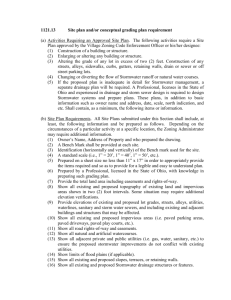

ENGINEERING PROCEDURE STORMWATER DRAINAGE SYSTEMS NEOM-NEN-PRC-315 Rev 01.00, May 2023 ©NEOM [2023]. All rights reserved. 4 Document History Revision code Description of changes Purpose of issue Date First Issue Issued for Implementation 08.05.2023 Rev 01.00 Document Approval Name Job Title Prepared by Reviewed by Approved by Fouad Youssif All Sector Dr. Mohamed Haj-Maharsi Senior Mechanical Specialist - ETSD Executive Director, Technical Consultancy- ETSD Document Preface Key Stakeholders: Proponent, Proponent’s representative, ETSD, NEOM Water, Mechanical/Infrastructural Engineers of Record, Independent Mechanical/Infrastructural Engineering Consultant Added Value: Outlines the requirements for the stormwater drainage systems design following NEOM Design Guidelines for wet utilities including runoff calculations: time of concentration, design return period, runoff quantity. Furthermore, it tackles the hydraulic design including open channels, gravitational stormwater pipes, drainage elements, manholes, pipes design velocities, pipe diameters and gradients in addition to the design criteria for sustainable drainage systems to mimic natural drainage. Impact: Unification of stormwater drainage design systems DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 2 OF 37 Contents 1 PURPOSE ..................................................................................................................5 2 SCOPE .......................................................................................................................5 3 DEFINITIONS .............................................................................................................5 3.1 Terms......................................................................................................................... 5 3.2 Abbreviations ............................................................................................................. 5 4 REFERENCES ...........................................................................................................6 4.1 NEOM Documents ..................................................................................................... 6 4.2 Other Documents....................................................................................................... 6 5 DESIGN ......................................................................................................................7 5.1 Philosophy ................................................................................................................. 7 5.2 Procedure .................................................................................................................. 8 5.2.1 Description of Project Location .................................................................................. 8 5.2.2 Determination of Used Software, Available Data and Summary of Methodologies ... 8 5.2.3 Site Visit Requirements ............................................................................................. 8 5.2.4 Topography and Survey ............................................................................................ 8 5.2.5 Rainfall Data Analysis ................................................................................................ 8 5.2.6 Hydrological Analysis................................................................................................. 8 5.2.7 Runoff Calculations.................................................................................................... 8 5.2.8 Pavement Drainage ................................................................................................. 15 5.2.9 Hydraulic Design of Storm Drain Systems ............................................................... 20 5.2.10 Design Guidelines.................................................................................................... 23 5.2.11 Sustainable Stormwater Drainage ........................................................................... 31 6 DESIGN REQUIREMENTS ......................................................................................35 6.1 General .................................................................................................................... 35 6.2 Preliminary Design................................................................................................... 35 6.3 Detailed Design ....................................................................................................... 36 6.4 Issue for Construction .............................................................................................. 36 7 APPENDICES ..........................................................................................................37 Appendix A Stormwater Drainage Systems Checklist DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 3 OF 37 List of Tables Table 1: Runoff Coefficients Associated with the Rational Formula (ASCE/EWRI 45-05)...... 9 Table 2: Runoff Adjustment Factors (Riyadh Municipality (2012) Engineering Guidelines for Flood Protection Criteria for Riyadh City, First Edition, in Arabic)......................................... 10 Table 3: Kerby Equation Retardance Coefficient Values ...................................................... 13 Table 4: Kirpich Formula Correction Factor for Specific Flow Conditions (Rossmiller)......... 14 Table 5: Storm Return Periods ............................................................................................. 15 Table 6: Minimum Design Return Period and Allowable Water Spread ............................... 17 Table 7: Manning’s Roughness Coefficients for Pipes ......................................................... 25 Table 8: Maximum Manhole Spacing .................................................................................... 27 Table 9: SuDS Design Criteria .............................................................................................. 32 Table 10: Table SuDS Selection Matrix for Site Conditions .................................................. 33 List of Figures Figure 1: Gutter Parameters ................................................................................................. 15 Figure 2: Example of flanking inlets ...................................................................................... 17 Figure 3: Water bypasses the first inlet ................................................................................. 18 Figure 4: Grate inlet with longitudinal bars parallel to the direction of traffic ......................... 19 Figure 5: Bicycle-Safe Grate ................................................................................................. 19 Figure 6: Curb inlets.............................................................................................................. 20 Figure 7: Hydraulic and energy grade lines in pipe flow ....................................................... 22 DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 4 OF 37 1 Purpose The purpose of the Stormwater Drainage Systems Procedure is to provide well defined steps to accomplish the design of the stormwater drainage systems based on the NEOMNWA-TGD-052 engineering practices, national and international codes and standards and in compliance with NEOM-NEN-SCH-005. 2 Scope This NEOM procedure covers the minimum requirements for developing appropriate drainage design systems for NEOM facilities. Stormwater runoff shall be properly managed to maintain and enhance existing conditions and not cause adverse impact on groundwater, surface and coastal environment or culturally valued spaces. As such, this procedure shall be read in conjunction with NEOM Flood Risk & Stormwater Drainage (NEOM-NWA-TGD-052). The Procedure for Hydrological Study (NEOM-NEN-PRC-012) shall also be referred to as a basis for the assessment of the hydrologic conditions and associated flood risks from water courses generated from contributing catchments. 3 Definitions For a comprehensive list of definitions for the terms and abbreviations used at NEOM, see the List of Definitions and Abbreviations (NEOM-NEN-SCH-006). 3.1 Terms Term Definition none 3.2 Abbreviations Abbreviation Definition ASCE American Society of Civil Engineers CN Curve Number FHWA Federal Highway Administration IDF Intensity Duration Frequency SCS Soil Conservation Service SuDS Sustainable Drainage Systems DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 5 OF 37 4 References 4.1 NEOM Documents 4.2 Document no. Document title NEOM-NEN-PRC-005 Stage Deliverables Procedure NEOM-NEN-PRC-006 Safety in Design Procedure NEOM-NEN-PRC-008 NEOM Document Numbering and Revision Procedure NEOM-NEN-PRC-010 Drawing and Drafting Procedure NEOM-NEN-PRC-012 Procedure for Hydrological Study NEOM-NEN-PRC-014 Management and Application of NEOM Standard NEOM-NEN-PRC-020 Asset Naming Conventions Procedure NEOM-NEN-PRC-021 Stage Review and Approval Procedure NEOM-NEN-SCH-005 List of Technical Codes & Standards NEOM-NWA-TGD-052 Flood Risk & Stormwater Drainage Other Documents Document no. Document title ASCE/EWRI 45-05 Standard Guidelines for the Design of Urban Stormwater Systems, American Society of Civil Engineers, 2006. − CIRIA, Sustainable drainage systems (SuDS) Manual (C753), London, 2016. − Federal Highway Administration, Urban Drainage Hydraulic Engineering Circular No. 22, USA, 1996. − Federal Highway Administration, Hydraulic Design of Energy Dissipators for Culverts and Channels, Hydraulic Engineering Circular No. 14, USA, 2006. − Kirpich Z. P., “Time of concentration of small agricultural watersheds”, J. Civ. Eng. 10(6):362, 1940. − Ministry of Communications, Highway Design Manual. Volume 2, Book 1 of 2, section 2.07: Hydrology, Riyadh, Kingdom of Saudi Arabia, 1992. − MoMRA. Scope of Work for Stormwater Masterplanning. − Riyadh Municipality, Engineering Guidelines for Flood Protection Criteria for Riyadh City, First Edition, in Arabic, 2012. − Natural Resources Conservation Service (NRCS). (1986). Urban Hydrology for Small Watersheds – Technical Release 55, Washington, D.C. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. Design Manual, PAGE 6 OF 37 5 Design 5.1 Philosophy The design of any stormwater drainage system involves the collection of data, familiarity with the project site and an understanding of the hydrologic and hydraulic principles and drainage policies associated with that design. The design of stormwater drainage system should comply with NEOM Flood Risk & Stormwater Drainage procedures (NEOM-NWATGD-052). The procedure follows the stormwater drainage philosophy mentioned under NEOM-NWATGD-052 Section 6.9. The storm water drainage main philosophy is to minimise the impact of future construction, this shall be performed through sustainable approach: • Sustainable drainage systems (SuDS) that mimics the natural drainage processes that efficiently and sustainably drain surface water while reducing the quantity of surface water, minimising pollution and managing the impact on water quality of local water bodies. • Where it is not possible to accommodate drainage using SuDS alone, conventional solutions shall be introduced such as as gullies, interceptors, drainage collection pipe networks, sumps and pumping stations. Road pavement drainage, access roads and others are all areas /systems to be drained either through Sustainable drainage systems or conventional systems. This procedure considers urban drainage systems including: • Road pavement drainage • Roadside median channels • Storm drainage pipes • Drainage of access roads • Drainage of hard standings • Drainage of building roofs. Effective drainage of surfaces is essential to the traffic safety. Water on the pavement can interrupt traffic, reduce skid resistance, increase potential for hydroplaning, limit visibility due to splash and spray, and cause difficulty in steering a vehicle when the front wheels encounter puddles. Pavement drainage requires consideration of surface drainage, gutter flow, and inlet capacity. The design of these elements is dependent on storm frequency and the allowable spread of storm water on the pavement surface. Roadside channels and storm drainage pipes collect and convey stormwater from the pavement surface, roadside, and median areas. These drains may dispose their flow to a storm drain piping system via a drop inlet, to a detention or retention basin or other storage component, or to an outfall channel. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 7 OF 37 5.2 Procedure 5.2.1 Description of Project Location The designer shall refer to NEOM-NEN-PRC-012 – Section 4.2. 5.2.2 Determination of Used Software, Available Data and Summary of Methodologies The designer shall refer to NEOM-NEN-PRC-012 – Section 4.3. 5.2.3 Site Visit Requirements The designer shall refer to NEOM-NEN-PRC-012 – Section 4.4. 5.2.4 Topography and Survey The designer shall refer to NEOM-NEN-PRC-012 – Section 4.5. 5.2.5 Rainfall Data Analysis The designer shall refer to NEOM-NEN-PRC-012 – Section 4.6. Regarding Impact of Climate Change in section NEOM-NEN-PRC-012 - Section 4.6, this will be superseded and replaced with updated criteria represented in NEOM-NWA-TGD-052Section 6.3.2 for Temporary and Permanent structures. 5.2.6 Hydrological Analysis The designer shall refer to NEOM-NEN-PRC-012 – Section 4.7. 5.2.7 Runoff Calculations 5.2.7.1 The Rational Method The Rational Method is a method widely used for determining the peak discharge for a given area for urban drainage design. The rational equation is expressed as follows from Eq (9). Where: 𝑄𝑄 = 𝐹𝐹𝐹𝐹 𝐶𝐶𝐶𝐶𝐶𝐶 Eq. 1 • Q is the peak flow (m3/s). • F is the runoff adjustment factor related to the return period of the event. • k is a conversion factor equal to 0.278. • C is a dimensionless runoff coefficient. • I is the rainfall intensity for a specific time of concentration (Tc) and storm return period (mm/h), from IDF curves. • A is the catchment area contributing to the flow (km2). The runoff coefficient (C) represents the ratio of runoff to rainfall. It is determined according to Table 4 for urban areas. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 8 OF 37 Where a drainage area is composed of subareas with different runoff coefficients, a composite coefficient for the total drainage area is calculated using the following equation: 𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝐶𝐶 = ∑(𝐶𝐶 𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼 𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 )(𝐴𝐴 𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼𝐼 𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 ) Eq. 2 𝐴𝐴 𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇 𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 The runoff adjustment factor is used to account for the fact that less frequent, higher intensity storms require adjusted runoff coefficients because infiltration and other losses have a proportionally smaller effect on runoff. Adjustment factors (F) for storms of different return periods are listed in Table 1. Rainfall intensity (I) indicates the rate at which it is falling. Rainfall at a duration equal to the time of concentration (Tc) is used to calculate the peak flow in the Rational Method. It is selected from the IDF (intensity-duration-frequency) curves. These can be obtained as described in the Procedure for Hydrological Study. Table 1: Runoff Coefficients Associated with the Rational Formula (ASCE/EWRI 45-05) Type of Drainage Area Runoff Coefficient, C* Business Downtown areas 0.70–0.95 Neighborhood areas 0.50–0.70 Residential Single-family areas 0.30–0.50 Multi-units, detached 0.40–0.60 Multi-units, attached 0.60–0.75 Suburban 0.25–0.40 Apartment dwelling areas 0.50–0.70 Industrial Light areas 0.50–0.80 Heavy areas 0.60–0.90 Parks, cemeteries 0.10–0.25 Playgrounds 0.20–0.40 Railroad yard areas 0.20–0.40 Unimproved areas 0.10–0.30 Lawns Sandy soil, flat, 2% 0.05–0.10 Sandy soil, average, 2 - 7% 0.10–0.15 Sandy soil, steep, 7% 0.15–0.20 Heavy soil, flat, 2% 0.13–0.17 Heavy soil, average, 2 - 7% 0.18–0.22 Heavy soil, steep, 7% 0.25–0.35 Streets DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 9 OF 37 Type of Drainage Area Runoff Coefficient, C* Asphaltic 0.70–0.95 Concrete 0.80–0.95 Brick 0.70–0.85 Drives and walks 0.75–0.85 Roofs 0.75–0.95 * Higher values are usually appropriate for steeply sloped areas and longer return periods because infiltration and other losses have a proportionally smaller effect on runoff in these cases. Table 2: Runoff Adjustment Factors (Riyadh Municipality (2012) Engineering Guidelines for Flood Protection Criteria for Riyadh City, First Edition, in Arabic) 5.2.7.2 Return Period Runoff Adjustment Factor 10 years or less 1.0 25 years 1.1 50 years 1.2 100 years 1.25 The SCS Unit Hydrograph Method The United States National Resources Conservation Service (SCS) hydrograph method is usually used to estimate flows from medium to large size catchment areas. This method takes into consideration catchment characteristics such as the soil type, cover type, surface treatment, hydrological condition and antecedent runoff condition. These are reflected by a Curve Number (CN). This number typically ranges from 25 (for low runoff depressions) to 98 (for paved impervious areas). The data and maps provided by the Saudi Geological Survey (SGS) shall be used to determine the surface runoff coefficient, to be verified through field visits. Values of the surface runoff coefficient shall be calculated based on the soil types and land uses within each basin. The peak discharge values shall then be calculated using the average surface runoff coefficient for each drainage basin and the rainfall intensity. For information regarding hydrological analysis, the designer shall refer to NEOM-NENPRC-012. 5.2.7.3 Time of Concentration and Travel Time The time of concentration (Tc) is defined as the time needed for a drop of water to travel from the hydraulically most distant point in the watershed to the point of reference downstream. Tc is computed by summing all the travel times for consecutive components of the drainage conveyance system. Its value depends on the nature of the surface and the length of the possible pathways to reach the end of the basin. The flow path shall be separated into several reaches if there are breaks in the slopes and changes in the topography. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 10 OF 37 When applicable, the Kerby-Kirpich method (Roussel et al. 2005) can be used for estimating Tc. The National Resources Conservation Service (1986) method is also commonly used and acceptable. Both of these methods estimate Tc as the sum of travel times for discrete flow regimes. One good practice is to run both methods concurrently and compare results. Natural Resources Conservation Service (NRCS) Method for Estimating Tc The NRCS method for estimating Tc is applicable for small watersheds, in which the majority of flow is overland flow such that timing of the peak flow is not significantly affected by the contribution flow routed through underground storm drain systems. Water moves through a watershed as: • Sheet flow tsh • Shallow concentrated flow tsc • Open channel flow tch. Time of concentration (Tc) is the sum of t values for the various consecutive flow segments can be obtained from Eq (1). Tc = tsh + tsc + tch Eq. 3 Sheet flow Sheet flow is flow over plane surfaces. It usually occurs in the headwater of streams. With sheet flow, the friction value (Manning’s n) is an effective roughness coefficient that includes the effect of raindrop impact; drag over the plane surface; obstacles such as litter, crop ridges, and rocks; and erosion and transportation of sediment. Sheet flow have very shallow flow depths of about 3cm (0.1 foot). For sheet flow of lengths less than 30m (100 feet), use Manning’s kinematic solution to compute tsh from Eq (2). If a low slope condition or a transitional slope condition exists, the designer should consider using an adjusted slope in calculating the time of concentration. Where: 𝑡𝑡𝑠𝑠ℎ = ( )0.8 0.007 𝑛𝑛𝑛𝑛 (𝑃𝑃2 )0.5 𝑠𝑠0.4 • tsh = sheet flow travel time (hr) • n = Manning’s roughness coefficient • L = sheet flow length (ft) (100 ft. maximum) • P2 = 2-year, 24-hour rainfall (in) • s = sheet flow slope (land slope, ft/ft) Eq. 4 Shallow concentrated flow After a maximum length of 30m (100 feet), sheet flow usually becomes shallow concentrated flow. Shallow concentrated flow travel time is computed from Eq. (3). Where: DOCUMENT CODE: NEOM-NEN-PRC-315 𝑡𝑡𝑠𝑠𝑠𝑠 = 𝐿𝐿 3600𝐾𝐾𝑆𝑆 0.5 Eq. 5 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 11 OF 37 • tsc = shallow concentrated flow time (hr) • L = shallow concentrated flow length (ft) • K = 16.13 for unpaved surface, 20.32 for paved surface • s = shallow concentrated flow slope (ft/ft) Channel Flow Channels flows are assumed to begin where surveyed cross section information has been obtained, where channels are visible on aerial photographs. Manning’s equation or water surface profile information can be used to estimate average flow velocity, refer to Eq (4). Manning’s equation is: Where: 1 𝑉𝑉 = 𝑛𝑛 𝑅𝑅2⁄3 𝑆𝑆 1⁄2 Eq. 6 • V = average velocity (m/s) • R = hydraulic radius (m) and is equal to A/P • A = cross sectional flow area (m2) • P = wetted perimeter (m) • s = slope of the hydraulic grade line (channel slope, m/m) • n = Manning’s roughness coefficient. After average velocity is computed, tch for the channel segment can be estimated using the travel time from Eq. (5). Travel time (Tt) is the ratio of flow length to flow velocity: Where: 𝑇𝑇𝑡𝑡 = • Tt = travel time (s) • L = flow length (m) • V = average velocity (m/s) 𝐿𝐿 𝑉𝑉 Eq. 7 Kerby-Kirpich Method Kerby-Kirpich approach requires comparatively few input parameters, and considered as a straightforward to apply, and produces readily interpretable results. The Kerby-Kirpich approach produces time of concentration estimates consistent with watershed time values independently derived from real-world storms and runoff hydrographs. The total time of concentration is obtained by using adding the overland flow time (Kerby) and the channel flow time (Kirpich), refer to Eq. (6). 𝑡𝑡𝑐𝑐 = 𝑡𝑡𝑜𝑜𝑜𝑜 + 𝑡𝑡𝑐𝑐ℎ DOCUMENT CODE: NEOM-NEN-PRC-315 Eq. 8 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 12 OF 37 Where: • tov = overland flow time • tch = channel flow time • The minimum value of tc shall not be less than 10min. The Kerby-Kirpich method for estimating tc is applicable to watersheds ranging from 0.25 square miles (0.65 km2) to 150 square miles (388.5 km2), main channel lengths between 1 and 50 miles (80km), and main channel slopes between 0.002 and 0.02 (ft/ft) (Roussel et al. 2005). The Kerby Method For small watersheds where overland flow is an important component of overall travel time, the Kerby method can be used. The Kerby equation is: Where: Eq. 9 𝑡𝑡𝑜𝑜𝑜𝑜 = 1.44 (𝐿𝐿. 𝑛𝑛)0.467 𝑆𝑆 −0.235 • tov = overland flow time of concentration, in minutes • L = the overland-flow length, in meters • n = a dimensionless retardance coefficient • S = the dimensionless slope of terrain conveying the overland flow In the development of the Kerby equation, the length of overland flow was as much as 1,200 feet (366 meters). Hence, this length is considered as the upper limit. The dimensionless retardance coefficient used is similar in concept to the well-known Manning’s roughness coefficient. Table 3: Kerby Equation Retardance Coefficient Values Dimensionless retardance coefficient (N) Generalized terrain description Pavement 0.02 Smooth, bare, packed soil 0.10 Poor grass, cultivated row crops, or moderately rough packed surfaces 0.20 Pasture, average grass 0.40 Deciduous forest 0.60 Dense grass, coniferous forest, or deciduous forest with deep litter 0.80 The Kirpich Method For channel-flow component of runoff, the Kirpich equation can be be obtained from Eq (8) 𝐿𝐿0.77 𝑡𝑡𝑐𝑐ℎ = 0.0195 𝑥𝑥 0.385 𝑆𝑆 DOCUMENT CODE: NEOM-NEN-PRC-315 Eq. 10 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 13 OF 37 Where: • tch = the time of concentration, in minutes • L = the channel flow length, in meters • S = the dimensionless main-channel slope The equation is valid for natural basins with well-defined channels, overland flow on bare earth and mowed grass roadside channels. For other flow conditions, the result of the equation must be multiplied by a correction factor as listed in Table 4. If a low slope condition or a transitional slope condition exists, the designer should consider using an adjusted slope in calculating the time of concentration. Table 4: Kirpich Formula Correction Factor for Specific Flow Conditions (Rossmiller) Flow Conditions 5.2.7.4 Correction Factor Overland flow on grassed surface 2.0 Overland flow on concrete or asphalt surface 0.4 Flow in concrete channels 0.2 Runoff Quantities For drainage areas up to 100 hectares (1 km2), the runoff shall be calculated using the Rational Method. For larger drainage areas, the SCS Unit Hydrograph Method shall be used. 5.2.7.5 Storm Return Period The frequency of the storm event represents the number of occurrences of an event within a specified period. The selection of return period is an economic question rather than a meteorological decision. When selecting design return periods, it is important to consider the potential damage that would result from a flood that exceeds the design event, especially in urban areas. To do this, the designer shall consider the following: 1. Potential for loss of life 2. Effect of potential flooding of important installations 3. Potential for isolation of hospitals and restriction of access for emergency vehicles. The final design storm return period shall balance the risk of sociological and environmental impacts against economic and physical constraints. The design shall satisfy two different levels of protection. The first shall cause minimal disturbance to the public and overland flow and this shall be achieved via the storm return period. The second shall prevent significant structural flooding or potential loss of life or major erosion and scouring and this shall be achieved via the flood check. For information regarding classification of infrastructure flood risk vulnerability and flood zones, the designer shall refer to NEOM-NWA-TGD-052. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 14 OF 37 Table 5: Storm Return Periods 5.2.8 Drainage Elements Design Storm Return Period Pavement drainage, surface drainage (curbs, gutters, inlets, gullies) refer to Table 6 Minor stormwater network (pipes, swales, ditches, minor open channels) refer to Section 5.2.10.3 Major drains conveying and discharge (culverts and major open channels) refer to Section 5.2.10.3 Ponds (retention and detention ponds) refer to Section 5.2.10.15 Pavement Drainage Pavement drainage occurs in two different modes. One mode involves sheet flow across the pavement surface, which is predominantly affected by pavement type, condition, cross slope and texture. The other mode occurs where curbs contain and channelise runoff within the roadway gutter and a portion of the pavement until the stormwater can be removed from the surface, usually through inlets. Conventional gutters begin at the intersection of the pavement surface and the inside base of the curb and usually extend from the curb toward the roadway centreline at a width of 0.3 m to 1.8 m. They are usually constructed with cement concrete or asphaltic concrete but are not necessarily the same material as the pavement. If the gutter cross slope varies from the pavement cross slope, it is called a composite gutter. The gutter may also have the same cross slope as the pavement as shown in Figure 1. Figure 1: Gutter Parameters The curb and gutter form a triangular channel that can be an efficient hydraulic conveyance facility, often conveying low rainfall intensity events without interruption to traffic. However, when the design storm flow occurs, the width of runoff may spread to include not only the gutter width but also any parking lanes or shoulders and certain portions of the travelled surface. This spread or ponded width is what the hydraulics designer is most concerned about in curb and gutter flow. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 15 OF 37 The main target of storm water management is to restrict the spread of flow of rainwater on ground surface to a limit that will not obstruct or pose any hazard to vehicular traffic by collecting and disposing of the runoff water. This should be accommodated through the design of a storm water drainage network that collects the drainage water and drains it to a proper drainage facility outside of the road. The next sub-sections (Inlet Location and Sizing and Inlet Types) are guides on how to drain water from roads, especially in low areas, so that no stagnation occurs for prolonged periods. 5.2.8.1 Inlet Location and Sizing Inlets are important features of curb-and-gutter-type pavement drainage that enable stormwater to be removed from the roadway area. 1. Inlets must be properly located and sized for the curb and gutter drainage to be efficient. 2. The minimum longitudinal fall at the bottom of the drainage curb face shall be 0.5%. 3. Designers shall check the profile of the inner face of drainage curbs in areas of superelevation application where combinations of profile grade slopes and super-elevation application can result in flat or nearly flat profiles. The following information is necessary for the process of locating inlets: 1. Plan and profile of the roadway 2. Topographic maps of the adjacent area 3. Allowable water spread 4. Typical roadway cross section 5. Superelevation information. There are several locations where inlets may be necessary with little regard to contributing drainage area. These locations shall be marked on the plans prior to any computations regarding discharge, water spread, inlet capacity, or flow bypass. Examples of such locations are: 1. Sag point in the gutter grade 2. Immediately upstream of median breaks and entrance/exit ramp gores 3. Immediately upgrade of bridges (to prevent pavement drainage from flowing onto dge decks) 4. Immediately downstream of bridges (to intercept bridge deck drainage) 5. Immediately upgrade of cross slope reversals (e.g. where the gradient of the road is reversed in horizontal curves due to super elevation) 6. Immediately upgrade from pedestrian crosswalks 7. At the end of channels in cut sections 8. Behind curbs, shoulders or sidewalks to drain low areas. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 16 OF 37 In locations where significant roadway ponding may occur (e.g., underpasses, sag vertical curves), a recommended practice is to place flanking inlets on each side of the inlet at the low point in the sag. This is illustrated in Figure 2. The purpose of the flanking inlets is to act as relief for the inlet at the low point in case it becomes clogged or if the design spread is exceeded. Figure 2: Example of flanking inlets The limits of allowable water spread shall be set after considering the following: volume and speed of the traffic; number of traffic lanes; absence or presence of gutters, shoulders and/or parking lanes; extent of the roadway area that can be allocated for water spread according to a certain design stormwater return period; and safety and travel convenience. Generally, a water spread of 1.8 meter (≈ half a driving lane) is acceptable. Where a paved shoulder exists and the traffic allowable speed is less than 70 km/hour, the spread can equal the shoulder width + 1m. Suggested minimum design return periods and allowable water spread are presented in Table 6. Table 6: Minimum Design Return Period and Allowable Water Spread Roadway Classification Criterion Minimum Design Return Period Allowable Water Spread Hi-volume or divided or bi-directional < 70 km/hr 10 years Shoulder + 1m > 70 km/hr 10 years Shoulder Collector < 70 km/hr 10 years 1/2 driving lane > 70 km/hr 10 years Shoulder Low Average Daily Traffic 5 years 1/2 driving lane High Average Daily Traffic 10 years 1/2 driving lane Local streets Source: FHWA, “Urban Drainage Design Manual”, Hydraulic Engineering Circular 22 The maximum spacing between inlets shall not exceed 100 m. The procedure for spacing inlets can be summarised as follows: 1. Calculate flow and spread in the gutter starting from the upstream side of the catchment. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 17 OF 37 2. Place tributary area, which is from high point to location of the first inlet, where spread approaches the spread limit. 3. Calculate the amount of water intercepted by the inlet, check the inlet efficiency. The efficiency shall be a minimum of 75%. 4. Include the water that bypasses the first inlet in the flow and spread calculation for the next inlet (refer to Figure 3). 5. Place the next inlet where spread approaches the spread limit. 6. Repeat this procedure to the end of system. Figure 3: Water bypasses the first inlet 5.2.8.2 Inlet Types Several types of inlets are available for intercepting the water flow along the curb and gutter, such as grate inlets, curb-opening inlets, slotted drain inlets, and combination inlets. Factors influencing inlet type selection include: hydraulic efficiency, pedestrian and bicycle safety, debris handling characteristics, structural strength, and installation costs. Grate inlets consist of an opening in the gutter or ditch covered by a grate. They are commonly used inlet structures that are available in a wide variety of shapes and sizes. They can be placed in the gutter on a continuous grade or at sag locations. Grate inlets, as a class, perform satisfactorily over a wide range of gutter grades but they generally lose capacity with increase in grade, but to a lesser degree than curb opening inlets. In a sag location, the capacity of a grate inlet is dependent mainly on the open area of the grate and the depth of allowable ponded water above the grate. At ponding depths that completely submerge the grate, the concept of orifice flow is usually applied to the design of sag location grates. Because grates at sag locations are particularly prone to clogging, it is common practice to apply a safety factor (typically 50%) to the required inlet area. Generally, if used in curb and gutter, it is recommended that they are supplemented with a curb opening to provide a combination sag inlet. Designers shall provide assumptions regarding the nature of clogging to compute the capacity of a partially clogged grate. If the area of a grate is covered by debris so that the debris-covered portion does not contribute to interception, the effective perimeter should be DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 18 OF 37 reduced accordingly. Generally, regular maintenance is essential for keeping the inlets free of foreign material. Important factors influencing the interception capacity of an on-grade grate inlet are: length and width of grate, shape and size of bars in grate, gutter geometry, depth and velocity of approaching flow, and orientation of bars (vertical and horizontal). Grates-on-grade with longitudinal bars parallel to the direction of traffic (Figure 4) are generally more efficient than those with transverse bars. However, in areas where bicycle traffic is anticipated, parallel bars require special provisions such as narrowing the space between bars or adding transverse bars to ensure the safety of bicyclists (Figure 5). These provisions tend to reduce hydraulic efficiency. Grates with transverse bars are bicycle safe; however, when used on steep slopes, they can be very inefficient because of the tendency for the water to splash over the grate without entering the system. Transverse bar grates and parallel grates with transverse bars are more susceptible to clogging with debris than grates with longitudinal bars only. Figure 4: Grate inlet with longitudinal bars parallel to the direction of traffic Figure 5: Bicycle-Safe Grate Inlets with the primary opening in the face of the curb are referred to as curb-opening inlets. They offer little interference to traffic and are relatively free from clogging by debris. Curb openings can be placed on a continuous grade or at sag locations. They are most effective on flatter slopes, in sags, and with flows which typically carry significant amounts of floating debris. The interception capacity of curb-opening inlets decreases as the gutter grade steepens. Consequently, the use of curb-opening inlets is recommended in sags and on grades less than 3%. Of course, they are bicycle safe as well. The most hydraulically efficient type of curb-opening inlet has a cantilevered top slab and a depression of the gutter flowline at the inlet of at least 50 mm (See Figure 6). Curb inlets without this depression are significantly less hydraulically efficient. For safety precautions, the vertical rise of the opening shall be limited to prevent children from entering the inlet. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 19 OF 37 Figure 6: Curb inlets The required length of a curb-opening is a function of the amount of water to be intercepted, the depth of flow, the depression height and, for an on-grade curb, the allowable carryover. Curb-opening inlets are usually more adaptable for use at sag points than grate inlets because of their larger, more hydraulically efficient opening and their reduced tendency to clog. The interception capacity of curb inlets on continuous grades and particularly on steeper slopes can be increased by increasing gutter cross slope, increasing the gutter depression and/or by lengthening the inlet. Slotted drain inlets have been used successfully for many years to solve various drainage problems. They have been used to intercept sheet flow, gutter flow with or without curbs, modify existing drainage systems to accommodate roadway widening or increased runoff and reduce ponding at flush grate inlets. Slotted drain inlets are susceptible to clogging from sediments and debris and are not recommended for use in environments where significant sedimentor debris loads may be present. The following inlet dimensions are generally acceptable: 5.2.9 1. 0.6 m x 0.6 m for grate inlet clear opening (WxL) 2. 1 m for a curb inlet opening (L). Hydraulic Design of Storm Drain Systems Storm drains are primarily designed for the collection of rain generated over roads, car parks, service roads, open spaces, landscaped areas and from overland flow. Generally, the storm drain receives surface water through inlets and conveys the water through conduits to an outfall. The storm drain utilises pipe, box, or other enclosed conduits to convey the surface water and includes inlet structures (excluding the actual inlet opening), manholes, laterals (or branches), main lines (or trunks), and miscellaneous structures. 5.2.9.1 Flow Type Assumptions Two approaches may be used to size an enclosed conduit when steady uniform flow is assumed. One is termed “open-channel” flow and the other is “pressure” or “surcharged” flow. 1. Open-channel flow design requires the conduit to be sized so that the surface of the design flow in the conduit is open to atmospheric pressure. 2. Pressure flow design requires the flow in the conduit to be at a pressure greater than atmospheric, i.e. there is no flow surface within the conduit exposed to atmospheric pressure. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 20 OF 37 Open-channel flow design Open-channel flow design is recommended because it provides a reserve capacity, which can be considered a safety factor. A safety factor is needed because the methods of runoff estimation are not exact and, once placed, storm drains are difficult and expensive to replace. Using open-channel flow, design efficiency can be realized by sizing the conduit to operate as near to “full flow” as possible. For circular pipes, maximum capacity is achieved at a flow depth equal to around 94% of the diameter of the pipe. However, it is advisable to design pipes at a flow depth not exceeding 75% of the pipe diameter and keep the remaining spare capacity as a freeboard to accommodate the following: Future increase in runoff volume due to increase in impervious areas because of urban expansion and/or other developments, and possible reduction in pipe capacity due to sedimentation and/or aging. Pressure flow design If the pressure flow approach is approved by concerned authorities for cost saving or other constraints, the pipes will be sized using the same procedure discussed above. In addition, all head loss coefficients in pipes and junctions shall be estimated. Then, a hydraulic grade line is computed to account for the effect of the outfall tailwater, friction, and junction losses on the system during a particular storm event. The grade line aids the designer in determining the acceptability of the proposed system by establishing the elevations along the system to which the water will rise. If any allowable highwater elevation is exceeded, then adjustments to the trial design must be made to reduce the highwater elevation to an acceptable level. 5.2.9.2 Hydraulic Capacity The hydraulic capacity of a storm drain is controlled by its size, shape, slope, and friction resistance. Several flow friction formulas have been advanced which define the relationship between flow capacity and these parameters. The most widely used formula for gravity flow in storm drains is Manning’s Equation. The Manning equation is used for computing flow for open channel analysis where uniform flow exists or can be reasonably assumed. This can be expressed as follows: Where: 𝑄𝑄 = 1 𝑛𝑛 𝑅𝑅2⁄3 𝑆𝑆 1⁄2 𝐴𝐴 Eq. 11 • Q = the discharge in m3/s • R = hydraulic radius (m) and is equal to A/P • A = cross sectional flow area (m2) • P = wetted perimeter (m) • s = slope of the hydraulic grade line (channel slope, m/m) • n = Manning’s roughness coefficient. The Manning’s roughness coefficients related to pipes are given in Table 7. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 21 OF 37 Another widely used equation for gravity and pressure flow in storm drains is the ColebrookWhite equation, used mainly in computer programs because of the complexity of the equation that renders manual calculations difficult. 5.2.9.3 Energy Grade Line/Hydraulic Grade Line The Energy Grade Line (EGL) is an imaginary line that represents the total energy along a channel or conduit carrying water. Total energy includes elevation (potential) head, velocity head and pressure head. The calculation of the EGL for the full length of the system is critical to the evaluation of a storm drain. To develop the EGL, it is necessary to calculate all losses through the system. The energy equation states that the energy head at any cross section must equal that in any other downstream section plus losses. The losses are typically classified as either friction losses or local losses. Knowledge of the location of the EGL is critical to understanding and estimating the location of the hydraulic grade line (HGL). The hydraulic grade line (HGL) is a line coinciding with the level of flowing water at any point along an open channel. In closed conduits flowing under pressure, the hydraulic grade line is the level to which water would rise in a vertical tube at any point along the pipe. The hydraulic grade line is used to aid the designer in determining the acceptability of a proposed storm drainage system by establishing the elevation to which water will rise when the system is operating under design conditions. HGL, a measure of flow energy, is determined by subtracting the velocity head (V2/2g) from the EGL. Figure 7 illustrates the energy and hydraulic grade lines for open channel and pressure flow in pipes. When water is flowing through the pipe and there is a space of air between the top of the water and the inside of the pipe, the flow is considered as open channel flow and the HGL is at the water surface. When the pipe is flowing full under pressure flow, the HGL will be above the crown of the pipe. When the flow in the pipe just reaches the point where the pipe is flowing full, this condition lies in between open channel flow and pressure flow. At this condition the pipe is under gravity full flow and the flow is influenced by the resistance of the total pipe circumference. Under gravity full flow, the HGL coincides with the crown of the pipe. Figure 7: Hydraulic and energy grade lines in pipe flow Inlet surcharging and possible access hole lid displacement can occur if the hydraulic grade line rises above the ground surface. A design based on open channel conditions must be carefully planned as well, including evaluation of the potential for excessive and inadvertent flooding created when a storm event larger than the design storm pressurises the system. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 22 OF 37 As hydraulic calculations are performed, frequent verification of the existence of the desired flow condition shall be made. Storm drainage systems can often alternate between pressure and open channel flow conditions from one section to another. 5.2.9.4 Energy Losses For information regarding energy losses, refer to the standard guidelines for the design of urban stormwater systems developed by ASCE/EWRI 45-05. 5.2.9.5 Computer Hydraulic Analysis Computer hydraulic analysis and simulation of the network shall be carried out to enable the selection and recommendation of the most feasible alternative. This will allow the optimisation of the pipe sizes and the relevant flow velocities regarding the various available alternatives for the stormwater collection network. Commercial software for the hydraulic design, analysis and simulation of a gravity network shall be used. StormCAD, SewerGEMS and Infoworks CS are mainly used for the design and analysis of gravity and pressure flows through pipe networks and pump stations. 5.2.10 Design Guidelines The designer shall study the minimum requirements to manage stormwater quantity and quality from proposed urban developments and target to maintain pre-development discharge rates, volumes, velocities to comply with NEOM Flood Risk & Stormwater Drainage procedures (NEOM-NWA-TGD-052). Provision of hard infrastructure solutions is discouraged, on the other hand, natural methods that encourage infiltrations should be prioritized. Where it is not possible to accommodate drainage using SuDS alone, conventional solutions shall be introduced, these may be permitted subject to approval from the Regulatory Approval Body. This section focuses on design guidelines using conventional solutions. 5.2.10.1 General Procedure The general procedure for the design of a typical storm drain is given in brief below: 1. Define catchments and sub-areas and show the natural drainage flow directions. 2. Locate suitable outlets to the sub-areas. 3. Calculate rainfall runoff from each sub-area. 4. Calculate the flow widths along roads and streets (proposed as well as existing). 5. If flow widths are unacceptable, provide gully inlets and underground drainage to reduce the widths. 6. Provide gully inlet locations and drainage lines with particular attention to the need of drainage sags and road intersections. 7. Calculate preliminary pipe sizes. 8. Place the pipes in the drainage line, with cover and grading requirements met and junctions and access chambers at appropriate locations. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 23 OF 37 9. Compare alternative lines for cost and efficiency as different layouts provide different advantages. 10. Optimise the design so that all design parameters are met and the following are considered: a. Conflict with existing utilities is avoided. b. Deep trenching is minimised. c. The design is cost effective. d. The selected outfall level is sufficiently low to allow for gravity flow. e. The number of outfalls is restricted where pollution control is required. 5.2.10.2 Storm Networks Considerations The stormwater system for any plot shall utilise the open spaces and landscaped areas to contain the stormwater runoff generated over building roofs and impervious surfaces, as feasible. The road edge will normally be demarcated by upstand curbs with adjacent sidewalks sloping towards the curb line especially in urban and semi-urban areas. Consequently, most rainfall falling within the right-of-way will end up at the road edge adjacent to the curb line. In addition, surface water reaching the road from external sources such as roof drainage from adjacent properties can be intercepted by the installation of drainage inlets at regular intervals which are linked to a pipe network discharging to a convenient natural water course or open channel drainage system. 5.2.10.3 Drainage Concept A major/minor system approach shall be considered for the planning and design of urban stormwater systems. 1. A minor system is intended to collect and convey runoff from frequent storm events such that nuisance flooding is minimised. Street drainage systems are to be designed for a 10-year storm event. The minor system consists of ditches, pipes and other conduits, open channels, pumps, water quality control facilities, etc. 2. The major system is intended to safely convey runoff that is in excess of the capacity of the minor drainage system and thereby manage the risk of inundation to adjacent land or buildings. This usually occurs during more infrequent storm events, such as the 25-, 50-, and 100-year storms. The major system typically consists of a network of overland flow paths including roads, natural channels and streams, engineered waterways, culverts, community retention/detention basins, and other facilities that are provided for the runoff to flow to natural or manmade receiving channels. The designer shall determine (at least in a general sense) the flow pathways and related depths and velocities of the major system under less frequent or check storm conditions (typically a 100-year event with a 10% allowance for the impact of climate change to be used as the main reference). Designer to refer also to NEOM Flood Risk & Stormwater Drainage procedures (NEOM-NWA-TGD-052) for Climate Changes Allowances. The development of a conceptual storm drainage plan shall consist of the following preliminary activities: 1. Identify spacing between inlets DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 24 OF 37 2. Locate main outfall 3. Locate storm mains and other conveyance elements 4. Define detention strategy and storage locations 5. Define elements of major drainage system 5.2.10.4 Design Velocities 1. Minimum flow velocity shall be self-cleansing and prevent solids sedimentation, not less than 0.6 m/s. 2. Maximum flow velocity in pipes shall be non-eroding, not more than 4.0 m/s. 3. Maximum velocities in fully lined channels shall preferably be not more than 4.5 m/s for grouted riprap and 6 m/s for reinforced concrete. 5.2.10.5 Pipe Diameters and Gradient 1. For concrete pipes aligned adjacent to the curb or hardshoulder, minimum pipe diameter shall be 400 mm in the collection network (mainlines and laterals). The minimum pipe slope shall not be less than 0.1%. 2. For PVC-U pipes aligned adjacent to the curb or hardshoulder, minimum pipe diameter shall be 300 mm and laid at a minimum gradient of 1 in 150. 3. For inlet pipes and gully connections, minimum pipe diameter shall be 150 mm. 4. At changes in pipe diameter, the pipes are to be designed soffit to soffit. 5.2.10.6 Pipe Cover 1. Minimum pipe cover under road pavements shall be 1200 mm (concrete encasement is required for shallower cover). 2. Minimum pipe cover under landscape area and deserted areas (not exposed to traffic) shall be at least 800 mm. 5.2.10.7 Pipe Materials The pipe materials and their corresponding Manning’s roughness coefficient are provided in Table 7. Table 7: Manning’s Roughness Coefficients for Pipes Pipe Material Manning’s n* Concrete 0.012–0.014 Plastic (PVC-U, PE and GRP) 0.010–0.012 * Lower values are usually for well-constructed and maintained (smoother) pipes 5.2.10.8 Box Channels For pipe diameters larger than 1200 mm, reinforced concrete box channels will be used and junction boxes or manholes must be provided at every junction and every change in box size, grade, or direction of flow, noting that the distance between manholes shall not exceed 150 m. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 25 OF 37 5.2.10.9 Culverts Culverts are relatively short conduits typically used for road crossings of small to moderatesized streams. Culverts are generally constructed in reinforced concrete material. Culverts cause an abrupt change in streamflow characteristics. The acceleration of flow that occurs causes head losses. Flow within the culvert can range from tranquil to rapid, and the structure can flow either partially full or under pressure. Hydraulic analysis of culverts requires consideration of tailwater conditions, friction losses related to the culvert material and flow character, inlet and outlet losses, and minor losses within the culvert due to bends or other streamflow perturbations. For more information regarding hydraulics of the flow of water within culvert, refer to the standard guidelines for the design of urban stormwater systems developed by ASCE/EWRI 45-05 and the Federal Highway Administration (FHWA) including Hydraulic Engineering Circular 22. 5.2.10.10 Manholes The purpose of manholes is to provide access to a storm drain for inspection and maintenance. They are usually placed at changes in direction, grade and storm drain size and at conduit intersections and intervals along long stretches of conduit. Manholes shall not be placed under carriageways to avoid any interruption to the circulation during maintenance. Conduits passing through manholes shall have good hydraulic properties to minimise head loss. The surface topography shall also be given consideration when locating a manhole. 1. Manholes are usually constructed out of cast-in-place concrete or precast concrete. 2. Manholes shall have a minimum clear cover opening of 600 mm in diameter and covers shall be set at final paved level or 300 mm above final ground level in open areas. 3. Their chamber rings are usually circular with a minimum diameter of 1200 mm and their chamber base is usually square. Manholes shall be designed to withstand both the live and dead load forces that may be imposed on them. The diameter is often a function of depth with deeper manholes having larger diameters. The minimum internal diameter of manholes shall be: 1. 1200 mm for pipes with diameters of 600mm or less 2. 1800 mm for pipes with diameters larger than 600mm and for junction manholes Access to manholes shall be allowed via removable ladders of corrosion resistant material. For manholes deeper than 3.5 m, the designer shall provide additional facilities such as a safety cage to ensure safe access to the manhole. The manhole frame and cover are normally made from cast iron. They must be designed to have adequate strength to support the expected load. A good fit between cover and frame is essential, and it is preferable to place the manhole away from traffic. The cover shall be removable or hinged. The principal defence against a cover being lifted by children is a cover weight in excess of 45 kg. Covers that can be bolted down are required where there is possibility of vandalism, pressure system and/or other conditions. 1. Minimum depth of soil cover for pipes without concrete encasement is 1.20 m. 2. Minimum depth of soil cover for pipes with concrete encasement is 0.60 m. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 26 OF 37 3. Where a utility crossing a storm water drainage pipe/culvert, the minimum vertical clearance between two pipes will be ≥0.30 m. 4. Maximum spacing between manholes will depend on pipe diameter, according to the classification in Table 9. Manhole covers shall be capable of bearing a traffic load based on HL-93 AASHTO Truck Load, refer also to MOMRA specifcations in Urban Areas (MA-100-C-V1/1) covering several sections for manhole frames and covers and, in particular, section 20. Manhole covers shall be single sealed or doubled sealed. • A single seal cover can be airtight when the groove is filled with grease or other suitable compounds. It will prevent sewage gases from escaping to the surface, especially when installed within residential or commercial areas. • A double-seal manhole covers has double the arrangement of a single-seal cover. This creates an airtight and a water-tight seal. This feature is guaranteed to prevent gas escape, and the seepage of surface water through the cover, thus causing damage to the underground utilities within the chamber. This is best-suited for internal sewage manhole covers Securing covers can be achieved in 2 different methods: Bolting a sealed manhole cover can increase its sealing efficiency, but the bolting should not disturb the sealing system. The locking feature achieves two very important goals: it prevents theft and vandalism. It also secures a tight fit preventing rocking: 1. Using stainless steel bolts: the manhole cover is directly bolted on the frame using stainless steel bolts. This method is highly advisable for sealed manhole covers. Hexagonal and socket head bolts can be used in this method. 2. Cam lock: in this method, the manhole cover is secured to the frame using a ductile iron cam mechanism attached to special stainless-steel bolts or hexagonal head bolts. The cam lock provides improved security to the frame and cover assembly, also eliminating loose and missing fasteners. Table 8: Maximum Manhole Spacing Pipe Diameter (mm) Maximum Manhole Spacing (m) ≤400 50 500–900 100 1000–1200 150 Manholes can be divided according to their depths, i.e shallow manholes and deep manholes Shallow manholes: These types of manholes are about two to three feet or 75-90 centimeters of shallow depth. They are normally placed at the starting of a sewer or drainage water conduit passage and in the areas that are not subjected to heavy traffic. These types are known as inspection chambers with a light lid. Deep manholes: Any manholes deeper than 150 centimeters and fitted not subjected to heavy traffic are considered as deep manholes. These manholes are always incorporated DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 27 OF 37 with a heavy manhole cover and a built-in ladder to ease the personnel’s entry and exit if required. The loads acting on the manholes differ according the project’s conditions. In this respect, the structural design of the manholes lies under the responsibility of the structural designer. Designer shall refer to MOMRA standards for Bridges, Tunnels, Culverts, and Pedestrian Bridges Specifications in Urban Areas (MA-100-C-V1/1) covering several sections for manhole frames and covers and, in particular, Section 20 for Drainage Systems. In addition to the use of manholes for inspection and maintenance, rodding eye systems can be used for special cases, such as hard standings areas close to building and ramps entering garages and hardscape areas. Rodding eye systems provide an access opening in a drainage installation for the purposes of gaining full-bore access to the interior of a drain for internal cleaning, and which remains permanently accessible after completion of the installation but does not include an inspection chamber or manhole. 5.2.10.11 Freeboard Water level shall be allowed to rise in the stormwater drainage networks up to a maximum of 200 mm below the cover level of the manholes. 5.2.10.12 Outfalls An outfall transfers collected stormwater from a storm drain to an acceptable point of release in either a natural or constructed facility without adverse effects to roads, the community, the environment, or any property owner. An outfall may be either an open channel or a closed conduit but has no prescribed length. Generally, the outfall for the storm drainage system shall discharge into a natural low, existing storm drainage system, or a channel. The design engineer shall determine the tail water for the downstream drain to find the impact on the proposed outfall. If the outfall of the storm drain system is into a wadi, stream, major drainage pipe or ponds, the design engineer shall consider the coincidental probability of the peaks of both systems occurring at the same time. The tail water for the downstream shall be checked with the peak of the storm drain system. The designer should consider at least the following aspects of outfalls that may affect the hydraulic design of the storm drain: • The flowline elevation of the proposed storm drain outlet should be equal to or higher than the flowline of the outfall. • The highwater elevation at the outlet of the outfall must be estimated for the normal operating conditions of the storm drain. In normal design, this elevation is the elevation at which to begin the hydraulic grade line determination. • In situations where the highwater at the outfall outlet is expected to influence significantly the flow in the outfall, a water surface profile for an open channel outfall or hydraulic grade line for a closed conduit outfall should be computed, beginning with the highwater elevation in the outfall outlet. The computation should continue up to the outlet of the storm drain system. The resulting elevation can then be used as the tailwater for the hydraulic grade line check in the storm drain system. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 28 OF 37 • There may be instances in which an excessive tailwater causes flow to back up the storm drain system and out of inlets and access holes, creating unexpected and perhaps hazardous flooding conditions. The potential for this should be considered. • Energy dissipation may be required to protect the outfall and the storm drain outlet. Also, if the outlet discharge impinges on the opposite bank of the outfall, then protection to that bank should be provided. Protection is usually required at the outlet to prevent erosion of the outfall bed and banks. Riprap aprons or energy dissipators should be provided if high velocities are expected. • Where practicable, the outlet of the storm drain should be positioned in the outfall channel so that it is pointed in a downstream direction. This will reduce turbulence and the potential for excessive erosion. • For assets having security requirements, every outfall structure shall incorporate a safety grill to prevent unauthorized access into the outfall pipes. The grill shall be fabricated with stainless steel bars. The size and the maximum spacing of bars shall be designed in coordination with NEOM Security requirements. 5.2.10.13 Outlet Protection Any network systems or culverts tend to accelerate flow velocity at outlet. The designer shall provide stone riprap or other outlet protection that must be designed to handle a range of velocities. The designer shall extend riprap sufficiently downstream until streamflow lines fill channel and velocities become nonerosive. For further information and design procedure, the designer shall refer to FHWA, 2006a, “Hydraulic Design of Energy Dissipators for Culverts and Channels”, Hydraulic Engineering Circular 14. 5.2.10.14 Oil Separator Oil separators before discharge from facilities shall be considered to prevent oils and grease entering the stormwater drainage system. Use of water quality inlets is best limited to controlled runoff applications (e.g. maintenance yards, parking lots, certain industrialised areas) where high concentrations of oils are expected. 1. Oil and grit separators consist of a series of chambers designed to trap and retain sediments and hold floatables (e.g. oil, debris). 2. The oil water separators include coalescing plates, which allow the oils to combine and collect at the top of the oil water separator. 3. Oil water separators shall be located on the outlet of a drain from a facility that is suspected to discharge significant quantities of oil such as vehicle maintenance areas. 4. Sizing of the storage chambers is generally based on contributing drainage area and, therefore, cost and size limit their application to relatively small discharges. 5. On a periodic basis, these oils are removed from the oil water separator by a disposal company. 6. Measures to control sediments and erosion shall be used before discharging into an inlet (culvert, channel, catch basin, etc.) in cases where surface drainage flows over DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 29 OF 37 untreated soils. These measures can include riprap or gravel layers, sand/silt separation basin, vegetation, and soil stabilization. 5.2.10.15 Storage Facilities Stormwater drainage systems can discharge, after treatment, to natural watercourses (sea, wadies, streams) subject to environmental agency approval. Two common classifications of ponds are either Wet or Dry. Both types of ponds provide both stormwater attenuation and treatment. 1. Wet ponds, known as retention ponds, continually have a pool of water in them called dead storage. 2. Dry ponds, detention ponds, do not have dead storage and dry out between storms. Detention Ponds Stormwater detention ponds are used for the temporary storage of runoff to reduce the peak rate of runoff from a given area. The stormwater runoff is then released at a lower controlled rate. Because these ponds are normally dry and only contain water for relatively short periods of time, they can be constructed as part of parking lots, athletic fields, and others. 1. An emergency overflow shall be provided to convey excessive inflows or clogging of the main outlet. 2. Outlet flows shall be controlled by a structure with easy access for maintenance. 3. The relationship between storage, discharge, and elevation shall be determined. 4. The volume of the detention pond can be calculated using a storage routing model, with inflow and outflow varying with time. 5. Using the storage routing model,the design one-hundred-year ultimate inflow hydrograph will be analyzed through the basin and outflow structure with appropriate tail water condition. 6. The detention volume and outflow structure shall be adjusted, if necessary, until the allowable one-hundred-year ultimate is not exceeded, and the detention basin fills to or near the design maximum allowable water surface elevation. 7. Access shall be provided for maintenance. 8. The pond bottom shall slope towards the outlet. 9. Where a rapid raise in water level is expected or the design depth is greater than 1.2m, the facility shall be surrounded by a high fence with warning signs. 10. It is highly recommended that side slopes to the pond shall be 3:1 (H:V) or flatter. 11. It is recommended that the minimum length to width ratio for ponds be 1.5:1. Retention Ponds Retention ponds are pools designed with additional storage capacity to attenuate surface runoff during rainfall events for a period of several days or more. They can be used for recreation, water treatment, and water supply with landscaped banks and surroundings to provide additional storage capacity during rainfall events. Retention ponds can also be used for groundwater recharge. The design criteria for retention ponds are the same as those for DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 30 OF 37 detention ponds but with a zero discharge from the pond. Release is via evaporation and infiltration only. 1. Permeable bottom shall be provided for infiltration. 2. An emergency overflow shall be provided to convey excessive inflows greater than the one-hundred-year ultimate and for multiple storms over a short period of time. 3. The pond shall be protected from pollutants so that they do not settle, prevent infiltration and may contaminate the groundwater. 4. The volume of the retention pond will be designed to store at a capacity of the 100year event and the 24-hour storm. 5. Drains shall be provided to ensure emptying of the pond for cleaning purposes and emergency operations. 5.2.10.16 Design Lifetime for the System Component The expected service lifetime of a permanent network is 50 years while the expected service lifetime of a temporary network is 10 years. 5.2.11 Sustainable Stormwater Drainage Conventional drainage systems are now struggling to cope with rapid urbanisation and extremes in rainfall due to climate change. As such, a different approach to urban water management has resulted in the concept of Sustainable Drainage Systems (SuDS) which mimic natural drainage processes to reduce the effect on the quality and quantity of runoff from developments and provide amenity and biodiversity benefits. SuDs are composed of a sequence of management practices and strategies with control structures that are designed to drain surface water in an efficient and sustainable manner. The treatment stages in the process of implementing SuDS include: 1. Prevention – prevent runoff and pollution as close as possible to the source. 2. Source control – control runoff at or close to its source (green roofs, permeable pavements, filterstrips, rain gardens, living walls). 3. Site control – manage water received from source control features (soakaways, ponds, swales). 4. Regional control – control and store the clean runoff received from the site (wetlands, ponds). 5. Conveyance features – move water between the different treatment stages. This shall be done via aboveground features to maximise wildlife and people benefits. There are some key principles that influence the planning, choice of SuDS measure to be implemented and the choice of the design process, enabling SuDS to mimic natural drainage by: 1. Ensuring attenuation by creating storage location and releasing stormwater slowly. 2. Harvesting rainfall when possible. 3. Allowing infiltration (where appropriate) to reduce impact on groundwater recharge. 4. Reducing water velocities on the land surface. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 31 OF 37 5. Filtering out pollutants. 6. Creating areas where sediments are prone to settle out by controlling the flow of the water. The designer will provide flow modelling for the undeveloped condition based on a 10-year return period. In addition, the designer will provide necessary SuDS for the developed condition to ensure that the storm water runoff for the 10-year return period remains with their same values prior to urbanisation. 5.2.11.1 Design Criteria The design of SuDS will comply with NEOM Flood Risk & Stormwater Drainage procedures (NEOM-NWA-TGD-052). Water quantity, quality, amenity and biodiversity design criteria are presented in Table 9. Table 9: SuDS Design Criteria Pillar name Design Criteria Water Quantity Runoff shall be harvested for reuse. Peak runoff discharges shall be controlled for the 1:100 design event. Discharges to surface water shall be prioritised. Peak runoff discharges shall be released from ponds to natural watercourses for the 1:2 year return period. Natural hydrological systems shall be preserved and protected on the site. Wadi running through the site shall be recreated as a green corridor for the management of surface water. SuDS shall drain sufficiently fast so as not to reduce the management of runoff from subsequent rainfall. Surface water shall be retained within the SuDS for events up to the critical 1:25 year event and contained within appropriate exceedance routes and storage areas up to the critical 1:100 year event. System shall be flexible to be suitably adapted during design life following climate change or urban creep. Water Quality Critical areas shall have adequate pollution control measures to minimise the risk of pollution to surface and ground waters. Amenity Water shall be used to support vegetation to enhance public space, civic space and the road environment. Multi-functionality uses for SuDS shall be maximised. Side slopes for water features shall be kept accessible and swales and ponds shall be kept shallow, easily accessible and easy to maintain. Biodiversity Natural local habitats shall be protected. Natural wadis shall be recreated. Trees shall be planted. Habitat connectivity shall be enhanced through green corridors. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 32 OF 37 5.2.11.2 Recommendations for designing SuDS to respond to common site conditions Certain site conditions can influence the choice of SuDS suitable for any specific project. Table 10: Table SuDS Selection Matrix for Site Conditions Condition SuD Groundwater less than 3 m below ground surface Green Roof Notes Rainwater Harvesting Permeable Paving With liner and underdrain Filter Strip Bioretention Area With liner and underdrain Swale With liner Hardscape Storage If aboveground Pond With liner Wetland Impermeable soil type Green Roof Rainwater Harvesting Permeable Paving With underdrain Filter Strip Bioretention Area Swale Hardscape Storage Pond Wetland Underground Storage Existing infrastructure Green Roof Rainwater Harvesting Permeable Paving Relocate to marked corridor Filter Strip Bioretention Area With structural grid in soil Underground storage Topography: site on a flat site (<5% slope) Green Roof Source control Rainwater Harvesting Source control Soakaway Source control Permeable Paving Source control Filter Strip Source control Bioretention Area With short kerb and rill length Swale Provide some gradient Hardscape Storage Pond Try to keep flow above ground Wetland Try to keep flow above ground Underground Storage DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 33 OF 37 Condition SuD Topography: site on a steep site (515% slope) Green Roof Notes Rainwater Harvesting Permeable Paving If terraced Bioretention Area If terraced Swale If installed along contour Hardscape Storage If terraced Wetland If terraced Underground Storage Topography: site on a very steep site (>15% slope) Green Roof Limited space Green Roof Rainwater Harvesting Underground Storage Rainwater Harvesting Soakaway Permeable Paving Bioretention Area Rill or Channel Hardscape Storage Micro-wetland Underground Storage High risk contamination area Proximity to protected species or habitat Green Roof Source control Rainwater Harvesting Source control Permeable Paving With liner and spill isolation Bioretention Area With liner and spill isolation Swale With liner and spill isolation Hardscape Storage With liner and spill isolation Wetland Treatment of predicted waste Underground Storage With liner and spill isolation Green Roof Rainwater Harvesting Soakaway Permeable Paving Filter Strip Bioretention Area Swale Hardscape Storage Pond Wetland Underground Storage Source: Water, People, Places: A guide for Master Planning sustainable drainage into developments DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 34 OF 37 For further information on Sustainable Drainage Systems, the designer shall refer to NEOM Flood Risk & Stormwater Drainage procedures (NEOM-NWA-TGD-052) 6 Design Requirements 6.1 General 6.2 • Stormwater drainage design shall be done by a qualified stormwater drainage consultant to be approved by NEOM. Any design by contractors or non-qualified stormwater consultants shall not be accepted. • The designer shall submit all drawings in PDF/CAD with readable scale showing key plan and legend. • All submittals must be complete and self-explanatory and must not be based on a submittal previously commented and/or rejected by reviewers. • Any changes to the approved designs must be approved by the reviewer. • List of design deliverables shall comply with the NEOM Plan of Work (PRC-029) and NEOM Stage Deliverable Procedure (PRC-005). Preliminary Design The Preliminary Design Package shall include but is not limited to the following: • Preliminary Design Report including but not limited to: − An introduction for the project including the objectives and vision − Project site location plan showing the existing site boundary − Design criteria − Catchments/subcatchments area plan contributing or expected to contribute to the proposed network − Hydraulic design calculations and technical calculation sheets that contains (diameters, levels, slopes, catchment areas, catchments’ time of concentration, intensities, pipe flows, pipe velocities − Sizing design calculations for any proposed structures • Hydraulic modelling using the Rational Method (Steady State) for the proposed network • Site survey and site context including • − Topographic survey of the natural terrain to be submitted in CAD digital format “AutoCad” with (X, Y) coordinates and with an elevation (Z) relative to a specified datum − Proposed finished grading to be submitted in CAD with the same format indicated above Drawings of the design elements as applicable and requested including but not limited to DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 35 OF 37 6.3 − Proposed site location plan − Proposed site grading plan − Layout and part plans of the proposed stormwater network − Preliminary profile of the main collector to assure that outfall’s location and level are appropriate and feasible − Utility disposition with typical sections of the right of way (ROW) showing the details of the service corridor to assure no clash between the stormwater system and other utilities Detailed Design The Detailed Design Package shall include but is not limited to the following: 6.4 • Detailed Design Report with full and detailed design updated calculations • Hydraulic modelling for the proposed network using an unsteady state method to optimise the network sizes and estimate ponds volume if required • Detailed design drawings including the following: − List of drawings − Proposed site location plan − General site layout − Proposed site grading plan − Detailed layout plans showing all stormwater drainage system − Detailed profile drawings − Details of design elements such as catchbasins, gutters, manholes, trench and pipe bedding, outlets, ponds, etc. • All applicable standard specifications • All particular specifications • Bill of Quantities for the system. Issue for Construction The Issued for Construction Package shall include but is not limited to the following: • IFC drawings including the following: − List of drawings − Proposed site location plan − General site layout − Proposed site grading plan DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 36 OF 37 7 − Detailed layout plans showing all stormwater drainage system with catchbasins’ locations and corresponding calculations (e.g. with output calculations from FlowMaster by Bentley) − Detailed profile drawings − Details of design elements such as catchbasins, gutters, manholes, trench and pipe bedding, outlets, ponds, etc. Appendices Appendix A Stormwater Drainage Systems Checklist DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. PAGE 37 OF 37 Appendix A Stormwater Drainage Systems Checklist DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A A.1 Stormwater Drainage Systems Checklist The Designer/Contractor shall implement and ensure compliance with the following checklist: Contract Number: Originator: Project/ Asset Name: Date: Department/Sector Work Inspection Request (WIR) reference number: 1. INTRODUCTION Check all applicable Insert your comments here ☐ 1. Include the study goals and requirements ☐ 2. Include a history of floods in the area ☐ 3. Describe the study area and field visits ☐ 4. Include the collection of the existing system ☐ 5. Include the collection of identified floodplains ☐ 6. Include site photos DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A 2. TOPOGRAPHIC SURVEY Check all applicable Insert your comments here ☐ 1. Include a site map for the development area superimposed on the most recent topographic map ☐ 2. Include a map of the site map for the development area with existing/natural contour lines ☐ 3. Include a recent ground topographic survey with WGS84-UTM system ☐ 4. Include the proposed site grading plan ☐ 5. Include a detailed survey of all the existing drainage systems in the study area (networks / pond / open channels), if present 3. HYDROLOGICAL STUDY Check all applicable Insert your comments here ☐ 1. Include the proposed land use map for the study area ☐ 2. Calculate the Runoff Coefficient of Rational Method based on the proposed land use map ☐ 3. Calculate the Curve Number based on the geological map / soil types / land cover and the proposed land use map DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here ☐ 4. Include the delineation of subcatchments for modelling ☐ 5. Calculate time of concentration ☐ 6. Include a comprehensive morphology description of the study area 4. METEOROLOGICAL STUDY AND ANALYSIS OF RAIN DATA Check all applicable Insert your comments here ☐ 1. Include a map stating the locations of existing meteorological stations near the study area ☐ 2. Include a table containing the maximum daily rainfall data (mm/day), preferably from the General Authority of Meteorology and Environment ☐ 3. Include statistical data analysis for rain data (HYFran-Plus, SMADA, Hydro freq) or similar ☐ 4. Include the program interface used in the statistical analysis of rainfall data ☐ 5. Include a table of statistical analysis from the program derived for the maximum depth of daily rain for different return periods for 2, 5, 10, 25, 50, and 100 years ☐ 6. Include the creation of IDF Curves for different return periods in the case of surface drainage for the design of rainwater and flood drainage networks. DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A 5. HYDRAULIC CALCULATIONS Check all applicable Insert your comments here ☐ 1. Apply the hydraulic design for urban drainage works using different programs: StormCad or SewerGems or any other similar program ☐ 2. Ensure the use of SI units in hydraulic calculations throughout the report ☐ 3. Prepare the calculations of drainage pipes and provide the results in tables or graphs ☐ 4. Define pavement drainage design return period ☐ 5. Prepare hydraulic calculations for surface drainage and pavement drainage including water spread calculations, etc. ☐ 6. Define spacing between inlets ☐ 7. Choose inlet types ☐ 8. Locate main outfall ☐ 9. Align storm mains and other conveyance elements ☐ 10. Define detention strategy and storage locations DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here ☐ 11. Identify type flow in storm drains (Open-channel/pressure) ☐ 12. Choose drain material and Manning’s coefficient ☐ 13. Design preliminary sizes ☐ 14. Check minimum and maximum velocities ☐ 15. Check minimum and maximum pipe diameters ☐ 16. Check minimum and maximum pipe covers ☐ 17. Check distance between manholes ☐ 18. Check freeboard in manholes ☐ 19. Compare alternative solutions for cost and efficiency as different layouts provide different advantages ☐ 20. Optimize the design so that all design parameters are met, taking into consideration the following: a. Conflict with existing utilities is avoided b. Deep trenching is minimised c. The design is cost effective d. The selected outfall level is sufficiently low to allow for gravity flow DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here e. The number of outfalls is restricted where pollution control is required ☐ 21. Check needs for sustainable urban drainage system ☐ 22. Check needs for oil separator 6. RESULTS Check all applicable Insert your comments here ☐ 1. Include a summary of the results of the hydrological and morphometric studies, hydraulic modelling, and calculations 7. PRELIMINARY DESIGN Check all applicable Insert your comments here ☐ 1. Include Preliminary Design Report with an introduction to the project showing the objectives and vision ☐ 2. Include Preliminary Design Report with project site location plan showing the existing site boundary ☐ 3. Include Preliminary Design Report with design criteria DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here ☐ 4. Include Preliminary Design Report with catchments/subcatchments area plan contributing or expected to contribute to the proposed network ☐ 5. Include Preliminary Design Report with hydraulic design calculations and technical calculation sheets that contains diameters, levels, slopes, catchment areas, catchments’ time of concentration, intensities, pipe flows, pipe velocities ☐ 6. Include Preliminary Design Report with sizing design calculations for any proposed structures ☐ 7. Include a copy of the hydraulic model using the Rational Method (Steady State) for the proposed network ☐ 8. Include site survey and site context ☐ 9. Include topographic survey of the natural terrain to be submitted in CAD digital format “AutoCAD” with (X, Y) coordinates and with an elevation (Z) relative to a specified datum ☐10. Include proposed finished grading to be submitted in CAD digital format “AutoCAD” with (X, Y) coordinates and with an elevation (Z) relative to a specified datum ☐ 11. Include drawings of proposed site location plan ☐ 12. Include drawings of proposed site grading plan ☐ 13. Include drawings of layout and part plans of the proposed stormwater network DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here ☐ 14. Include drawings of preliminary profile of the main collector to assure that outfall’s location and level are appropriate and feasible ☐ 15. Include drawings of utility disposition with typical sections of the right of way (ROW) 8. DETAILED DESIGN Check all applicable Insert your comments here ☐ 1. Include detailed design report with full and detailed design with updated calculations ☐ 2. Include hydraulic modelling for the proposed network using an Unsteady State method ☐ 3. Include detailed design drawings showing drawings list ☐ 4. Include detailed design drawings showing proposed site location plan ☐ 5. Include detailed design drawings showing general site layout ☐ 6. Include detailed design drawings showing proposed site grading plan ☐ 7. Include detailed design drawings showing detailed layout plans showing all stormwater drainage system DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here ☐ 8. Include detailed design drawings showing detailed profile drawings ☐ 9. Include detailed design drawings showing details of design elements such as catchbasins, gutters, manholes, trench and pipe bedding, outlets, ponds...etc. ☐ 10. Include all applicable standard specifications ☐ 11. Include all particular specifications ☐ 12. Include Bill of Quantities for the system 9. ISSUED FOR CONSTRUCTION Check all applicable Insert your comments here ☐ 1. Include detailed design drawings showing drawings list ☐ 2. Include detailed design drawings showing proposed site location plan ☐ 3. Include detailed design drawings showing general site layout ☐ 4. Include detailed design drawings showing proposed site grading plan DOCUMENT CODE: NEOM-NEN-PRC-315 REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A Check all applicable Insert your comments here ☐ 5. Include detailed layout plans showing all stormwater drainage system with catchbasins locations and corresponding calculations (e.g. with output calculations from Flowmeter by Bentely) ☐ 6. Include detailed design drawings showing detailed profile drawings ☐ 7. Include detailed design drawings showing details of design elements such as catchbasins, gutters, manholes, trench and pipe bedding, outlets, ponds...etc. 10.Site Change Order & As Built drawings Check all applicable Insert your comments here ☐ 1. Include updated survey points of the drainage system invert levels on as-built drawings. ☐ 2. Include updated BIM Model including the drainage system invert levels of the asbuilt drawings with reference to NEOM-NENPRC-009 Rev 04.00, September 2022 11.RECOMMENDATIONS Check all applicable Insert your comments here ☐ 1. Include recommendations with objectives and results of the urban drainage solutions ☐ 2. Include available alternatives to solve the drainage issues along with the recommended solutions Filled by: DOCUMENT CODE: NEOM-NEN-PRC-315 Submitted to: REVISION: 01.00 ©NEOM [2023]. All rights reserved. APPENDIX A