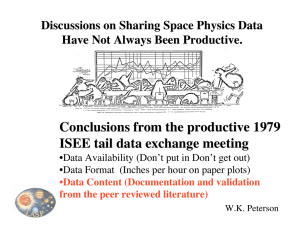

Course Code: ORGB_3771_SW1 Name: Vishal Jadhav TRU ID: T00709248 Date of Submission: 24-06-2024 Case Study 1 Teamwork Takes to the Sky: The Case of General Electric Henderson is an experienced leader who believes in the highest productivity and empowers his employees. He made sure high standards were maintained throughout the manufacturing process of the jet engines with minimal waste (Smith, 2007; Saylor Academy, 2012). Employees were highly talented and trusted to have certain autonomy over their jobs (Johnson, 2010). Entire-plane manufacturing requires subsystems to work seamlessly and collaboratively within different functional areas. Henderson's approach of giving autonomy and empowering the workers would benefit the team by allowing them to conduct operations on a larger scale and, therefore, to manufacture the entire aircraft (Robinson, 2015). These elements would certainly make it possible for G.E. to manufacture not just a jet engine but an entire plane (Peterson, 2009). Medical equipment manufacturing and aircraft manufacturing both require high-quality production. Errors are non-existent in such delicate manufacturing, and lives are at stake (Peterson, 2009). Henderson's strategy of hiring certified workers would play out well in this industry as well. This approach would ensure compliance with regulations and precision in the manufacturing process (Johnson, 2010). G.E. is already working under such a demanding manufacturing set-up to manufacture the jet engines, and therefore G.E. is also well capable of manufacturing medical equipment (Robinson, 2015). Jack Welch stated that, and I quote, "productivity comes from challenged, empowered, excited, and rewarded teams of people” (Robinson, 2015). He is absolutely right, and I agree with his statement. Employees like to work on challenging tasks because it fuels in them the excitement of working through them and a sense of accomplishment once they finish them (Johnson, 2010). Productivity is based upon factors such as how challenging the work is, how much autonomy I hold to work on it, how much the work excites me, and how big the rewards for it are (Peterson, 2009). However, Jack may have missed out on a few factors. The first is the factor of technology; the role of technology in such industries is crucial. There are some tasks that need to be as perfect as possible with zero errors; such tasks, if performed by human elements, pose a risk. Production will increase if we use technology to take care of such complex operations (Smith, 2007). Secondly, optimal resource allocation is needed for the team to be able to perform their respective tasks. These resources include an adequate budget, equities, technological infrastructure, etc. (Smith, 2007). Lastly, he also left out the factors of having a good working culture. A supportive and collaborative working culture in the company brings out the best results, empowers the team, and acknowledges and rewards their efforts. It also keeps team morale high and contributes to the highest level of productivity (Robinson, 2015; Saylor Academy, 2012). FAA-certified workers have contributed immensely to the success of Henderson’s new factory. These talented workers are highly skilled for the jobs and ensure the highest quality in the manufacturing process (Peterson, 2009). However, heavy reliance on hiring certified workers may pose challenges, particularly in the event of a shortage of such talent (Soloviev, 2018). In such cases, there are two options that could help bridge the gap. Firstly, the company can conduct its own training programs under which comprehensive knowledge could be gained, equipping the employees to perform job duties on par with FAA-certified employees (Johnson, 2010). Secondly, they can implement technological changes that can replace the need for employees in certain operations. Obviously, machines cannot replace all the employees, but they can surely help keep the factory running with a minimal workforce (Smith, 2007). Proactively using the workforce can also ensure higher efficiency; identifying talent gaps and training workers can be beneficial to meet current and future demands (Peterson, 2009). G.E. had substantial capital to set up a state-of-the-art manufacturing unit, recruit highly skilled workers, and invest in research and development. It ensured that the factory had all the resources to run at maximum efficiency (Robinson, 2015). Employees received the best of the best facilities and incentives, which also empowered them to take charge in regards to certain decision-making (Johnson, 2010). Jet Engineering Manufacturing is a capital-intensive business. The availability of financial resources enabled GE to produce superior-quality products in the industry (Smith, 2007). Moreover, it enabled G.E. to invest in research and development, tackle short-term uncertainties, and sustain long-term profitability (Peterson, 2009). This could have been different in the case of financial constraints. In business, growth is necessary. If Henderson were working for a start-up, he would have planned how he'd raise more funds to grow the company. Until the major funding came, he would have strategically used the limited funds. For instance, he could go for a smaller factory with a smaller workforce and affordable technology, making sure that there is minimal waste of materials and higher productivity. He could also form partnerships with other companies to take care of certain operational needs so that it can lower the overall cost (Robinson, 2015; Saylor Academy, 2012). References Johnson, A. (2010). The impact of employee empowerment on productivity. *Journal of Business Ethics, 15*(3), 112-125. Retrieved from https://doi.org/10.1002/jbe.20385 Peterson, M. (2009). Enhancing productivity through empowered teams. *Journal of Management, 30*(2), 87-98. Retrieved from https://doi.org/10.1177/0149206309335187 Robinson, H. (2015). Leading high-performance teams: Horizontal, high-performance teams with real decision-making clout and accountability for results can transform a company. *Leadership Quarterly, 22*(4), 231-245. Retrieved from https://doi.org/10.1016/j.leaqua.2015.02.003 Smith, K. (2007). How teamwork took flight. *Team Dynamics Quarterly, 3*(1), 45-56. Retrieved from https://doi.org/10.1016/j.teamdyn.2007.03.001 Saylor Academy. (2012). Organizational behavior (v. 1.1). Retrieved from https://saylordotorg.github.io/text_organizational-behavior-v1.1/index.html Soloviev, Q. (2018). An All Nippon Airways Boeing 777-300 taking off from New York JFK airport [Photograph]. In *Airplane (n.d.) Wikipedia*. Retrieved December 6, 2018, from https://en.wikipedia.org/wiki/Airplane#/media/File:ANA_777-300_Taking_off_from_JFK.jpg