Computers and Geotechnics 172 (2024) 106430

Contents lists available at ScienceDirect

Computers and Geotechnics

journal homepage: www.elsevier.com/locate/compgeo

Research Paper

Simulation of cone penetration in soil using the material point method

Vibhav Bisht a, Rodrigo Salgado b, *, Monica Prezzi c

a

Software Engineer, Align Technology, 3030 Slater Rd, Morrisville, NC 27560, United States

Charles Pankow Professor in Civil Engineering, Lyles School of Civil Engineering, Purdue Univ., West Lafayette, IN 47907, United States

c

Professor of Civil Engineering, Lyles School of Civil Engineering, Purdue Univ., West Lafayette, IN 47907, United States

b

A R T I C L E I N F O

A B S T R A C T

Keywords:

Generalized interpolation material point

method

MPM

Cone penetration

Critical state model

Realistic simulation of cone penetration in soil presents two main challenges: (1) a numerical scheme that is

accurate under large deformations and that does not resort to overly simplifying assumptions, and (2) a

constitutive model that can accurately predict the stress–strain response of soil under a wide variety of loading

conditions. This paper presents a brief overview of the progress made towards realistic cone penetration simu­

lation. The choice of numerical scheme (the material point method) and constitutive models (bounding surface

models) used for simulating cone penetration in this study are discussed. For sand, 15 cone penetration simu­

lations are performed at different relative densities subjected to different effective stress values. The simulation

results are compared against those from cavity expansion analyses. For clays, cone penetration simulations are

performed at different overconsolidation ratios and initial effective stress. Simulation results are then compared

against cone penetration tests (CPTs) performed in the field. Based on the simulations, cone factor values are

evaluated. The advantages of the current approach and its application to improvement of CPT interpretation are

discussed.

1. Introduction

1.1. Cone penetration simulation

The cone penetration test (CPT) is now firmly established as one the

key site investigation tools available to geotechnical engineers in both

routine and challenging problems. It has features that have made it an

attractive alternative to higher-end laboratory testing or other in situ

tests (Salgado et al., 2022). First, it is economical with respect to so­

phisticated laboratory testing, yet can produce most of the results

desired from high-end testing if its results are interpreted using state-ofthe-art methods. Second, it produces reliable, repeatable results if per­

formed to standard. Third, it is quasi-static, eliminating the challenge of

considering dynamic load effects. However, its interpretation must be

based on rigorous mechanics. Computational simulations of cone

penetration in soil should therefore form the basis for establishing re­

lationships between cone resistance qc and soil state variables or state

properties, but these simulations face challenges.

The key challenges to accurate, realistic simulations of cone pene­

tration in soil are: (1) the occurrence of large displacements, de­

formations, and rotations in the soil, and (2) the evolving loading paths

at points in the soil surrounding the advancing cone penetrometer,

which range all the way from triaxial compression to triaxial extension

paths. Large deformations are problematic because the methods of

analysis that would typically be used for geotechnical analysis, like the

finite element method (FEM), lose accuracy and may not even converge

to a solution after the computational mesh distorts beyond some limit.

Simulation accuracy requires that the constitutive model used to

represent the soil be able to simulate soil response correctly, irrespective

of the loading path to which the soil is subjected.

The CPT has developed as a tool much faster than the ability to model

it theoretically. This is far from uncommon in geotechnical engineering:

the development of methods of testing or the invention of new types of

geotechnical structures or foundation elements typically precede efforts

to model them. Initial methods of interpretation of the CPT were

therefore semi-empirical or based on analyses of an approximate nature.

To remedy the gap in the theoretical basis for CPT interpretation, efforts

started early.

Initial attempts relied on modeling the soil as a rigid-plastic material

with either a Tresca or Mohr-Coulomb yield surface and applying the

notion of a limiting equilibrium to an axially loaded penetrometer and a

surrounding soil mass. The Durgunoglu and Mitchell (1975) model was

* Corresponding author.

E-mail address: rodrigo@ecn.purdue.edu (R. Salgado).

https://doi.org/10.1016/j.compgeo.2024.106430

Available online 29 May 2024

0266-352X/© 2024 Elsevier Ltd. All rights are reserved, including those for text and data mining, AI training, and similar technologies.

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

the most successful of these early models, but fell short when people

tried to use it. A major shortcoming of the model was its reliance on

perfect plasticity and an interpretation based on estimating “the” fric­

tion angle of the soil. As discussed elsewhere (e.g., Salgado, 2012), the

mobilized friction angle varies across the soil domain in any boundaryvalue problem involving real soil, so any method based on such an oversimplification of soil response is fatally flawed.

The next main thrust in developing a framework for CPT simulations

was cavity expansion theory (e.g., Salgado et al., 1997; Salgado and

Prezzi, 2007; Salgado and Randolph 2001). Cavity expansion theory was

an approximation to the problem based on the requirement that the cone

must expand a cylindrical cavity in the soil in order to advance. These

efforts concentrated on the use of simple elasto-plastic soil models with

Tresca or Mohr-Coulomb yield criteria, although with some modifica­

tions attemping to capture the effects of soil nonlinearities. Salgado and

Randolph (2001b) proposed a framework that can accommodate a

broad range of constitutive models, and cavity expansion analysis based

on that formulation and a relationship between cone resistance and

cylindrical cavity limit pressure produced useful relationships that can

be used in CPT interpretation (Salgado and Prezzi, 2007). However,

cavity expansion process cannot provide a close approximation to the

stress, displacement, and strain fields around an advancing cone

penetrometer.

The strain path method (Teh and Houlsby, 2009) was proposed for

analysis of cone penetration in clay, and it was a reasonable approxi­

mation to the penetration process, but its impact was again limited by a

simple elasto-plastic model with a Tresca yield criterion. Early appli­

cation of the FEM also met with difficulties. In geomechanics applica­

tions, FEM has traditionally followed a Lagrangian approach. This

means that the nodes of a mesh are tracked throughout the analysis, and

it is through node displacements that solutions are obtained. Deforma­

tion follows from relative node displacements, and stress follows from

deformation. After considerable deformation has occurred, mesh ele­

ments may be so distorted that accurate solutions are no longer possible.

In fact, a solution may not even be possible, accurate or not, with the

analysis crashing instead.

The Arbitrary Lagrangian-Eulerian (ALE) FEM approach (Belytschko

and Kennedy, 1978) and the material point method (MPM) (Sulsky

et al., 1994) were proposed to avoid this limitation. In ALE FEM, mesh

distortion is limited by remeshing or node repositioning after some

threshold level of deformation has happened. When nodes are reposi­

tioned or a new mesh formed, we need to map the state variables from

quadrature points on the old mesh to quadrature points on the new

mesh. The remapping can lead to stress states that lie outside the yield

surface for plasticity models with single yield surface or outside the

bounding surface for bounding surface models. Remapping can be

challenging with bounding surface models or complex models with

several variables to map. In contrast to ALE FEM, MPM does not require

remapping of variables because the state variables are carried by the

same material points throughout the computations. The material point

method and its application to cone penetration simulation is discussed

next.

displacements being the basis for the solution. Whereas grid nodes do

move during a computation step, they can be repositioned to their

original locations before the next computation time. It may also be ad­

vantageous to consider parts of the grid to either translate in some di­

rection or to compress one-dimensionally. This means that, whether the

grid remains static, moves in some direction or is unidirectionally

compressed in MPM, it does not get distorted as in FEM, which means

that there are no difficulties associated with mesh distortion.

The second most important implication of the use of material points

instead of Gauss points in an analysis is that the absolute rigor of FEM

with respect to the calculation of integrals over the element domain is

lost. This happens mainly because Gauss integration is no longer

possible, because the material points will, for practical purposes, never

be at the locations required by Gauss integration. This is not fatal, but a

number of remedial measures must be taken to limit any error from this

partial loss of rigor.

This paper presents in detail strategies to realistically simulate cone

penetration in both sands and clays by: (1) using MPM, which is well

suited for simulation of large-deformation problems, and (2) using

advanced bounding surface models with anisotropic hardening that

accurately capture soil behavior under a wide variety of loading con­

ditions. The MPM formulation used in the simulations discussed here is

discussed in detail by Bisht and Salgado (2018), Bisht et al., (2021b),

and Salgado and Bisht (2021). In the following sections, key features of

their implementation is discussed. For alternative MPM formulations

simulating cone penetration, please see the works of Ceccato et al.

(2016), Martinelli and Galavi (2021), Tehrani and Galavi (2018), Tran

and Sołowski (2019), and Yost et al. (2022).

1.2.1. Type of MPM

The original MPM scheme (Sulsky et al., 1994)—in which the ma­

terial points are actual points, lacking dimensionality—produces large

stress oscillations when material points cross element boundaries due to

the discontinuity of the gradient of shape functions across elements.

Numerous MPM schemes can be found in the literature that attempt to

reduce these stress oscillations through the construction of higher-order

shape functions (Bardenhagen and Kober, 2004; Sadeghirad et al.,

2011,2013; Steffen et al., 2008; Zhang et al., 2011). A common

approach is to assign the material “point” a domain—typically a rect­

angle in two-dimensional analyses (Bardenhagen and Kober, 2004;

Sadeghirad et al., 2011,2013). Further distinctions can be made

depending on how the domain is chosen to evolve. In this study, the

uniform Generalized Interpolation Material Point Method (uGIMP)

(Bardenhagen and Kober, 2004) has been adopted. In uGIMP, the par­

ticle domain does not evolve with material deformation. The relatively

simple particle domain evolution scheme offers two key benefits: (1) the

scheme is robust, and (2) it uses less computational power than methods

in which the material point domain is tracked more accurately. Since

particle domains are not tracked in uGIMP, gaps and overlaps between

the material point domains may occur for extremely large deformations.

Despite this limitation, uGIMP has been shown to provide similar results

to those of the convected particle domain interpolation method (Sade­

ghirad et al., 2011)–in which particle domains are partially tracked–for

(1) jacked piles simulations (Lorenzo et al., 2018), and (2) standard

MPM simulations of the cone penetration problem (Bisht et al., 2021a).

1.2. Modeling cone penetration using the MPM

The material point method can be best understood as a variant of the

finite element method in which Gauss points are replaced by so-called

material points. A material point (“MP”) may be a point (as in clas­

sical MPM), but it may also be a small area (for two-dimensional anal­

ysis) or small volume (for three-dimensional analysis). In contrast with

Gauss points, material points may move within and even across ele­

ments. This key difference between FEM and MPM has a number of

computational consequences.

The most important and most useful implication of the use of ma­

terial points instead of Gauss points as used in ALE FEM is that the

approach is a pure Lagrangian approach, with material point

1.2.2. Boundary conditions

Imposition of Dirichlet boundary conditions in MPM is straightfor­

ward: velocities are applied directly on nodes for which boundary

conditions are imposed. For enforcement of Neumann boundary con­

ditions, the required tractions have to be computed. Two choices arise:

(1) computing traction magnitudes at the material point centroids using

traditional GIMP shape functions; (2) computing traction magnitudes at

the material point edge (Bisht and Salgado, 2018; Nairn and Guilkey,

2015) using shape functions proposed by Sadeghirad et al. (2011).

Computing traction at the material point centroids leads to stress

2

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

equations resulting from the governing equations of motion. The addi­

tional equations involving strain tensor components result from the

imposition of the incompressibility constraint on integration points.

Incompressibility or near incompressibility appears in Tresca solids in

the plastic range and at critical state for any soil model. Volumetric

locking often appears as strong spatial oscillations in the values of

fundamental variables—such as stress—that appears as a checkerboard

pattern when these variables are plotted as contour plots in the problem

domain.

In the finite element method, volumetric locking can be avoided by

using higher-order elements, which provide a sufficient number of

variables to overcome any excess equations from the incompressibility

constraint. Using traditional (Lagrangian) higher-order elements is not

an option in MPM, because the corresponding shape functions can take

negative values for some regions in an element, which in turn can lead to

negative mass at the corresponding nodes from a material point located

in such regions. The attending complications are discussed in detail in

Andersen and Andersen (2010) and Bisht et al., (2021a).

An effective way to deal with volumetric locking in MPM is the use of

the so-called non-linear B method (Hughes, 1980; Simo et al., 1985).

The method is based on the fact that volumetric locking can be pre­

vented by reducing the number of constraints imposed by incompres­

sibility in each element. For example, for linear quadrilateral (Q4)

elements, volumetric locking can be prevented if a reduced, single-point

quadrature rule is used (see Sloan and Randolph (1982)). The use of a

single Gauss point in reduced integration for Q4 elements is sufficient to

prevent volumetric locking in FEM, but this strategy is not applicable in

MPM, because the number of material points present within an element

at any given point cannot be controlled.

For MPM, Bisht et al., (2021a) used a large-deformation formulation

of the B method with the deformation gradient F split into a volumetric

and a deviatoric component, with the volumetric component calculated

only at the element center. The computational algorithm that results

requires that the gradient of the material point shape functions (material

point mapping functions) must be calculated also at the element center.

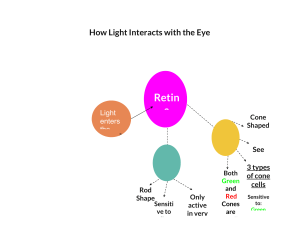

Fig. 1. Application of tractions to a body in uGIMP MPM: the tractions are first

applied on the edges of the material points (represented by thick lines) and then

mapped to the nodes of the element containing the material point.

oscillations near the corresponding boundary. These oscillations can be

avoided by computing traction at the material point edges. Therefore,

traction terms have been computed at the material point edges in this

study (Fig. 1).

1.2.3. Mesh and discretization

A structured irregular background grid (Woo and Salgado, 2017)

divided into moving and compressible zones (Kafaji, 2013) has been

used in this study. The grid is built using linear quadrilateral (Q4) ele­

ments. The grid offers three benefits: (1) element search, which needs to

be performed at each time step in MPM, can be performed quickly; (2)

use of a fine mesh near the cone-soil interface and a coarse mesh else­

where is possible; and (3) the moving and compressible zones can be

translated and compressed, respectively, in such a way as to enable the

fine mesh to remain near the cone-soil interface throughout the pene­

tration process.

An aspect of irregular discretization is that a material point may flow

into a grid element for which its domain is too large. In this case, the

material point domain is split into 4 material points with equal domain

sizes such that energy, momentum, and mass is conserved (Ma et al.,

2009). Splitting ensures that a sufficient number of material points per

element is maintained for adequate quadrature.

One limitation of the discretization strategy adopted in this study is

that Q4 elements are unable to exactly discretize a conical surface,

resulting in elements that contain both cone and soil material points.

The response of such elements is dominated by the material points

belonging to the cone, since the cone is assumed to be rigid, whereas soil

is compressible. The resulting error should decrease with finer dis­

cretization as the boundary between cone and soil can be resolved more

accurately. Bisht et al., (2021a) performed cone penetration in Tresca

material and compared the cone factor values obtained using uGIMP

with an irregular structured grid (used in this study) against cone factor

values obtained by simulations performed by Ceccato (2015), who used

an unstructured grid using the same material model parameters. Near

the end of penetration, both simulations computed a cone factor of 9.7.

A modified deformation gradient F at the material point P—obtained

from combining the deviatoric component of the deformation gradient

with the volumetric component of it at the element center—is then used

in stress integrations.

(P)

1.2.5. Time integration algorithm

An explicit time integration scheme with the Update Stress Last

(USL) algorithm (Wallstedt and Guilkey, 2008) has been used in this

study. For explicit time integration, the critical time step Δtcrit,wave (from

wave propagation) can be calculated using the Courant-Friedrichs-Lewy

(CFL) stability condition (Courant et al., 1967):

( )

h

(1)

Δtcrit,wave = min

cd

where h is the element size, and the speed of the compression wave is

given by:

√̅̅̅̅̅̅̅̅̅̅

cd = Ec /ρ

(2)

for dry soil, and

√̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅

Ec + Kw /η

cd =

(1 − η)ρs + ηρw

(3)

for saturated soil, with Ec being the modulus (typically Young’s modulus

or the constrained modulus), η the porosity, Kw the bulk modulus of

water, and ρ the material density.

For saturated soil, there is another timescale of interest: that of

excess pore-pressure dissipation due to consolidation. Mieremet et al.

(2016) showed that the critical time step Δtcrit,cons. for consolidation is

1.2.4. Volumetric locking

In numerical solutions to problems in mechanics involving incom­

pressible or nearly incompressible materials, a phenomenon known as

volumetric locking may occur. Volumetric locking is the insufficiency of

variables provided by the grid discretization to allow solution of all

3

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

Table 1

Parameter values used in stress-integration algorithm.

Parameter

Value

− 4

STOL

FTOL

10

10− 9

LTOL

10− 6

MAXITS

20

Table 2

Constitutive model parameters for Ottawa Sand.

Remarks

Parameters for

Number

Parameter

Value

Maximum local stress error for any sub-increment

The maximum tolerance within which a point is considered to

be at the yield surface

Determines whether a point at the yield surface follows a

purely plastic path or if it undergoes elastic unloading

The maximum iterations that will be performed to determine

the intersection at the yield surface for a point undergoing

transition from an elastic to a plastic state

Small-strain shear modulus

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Cg

ng

611

0.437

0.47

0.00065

0.15

0.05

1.21

1.9

2.2

0.081

0.20

0.71

0.35

2.20

0.240

0.81

1.2

0.78

1.31

0.31

0.39

0.780

Elastic shear modulus with Ramberg-Osgood

degradation

Poison’s ratio

Yield surface

Bounding, dilatancy and CS surfaces

State parameter and CSL in e-p’

given by:

Δtcrit,cons. = 2k[ηρsat + (1 − 2η)ρw ]/ηγw

Shape of bounding, dilatancy, CS surfaces in

the π plane

Plastic modulus

(4)

where γ w is the unit weight of water, k is hydraulic conductivity of the

soil, and ρsat is the saturated mass density of the soil. Thus, the critical

time step Δtcrit for saturated soil can be determined using:

)

(

(5)

Δtcrit = min Δtcrit,wave , Δtcrit,cons.

Flow rule

Dilatancy

Fabric dependent scalar

Fabric effect multiplier in H

Intercept of CSL

For explicit time integration, the stable time step is typically chosen

to be smaller than the critical time step by a factor κ known as the

Courant number (Courant et al., 1967):

Δtstable = κΔtcrit

allows the use of a larger scaled time step Δtms :

√̅̅̅

Δtms = ηΔtstable

(8)

μ

c2

D0

α

kh

Γc

1.2.8. Soil modeling using two-surface plasticity

The constitutive models used in the analyses reported later were two

two-surface plasticity models: the Loukidis and Salgado (2009)

(“LS2009″) for sand and the Chakraborty et al. (2013) (”CLS2013″)

model for clays. Both models rely on the critical state-based, bounding

surface plasticity framework, and share many features.

The LS2009 model—which is based on a model originally proposed

by Manzari and Dafalias (1997) and subsequently modified by Dafalias

and Manzari (2004)—is formulated in the critical-state framework, i.e.,

it takes into account the current state of the soil using the state

parameter ψ (Been and Jefferies, 1985), and expresses a number of key

quantities in terms of ψ . Features of soil mechanical response are

expressed through relationships that refer to four surfaces defined in

general stress space: the yield surface, the dilatancy surface, the

bounding surface, and the critical-state surface. In simple terms, the

peak shear strength ratio q/p’ increases with increasing size of the

bounding surface, which in turn increases with increasing negative

distance from the soil state point in e-lnp’ space to the critical-state line:

the more dilative the soil the greater its peak shear strength. In contrast,

contractive soil has a peak shear strength equal to the critical-state shear

strength, so the bounding surface coincides with the critical state sur­

face. The bounding surface for a dilative soil starts larger than the

critical state surface, changes size depending on the evolution of the

state parameter, and then, at sufficiently large shear strains, collapses to

the critical-state surface.

The dilatancy surface enables the model to describe the volumetric

response of the soil: sand contracts if the stress state lies within the

dilatancy surface and dilates if the stress state lies outside the dilatancy

surface. Through this surface, the model can capture the transition from

contractive to dilative response that is referred to as phase trans­

formation. Flow is nonassociated. The yield surface conceptually rep­

resents the same threshold of elastic response as in classical plasticity,

but it is very small because soil expresses inelastic response starting at

1.2.6. Contact

The cone is treated as a rigid body, whereas the soil is deformable.

Although several contact algorithms have been proposed in the MPM

literature (e.g. González Acosta et al., 2021; Hamad et al., 2017; Huang

et al., 2011; Ma et al., 2014), the contact forces between the cone and the

soil were computed using the contact algorithm proposed by Barden­

hagen et al. (2000) based on our prior experience with its use on

penetration problems. For computing the tangential friction force τ, the

Coulomb friction model was used:

τ⩽μN

m

Mcc

kb

kd

λ

ξ

c1

ns

h1

h2

elim

should remain at the yield surface, see Prager, 1961); and (3) selfconsistency (under elastic deformation, the hypo-elastic rate formula­

tion must be exactly integrable to deliver a hyper-elastic relation, see

Bruhns et al., 1999). It should be noted that the commonly used Jau­

mann stress rate does not satisfy the self-consistency criterion, resulting

in an oscillatory response in simple shear (Dienes, 1979; Zbib and

Aifantis, 1988).

In the USL approach, Wallstedt and Guilkey (2008) showed that κ ≈

0.4 yields suitable results for dynamic problems. However, for quasistatic problems such as cone penetration, a higher Courant number

(κ ≈ 0.7) can be used. Additionally, for quasi-static problems, artificially

increasing the material density using a mass scaling parameter η:

(7)

γ1

ν

*after Loukidis and Salgado (2009).

(6)

ρscaled = ηρ

α1

(9)

where μ is the coefficient of friction between soil and the cone pene­

trometer, and N is the normal force.

1.2.7. Stress integration algorithm

We have used an explicit stress-integration scheme with subincrementation and error control (Sloan, 1987; Sloan et al., 2001).

The algorithm breaks down the strain increment into several subincrements and computes the corresponding stress sub-increments

using the Modified Euler scheme. The algorithm contains several pa­

rameters that can be modified to increase the accuracy of the stress subincrements at the cost of computational speed. A brief description of the

parameters and their values chosen in this study are given in Table 1.

The modified kinetic logarithmic rate (Jiao and Fish, 2017,2018) has

been used as the objective stress rate in this study, and the Hencky strain

has been used as the strain measure. This combination of stress–strain

measures has been chosen because they satisfy a few key requirements:

(1) objectivity (the stress rate is frame-invariant, see Lubliner, 2008); (2)

yield stationarity (if the stress rate is zero, a point at the yield surface

4

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

and rate of deformation is reasonable, because cone resistance is more

significantly affected by compression loading paths, whereas the effect

of large rigid-body rotations is more impactful in loading paths

approaching simple shear.

Table 3

Constitutive model parameters for Boston Blue Clay.

Parameters for

Number

Parameter

Value

Poisson’s ratio

Small-strain shear modulus

Elastic moduli with degradation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

ν

0.25

250

5

0.036

1.138

0.187

0.53

1.305

0.2

0

2.7

1

0.95

0.31

1.1

Normal Consolidation Line

Stress Anisotropy

Shear Strength

Dilatancy surface

Flow rule

Hardening

Cg

ζ

κ

N

λ

K0,NC

Mcc

ns

kb

ρ

D0

c2

ξ

h0

1.2.9. Coupled MPM Formulation

Following the classical theory of poroelasticity by Biot (1941),

several noteworthy advancements in poroelasticity and its application to

geomechanics have been made, (e.g., Selvadurai, 1996,2007; Selvadurai

and Suvorov, 2016; Verruijt, 2015; Wang, 2000). In this study, the

governing equations are obtained based on the theory of mixtures (De

Boer, 2012) and uses the concept of volume fractions. In this approach,

each constituent of the mixture is smeared over the entire domain with

reduced density to create a homogenized continuum. Each individual

constituent in the mixture must satisfy the governing equations.

A 2-phase, 1-point formulation is used to discretize saturated soil, i.

e., soil and water are discretized using a single set of material points. The

primary advantage of a 1-point formulation is that it is less taxing on

computational resources as opposed to using a 2-point formulation (soil

and water are discretized using 1 material point each). A review of the

applicability and advantages of the 1-point and 2-point formulations can

be found in Ceccato et al. (2018).

*after Chakraborty et al. (2013).

very small strains. The yield surface hardens kinematically, and the

bounding surface and dilatancy surface harden isotropically. The model

relies on degradation of the small-strain initial shear modulus to accu­

rately capture clay response at small-strain levels. The model can cap­

ture some complex features of soil response, including stress–strain

nonlinearity from small strains, initial fabric anisotropy, phase trans­

formation and response under various loading paths.

The LS2009 model for sand requires 22 input parameters. In the

simulations discussed later, we use the model parameters for Ottawa

Sand given by Loukidis and Salgado (2009) (Table 2).

The CLS2013 model has a critical state line (“CSL”) that is parallel to

the normal consolidation line (“NCL”), from which soil unloading and

reloading in e − lnpʹ space occurs along straight unloading–reloading

lines. The CSL is assumed to be unique, implying that specimens having

the same void ratio will reach the same pʹ at critical state when loaded

under undrained conditions, irrespective of whether the shearing fol­

lowed an undrained triaxial compression or undrained triaxial extension

loading path. The model defines three surfaces in stress space: the yield

surface, the dilatancy surface, and the bounding surface. They function

essentially in the same way as in LS2009 for sand. The yield surface is

also small for CLS2013, and thus a plastic process is operative near the

cone throughout the entire penetration process. The bounding surface is

made up of two distinct, but connected surfaces: a shear bounding sur­

face and a flat cap. The flat cap is used to capture the yielding of clays in

isotropic compression or compression at small ratios of shear stress to

mean effective stress. The model relies on degradation of the smallstrain initial shear modulus to accurately capture clay response at

small-strain levels. The model also contains parameters to capture the

strain-rate dependent shear strength in clays and the transition of clays

beyond critical state to a residual state.

For the analysis performed here, the CLS2013 model for clay requires

15 parameters (Table 3). In the simulations discussed later, we use the

calibrated values of model parameters for Boston Blue Clay (BBC) that

are specified in Chakraborty et al. (2013) without modification, with

one exception: we ignore strain-rate dependence in the clay response for

computational reasons. Ignoring strain-rate dependence is justified

because the strain-rate effects are small, since cone penetration is a

quasi-static process. Additionally, for BBC, the shear bounding surface

and the critical state surface are assumed to coincide based on data from

Ladd and Varallyay (1965).

The values of parameters for LS2009 model for sands and CLS2013

model for clays described in Table 2 and Table 3 respectively were

originally calibrated using a small-strain formulation. For very large

rates of rotation, it is conceivable that recalibration of the models would

make a nonnegligible difference, but for the calculation of cone resis­

tance, direct use of the model calibrated in terms of stress rate and strain

rate in a formulation in terms of modified kinetic logarithmic stress rate

1.2.10. A computation time step in an MPM simulation

During a time step in an MPM simulation, we follow the steps out­

lined below.

1. Initialize

a. Initialize all variables at material points and grid nodes; set time

t =0

b. Determine an appropriate time increment Δt

2. Compute shape functions and shape function gradients

For each material point P:

a. Compute GIMP functions S(IP) and their gradients S,j

(IP)

at particle P

and at element center C.

b. If P is at a traction or pressure boundary, compute CPDI shape

functions at P

3. For coupled problems, compute updated momentum of water

For each node I:

a. Compute nodal mass of the water mw and weighted nodal mass of

(I)

̃ (I)

water m

w :

m(I)

w =

∑

S(IP) m(P)

w

P

∑

(P)

̃ (I)

m

S(IP) m(P)

w =

w /η

P

b. Compute nodal momentum Pwi due to water and porosity(I)

̃(I) due to water:

weighted nodal momentum P

wi

P(I)

wi =

∑

(P)

S(IP) m(P)

w vwi

̃(I) =

P

wi

∑

(P)

S(IP) η− 1 m(P)

w vwi

P

P

where vwi is velocity of water

c. Compute external forces Fext,wi and internal forces Fint,wi at the

(I)

(I)

nodes due to water:

∑

∑

(I)

(P)

(P)

Fext,wi

= FΓp +

S(IP) η− 1 m(P)

S(IP) fdragi

V (P)

w bi −

P

5

P

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

∑ (IP)

(I)

(P)

Fint,wi

=

S,j δij p(P)

w V

Table 4

An overview of the numerical setup used for the cone penetration simulations.

P

Implemented scheme

∫

where FΓp = dΩ N(I) pwi dΩ is the force from the pore pressure pw at

the boundary Γ of system domain Ω, b is the body force per unit

(

)

(P)

(P)

(P)

(P)

mass, fdragi = − η2(P) γ w k− 1(P) vwi − vsi

is the drag force due to

Type of MPM

Time integration

algorithm

Mesh

soil–water interaction derived assuming laminar flow, γw is the

unit weight of water, k is the hydraulic conductivity of the soil, δij

is the Kronecker-delta function, V is volume, N(I) is the finite

element top-hat shape function,

(I)

̃˙ =

d. Compute rate of change of weighted nodal momentum P

wi

(I)

updated nodal momentum Pwi

̃(I) m(I)

̃ (I)

=P

w due to water.

wi w /m

(I)CT

e. If I is a contact node, compute contact forces fwi due to water

(I)

(I)

(I)CT

(2000,2001) and update the nodal momentum Pwi ←Pwi +fwi Δt

due to water

4. Compute updated momentum of soil

For problems with no water, ignore forces due to water (terms with

subscript w)

For each node I:

∑

(I)

(P)

a. Compute nodal mass from the soil:ms = P S(IP) ms

∑ (IP) (P) (P)

(I)

b. Compute nodal momentum due to the soil: Psi = P S ms vsi

(I)

Fint,mi

=

(P)

v(P)

si ←vsi + Δt

(I)

P

∑ ʹ(P) (IP)

∑

(IP)

(P)

σij S,j V (P) +

p(P)

w S,j δij V

(I)

(I)

(I)

(I)

(I)

(I)CT

e. If I is a contact node, compute contact forces fsi

due to soil using

the contact algorithm proposed by Bardenhagen et al.

(2000,2001) and update the nodal momentum Psi ←Psi +

(I)

(I)CT

fsi Δtdue to soil

5. Update material point state

For each material point P

2.1. Domain Discretization

(P)

a. Compute the velocity gradient vi,j (C) at the element center

(P)

b. Compute the deformation gradient Fij (for simplicity, we use

Fig. 2 shows the discretization for simulation of cone penetration in

sand. The mesh dimensions were chosen such that insignificant differ­

ences (<2% difference in qc values) were observed when meshes with

larger dimensions were used. The grid was initially discretized into 2 × 2

material points per element. Owing to the material point splitting

strategy used in this study, the number of material points varies through

the course of the simulation, increasing from approximately 6500

initially to ~13000 near the end of penetration. The essential boundary

conditions are imposed at the bottom, on the right, and at the line of

symmetry by forcing the required velocity terms to be zero. Neumann

boundary conditions are applied to the top of the soil.

lowercase subscripts to represent both the reference and current

configurations)

c. For coupled problems, compute the pore pressure increment using

∂pw

Kw

∂t = η [(1 −

I

Table 4 summarizes the numerical setup used for performing the

cone penetration simulations in sand (and also clay simulations, which

are discussed later). The sand simulations were performed assuming

drained conditions. In the sub-sections below, we justify the use of these

values.

Ṗsi Δt.

(I)

∑

(I)

S(IP) P(I)

si /ms

2. Penetration in sand

Ṗsi = − Ṗwi +Fext,mi − Fint,mi due to soil and update Psi ←Psi +

(I)

I

6. Update grid and reset

a. Adjust (translate/compress/reset) background grid

b. Update time t←t + Δt.

c. If t < tend , go to step 2; otherwise exit

P

∫

where FΓt = dΩ N(I) ti dΩis the external force contribution from

tractions t.

d. Compute

rate

of

change

of

nodal

momentum

(I)

∑

(I)

S(IP) Ṗsi /m(I)

s

(P)

x(P)

si ←xsi + Δt

∑

∑

(P) (IP)

(P) (IP)

m(P)

+

m(P)

w bi S

s bi S

P

Modified kinematic logarithmic rate and Hencky strain

critical state.

the mixture:

P

Clay: μf = 0.30 (from Bisht

tms : scaled time increment; MPs: material points; hmin,w : minimum element

width; dc : cone diamater; K0 : coefficient of lateral earth pressure; vcone : pene­

tration velocity of cone; μf : coefficient of friction; δcs : interface friction angle at

c. Compute external forces Fext,mi and internal nodal forces Fint,mi for

(I)

Sand: Fixed tms = 2 × 10− 5 s

Clay: Fixed tms = 2 × 10− 5 s

Sand: hmin,w = 6.33 mm,

which is ~the size of the

shear band

Clay:hmin,w =

4.46 mm (dc /8)

Sand: vfinal = 10 cm/s

Clay:vfinal = 20 cm/s

(

)

Sand:μf = 0.31 δcs = 17.40

et al., 2021b)

Explicit with automatic sub-stepping and error control

Stress integration

algorithm

Objective stress

rate and strain

measure

using the contact algorithm proposed by Bardenhagen et al.,

Fext,mi = FΓt + FΓp +

Structured irregular grid

with moving and

compressible zones with

initially 2 × 2 MPs per

element

{

0 − vfinal

t ≤ 1s

vcone =

vfinal

t > 1s

Coulomb friction model (

Bardenhagen et al., 2000);

Penetration

velocity

Contact algorithm

(I)

(I)

(I)

̃(I) ←P

̃(I) + P

̃˙ Δt. Compute

Fext,wi − Fint,wi due to water and update P

wi

wi

wi

(I)

uGIMP

Explicit − USL

Remarks

η)∇.vs + η∇.vw ], where Kw is the bulk modulus of

water

d. Using the objective stress rate, update the stresses and internal

variables using Fij

(P)

)

(

(P)

e. Update the material point volume V (P) ← detFij V (P) and soil

2.2. Minimum element size for sand

matrix density. For coupled problems, update the porosity

)

(

)

(

(P)

η(P) ←1 − 1 − ηt = 0(P) / detFij .

For sand, the minimum element size was chosen to be approximately

equal to the width of the shear band. Data from experimental tests

performed on sand (e.g., Alshibli and Hasan, 2008; Alshibli and Sture,

1999; Desrues and Viggiani, 2004) suggest that a shear band thickness of

(P)

f. Update the material point velocity of the soil matrix vsi and po­

(P)

sition xsi :

6

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

Fig. 2. Schematic of cone penetration simulation in sand.

roughly 8 − 20D50 (approximately 6–14 mm) is formed after sustained,

localized shearing. Accordingly, the minimum element size (width w ×

height h) is taken to be 6.33 mm × 5.95 mm (8.8D50 × 8.3D50 or dc /6 ×

dh /3; with dh being the height of the cone tip). A smaller minimum

element size of dc /12 × dh /6 resulted in a moderate ∼ 5% reduction in

qc values.

2.4. Initial stress field

Five vertical surcharge values were used in the cone penetration

simulations (25, 50, 75, 100, and 200 kPa). By vertical “surcharge” we

mean the vertical stress applied at the top of the soil. The initial vertical

effective stress σʹv for any point within the model was then determined by

adding the applied surcharge to the self-weight of the soil. For the initial

horizontal effective stress σʹh , Salgado (2022) suggests that the lateralearth pressure K0 can be taken as 0.4–0.5 for sand ranging from high

to low relative densities. In our simulations, K0 = 0.45 was assumed.

The initial stress field was applied at the “zeroth” time step by specifying

the required stresses at the material point centroids.

2.3. Time increment

To compute the time increment for performing explicit analysis, we

note that the maximum modulus yields the smallest time step. We es­

timate the maximum small-strain shear modulus for the LS2009 sand

model using Hardin and Richart (1963):

Gmax = Cg

(2.17 − e)2 ʹng 1− ng

p pA

1+e

2.5. Contact forces

(10)

Han et al. (2018) performed interface direct shear tests for smooth

steel on Ottawa 20–30 sand and measured the interface friction angle

δcs = 17.40 , which corresponds to a friction coefficient of μf = 0.31.

Additional simulations performed by varying the friction coefficient

μf = 0.2 − 0.4 resulted in small changes in qc values (< 5% variation

across all simulations).

where Cg = 611 and ng = 0.437 are model parameters, pA = 100 kPa is

the reference stress, e is the void ratio, and pʹ is the mean effective stress.

Since pʹ cannot be determined a priori, a reasonably high value of pʹ =

10 MPa was used. For DR = 90%, we get a void ratio e = 0.524.

Plugging these values into Eq. (10), we get Gmax = 813 MPa and con­

strained modulus Ec,max = 1974 MPa.

Assuming κ = 0.7 and η = 25, and noting that the minimum element

size hmin used in this study was 5.95 mm, a scaled time step Δtms = 2.0 ×

10− 5 s was computed. Simulations performed using smaller η values

yielded nearly identical results (<1% difference in qc values). Hence, a

fixed time step Δtms = 2.0 × 10− 5 s was used in all the simulations.

2.6. Cone penetration velocity

In the field, cone penetration is typically performed at a penetration

velocity vcone = 2 cm/s. In this study, a higher cone velocity vcone was

used to reduce the simulation time. The vcone was increased linearly from

0 to 10 cm/s for t⩽1 s, and then kept constant at 10 cm/s for t > 1 s. For

7

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

qc (MPa)

qc (MPa)

0

0

2

4

6

8

0

4

0

4

8

12 16 20

0

10

8

qc (MPa)

12

16

0

4

8

12

16

Depth (mm)

100

200

300

400

500

600

0

5

10 15 20 25

Depth (mm)

100

200

DR=30%

DR=60%

300

DR=90%

400

500

600

Fig. 3. Cone resistance (qc ) vs. penetration depth curves in sand obtained using MPM simulations for different initial vertical effective stress and relative densities.

comparison purposes, a simulation with vcone = 5 mm/s was performed

that yielded nearly identical results (<2% difference in qc values) to

those computed using vcone = 10 cm/s.

horizontal effective stress values (22.5 kPa⩽σh ⩽450 kPa). By performing

regression on the cavity expansion analyses results, coupled with anal­

ysis linking cone resistance to limit cavity pressure, they proposed the

following relationship to compute qc for sand:

( ʹ )0.841− 0.0047DR

qc

σ

= 1.64exp[0.1041ϕc + (0.0264 − 0.0002ϕc )DR ] h

pA

pA

(11)

2.7. Results

Cone penetration simulations were performed in sand at 3 different

relative densities (30%, 60%, 90%) and 5 different surcharge values (25

kPa, 50 kPa, 75 kPa, 100 kPa, 200 kPa) for a total of 15 simulations. The

cone resistance qc vs penetration depth d curves are shown in Fig. 3. The

curves are relatively smooth and show some expected results: (1) for a

fixed relative density, qc increases, and the penetration distance

required for its complete mobilization decreases with increasing sur­

charge values; and (2) for a fixed surcharge value, qc increases, and the

penetration distance required for its complete mobilization increases

with increasing penetration depth.

Salgado and Prezzi (2007) performed a series of cavity expansion

analyses for a wide range of relative densities (0⩽DR ⩽100) and initial

where ϕc is the critical-state friction angle in degrees, and pA = 100 kPa

is a constant.

Table 5 compares the steady-state qc values obtained from the MPM

simulations against qc values determined estimated using cavity

expansion theory (Eq. (11)) for all test cases. The results indicate that

cavity expansion analysis provides larger qc values compared to MPM,

particularly for loose sands, for which the overprediction can be as large

as 25%. For a low surcharge value of 25 kPa, MPM and cavity expansion

output qc values that differ by 17.6%, 2.4%, and 14.0% for loose,

medium-dense, and dense sands respectively. Tehrani and Galavi (2018)

8

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

3.2. Numerical setup

Table 5

A summary of the results from cone penetration test simulations performed in

this study.

Sand

Classification

DR

(%)

Surcharge

(kPa)

qc MPM

(MPa)

qc CE

(MPa)

Error

(%)

Loose

30

25

50

75

100

200

1.4

2.0

2.6

3.1

4.9

1.7

2.5

3.2

3.8

6.1

17.6

20.0

18.8

18.4

19.7

Medium-Dense

60

25

50

75

100

200

4.0

5.1

6.0

6.9

9.7

4.1

5.6

6.8

7.9

11.4

2.4

8.9

11.8

12.7

14.9

Dense

90

25

50

75

100

200

8.6

11.9

14.0

15.7

21.2

10.0

12.6

14.5

16.2

21.3

14.0

5.6

3.4

3.1

0.5

Fig. 5 shows the discretization for simulation of cone penetration in

clay. Initially, each element contained 2 × 2 material points. The bottom

boundary was fixed, and the two side boundaries were roller boundaries

restricting horizontal movement. All three boundaries were assumed to

be impermeable. The number of material points varied from ~15000

initially to ~ 25000 near the end of penetration. In contrast to sand, the

strategy of choosing a minimum element size that approximates the

width of the shear band was unavailable for clays due to the wide range

of shear band thickness, varying from 0.1 mm to 2 cm (Chakraborty

et al., 2013; Kang et al., 2015; Lin and Penumadu, 2006; Moore and

Rowe, 1988; Vardoulakis, 2002), reported in the literature for clays.

Bisht et al., (2021b) performed several cone penetration simulations in

Boston Blue Clay and reported that a minimum element size of a mesh

size of dc /8 (4.46 mm) resulted in reasonably accurate qc values, and this

value has been used in our analyses. Given the low hydraulic conduc­

tivity at the test site, cone penetration in Boston Blue Clay is expected to

occur under completely undrained conditions. The simulations were

performed with a time step size of Δts = 2 × 10− 5 s with a mass scaling

parameter fms = 200. The cone was assumed to be partially rough (μ =

0.3) and was advanced at a rate of 0.2 m/s to reduce the computational

runtime. The constitutive model (Chakraborty et al., 2013) used in this

study accounts for strain-rate effects. To prevent the artificially higher

penetration rate from affecting the simulated cone penetration response,

the model parameters accounting for strain-rate dependence were set to

zero. As discussed earlier, this assumption is justifiable because: (1)

strain-rate effects are expected to be small given that cone penetration is

a quasi-static process, (2) low hydraulic conductivity of the clay at the

test site ensures that penetration will occur under undrained conditions

for penetration velocities of 0.02 m/s and higher. Additionally, pene­

tration at a slower rate of 0.1 m/s gave near identical qc values.

In the simulations, the geostatic stresses and pore pressures were

assigned to the material points in the beginning of the zeroth time step.

The initial stress field was assumed to be constant with depth over the

few diameters of travel path required for a steady state qc value to be

obtained. This approximation is acceptable because the variation in

stresses with depth due to gravity is small compared to the initial stress

values.

DR = Relative Density, MPM = material point method, CE = cavity expansion

theory, Error = 1 – (qc MPM / qc CE).

simulated cone penetration using MPM in Baskarp sand at 3 different

relative densities—30, 50, and 90%— and a surcharge of 25 kPa. They

compared the qc values obtained using MPM against those obtained

from cavity expansion analyses (Eq. (11)) and found that they were in

very good agreement. This is interesting to note because Eq. (11) was

calibrated

for

initial

horizontal

effective

stress

values

(22.5 kPa⩽σ h ⩽450 kPa) with K0 = 0.45, implying initial vertical effec­

tive stress values 50 kPa⩽σʹv ⩽1000 kPa. The results suggest that Eq. (11)

may provide reasonably accurate results even beyond the range of

values against which it was calibrated.

One advantage that MPM simulations provide over cavity expansion

analysis is that we can analyze the values of field variables. Fig. 4 plots

the mean stress values near the end of cone penetration for different

relative densities at an initial vertical effective stress of 200 kPa. A

typical “pressure bulb” pattern is formed below the cone, with the mean

stresses generated for dense sands being significantly greater than those

for loose sand. Some oscillations in the mean stress values are observed,

particularly near the cone-soil interface. As noted earlier, these oscilla­

tions occur because elements near the cone-soil interface may contain

material points belonging to soil and cone. The cone, being rigid, largely

determines the deformation of the element, which affects the stress

computations for the material points belonging to soil.

3.3. Results

Cone penetration resistance vs depth curves at depths of 5.6 m and

6.0 m are shown in Fig. 6. A steady-state cone penetration resistance is

reached after roughly 2 cone diameters of penetration. This is consistent

with the results of Moug et al. (2019), who simulated cone penetration

at the same test site using FLAC (Itasca, 2016) and observed that a

steady-state was reached after 2–6 cone diameters of penetration.

A comparison of the simulated cone resistance values and the cone

resistances measured in the field is provided in Table 7. The simulated

values fall within the range of the measured cone resistances at depths of

6.0 m and 9.6 m. At a depth of 5.6 m, the cone resistance computed using

MPM is 5.4% higher than the cone resistance measured in the field (from

CPT-1). This variation is small, and could be due to errors in estimation

of the in situ stress state, errors in the simulation strategy (e.g., the shape

of the cone or the friction coefficient between the soil and clay), or errors

in the constitutive model. Notably, the difference in the simulated CPT

value using MPM and CPT-1 (42 kPa at 5.6 m) is less than the difference

in cone resistances between CPT-1 and CPT-2 (222 kPa at 5.6 m).

3. Penetration in clay

In this section, we investigate the ability of MPM to simulate cone

penetration by performing simulations for a Boston Blue Clay (BBC)

deposit located at a test site near Newbury, Massachusetts. Clay prop­

erties at the test site have been characterized by Landon (2007). The

numerical setup used for the simulation closely follows the work of Bisht

et al., (2021b). A summary of the numerical setup used is provided in

Table 4. Key features and a description of the site properties follow.

3.1. Initial field conditions

Landon (2007) collected soil samples at several depths to determine

the properties of the soil at the Newbury test site. Additionally, two cone

penetration tests were performed that were spaced roughly 10 m apart.

Key soil properties and cone resistances are provided in Table 6. The

groundwater level was at a depth of 1.7 m. The hydraulic conductivity

varied from k = 10− 10 to 10− 9 m/s.

3.4. Cone factor

For cone penetration under undrained conditions, the undrained

shear strength su is often estimated in practice using:

qc = Nk su + σ v

9

(12)

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

Fig. 4. Mean stress values for cone penetration in sand for initial vertical effective stress equal to 200 kPa and various relative densities plotted at a penetration depth

of 550 mm (end of penetration).

extension (UDTXE), and undrained simple shear (UDSS) shearing sim­

ulations were performed using the CLS2013 model. The soil properties

were set to the values estimated by Landon (2007) to estimate Nk. The

results of the simulations are provided in Table 8.

The su values obtained from UDTXC, UDTXE, and UDSS represent the

wide range of su values that could be observed depending on the stress

path to which an element is subjected. Cone factors are obtained by

substituting the su values and qc values obtained from MPM simulations

into Eq. (12). To determine a single value of the cone factor for a given

depth, the cone factors from the three test conditions are averaged, and

Nk,avg = 15.4, 15.7, and 14.4 are obtained at depths 5.6 m, 6.0 m, and

9.6 m respectively. These values lie in the upper range of cone factor

values reported in the literature.

Three important points should be noted when interpreting the Nk

values:

Table 6

Boston Blue Clay properties at Newbury (after Landon, 2007).

Depth (m)

5.6

6.0

9.6

σʹv0 (kPa)

OCR

CPT-1 (kPa)

CPT-2 (kPa)

66.7

69.9

96.6

4.3

3.3

2.2

778

718

730

556

565

580

where Nk is known as the cone factor. Obtaining a singular Nk value

through Eq. (12) presents challenges because undrained shear strength

values may vary for each element depending on the stress path that the

element has experienced. Consequently, a range of Nk values have been

reported in the literature. Salgado (2022) provides a comprehensive

overview of Nk values that have been reported: values range from 8.5 to

24.5, but most fall within the 9–15 range, and outliers are likely due to

partially drained penetration or other experimental error.

Given that soil elements surrounding a cone penetrometer that is

advancing through the soil may experience stress paths ranging from

triaxial compression to triaxial extension, single-element loading simu­

lations—undrained triaxial compression (UDTXC), undrained triaxial

(1) There is a large variation between the Nk values obtained from

UDTXC (12.2–13.3) and UDSS (13.2–14.6) on one hand to those

obtained from UDTXE (17.6–19.2) on the other. If more elements

that more significantly impact the calculated qc value were sub­

jected to stress paths more closely resembling UDTXC or UDSS

10

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

Fig. 5. Schematic of cone penetration simulation in Boston Blue Clay. (For interpretation of the references to colour in this figure legend, the reader is referred to the

web version of this article.)

than UDTXE,1 a weighted average Nk,avg value would be more

appropriate, and this average would be lower than the un­

weighted average.

(2) Nk,avg is likely overestimated because the qc values obtained using

MPM were obtained using a stair-stepped discretized cone (see

Fig. 5).

(3) As suggested by Salgado et al. (2022), it is not evident which su

should be used to determine Nk . The best possible approach may

lie in not using Nk,avg at all, instead using the Nk that yields su that

is required by the design method.

4 Summary and conclusions

This paper reviews our ability to realistically simulate cone pene­

tration in both sand and clay. Bounding surface models capable of

reproducing stress–strain response for a wide variety of loading condi­

tions and different types of soils were used to simulate soil response. This

capability of bounding surface models comes at the cost of complexity:

the LS2009 model (Loukidis and Salgado, 2009) for sand requires 22

input parameters, whereas the CLS2013 (Chakraborty et al., 2013)

model for clay requires 15 parameters if parameters required to capture

strain-rate-dependence and residual state are ignored (22 if included).

This complexity may impede the use of some numerical schemes that are

used for simulating large deformation problems, such as ALE, which

require the mapping of state variables from old Gauss Point locations to

new Gauss Point locations. This mapping is an approximation, which,

for highly complex models, can lead to issues in achieving an “equilib­

rium” stress-state once the variables are mapped.

To circumvent this issue, the material point method, which does not

require the mapping of state variables, was adopted. However, this too

comes at a cost: the numerical integration in MPM is not guaranteed to

yield the correct integral even for small-deformation elastic problems. In

this study, we discussed several strategies that were adopted to mini­

mize errors in MPM while maintaining computational feasibility, such as

the use of an irregular moving-compressible grid, the B strategy for

mitigating volumetric locking, use of an adaptive sub-incrementation

Although it is difficult to provide an exact value to the amount of

over-estimation as a result of stair-stepped discretization, a reasonable

assumption would be that qc values for a stair-stepped discretized cone

would lie roughly between that of a perfectly discretized cone and a flat

cone. Simulations performed with a flat cone under identical conditions

provided qc values that were ~8% higher than qc values obtained using a

stair-stepped discretization. Correcting the qc values for this difference

would lead to an unweighted average cone factor Nk,avg = 13.7.

1

This indeed appears to be the case, as elements located below the cone tend

to experience loading more akin to TXC, and they, intuitively, are more im­

pactful than elements to the sides, which would experience loading paths more

associated with TXE.

11

V. Bisht et al.

Computers and Geotechnics 172 (2024) 106430

Fig. 6. Cone resistance qc vs. normalized penetration depth d/dc curves obtained from MPM simulations for penetration at depths of: (a) 5.6 m; (b) 6.0 m; and (c) 9.6

m (the two red lines indicate cone resistances obtained from the two in situ CPT tests).

prefer to use an Nk, value corresponding to the undrained shear

strength—UDTXC, UDTXE, or UDSS— required by the design method

being used.

MPM appears to offer a solid base on which to build methods of

interpretation of CPT results. To broaden this base, extension of analyses

to different types of sands and clays and their mixtures is desirable.

Methods of interpretation must then account for other factors, such as

spatial variability of soil state variables, which can also be advanced by

designing suitable MPM simulations.

Table 7

Comparison of CPT resistances measured in the field (after Landon (2007)) and

computed using MPM simulations.

Depth (m)

5.6

6.0

9.6

*

CPT-1 (kPa)

CPT-2 (kPa)

CPT (MPM)

778

718

730

556

565

580

820

704

650*

after (Bisht et al., 2021c).

CRediT authorship contribution statement

Table 8

Nk values determined using single-element loading simulations.

Depth (m)

5.6

6.0

9.6*

*

UDTXC

UDTXE

UDSS

Vibhav Bisht: Writing – review & editing, Writing – original draft,

Software, Methodology, Conceptualization. Rodrigo Salgado: Writing –

review & editing, Writing – original draft, Methodology, Conceptuali­

zation. Monica Prezzi: Writing – review & editing, Writing – original

draft, Methodology, Conceptualization.

Nk,ave

su (kPa)

Nk,TXC

su (kPa)

Nk,TXE

su (kPa)

Nk,SS

55.0

44.6

38.8

13.0

13.3

12.2

38.0

30.9

27.0

18.8

19.2

17.6

49.6

40.6

35.9

14.4

14.6

13.2

15.4

15.7

14.4

Declaration of competing interest

after (Bisht et al., 2021c).

The authors declare that they have no known competing financial

interests or personal relationships that could have appeared to influence

the work reported in this paper.

scheme with error control for constitutive model integration, and the

accurate imposition of tractions.

Cone penetration simulations were performed for sands at different

relative densities and vertical effective stresses. Cone resistance values

obtained from MPM were found to be smaller than those predicted using

cavity expansion analysis for all cases, indicating that cavity expansion

analysis may slightly overpredict cone resistances. For clays, the MPM

cone penetration simulations were compared with field results for Bos­

ton Blue Clay at different depths and OCR values, and the penetration

values were found to be, for practical purposes, within the range of the

CPT values recorded in the field. An average cone factor of 13.7 was

computed using the cone resistances computed using MPM and su values

obtained from single-element simulations performed under UDTXC,

UDTXE, and UDSS conditions. Although the cone factor Nk,avg = 13.7 is

within the range of values, 9–15, found in the literature, this value is

likely an overestimate of the cone factor, because of limitations in cone

discretization within MPM. However, instead of Nk,avg, a designer may

Data availability

Data will be made available on request.

References

Alshibli, K.A., Hasan, A., 2008. Spatial variation of void ratio and shear band thickness in

sand using X-ray computed tomography. Géotechnique 58 (4), 249–257.

Alshibli, K.A., Sture, S., 1999. Sand shear band thickness measurements by digital

imaging techniques. J. Comput. Civ. Eng. 13 (2), 103–109.

Andersen, S., Andersen, L., 2010. Analysis of spatial interpolation in the material-point

method. Comput. Struct. 88 (7–8), 506–518.

Bardenhagen, S.G., Brackbill, J.U., Sulsky, D., 2000. The material-point method for

granular materials. Comput. Methods Appl. Mech. Eng. 187 (3–4), 529–541.

Bardenhagen, S.G.G., Guilkey, J.E.E., Roessig, K.M.M., Brackbill, J.U.U., Witzel, W.M.M.,

Foster, J.C., 2001. An improved contact algorithm for the material point method and

12

Computers and Geotechnics 172 (2024) 106430

V. Bisht et al.

application to stress propagation in granular material. Comput. Model. Eng. Sci. 2

(4), 509–522.

Bardenhagen, S.G., Kober, E.M., 2004. The generalized interpolation material point

method. Comput. Model. Eng. Sci. 5 (6), 477–495.

Been, K., Jefferies, M.G., 1985. A state parameter for sands. Géotechnique 35 (2),

99–112.

Belytschko, T.B., Kennedy, J.M., 1978. Computer models for subassembly simulation.

Nucl. Eng. Des. 49 (1–2), 17–38.

Biot, M.A., 1941. General theory of three-dimensional consolidation. J. Appl. Phys. 12

(2), 155–164.

Bisht, V., Salgado, R., 2018. Local transmitting boundaries for the generalized

interpolation material point method. Int. J. Numer. Meth. Eng. 114 (11),

1228–1244.

Bisht, V., Salgado, R., Prezzi, M., 2021a. Analysis of Cone Penetration Using the Material

Point Method. Springer International Publishing.

Bisht, V., Salgado, R., Prezzi, M., 2021b. Simulating penetration problems in

incompressible materials using the material point method. Comput. Geotech. 133,

103593.

Bisht, V., Salgado, R., Prezzi, M., 2021c. Material point method for cone penetration in

clays. J. Geotech. Geoenviron. Eng. 147 (12), 1–16.

Bruhns, O.T., Xiao, H., Meyers, A., 1999. Self-consistent Eulerian rate type elastoplasticity models based upon the logarithmic stress rate. Int. J. Plast 15 (5), 479–520.

Ceccato, F., 2015. Study of Large Deformation Geomechanical Problems with the

Material Point Method. Universit‘a degli Studi di Padova.

Ceccato, F., Beuth, L., Vermeer, P.A., Simonini, P., 2016. Two-phase material point

method applied to the study of cone penetration. Comput. Geotech. 80, 440–452.

Elsevier Ltd.

Ceccato, F., Yerro, A., Martinelli, M., 2018. Modelling soil-water interaction with the

material point method. Evaluation of single-point and double-point formulations. In:

Numerical Methods in Geotechnical Engineering IX. CRC Press, pp. 351–357.

Chakraborty, T., Salgado, R., Loukidis, D., 2013. A two-surface plasticity model for clay.

Comput. Geotech. 49, 170–190.

Courant, R., Friedrichs, K., Lewy, H., 1967. On the partial difference equations of

mathematical physics. IBM J. Res. Dev. 11 (2), 215–234.

Dafalias, Y.F., Manzari, M.T., 2004. Simple plasticity sand model accounting for fabric

change effects. Journal of Engineering mechanics 130 (6), 622–634. https://doi.org/

10.1061/(ASCE)0733-9399(2004)130:6(622).

De Boer, R., 2012. Theory of Porous Media: Highlights in Historical Development and

Current State. Springer Science & Business Media.

Desrues, J., Viggiani, G., 2004. Strain localization in sand: an overview of the

experimental results obtained in Grenoble using stereophotogrammetry. Int. J.

Numer. Anal. Meth. Geomech. 28 (4), 279–321.

Dienes, J.K., 1979. On the analysis of rotation and stress rate in deforming bodies. Acta

Mech. 32 (4), 217–232.

Durgunoglu, H.T., Mitchell, J.K., 1975. Static penetration resistance of soils. In:

Conference on In Situ Measurement of Soil Properties, pp. 151–189.

González Acosta, J.L., Vardon, P.J., Hicks, M.A., 2021. Development of an implicit

contact technique for the material point method. Comput. Geotech. 130 (June 2020),

103859.

Hamad, F., Giridharan, S., Moormann, C., 2017. A penalty function method for

modelling frictional contact in MPM. Procedia Eng. 116–123. Elsevier B.V.

Han, F., Ganju, E., Salgado, R., Prezzi, M., 2018. Effects of interface roughness, particle

geometry, and gradation on the sand-steel interface friction angle. J. Geotech.

Geoenviron. Eng. 144 (12), 04018096.

Hardin, B.O., Richart, J.F.E., 1963. Elastic wave velocities in granular soils. J. Soil Mech.

Found. Div. 89 (1), 33–65.

Huang, P., Zhang, X., Ma, S., Huang, X., 2011. Contact algorithms for the material point

method in impact and penetration simulation. Int. J. Numer. Meth. Eng. 85 (4),

498–517.

Hughes, T.J.R., 1980. Generalization of selective integration procedures to anisotropic

and nonlinear media. Int. J. Numer. Meth. Eng. 15 (9), 1413–1418.

Itasca, 2016. FLAC–Fast Lagrangian Analysis of Continua, Version 8.0. Itasca Consulting

Group, Minneapolis.

Jiao, Y., Fish, J., 2017. Is an additive decomposition of a rate of deformation and

objective stress rates passé? Comput. Methods Appl. Mech. Eng. 327, 196–225.

Elsevier B.V.

Jiao, Y., Fish, J., 2018. On the equivalence between the multiplicative hyper-elastoplasticity and the additive hypo-elasto-plasticity based on the modified kinetic

logarithmic stress rate. Comput. Methods Appl. Mech. Eng. 340, 824–863. Elsevier B.

V.

Kafaji, I.K., 2013. Formulation of a Dynamic Material Point Method (MPM) for

Geomechanical Problems. Institut für Geotechnik der Universität Stuttgart.

Kang, F., Han, S., Salgado, R., Li, J., 2015. System probabilistic stability analysis of soil

slopes using Gaussian process regression with Latin hypercube sampling. Comput.

Geotech. 63, 13–25. Elsevier Ltd.

Ladd, C., Varallyay, J., 1965. The influence of the stress system on the behavior of

saturated clays during undrained shear. Research report no R65-11, Department of

Civil Engineering, MIT, Cambridge, MA.

Landon, M.M., 2007. Development of a Non-Destructive Sample Quality Assessment

Method for Soft Clays. University of Massachusetts Amherst.

Lin, H., Penumadu, D., 2006. Strain localization in combined axial-torsional testing on

kaolin clay. J. Eng. Mech. 132 (5), 555–564.

Lorenzo, R., da Cunha, R.P., Cordão Neto, M.P., Nairn, J.A., 2018. Numerical simulation

of installation of jacked piles in sand using material point method. Can. Geotech. J.

55 (1), 131–146.

Loukidis, D., Salgado, R., 2009. Modeling sand response using two-surface plasticity.

Comput. Geotech. 36 (1–2), 166–186. Elsevier Ltd.

Lubliner, J., 2008. Plasticity Theory. Courier Corporation.

Ma, J., Wang, D., Randolph, M.F., 2014. A new contact algorithm in the material point

method for geotechnical simulations. Int. J. Numer. Anal. Meth. Geomech. 38 (11),

1197–1210.

Ma, S., Zhang, X., Lian, Y., Zhou, X., 2009. Simulation of high explosive explosion using

adaptive material point method. CMES – Comput. Model. Eng. Sci. 39 (2), 101–123.

Manzari, M.T., Dafalias, Y.F., 1997. A critical state two-surface plasticity model for

sands. Géotechnique 47 (2), 255–272.

Martinelli, M., Galavi, V., 2021. Investigation of the material point method in the

simulation of cone penetration tests in dry sand. Comput. Geotech. 130 (November

2020). Elsevier Ltd.

Mieremet, M.M.J., Stolle, D.F., Ceccato, F., Vuik, C., 2016. Numerical stability for

modelling of dynamic two-phase interaction. Int. J. Numer. Anal. Meth. Geomech.

40 (9), 1284–1294.

Moore, I.D., Rowe, R.K., 1988. Numerical models for evaluating progressive failure in

earth structures—A review. Comput. Geotech. 6 (3), 217–239.

Moug, D.M., Boulanger, R.W., DeJong, J.T., Jaeger, R.A., 2019. Axisymmetric

simulations of cone penetration in saturated clay. J. Geotech. Geoenviron. Eng. 145

(4), 04019008.

Nairn, J.A., Guilkey, J.E., 2015. Axisymmetric form of the generalized interpolation

material point method. Int. J. Numer. Meth. Eng. 101 (2), 127–147.

Prager, W., 1961. An elementary discussion of definitions of stress rate. Q. Appl. Math.

18 (4), 403–407.

Sadeghirad, A., Brannon, R.M., Burghardt, J., 2011. A convected particle domain

interpolation technique to extend applicability of the material point method for

problems involving massive deformations. Int. J. Numer. Meth. Eng. 86 (12),

1435–1456.

Sadeghirad, A., Brannon, R.M., Guilkey, J.E., 2013. Second-order convected particle

domain interpolation (CPDI2) with enrichment for weak discontinuities at material

interfaces. Int. J. Numer. Meth. Eng. 95 (11), 928–952.

Salgado, R., 2012. The mechanics of cone penetration: contributions from experimental

and theoretical studies. Geotech. and Geophys. Charact. 4, 131–135.

Salgado, R., 2022. The Engineering of Foundations, Slopes and Retaining Structures. CRC

Press, Boca Raton.

Salgado, R., Bisht, V., 2021. Advances in the solution of geotechnical boundary-value

problems. Comput. Geotech. 138 (July), 104183. Elsevier Ltd.

Salgado, R., Mitchell, J.K., Jamiolkowski, M., 1997. Cavity expansion and penetration

resistance in sand By R. Salgado’, Associate Member, ASCE. J. Geotech. Geoenviron.

Eng. 123 (April), 344–354.

Salgado, R., Bisht, V., Prezzi, M., 2022. Material Point Method simulations of cone

penetration and CPT interpretation. In: Cone Penetration Testing 2022. CRC Press,

pp. 16–27.

Salgado, R., Prezzi, M., 2007. Computation of cavity expansion pressure and penetration

resistance in sands. Int. J. Geomech. 7 (4), 251–265.

Salgado, R., Randolph, M.F., 2001a. Int. J. Geomech. 2001.1:175–192. Int. J. Geomech. 1

(2), 175–192.

Salgado, R., Randolph, M.F., 2001b. Analysis of cavity expansion in sand. Int. J.

Geomech. 1 (2), 175–192.

Selvadurai, A.P.S., 2007. The analytical method in geomechanics. Appl. Mech. Rev. 60

(3), 87–106.

Selvadurai, A.P., Suvorov, A.P., 2016. Thermo-Poroelasticity and Geomechanics.

Cambridge University Press.