The Impact of Mica Band Heaters on High-Temperature Performance!

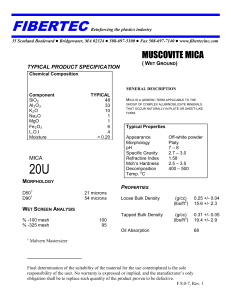

advertisement

THE ROLE OF MICA BAND HEATERS IN HIGH-TEMPERATURE APPLICATIONS! Introduction What Are Mica Band Heaters? Mica band heaters are a type of industrial heating element designed to provide efficient and uniform heat distribution in high-temperature applications. Composed primarily of mica insulation, these heaters are known for their excellent thermal conductivity and durability. Understanding Mica Band Heaters Composition and Structure These heaters are typically made of nickel-chromium resistance wire, wound around a mica core and insulated with mica sheets. The entire assembly is enclosed in a stainless steel sheath, providing robustness and resistance to high temperatures. How They Work These heaters operate on the principle of electrical resistance. When an electric current passes through the resistance wire, it generates heat, which is then transferred to the surface needing heating. The mica insulation ensures even heat distribution and minimizes heat loss. Advantages of Mica Band Heaters Efficient Heat Transfer One of the standout features of mica heaters is their ability to transfer heat efficiently. The mica insulation and metal sheath work together to ensure rapid and uniform heating, which is essential for maintaining consistent temperatures. Durability and Longevity Thanks to their robust construction, M B heaters are highly durable and can withstand harsh industrial environments. This durability translates to a longer lifespan, reducing the frequency of replacements and maintenance costs. Common Applications of M B Heaters Plastic Processing Industry In the plastic processing industry, precise temperature control is crucial for producing high-quality products. These heaters are commonly used in injection molding and extrusion processes to maintain the necessary heat levels. Food Processing Industry Maintaining consistent temperatures is vital in the food processing industry to ensure product quality and safety. Mica heaters provide reliable heating solutions for equipment such as fryers, ovens, and packaging machines. Mica Band Heaters in Plastic Processing Role in Injection Molding Injection molding requires precise temperature control to ensure the plastic material flows correctly and forms the desired shape. Mica heaters are used to heat the barrels of injection molding machines, ensuring the plastic melts uniformly. Benefits in Extrusion Processes In extrusion processes, plastic materials are forced through a die to create specific shapes. Mica heaters ensure the extrusion barrels maintain the optimal temperature, preventing defects and ensuring consistent product quality. Mica Band Heaters in the Food Processing Industry Maintaining Optimal Temperatures In food processing, maintaining the correct temperature is crucial for cooking, frying, and baking processes. Mica heaters provide reliable and consistent heat, ensuring the food is cooked evenly and thoroughly. Ensuring Consistent Quality Temperature fluctuations can affect the quality of food products. By using these heaters, food processors can maintain consistent temperatures, resulting in high-quality products with a uniform taste and texture. Conclusion Mica heaters are essential components in various high-temperature applications, providing efficient, reliable, and cost-effective heating solutions. Their durability, energy efficiency, and ability to maintain precise temperatures make them a preferred choice across multiple industries. As technology continues to advance, M C heaters will likely see further improvements, ensuring they remain a vital tool in industrial heating applications. Source Blog: https://ext6434482.livejournal.com/3018.html