Flanges, NPS 26 Through NPS 60. Links and References: https://www.asme.org/products; Carucci, Vincent. Overview of Pressure Vessel Design; Farr, James. Guidebook for the Design of ASME Section VIII Pressure Vessels, 2001; Companion Guide to the ASME Boiler & Pressure Vessel Code (BPVC), 2009; OSHA Technical Manual – Section IV, Chapter 3, 2004. ©2012 Jurandir Primo 55 de 55