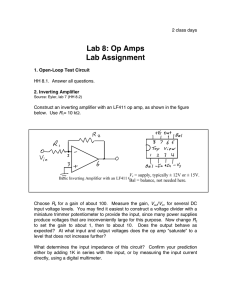

XTi Tracker Operation Ben Carroll 8/21/2006 What is a tracker? • A tracker connects between the power supply and the amplifier stage. • It continuously adjusts the rail voltage to the amplifier output stage to the minimum needed. • Creates a more efficient system than two step supplies such as VZ, H, or G • Is not as efficient a comparable BCA design. Why use a tracker ? • Improved electrical efficiency – Increases the overall amplifier output power capability from the output semiconductors – For a given output power it reduces the current drawn from the wall, which leads to a smaller power supply and line cord. – For a given output power, the main amplifier and power supply heatsinks can be significantly smaller • Ability to limit the maximum voltage across the output semiconductors Prior Art - tracker Half Bridge Full Bridge Output Output Prior Art – Class H Output Xti implementation Two inductors added to traditional Class H design Output Tracker at Work • Black trace is the tracker output • Upper blue trace is the amplifier output • Lower blue trace is the tracker’s error amp output Unique properties of this implementation • Lower amplifier rails supply both the output stage and the control supply • Tracker power stage is not switching at idle • Partial power processing – Further increases efficiency – Reduces voltage stress on MOSFET and Diode XTi4000 –7 schematic Xti4000 –8 schematic Circuit commonality • Four nearly identical circuits – Look at blocks for only one Channel Functional Blocks •Each one is comprised of: –Precision half wave rectifier –PWM level translator and offset generation –Gate Driver –Error Amplifier –Power Stage –Error Signal translator Error signal translator TL494 Control IC –TL494 control IC Error Amp Precision half wave … PWM level translator Power stage Gate Driver Precision half wave rectifier • D60 diode pair form a precision half wave rectifier • Inverting stage • D50 clamps the maximum drive signal. R714 sets the scaling. • R397 sets the static offset • C277 and R392 are a feedforward compensation network • C223 locally compensates the op-amp • C174 is a peak hold cap Error Amplifier • Inverting error amplifier, with inverting terminal at a virtual ground. • R701 and R699 form the DC feedback path. C255, R742, R94 form the AC path • D73 forms an error amp clamp • The drive signal at C174 is inverted • The error amp out signal is not inverted Error signal translator (Old) • Translates the error amp out signal to one that matches the input voltage range of the TL494 control IC • 4V = minimum duty cycle • 0.5V= maximum duty cycle • Translation is dependant on the accuracy of the +/15V rails Error signal translator (New) • Revised circuit used in –8 and later PWA • Uses TL494 Vref supply instead of +/-15V supply • Significant portion of Vref tolerance is canceled out Vref Vref TL494 Control IC • Internal Oscillator running at about 500kHz • R324 increases the maximum duty cycle, D33 is needed when C71 is discharged • Translated error amp signal is injected on pin #3 • Inverted PWM output can be seen on pins 8 and 11 • Vref is 5V PWM level translator • Similar to circuit used on Itech and drive pack • Consists of two grounded base stages. • R77 and R734 sets the translator current • R734 removes charge from Q55 base, to speed the part up at turn off • Q46 is never active, its parasitic capacitance cancels out capacitance in Q62 Gate Driver • IR2106 (U26) translates the high side (positive) gate drive signal and buffers the low side (negative) signal • Q33 and Q42 form a buffer to increase the drive current capability • D79 and D77 protect the IR2106 from overvoltage transients • Power for high side gate drive is fed from two source: – Current source – Bootstrap (D32) Power Stage • Each channel requires two power stages, each with one MOSFET and Diode • D176 and D177 are flyback diodes Questions?