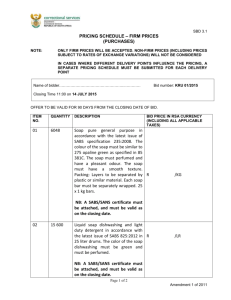

© SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. ISBN 978-0-626-26724-7 SANS 1574-2:2012 Edition 1 SOUTH AFRICAN NATIONAL STANDARD Electric flexible cables with solid extruded dielectric insulation Part 2: PVC insulated flexible cables for domestic, office and similar environments (cords) Published by SABS Standards Division 1 Dr Lategan Road Groenkloof Private Bag X191 Pretoria 0001 Tel: +27 12 428 7911 Fax: +27 12 344 1568 www.sabs.co.za © SABS © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Table of changes Change No. Date Scope Foreword This South African standard was approved by National Committee SABS TC 66, Electric cables, in accordance with procedures of the SABS Standards Division, in compliance with annex 3 of the WTO/TBT agreement. This document was published in December 2012. This document supersedes SANS 60227-5:2006 (edition 1.2). SANS 1574 consists of the following parts, under the general title Electric flexible cables with solid extruded dielectric insulation: Part 1: General. Part 2: PVC insulated cables for domestic, office and similar environments (cords). Part 3: PVC-insulated cables for industrial use. Part 4: Rubber-insulated cables for domestic, office and similar environments (cords). Part 5: Rubber-insulated cables for industrial use. Annexes A and B are for information purposes only. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Contents Page Foreword 1 Scope ..................................................................................................................................... 3 2 Normative references ............................................................................................................. 3 3 Definitions .............................................................................................................................. 4 4 General requirements ............................................................................................................ 4 5 Specific requirements for types of flexible cords in common use .......................................... 9 6 Packing and marking ............................................................................................................. 14 7 Inspection and methods of test ............................................................................................... 14 Annex A (informative) System for designation of harmonized cables and cords ................... 17 Annex B (informative) Guide to the use of insulated flexible cables ......................................... 18 Bibliography.............................................................................................................................. 20 1 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 This page is intentionally left blank 2 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Electric flexible cables with solid extruded dielectric insulation Part 2: PVC insulated flexible cables for domestic, office and similar environments (cords) 1 Scope 1.1 This part of SANS 1574 specifies the characteristics of single-core flexible insulated wires and multi-core flexible cords, of rated operating voltage up to and including 300 V to earth and 500 V between conductors, and is intended for use with electrical appliances in domestic, office and similar applications. Insulating and sheathing materials of PVC are covered. NOTE 1 Unsheathed PVC insulated Ripcord has been removed from the SANS 1574 series for safety reasons. Type P3 and P10 products are recommended as replacements for this product. 2 NOTE 2 Cords of 4 mm are excluded from this part of the standard and it is recommended that cables of this size, which are intended for industrial use, be manufactured to SANS 1574-3. 1.2 Specific requirements are given for a number of types of cords in common use but this standard covers any type of cord or wire that falls within the limitation of 1.1. The types for which specific requirements are given are the following: a) Type P1 :Normal duty, non-sheathed, 300/500V single core (H05V-F); b) Type P3 :Light duty, sheathed, flat 300/300V (H03VVH2-F); c) Type P5 :Normal duty, sheathed, circular 300/500V (H05VV-F); d) Type P7 :Light duty, sheathed, circular 300/300V (H03VV-F); e) Type P10 :Normal duty, sheathed, flat 300/500V (H05VVH2-F); f) Type P14 :Light duty extensible lead 300/300V (H03VVH8-F and H03VVH2H8-F); and g) Type P15 :Normal duty extensible lead 300/500V (H05VVH8-F and H05VVH2H8-F). 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For updated references, the latest edition of the referenced document (including any amendments) applies. Information on currently valid national and international standards may be obtained from the SABS Standards Division. SANS 1411-1, Materials of insulated electric cables and flexible cords – Part 1: Conductors. 3 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 SANS 1411-2, Materials of insulated electric cables and flexible cords – Part 2: Polyvinyl chloride (PVC). SANS 1507-1, Electric cables with extruded solid dielectric insulation for fixed installations (300/500 V to 1 900/3 300 V) – Part 1: General. SANS 5515, Flexing test on flexible cords. SANS 1574-1, Electric flexible cores, codes and cables with solid extruded dielectric insulation – Part 1: General. SANS 5526, Dielectric resistance of electric cables. SANS 6205, Extensibility test for extensible leads. SANS 6208, Extension test for extensible leads. SANS 6282-1, Test methods for bare conductors and conductors of insulated electric cables – Part 1: Conductor resistance. SANS 6284-3, Test methods for cross-linked polyethylene (XLPE) insulated electric cables – Part 3: Tests on finished cable. SANS 60811-1-1/IEC 60811-1-1, Common test methods for insulating and sheathing materials of electric cables and optical cables – Part 1-1: Methods for general application – Measurement of thickness and overall dimensions – Tests for determining mechanical properties. SANS 62230/IEC 62230, Electric cables – Spark-test method. 3 Definitions For the purposes of this document, the definitions given in SANS 1411-1, SANS 1411-2, SANS1507-1 and SANS 1574-1 apply. 4 General requirements 4.1 Operating voltage The maximum operating voltage (Uo/U) of a flexible cord shall be 300/300 V or 300/500 V. 4.2 Materials and construction 4.2.1 Conductors Conductors shall comply with the requirements for class 5 plain or tinned copper of SANS 1411-1, unless otherwise stated in the relevant specific requirements given in clause 5. 4.2.2 Insulation 4.2.2.1 Material The insulation shall be of solid extruded dielectric of one of the types given in column 2 of table 1, and shall comply with the relevant requirements of the applicable specification given in column 3. 4 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 4.2.2.2 Application The insulation shall be closely applied to the conductor or separator. It shall be possible to remove the insulation without damage to the insulation itself or to the conductor or to any coating. 4.2.2.3 Thickness and insulation resistance Unless otherwise stated in the relevant specific requirements given in clause 5, the nominal thickness and the insulation resistance shall comply with the requirements given in table 4, for nominal thickness, as appropriate to the type of material, conductor size and operating voltage. When the thickness of the insulation is determined in accordance with 7.5.1, the average thickness shall be at least equal to the nominal value, and the minimum thickness at any point shall be not less than the corresponding minimum value given in table 4. 4.2.2.4 Spark testing of insulation During manufacture, the core insulation shall have been continuously spark tested, using the method given in SANS 62230 at an a.c. (r.m.s.) spark test voltage of 5 000 V without breakdown of the dielectric. Alternatively, a dc spark test voltage of 7 500 V may be used. 4.3 Core identification 4.3.1 Identification Cores of flexible cords shall be identified by colouring up to seven cores and by numbering for more than seven cores. The colours shall be as given in table 2, unless otherwise stated in the relevant specific requirements given in clause 5. 4.3.2 Colour application Colour shall be applied a) throughout the thickness of the insulation; or b) in a durable manner on the entire surface of the insulation. 4.3.3 Earthing cores An earthing core shall be coloured green and yellow, and the combination of the colours shall be such that one of the colours covers not less than 30 % and not more than 70 % of the surface of the core, and the other covers the remainder of the surface. There shall be no green/yellow coloured core in a two-core cord or in any non-earthing type cord. NOTE The combination of green/yellow is reserved exclusively for the identification of the earthing core (see annex A). 4.3.4 Assembly of cores 4.3.4.1 General Unless otherwise stated in the relevant specific requirements given in clause 5, cores of a multicore flexible circular cord shall be compactly laid up (when relevant, in the correct sequence of their identification colours (see table 2)), with an acceptable lay or straight in the case of flat cables with parallel cores. 5 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 4.3.4.2 Fillers Fillers may be applied either separately or integrally with the sheath and shall be used in the interstices of the flexible cord where necessary, to give the completed flexible cord an acceptable compact circular profile. 4.4 Protective covering 4.4.1 Material A protective covering, where required, shall consist of one of the materials given in column 2 of table 3. In the case of an extruded sheath, the covering may fill the interstices between the cores but shall not adhere to the cores. The core assembly may be surrounded by a separator tape, provided that it does not adhere to the cores. Circular flexible cords shall have an acceptable circular cross-section (see 4.4.4). 4.4.2 Thickness Unless otherwise stated in clause 5, the nominal thickness of an extruded sheath shall be as given in table 5, 8 or in table 9, as appropriate. When the average thickness of the sheath is determined in accordance with 7.5.1, it shall be at least equal to the nominal value, and the minimum thickness at any point shall be not less than the corresponding minimum value given in the tables. 4.4.3 Overall diameter limits For a type of flexible cord covered by the specific requirements of clause 5, the mean overall diameter, determined in accordance with 7.5.2, shall not exceed the upper limit appropriate to the cable. 4.4.4 Ovality For a circular flexible cord, the difference between any two values of the overall diameter of circular sheathed cores at the same cross-section (the ovality), determined in accordance with 7.5.3, shall not exceed 15 % of the upper limit appropriate to the cord. 4.5 Electrical requirements for finished flexible cords 4.5.1 Conductor resistance When determined in accordance with 7.4.1, the d.c. resistance of each conductor shall not exceed the appropriate maximum value given in SANS 1411-1. 4.5.2 Voltage withstand When a flexible cord is tested in accordance with 7.4.2, each core of the flexible cord shall withstand, for 5 min or 10 min, as relevant, without breakdown of the dielectric, a test voltage of the appropriate value given in table 6. 4.5.3 Spark test During manufacture, the core insulation shall have been continuously spark tested, using the method given in SANS 62230 at an a.c. (r.m.s.) spark test voltage of 5 000 V without breakdown of the dielectric. Alternatively, a d.c. spark test voltage of 7 500 V may be used. 6 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 4.6 Insulation resistance of PVC-insulated flexible cords When a flexible cord is tested in accordance with 7.4.4, the resistance of the insulation of the flexible cord shall be at least equal to the value given in the appropriate columns of table 4. 4.7 Electrical mechanical strength requirements 4.7.1 Flexing test When a cord other than a single-core cord is tested in accordance with 7.6.1, no open circuit of any conductor or short circuit between cores shall occur during flexing and no breakdown of insulation shall occur when the cord is subsequently subjected to the voltage withstand test of 7.4.2. 4.7.2 Extension test for extensible leads When an extensible lead is tested in accordance with 7.6.2, the coil shall return to 150 % (or less) of its original coiled length within 30 s after the fifth extension. 4.7.3 Extensibility test for extensible leads When an extensible lead is tested in accordance with 7.6.3, there shall be no electrical discontinuity in any of the cores during the test and no breakdown of the insulation shall occur when the lead is subsequently subjected to the withstand voltage test of 7.4.2. Table 1 — Types of insulating material 1 2 3 Insulation Types Applicable specification D2, D3, D4, D5, D6 SANS 1411-2 Thermoplastic, PVC based Table 2 — Core identification 1 2 Cores Colours Single-core Two core Green/yellow, or other mono-coloursa Blue, brown Three-core (earthing type) Three-core (non-earthing type) Green/yellow, blue, brown Blue, brown, black Four-core (earthing type) Four-core (non earthing type) Green/yellow, black, blue, brown Black, blue, brown, violet Five-core (earthing type) Five-core (non earthing type) Green/yellow, blue, brown, black, violet Blue, brown, black, violet, pink Seven-core (earthing type) Seven-core (non-earthing type) Green/yellow, blue, brown, black, violet, pink, orange Blue, brown, black, violet, pink, orange, turquoise a In addition to the combination green/yellow, the following other mono-colours are recognized: green, yellow, black, blue, brown, grey, orange, pink, red, turquoise, violet and white. 7 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Table 3 — Types of protective covering 1 2 3 Covering Type Applicable specification S3, S4, S5 SANS 1411-2 Thermoplastic, PVC based Table 4 — Thickness and insulation resistance of PVC insulation 1 2 3 4 Thickness of insulation Conductor size mm 5 Minimum insulation resistance at 70 0C mm 6 7 Thickness of insulation Minimum insulation resistance 0 at 70 C mm 2 nom. min. nom. mΩ.km 300/300 V min. mΩ.km 300/500V 0,50 0,75 0,5 0,5 0,35 0,35 0,012 0,011 0,6 0,6 0,44 0,44 0,012 0,011 1 1,5 2,5 - - - 0,6 0,7 0,8 0,44 0,53 0,62 0,010 0,010 0,009 Table 5 — Thickness of PVC sheathing of flexible cords 1 2 3 4 5 Conductor size mm² 6 7 8 9 10 11 Thickness mm 2-core Light duty 3-core 4-core 5-core More than 5-core nom. min. nom. min. nom. min. nom. min. nom. min. 0,5 0,6 0,41 0,6 0,41 0,6 0,41 - - - - 0,75 0,6 0,41 0,6 0,41 0,6 0,41 - - - - 0,5 0,8 0,58 0,8 0,58 0,8 0,58 0,9 0,67 0,9 0,67 0,75 0,8 0,58 0,8 0,58 0,8 0,58 0,9 0,67 0,9 0,67 1,0 0,8 0,58 0,8 0,58 0,9 0,67 0,9 0,67 0,9 0,67 1,5 0,8 0,58 0,9 0,67 1,0 0,75 1,1 0,84 1,1 0,84 2,5 1,0 0,75 1,1 0,84 1,1 0,84 1,2 0,92 1,2 0,92 Normal duty 8 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Table 6 — Test voltages 1 2 Rated Voltage 3 10 min test 5 5 min test Between conductors Between conductors and earth Between conductors - 2000 - 2 000 2 000 V 300/300 300/500 4 2000 Between any conductor and earth 2 000 5 Specific requirements for types of flexible cords in common use 5.1 General The specific requirements for types of flexible cords in common use are as follows: a) Type P1 :Normal duty, non-sheathed, 300/500V single core (H05V-F); b) Type P3 :Light duty, sheathed, flat 300/300V (H03VVH2-F); c) Type P5 Normal duty, sheathed, circular 300/500V (H05VV-F); d) Type P7 :Light duty, sheathed, circular 300/300V (H03VV-F); e) Type P10 :Normal duty, sheathed, flat 300/500V (H05VVH2-F); f) Type P14 :Light duty extensible lead 300/300V (H03VVH8-F and H03VVH2H8-F); and g) Type P15 :Normal duty extensible lead 300/500V (H05VVH8-F and H05VVH2H8-F). 5.2 Type P1 – Normal-duty, non-sheathed cord, 300/500 V single-core harmonized code designation: H05V-F NOTE It is customary to refer to the above as “flexible cables”, particularly when used in the context of internal wiring. 5.2.1 Construction The conductor(s) shall comply with the requirements for a class 5 conductor of SANS 1411-1. The insulation shall comply with the requirements for type D3 insulation of SANS 1411-2. The cord shall comply with the requirements of table 7. 5.2.2 Colours for core identification Green/yellow, blue or other colours (see table 2 for recognized colours). 9 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Table 7 — Specific requirements for type P1 cords 1 Conductor size 2 3 Thickness of insulation mm ² 0,5 0,75 1 mm nom. 0,6 0,6 0,6 min. 0,44 0,44 0,44 4 Mean overall diameter of each core (upper limit) mm 5 Minimum insulation resistance at 70°C 2,6 2,8 3,0 0,012 0,011 0,010 mΩ.km 5.3 Type P3 and P7 – PVC insulated, PVC sheathed light duty cord, 300/300V parallel 2 or 3 core, circular 2 core, 3 core and 4 core. Harmonized code designations: Parallel flat cords: HO3VVH2-F (type P3) Circular cords: HO3VV-F (type P7) 5.3.1 Construction The conductor shall comply with the requirements for a class 5 conductor of SANS 1411-1. The insulation shall comply with the requirements for type D3 of SANS 1411-2. A flat cord shall be formed from two or three cores laid parallel and sheathed with PVC that complies with the requirements for type S3 of SANS 1411-2. A circular cord shall be formed from two, three or fours cores twisted together and sheathed with PVC that complies with the requirements for type S3 of SANS 1411-2. The cords shall be of an acceptably circular cross-section and a centre filler may be used where necessary. The sheath may fill the interstices between the cores but shall not adhere to the cores. The assembly of cores may be surrounded by a separator, provided that it does not adhere to the cores. The cords shall comply with the requirements of table 8. 5.3.2 Colours for core identification The following are the colours for core identification: a) 2-core: blue and brown; b) 3-core: green/yellow, blue and brown; and c) 4-core: green/yellow, black, blue and brown. 10 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Table 8 — Specific requirements for type P3 or type P7 cords 1 Number of cores and conductor size 2 3 Thickness of insulation mm² 4 5 Thickness of sheath 2 × 0,5 2 × 0,5 2 × 0,75 2 x 0,75 nom. 0,5 0,5 0,5 0,5 mm min. 0,35 0,35 0,35 0,35 nom. 0,6 0,6 0,6 0,6 mm min. 0,41 0,41 0,41 0,41 3 × 0,5 3 × 0,75 0,5 0,5 0,35 0,35 0,6 0,6 0,41 0,41 0,35 0,35 0,6 0,6 0,41 0,41 4 × 0,5 0,5 4 × 0,75 0,5 a Indicative value only 6 7 Overall dimensional limits 8 Minimum insulation resistance at 70°C mm upper 3,7 × 5,9 5,9 3,8 × 6,3 6,3 0,012 0,012 0,011 0,011 4,9 5,2 6,3 6,3 0,012 0,011 5,6 6,0 6,8 7,4 0,012 0,011 lowera 3,0 × 4,9 4,6 3,2 × 5,2 4,9 mΩ.km 5.3 Type P5 and P10 – PVC-insulated, PVC-sheathed normal-duty cord, 300/500 V parallel 2 core, circular 2 core, 3 core, 4 core and 5 core. Harmonized core designations: Flat cords: HO5VVH2-F (type P10). Circular cords: HO5VV-F (type P5) 5.3.1 Construction The conductor(s) shall comply with the requirements for a class 5 conductor of SANS 1411-1. The insulation shall comply with the requirements for the type D3 of SANS 1411-2. A flat cord shall be formed from two or three cores laid parallel and sheathed with PVC that complies with the requirements for type S3 of SANS 1411-2. A circular cord shall be formed from two, three or four cores twisted together and sheathed with PVC that complies with the requirements for type S3 of SANS 1411-2. The cords shall be of an acceptably circular cross-section and a centre filler may be used where necessary. The sheath may fill the interstices between the cores but shall not adhere to the cores. The assembly of cores may be surrounded by a separator, provided that it does not adhere to the cores. The cord shall comply with the requirements of table 9. 5.3.2 Colours for core identification The following are the colours for core identification: a) 2-core: blue and brown; b) 3-core: green/yellow, blue and brown; c) 4-core: green/yellow, black, blue and brown; and d) 5-core: green/yellow, black, blue, brown and violet. 11 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Table 9 — Specific requirements for type P5 and type P10 cords 1 Number of cores and conductor size mm² 2 3 Thickness of insulation mm min. 0,44 0,44 0,44 0,44 0,44 0,53 0,62 4 5 Thickness of sheath 8 Minimum insulation resistance at 70°C mΩ.km mm min. 0,58 0,58 0,58 0,58 0,58 0,58 0,75 lowera 5,6 3,7 × 6,0 5,7 3,9 × 6,4 5,9 6,8 8,4 mm upper 7,0 4,5 × 7,2 7,2 5,2 × 8,0 7,5 8,6 10,6 0,012 0,011 0,011 0,010 0,010 0,010 0,009 2 × 0,5 2 × 0,75 2 × 0,75 2×1 2 ×1 2 × 1,5 2 × 2,5 nom. 0,6 0,6 0,6 0,6 0,6 0,7 0,8 3 × 0,5 3 × 0,75 3 × 0,75 3×1 3×1 3 × 1,5 3 ×2,5 0,6 0,6 0,6 0,6 0,6 0,7 0,8 0,44 0,44 0,44 0,44 0,44 0,53 0,62 0,8 0,8 0,8 0,8 0,8 0,9 1,1 0,58 0,58 0,58 0,58 0,58 0,67 0,84 5,8 3,7 × 8,3 6,0 3,9 ×8,9 6,3 7,4 9,2 7,2 4,5 × 9,5 7,6 5,2 ×10,5 8,0 9,4 11,4 0,012 0,011 0,011 0,010 0,010 0,010 0,009 4 × 0,5 4 × 0,75 4×1 4 × 1,5 4 × 2,5 0,6 0,6 0,6 0,7 0,8 0,44 0,44 0,44 0,53 0,62 0,8 0,8 0,9 1,0 1,1 0,58 0,58 0,67 0,75 0,84 6,6 6,9 7,1 8,4 10,1 8,3 8,6 9,0 10,5 12,5 0,012 0,011 0,010 0,010 0,009 0,44 0,44 0,44 0,53 0,62 0,9 0,9 0,9 1,1 1,2 0,67 0,67 0,67 0,84 0,92 7,0 7,4 7,8 9,3 11,2 8,9 9,3 9,8 11,6 13,9 0,011 0,011 0,010 0,010 0,009 0,6 5 × 0,5 0,6 5 × 0,75 0,6 5×1 0,7 5 × 1,5 0,8 5 × 2,5 a Indicative value only nom. 0,8 0,8 0,8 0,8 0,8 0,8 1,0 6 7 Overall dimensional limits 5.4 Type P14 – PVC insulated and sheathed light duty extensible lead, 300/300 V 2 core and 3 core. Harmonized code designation: HO3VVH8-F (circular P7), HO3VVH2H8-F (flat P3) Prior to being coiled into extensible leads, the cords shall comply with the requirements for 2 core or 3 core type P3 (flat) or type P7 (circular) flexible cords. The cord shall be coiled to produce a helical lead (see figure 1) that will substantially maintain its form during use. The minimum internal diameter of the coiled lead shall comply with table 10. 12 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Drg.399 Figure 1 — Typical 2-core extensible lead Table 10 — Minimum internal diameter of extensible leads 1 2 Maximum overall cord diameter Minimum internal diameter of completed coil mm Up to 8,0 8,1 to 11,0 mm 8,0 12,0 NOTE The length of the straight section of each end of the lead should be sufficient to allow at least one rewiring operation. 5.5 Type P15 – PVC insulated and sheathed normal duty extensible lead, 300/500V, 2 core and 3 core. Harmonized code designation: HO5VVH8-F (circular P5) HO5VVH2H8-F (flat P10) Prior to being coiled into extensible leads, the cords shall comply with the requirements of 2 core or 3 core type P5 (circular) or P10 (flat) flexible cords of 0,75 mm², 1,0 mm² or 1,5 mm² conductor size. The cords shall be coiled to produce a helical lead (see figure 1) that will substantially maintain its form during use. The minimum internal diameter of the coiled lead shall comply with the requirements of table 10. 13 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 6. Packing and marking 6.1 Packing Flexible cables shall be packed on reels or in coils. 6.2 Marking of flexible cords 6.2.1 Indication of origin All flexible cords shall be provided with an indication of origin consisting either of an identification thread or threads or the continuous legible marking of the manufacturer's name or trademark. The marking shall be regarded as continuous if the gap between the end of one complete inscription and the beginning of the next does not exceed: – 550 mm if the marking is on the sheath, and – 275 mm in all other cases. – if coloured threads are used, the colours shall comply with those registered with the SABS, where applicable. The colours shall be easy to recognize or shall become recognizable by cleaning, if necessary, with petrol or other suitable solvent. The marking of the manufacturer's name or trademark, if used, shall be one of the three following alternative methods: – printed tape within the cable; – printing, indenting or embossing on the insulation of at least one core (the core coloured blue, if there is one); or – printing, indenting or embossing on the sheath, if there is one. 6.2.2 Marking of reels and coils Each reel or coil package shall bear the following information in legible and indelible marking: a) the manufacturer's trade name or trademark (or both); b) the rated voltage, the rated current, the conductor size of phase conductor(s), the number of cores, and the type identification; c) the length of cable; and d) when applicable, any special properties. 7 Inspection and methods of test NOTE Annex B gives the guidelines for the use of insulated flexible cables. 7.1 Inspection Visually inspect and then measure each specimen in the sample for compliance with all the relevant requirements of this standard for which tests to assess compliance are not given in 7.4 to 7.6 (inclusive). 14 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 7.2 Methods of test For convenience, the properties to be tested, the test category, the test methods and the subclause giving the requirements are listed in table 11. Table 11 — List of tests to be conducted 1 2 3 4 5 Component(s) Test property Test category Test method Requirement subsection Conductor Construction S SANS 1411-1 4.2.1 Insulation Physical properties S SANS 1411-2 4.2.2.1 Thickness Spark test Core identification Assembly of cores R R R, S R, S 7.5.1 (SANS 60811-1-1) SANS 62230 Visual examination Visual examination 4.2.2.3 4.2.2.4 4.3 4.3.4 Physical properties S SANS 1411-2 4.4.3.1 Thickness R 7.5.1 (SANS 60811-1-1) 4.4.3.2 Marking Conductor resistance Voltage withstand Insulation resistance R S S S Visual examination 7.4.1 (SANS 6282-1) 7.4.2 (SANS 6284-3) 7.4.4 (SANS 5526) 6.2 4.5.1 4.5.2 4.6 Overall diameter Ovality Flexing test Extension test (extensible leads) Extensibility test (extensible leads S S T S 7.5.2 (SANS 6284-3) 7.5.3 (SANS 6284-3) 7.6.1 (SANS 5515) 7.6.2 (SANS 6208) 4.4.3.3 4.4.3.4 4.7.1 4.7.2 T 7.6.3 (SANS 6205) 4.7.3 Sheath Finished flexible cable NOTE In column 3 of this table, a code letter is given that identifies the tests as suitable for use as routine tests (R), sample tests (S) or type tests (T), but compliance with the requirements of the standard may only be fully determined from the results of tests carried out on sample of completed cable(s), using all the test methods given and a sampling procedure agreed upon. During production control, a manufacturer may use any tests that he deems necessary to ensure compliance with the standard but, in the case of a dispute, only the appropriate standard test methods may be used. 7.3 Conditions of test The following conditions of test shall apply: a) unless otherwise stated in the method of test, all tests shall be carried out at ambient temperature and pressure; and b) unless otherwise specified in the method of test, the frequency of the alternating test voltage used shall be approximately 50 Hz, and the waveform shall be substantially sinusoidal. 15 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 7.4 Electrical tests 7.4.1 Conductor resistance Use SANS 6282-1. 7.4.2 Voltage withstand Use SANS 6284-3 7.4.3 Spark test Use SANS 62230. 7.4.4 Insulation resistance Use SANS 5526. 7.5 Dimensional tests 7.5.1 Thickness of insulation and sheath Use SANS 60811-1-1. 7.5.2 Overall diameter Use SANS 6284-3. 7.5.3 Ovality Use SANS 6284-3. 7.6 Mechanical tests on completed flexible cords 7.6.1 Flexing test Use SANS 5515 and conduct the test for 15 000 cycles, a cycle being on movement in each direction. 7.6.2 Extension test for extensible leads Use SANS 6208. 7.6.3 Extensibility test for extensible leads Use SANS 6205. 16 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Annex A (informative) System for designation of harmonized cables and cords 17 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Annex B (informative) Guide to the use of insulated flexible cables Details given in this annex are intended only as general technical guidance and not as an interpretation of any South African statutory requirements, where these apply. B.1 General B.1.1 Flexible cables are not intended to be laid underground. B.1.2 Cables of undue length are not recommended. B.1.3 Where cables are to be used in ambient temperatures below 0 °C, the manufacturer should be consulted. B.2 Temperatures and current ratings B.2.1 The cables are suitable for use where the combination of ambient temperature and temperature rise due to load results in a conductor temperature does not exceed: a) 70 °C for types D3 and D6 PVC insulation; b) 90 °C for types D4 PVC insulation; and c) 105 °C for types D5 PVC insulation; B.2.2 The maximum continuous currently ratings of these tables are tabulated in table B.1 below. Table B.1 — The maximum continuous current ratings of insulated flexible cables 1 2 3 Conductor size mm2 Single phase A Three phase A 0,5 3 3 0,75 6 6 1,0 10 10 1,5 16 16 2,5 25 20 These maximum continuous current ratings apply to the majority of cases in ambient temperature of 30 °C. Further information should be sought from the manufacturer in unusual cases, for example: a) where high ambient temperatures are involved, i.e. above 30 °C; b) where long lengths are used; 18 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 c) where ventilation is restricted; or d) where the cables are used for purposes such as the internal wiring of apparatus. B.2.3 In case of short circuit, the maximum conductor temperature (maximum duration 5 s) should not exceed: 160 °C for PVC insulation. NOTE The short circuit temperature is based on the intrinsic properties of the insulation material. It is essential that the accessories that are used in the system with mechanical or soldered connections (or with both) are suitable for the temperature adopted for the flexible cord. B.2.4 Table B.2 below gives the guidelines to the use of insulated flexible cords Table B.2 — Guide to the use of insulated flexible cords 1 2 3 Type ref. Type and use Comments P1 PVC-Insulated Non-sheathed (internal wiring) Fixed protected installation inside appliances or on lighting fittings (or both) P3 , P7 P5, P10 Suitable for installations in surfacemounted or embedded conduits, only for signalling or control circuits. Light PVC-sheathed In domestic premises, kitchens, offices; for light duties for light portable appliances. Not suitable for cooking or spaceheating appliances. Not suitable for outdoor use in industrial or agricultural buildings or for supplying non-domestic portable tools. For cords of 0,75 mm² conductor size, the same use and comments for the ordinary PVC-sheathed cord below are applicable. Cords of 0,5 mm² conductor size are suitable for small hand-held appliances (except those incorporating heated parts) when specified by the relevant appliance standard Where extra flexibility is required and provided there is no particular danger of damage, light PVC-sheathed cords may be used. For applications subject to frequent flexing or torsion (or both), circular twin cords are recommended instead of flat cords Ordinary PVC-sheathed In domestic premises, kitchens, offices; for household appliances, including damp situations, for medium duties (e.g. machines, spin dries and refrigerators) Suitable for cooking and heating appliances, provided that there is no risk of contact with hot parts and that the appliance is not subject to radiation, etc. 19 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SANS 1574-2:2012 Edition 1 Bibliography SANS 1574-3, Electric flexible cables with solid extruded electric insulation – Part 3: PVC-insulated cores and cables. © SABS 20 © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents. The standard must reside on an internal network or intranet and may only be used for reference purposes in compliance with SABS copyright rules. The standard or parts thereof may not be distributed in any form without permission from the SABS. SABS – Standards Division The objective of the SABS Standards Division is to develop, promote and maintain South African National Standards. This objective is incorporated in the Standards Act, 2008 (Act No. 8 of 2008). Amendments and Revisions South African National Standards are updated by amendment or revision. Users of South African National Standards should ensure that they possess the latest amendments or editions. The SABS continuously strives to improve the quality of its products and services and would therefore be grateful if anyone finding an inaccuracy or ambiguity while using this standard would inform the secretary of the technical committee responsible, the identity of which can be found in the foreword. The SABS offers an individual notification service, which ensures that subscribers automatically receive notification regarding amendments and revisions to South African National Standards. Tel: +27 (0) 12 428 6883 Fax: +27 (0) 12 428 6928 E-mail: sales@sabs.co.za Buying Standards Contact the Sales Office for South African and international standards, which are available in both electronic and hard copy format. Tel: +27 (0) 12 428 6883 Fax: +27 (0) 12 428 6928 E-mail: sales@sabs.co.za South African National Standards are also available online from the SABS website http://www.sabs.co.za Information on Standards The Standards Information Centre provides a wide range of standards-related information on both national and international standards. The Centre also offers an individual updating service called INFOPLUS, which ensures that subscribers automatically receive notification regarding amendments to, and revisions of, international standards. Tel: +27 (0) 12 428 7911 / 0861 27 7227 Fax: +27 (0) 12 428 6928 E-mail: info@sabs.co.za Copyright The copyright in a South African National Standard or any other publication published by the SABS Standards Division vests in the SABS or, in the case of a South African National Standard based on an international standard, in the organization from which the SABS adopted the standard under licence or membership agreement. In the latter case, the SABS has the obligation to protect such copyright. Unless exemption has been granted, no extract may be reproduced, stored in a retrieval system or transmitted in any form or by any means without prior written permission from the SABS Standards Division. This does not preclude the free use, in the course of implementing the standard, of necessary details such as symbols, and size, type or grade designations. If these details are to be used for any purpose other than implementation, prior written permission must be obtained. Details and advice can be obtained from the Manager – Standards Sales and Information Services. Tel: +27 (0) 12 428 6883 Fax: +27 (0) 12 428 6928 E-mail: sales@sabs.co.za © SABS. This non-printable standard is exclusively for approved users of the SABS’ Complete Collection of Standards and Related Documents.