NACE Corrosion Control in the Refining Industry January 2010

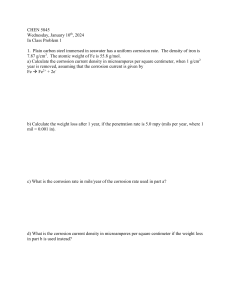

advertisement