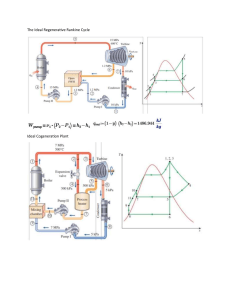

Heat-Recovery Steam Generators: Understand the Basics Gas turbines with heat-recovery - steam By understanding how gas-turbine heat-recovery steam generators differ from conventional steam generators, engineers can design and operate HRSG systems that produce steam efficiently. V. Ganapathy, ABCO Industries 32 • AUGUST 1996 • generators(HRSGs) can be found in virtually every chemical process industries (CPI) plant. They can be operated in either the cogeneration mode or the combined-cycle mode (Figure 1). In the cogeneration mode, steam produced from the HRSG is mainly used for process applications, whereas in the combined-cycle mode, power is generated via a steam turbine generator. Gas turbines have several advantages as a power source: they can be started up quickly; they come in packaged modules, with power outputs ranging from 3 MW to 100 MW, that can be easily assembled and erected; they have high efficiencies of 25% to 35% (on a lower heating value [LHV] basis); and they require little or no cooling water. Recent developments include large-capacity units of up to 250 MW, with low emission characteristics (less than 10 ppmv NOx), as well as high combustor operating temperatures (in the range of 2,200°F), which results in efficiencies higher than 35%; the exhaust gas temperature is also higher, which helps to generate high-pressure/high-temperature superheated steam, making the Rankine cycle efficient. The HRSG forms a major part of the steam system. In the combined-cycle mode, the efficiency of the combined gasturbine-plus-HRSG system can reach 5560% (LHV basis) with today's advanced machines, while in the cogeneration mode, system efficiency can be as high as 75-85%. CHEMICAL ENGINEERING The HRSG generates steam utilizing the energy in the exhaust from the gas turbine. However, some plants also have the capability of producing steam when the gas turbine is shutdown. This is done using a separate forced-draft fan along with a burner to generate hot gases, which are then used to generate steam. An isolating damper system (also called a bypass damper) with seal air fans is re quired in these units to ensure that hot gases do not leak to the fan when the gas turbine is running and that maintenance can be performed on the gas turbine when the fresh air fan is operating. Bypass dampers are also used in some units to ensure that the gas flow to the HRSG can be modulated in order to match steam generation with steam demand. However, if fresh air firing is not used, an isolating damper is not required. Recent trends in HRSG design include multiple-pressure units for maximum energy recovery, the use of hightemperature superheaters or reheaters in combined cycle plants, and auxiliary firing for efficient steam generation. In addition, furnace firing is often employed in small capacity units when the exhaust gas is raised to temperatures of 2,4003,000°F to maximize steam generation and thus improve fuel utilization. This article highlights some of the basic facts about gas turbine HRSGs. This information can help plant engineers, consultants, and those planning cogeneration projects make important decisions about the system and performance related aspects. HRSG temperature profiles and steam generation The starting point in the engineering of a HRSG is the evaluation of its steam generation capability and gas and steam temperature profiles. For a conventional fired steam generator, one can assume a desired steam flow rate and exit gas temperature and then fire the necessary amount of fuel to meet the steam demand. A HRSG behaves differently due to the low inlet gas temperature (900-1,050°F in the unfired mode) and the large gas/steam ratio. Arbitrarily assuming an exit gas temperature or steam generation rate can lead to "temperature cross situations" (discussed below). Figure 2 shows the typical gas and steam temperature profiles in a HRSG consisting of a superheater, evaporator, and economizer operating at a single pressure. Because the gas temperature entering the HRSG is low (900 -1,050°F in unfired units), the steam generation will also be lower than in conventional steam gen erators for the same gas flow. (Re CHEMICAL ENGINEERING PROGRESS • AUGUST 1996 • 33 member that conventional steam generators start out at 3,200°F or so, the adiabatic combustion temperature of the fuels used.) Hence, the economizer duty in the HRSG will also be low, leading to a high exit gas temperature. Also (again unlike in a conventional steam generator), the effect of steam pressure is significant - the higher the steam pressure, the higher the exit gas temperature from the evaporator and the lower the steam generation rate, leading to a smaller duty in the economizer and a higher exit gas temperature. This is the reason for considering multiple -pressure units, as well as deaeration steam coils and condensate heaters in HRSGs operating at high pressures. Two variables that directly affect steam production and the gas and steam temperature profiles are the pinch point and the approach point (Figure 2) (1). The pinch point is the difference between the gas temperature leaving the evaporator and the temperature of saturated steam. The approach point is the difference between the temperature of saturated steam and the temperature of the water entering the evaporator. Selection of these two variables also affects the size of the superheater, the evaporator, and the economizer. Based on the sizes of evaporators that can be built and shipped economically, the pinch and approach points for unfired HRSGs are usually in the range of 15°F to 30°F. (If one specifically wants to generate less steam, such as in a multiple-pressure HRSG generating more low-pressure steam than high-pressure steam, then a larger pinch and approach may be used.) Pinch and approach points are selected for a particular case or exhaust gas condition called the "design case." Unlike in a conventional steam generator, where the steam demand drives the design case, in a HRSG steam production is affected by the conditions of the exhaust gas leaving the gas turbine (such as flow rate, temperature, and gas analysis) and 34 • AUGUST 1996 • entering the HRSG. Also, these parameters vary with ambient conditions, elevation, gas turbine load, and fuel fired. Hence, the design case could be 60°F ambient condition at 100% load of the gas turbine, or any other accepted gas inlet parameters. Using exhaust gas parameters at this condition, one arrives at the design temperature profile, which forms the basis for sizing the HRSG. The HRSG is then designed, or sized, once the pinch and approach points are selected - that is, the surface areas are determined indirectly. Once selected, the pinch and approach points will vary if gas flow and exhaust gas temperature vary. These cases are called "off-design" cases. For example, at different ambient conditions and gas turbine loads, one can have different exhaust gas parameters, or one may have to burn CHEMICAL ENGINEERING PROGRESS auxiliary fuel to generate a desired quantity of steam. There is only one design case, but several off-design cases. Prudent engineering calls for the pinch and approach points to be es tablished in the unfired mode (2, 3) rather than in the fired mode, for several reasons: 1. Designs that can be physically and economically shipped can be established if pinch and approach points are chosen in the range suggested (Figure 2) in the unfired mode at the design ambient conditions. 2. A HRSG simulation approach is required to evaluate the pinch and approach points at fired conditions or at different ambient conditions (2, 3). If the pinch and approach were selected in the fired mode (which is not recommended), it is likely that the pinch point in the unfired mode could be too low, resulting in a huge, unwieldly, and uneconomical HRSG. Also, a low approach point in the fired mode could result in steaming in the economizer under unfired conditions. Economizer steaming should be avoided, as it results in operational problems such as vibration, water hammer, and possible deposition of salts in the economizer tubes, with the ultimate result being reduced performance. 3. If a superheater is used, it is not possible to estimate the degree of oversizing if the pinch and approach are selected in the fired mode. If the steam temperature is to be maintained over a wide load range, it is likely that the steam temperature will be lower than desired under unfired conditions. If pinch and approach points along with the desired steam temperature are selected in the unfired mode, then the steam temperature can certainly be maintained under fired conditions and can be controlled using attemperation or other means. A HRSG simulation program (such as the one developed by the author (2)) may be used to simulate the design and off-design performance of single, multiplepressure unfired and fired HRSGs (/). Simulation gives a good idea of what the HRSG can do at different gas inlet conditions, and can help one optimize temperature profiles and HRSG configurations and evaluate HRSG performance with different gas turbines. Simulation can also help one evaluate the effects of the exhaust gas analysis, which is important in steam-injected gas turbines, because gas specific heat and duty are impacted by gas analysis. of steam leaving the superheater (ts2), and steam pressure (Ps). Assuming a reasonable pressure drop in the superheater, we can determine the saturation temperature ( t s) at the evaporator. Once the pinch point is selected, we know the temperature of the gas leaving the evaporator ( t g3) and the approach point gives the temperature of the water leaving the economizer (tw2), since the saturation temperature is known. The heat loss (hl) ranges from 2% in small HRSGs to about 0.5% in large units. Methods of estimating heat losses are outlined elsewhere (2). Considering the energy balance across the superheater and evaporator (Figure 2), the energy absorbed by the superheater and evaporator is given by: Q1.2 = Wg C pg( tg1 - tg3 ) (hl) = Wsd[(h s2 - h w2 ) + (bd)(h f- h w 2)] (1) Since t g 1 and t g3 are known, Q 1 2 can be computed and the design steam flow (Wsd ) can be determined. The superheater duty is: Q1 = Wsd (h s2 - h v) = Wg C p g ( t g l - tg2 ) (hl) (2) From above, the temperature of the gas leaving the superheater ( t g2 ) can be determined, since all the other data are known. The economizer energy balance gives: Q3 = Wsd (h w2 - h w1 )(1 + bd) = W g Cpg ( tg3 - tg4 ) (hl) (3) The gas temperature leaving the economizer ( t g4) can be obtained from this. Thus, the complete gas/steam profiles and steam generation rate for the design case can be determined by assuming the pinch and approach points. In addition, once the pinch and approach points are selected, the logmean temperature differences ( ∆T) at Design temperature profile the various surfaces are fixed. Since calculatio ns from basic heat-transfer principles The starting point for determining surface area is given by S = QIUAT, gas and steam temperature profiles and the surface areas of all the compo steam generation is the assumption of pinch and approach points, as discussed above. The values that are known are gas flow rate (Wg, gas temperature at HRSG inlet ( t g1 ), feed water temperature (tw1), temperature nents, such as the superheater, evaporator, and economizer, are fixed once U is computed. (To calculate U one should have such mechanical data as tube size, fin density, tube pitch, etc.) But if U is not known, US is, which indirectly fixes the surface areas. Now, if we want to know how the HRSG behaves at different gas conditions, we have to perform off-design calculations and use the "surface areas" we have indirectly established. It may also be noted that we are using a pinch point of about 15-20°F, which results in a low AT in the evap orator and thus the need for large surface area. (The pinch point in a con ventional steam generator could range from 150°F to 400°F, so the ∆T is much higher and the required surface area much less.) This is why extended surfaces are a must in HRSGs. Don't select exit gas temperatures arbitrarily The right way to evaluate the design temperature profile is to assume pinch and approach points and perform the calculations outlined above. The exit gas temperature ( t g4 ) is determined as shown above. What happens if we try to assume a value for t g 4 ? From Figure 2, considering the heat balance across the superheater and evaporator and neglecting blowdown, we have: Wg Cp g( t g 1 - t g 3 ) (hl) = Ws d(h s2 - h w2 ) (4) Also, considering the complete HRSG: Wg Cpg (tg l - tg4 )(hl) = Wsd(h s2 – h w1 ) (5) Dividing Eq. 4 by Eq. 5 and neglecting the effect of specific heat, we have: (t g 1 - t g3 )/(tg 1 - t g4 ) = (h s2 - h w 2)/(hs 2 – h w1 ) = K (6) For steam generation to occur, two conditions must be met: tg3 > ts tg 4 >twl CHEMICAL ENGINEERING PROGRESS • AUGUST 1996 • 35 If either condition fails, a temperature cross (1,600 - 512)/(1,600 –tg4) = 0.7728, situation results, meaning that the HRSG or tg4 = 192°F, which is below the parameters are invalid and must be selected feed water temperature of 230°F. again. This is why we cannot arbitrarily This, too, is an invalid temperature select pinch and approach points and the profile. With a much higher pinch exit gas temperature. point we could have obtained tg4 Calculations for t have been carried out at above 230°F. This illustrates why various steam conditions for a typical gas pinch and approach points are best turbine and the results are presented in selected in the unfired mode, having Table l. It may be seen that as the steam values in the range suggested in Figpressure increases, the exit gas temperature ure 2, to ensure valid temperature increases. Also, as the steam temperature profiles. Simulation can also help deincreases at a given pressure, the amount of termine valid conditions. steam generated decreases for a given pinch point; this results in a decrease in the Evaluating economizer duty, thus increasing the exit off-design performance gas temperature. (The calculations are based We have seen how the "design on a gas inlet temperature of 900°F, feed temperature profile" is arrived at. Using water temperature of 230°F, pinch point of simulation, one can predict HRSG 20°F, and approach of 15°F.) performance at any other gas inlet Let us now see that an exit gas temperature conditions or steam parameters. This of 300°F, at conditions of, say, 600 psig and approach is discussed elsewhere (1,2). 750°F, cannot be achieved. Using data from the steam tables, K = 0.7728 at these conditions. From Eq. 6, (900 –tg3)/(900 - 300) = 0.7728, or tg3 = 436°F. This is below the saturation temperature of 492°F, which is not a valid temperature profile - hence, we say that temperature cross has occurred. Now let us see what happens if we select the pinch point in the fired mode with a gas inlet temperature of 1,600°F. Let us assume a 20°F pinch at the same pressure and temperature conditions as above. Using Eq. 6, g4 5• AUGUST 1996 • CHEMICAL ENGINEERING PROGRESS In simple terms, the factor US is obtained using the equation Q/∆T for each surface in the design case. Then in the off-design case, the values of US are corrected for the effects of gas flow, temperature, and composition. Then, the energy transferred across each surface is obtained through an iterative process using the following equation (after first assuming a steam flow rate to begin): Q = WgCpg(tgi - tgo) = Ws(ho -hi) = US∆T (7) The total energy transferred across each surface is computed, and the actual steam generation rate (Ws) is obtained from the sum of ΣQ/(∆h) for all the surfaces. This information is then used to correct the assumed steam flow. The problem gets more complicated if there are several modules, and gets complicated further still if auxiliary firing is used to generate the desired steam flow rate in a particular module. Simulation software, which performs these complex calculations in minutes, comes in handy in these s ituations. HRSG design features The HRSG generates steam, the quality and quantity of which depend on the flow and temperature of the exhaust gas entering it. Large cogeneration and combined-cycle plants generate high-pressure/high-tempera ture superheated steam (600-1,500 psig at 650-950°F), while small ca pacity plants (10-MW gas turbines and below) may generate low-pres sure saturated steam (100-300 psig). The superheated steam temperature in a HRSG is controlled using spray desuperheaters as in conventional boilers. Steam temperature varies with gas inlet conditions, so performance should be verified at various off-design cases. Multiple-pressure steam generation is employed in cases where the exit gas temperature from single-pressure-level generation would be considered too high or uneconomical. There are three types of HRSGs: unfired, supplementary-fired, and exhaust-fired (Figures 3-5). This is not a rigid classification, but it is widely used. Table 2 shows the main features and the typical steam outputs that can be expected for each of the three types. Figure 4b also shows a freshair-firing system, where a supplemen tary-fired HRSG is operated using air from a fan, a situation that arises, for example, when the gas turbine trips or is shut down for maintenance. Fig ure 4c shows a typical duct burner for a supplementary-fired HRSG. Unfired and supplementaryfired HRSGs The HRSG consists of single- or multiple-pressure modules depending upon the degree of energy recovery desired. A simulation of the tempera ture profiles must be performed (I) before designing the steam system for a given application. Unfired and supplementary-fired HRSGs are similar in appearance and constru ction, both being convective designs. The units are internally insulated with ceramic-fiber insulation with an alloy steel liner to hold the insulation in place. The insulation thickness ranges from 4-6 in. inunfired units to 810 in. in supplemen tary-fired units. Roughly two-thirds of the HRSGs purchased today are unfired due to their low first cost. CHEMICAL ENGINEERING PROGRESS 9 AUGUST 1996 • 37 Extended surfaces are widely used in the superheater, evaporator, and economizer. This is because a large surface area is required in these systems as a result of the low pinch and approach points and the low logmean temperature differences at the various heating surfaces. Extended surfaces make the HRSG design very compact. And, lower gas pres sure drops can be achieved with extended surfaces than with bare tubes (Table 3) (2). For evaporators and economizers with clean gas streams, such as exhaust from natural-gas -fired and dis tillate-oil-fired gas turbines, fin densities of 4 to 5 fins/in. are reco mmended. Fin height can vary from 0.5 to 1 in. Fin thickness is typically from 0.05 to 0.075 in. A low fin density is recommended for superheaters due to their low tube-side heat-transfer coefficient (3). Using a high fin density when the tube-side coefficient is low offers no added benefit. The use of fins, in gen eral, increases the tube wall and fin tip temperatures and the heat flux inside the tubes. When the tube-side co efficient is low, the temperature drop across the tube-side film is naturally high, resulting in high tube wall and fin tip temperatures even without fins. In fired units, a combination of bare and finned tubes is used to en sure that the tube wall and fin tip tem - 7• AUGUST 1996 • peratures remain safely within limits. The first few rows of tubes near the high-gas-temperature zone use bare tubes, and subsequent tube rows, where the gas is cooler, have extended surfaces. Surface areas can be misleading, particularly when finned tubes are used. The higher the fin density and the ratio of external-to-internal tube surface area, the lower the gas-side heattransfer coefficient and hence the lower the overall heat-transfer co efficient (Figure 6) (2, 4). Thus, a CHEMICAL ENGINEERING PROGRESS HRSG with surface area that is 100200% more than that of another design with a lower fin density can transfer the same duty. Therefore, one should look at the product of overall heat -transfer coefficient times surface area (US) instead of surface area alone. Table 4 illustrates the effects of fin geometry on superheater performance (3, 4). For example, a superheater can transfer the same duty with significantly different surface areas - the surface area in case 2 is more than double the surface area in case l, yet the duty (or energy transferred) is essentially the same. This is because of the poor fin configuration in case 2 due to the higher heat flux inside the tubes with the higher fin density, the tube wall and fin tip temperatures in case 2 are much higher than in case 1. Hence, the use of excess surface has negative implications, too. Comparing cases 2 and 3 illustrates how more duty is transferred with a lower surface area simply by selecting optimum fin configuration. Thus, engineers and purchasing managers should not make decisions using a spreadsheet that shows only the surface areas of different designs. Rather, a good evaluation should include the product of overall heattransfer coefficient (on an external surface area basis) and surface area. A supplementary-fired HRSG has a duct burner (Figure 4c) located upstream. A duct burner typically has a rectangular cross-section and fits into the ductwork carrying the exhaust gases. It consists of vertical or horizontal grids with holes that admit fuel (such as natural gas and distillate oil) into the exhaust gas stream. Generally, no additional air is used, except when the exhaust gas is injected with large quantities of steam, which reduces the amount of oxygen available for combustion. In these cases, a small fan (called an augmenting air fan) is also included with the burner. The duct burner raises the exhaust gas temperature from about 1,000°F to a maximum of 1,700°F in HRSGs with insulated casings and up to 2,400°F in HRSGs equipped with water-cooled furnaces. The gas pressure drop across the duct burner is low (on the order of 0.5 in. w.c.). This is important because each additional 4 in. w.c. gas pressure drop in the HRSG decreases the gas turbine power output by about I %. In large capacity units for combinedcycle plants, reheaters are installed in addition to superheaters to improve the Rankine cycle efficiency. Unlike in a Rankine cycle system based on a conventional steam generator, where the condensate is heated in external steam-to-water heat exchangers using steam extracted from the steam turbine, in a gas turbine HRSG the condensate or make-up water is heated in the HRSG itself to improve the efficiency of energy recovery. Deaeration steam may also be generated in the HRSG for the same reason. Thus, it is not unusual to see several modules in a HRSG. Multiple pressurelevel steam generation, CHEMICAL ENGINEERING PROGRESS AUGUST 1996 • 39 which increases the efficiency of en ergy recovery, is common in unfired and supplementary-fired HRSGs. Exhaust-fired HRSGsThe exhaustfired HRSG (Figure 5), in which the firing temperature ranges from 1,700°F to 3,000°F, uses a completely watercooled furnace to contain the flame, since the temperature could approach the adiabatic combustion temperature. The burner used is typically a register burner with a windbox, although a duct burner may be used up to 2,400°F. The gas turbine exhaust is used as hot air for combustion. In certain plants overseas, even solid fuels such as coal have been fired in these boilers using register burners. The gas pressure drop across the register burner is high (about 4-6 in. w.c.). The HRSG is typically a single 9• AUGUST 1996 • pressure unit in these systems, as the exit gas temperature can be brought down to a low level (on the order of 300°F), unlike in an unfired or supplementary-fired HRSG, which has a high exit gas temperature if a singlepressure system is used. Due to the high gas temperature entering the HRSG, the design is likely to consist of more bare tubes than finned tubes. A radiant furnace is required to cool the gases before they enter the superheater or convective sections. Auxiliary firing and system efficiency Typical gas turbine exhaust contains 1315% oxygen by volume. This is adequate to fire additional fuel in the burner to raise the exhaust gas temperature to about 3,000°F. The relationship between oxygen availability CHEMICAL ENGINEERING PROGRESS and natural gas or fuel oil input is (3): Q = 58.4W gO (8) where W g is the exhaust gas flow in lb/h, O is the oxygen consumed in %vol., and Q is the burner heat input in Btu/h (LHV basis). For example, if the exhaust gas conditions are 150,000 lb/h at 1,000°F with 15% oxygen, the energy required to raise the gas to 1,700°F is approximately Q = (150,000)(0.3) x (1,700 - 1,000) = 31.5 MM Btu/h; the oxygen consumed during com bustion will be: O = 31,500,000 [(150,000)(58.4)] = 3.6%. Thus, the exhaust gas still contains more than 11.4% oxygen. A HRSG simulation program has been used to evaluate the efficiency of supplementary firing on HRSG per formance, and the results are present ed in Table 5 and Figures 7 and 8. As the amount of firing increases, the efficiency of the system (as defined by ASME PTC 4.4 (S)) also increases. Note that the fuel utilization in the HRSG is nearly 100%. The additional boiler duty to generate 60,000 lb/h of steam is 59.90 - 22.67 = 37.23 MM Btu/h and the fuel added is 37.60 MM Btu/h (LHV basis). Thus, all of the fuel energy goes into generating steam, making the fuel utilization 100%, compared to the efficiency of a conventional steam generator of about 90%. There are two reasons for this: l. We know from basic combustion principles that in a conventional steam generator, as the excess air increases, the efficiency decreases. This CHEMICAL ENGINEERING PROGRESS • AUGUST 1996 • 41 is because the additional air must be heated from ambient conditions to the exit conditions. In a HRSG, on the other hand, the amount of excess air is reduced by firing only fuel in the exhaust gas without adding air. 2. The exit gas temperature in a single-pressure HRSG decreases as the firing temperature increases. In a conventional steam generator, the gas/steam ratio remains nearly constant at about unity at all loads, where as in a gas turbine HRSG, it decreases as steam generation increases. This results in a larger heat sink at the economizer and hence a lower exit gas temperature. Note that in a HRSG, the gas flow remains nearly the same at all steam generation levels. Therefore, engineers should first plan to generate additional steam in the HRSG before using conventional steam generators (6, 7). As discussed earlier, unfired and supplementaryfired HRSGs do not differ much except for changes in steam drum size, insulation thickness, valve sizes, and so on. Hence, it may be economical to consider these designs for firing up to 1,300-1,500°F to maximize steam generation at a high efficiency. The furnace-fired HRSG requires a completely different design with completely water-cooled membranewall furnaces, so a detailed cost evaluation is needed to determine the economic viability of this type of HRSG. Natural vs. forced circulation Natural-circulation HRSGs (as shown in Figures 3-5) are common in the U.S. In Europe, forced-circulation units (Figure 9) are more prevalent. In natural-circulation HRSGs, the tubes are vertical and gas flows horizontally. The widths of the various modules are limited by shipping considerations. Thus, large HRSGs may have modules 12 ft wide and 3050 ft tall. Downcomer pipes carry the hot saturated water to the bottom of the evaporator modules and riser pipes carry the steam/water mixture to the external steam drum, where 42 • AUGUST 199 6 • files, casing design, use of extended surfaces, and surface area require ments are similar between naturaland forced-circulation units. separation occurs. Saturated steam is then taken to the superheater. In forced-circulation HRSGs, the tubes are horizontal and gas flow is vertical. This configuration minimizes the use of land space. The cross-sectional area, though, is the same as in naturalcirculation systems. Pumps maintain circulation of the water/steam mixture through the evaporator tubes, which results in an additional operational expense. Failure of the pumps can cause shutdown and possibly evaporator tube failure. Keep in mind that the heat flux in side finned tubes is several times that in a comparable bare tube. Thus, fired HRSGs must be designed with care to prevent overheating of the tubes. In general, horizontal tubes cannot tolerate heat fluxes as high as vertical evaporator tubes can because in the latter gravity assists in providing good wetting of tube periphery. In addition, steam bubbles formed during boiling tend to concentrate on the top portion of the horizontal tubes, while water occupies the lower portion. This results in a varying temperature profile across the tube periphery due to the different heat-transfer coefficients of water and steam, which leads to higher thermal stresses. Other aspects of HRSG design, such as gas/steam temperature pro CHEMICAL ENGINEERING PROGRESS Improving HRSG efficiency Several options for improving energy recovery, even in a single-pressure steam system, are illustrated in Figure 10. Make-up water or condensate can be heated in the HRSG itself (Figure 10a). This reduces the amount of steam required for deaeration, improving the overall efficiency. If sulfuric acid vapor is present in the exhaust gases, the condensate temperature should be no lower than the acid vapor's dew point to prevent condensation of the corrosive vapors on the tube (4). This condensate heater option is generally used in natural-gasfired systems that do not contain acid vapors. Still, the water temperature entering the exchanger should be above the water vapor's dew point to prevent water condensation on the tubes. The second option is to generate lowpressure saturated steam or deaeration steam in the HRSG itself using a lowpressure evaporator (Figure 10b). This type of system is recommended if there is a possibility of acid vapor condensation, since the steam saturation temperature can be maintained above the acid's dew point. However, it is more expensive than the condensate heater option due to higher surface area requirements and the need for a drum, instrumentation, and controls. The exit gas temperature from the HRSG will naturally be higher than the saturation temperature of steam, whereas in the pre vious option, it could be much lower. The third option is to preheat the make-up water in a heat exchanger before it enters the deaerator, while simultaneously cooling the feed water before it enters the economizer (Figure 10c). The economizer requires a larger surface area, but this is an economical option compared to the deaerator. Condensing heat exchangers have also been used in some projects. Polytetrafluoroethylene (PTFE; e.g., Teflon) or similar corrosion-resistant material is used as a coating on the tubes to prevent corrosion from acid condensation. In such cases, the make -up water can enter the heater as cool as 60-80°F. Another option for lowering the exhaust gas temperature is to circulate more water than necessary through the economizer and recirculate the excess to the deaerator in order to reduce the deaeration steam requirements (Figure 1Od). Some plants, depending upon the steam system and the quantity and temperature of make-up water re quired, may use a combination of these methods. Evaluating operating data HRSGs often operate under different exhaust gas conditions and steam parameters than the design conditions - for example, if the ambient temperature or gas turbine load is different from what was selected for design of the HRSG. The questions then arise as to whether the HRSG is operating satisfactorily or not, and how the operating data CHEMICAL ENGINEERING PROGRESS 9 AUGUST 1996 • 43 range of 2-4 in. w.c., which must be considered in the overall design and performance evaluation. can be reconciled with any performance guarantees. One way to answer these questions is through HRSG simulation. One can use the operating data to simulate the design pinch and approach points, and then use this information to predict the HRSG off-design performance at the conditions specified in the proposal or guarantee. A comparison between the two sets of data can confirm whether or not the HRSG original design is adequate (8). Use of catalysts With stringent environmental regulations for carbon monoxide and nitrogen oxides, the use of catalysts for controlling emissions is becoming commonplace. Steam and water injection and modifications to the gas turbine combustor can reduce NOx levels to 30-40 ppm. However, some states require that NO, be reduced 13 • AUGUST 1996 • further to 9-15 ppm. Catalysts, in the form of selective catalytic reduction (SCR) systems (9), can be used in the HRSG to achieve this lower emission level. Catalyst performance is affected by gas temperature at the catalyst. Catalysts operate efficiently over a narrow range of gas temperatures. For NOx catalysts, the gas temperature range is typically 600-750°F; for CO catalysts it is 9001,200°F. The catalyst supplier specifies this temperature window, which depends on the materials used. In order to achieve temperatures within this window at all loads of the HRSG, the heat-transfer surfaces may have to be split to find a good location for the SCR (Figure 11). Provision should be made for an ammonia injection grid upstream of the NOx catalyst. The catalyst also has a high gas pressure drop, in the CHEMICAL ENGINEERING PROGRESS Turbine exhaust characteristics Two important variables that affect flow rate and temperature of the gas turbine exhaust are ambient temperature and load, as mentioned earlier. These parameters, in turn, affect HRSG performance. At higher ambi ent temperatures, the exhaust gas flow is lower and the exhaust gas temperature is higher, and vice versa. As the gas turbine load decreases, the exhaust gas temperature also decreases but the mass flow does not vary much. As a result of the variations in exhaust gas flow and temperature, the HRSG steam flow and temperature will also be affected (Figure 12). Therefore, engineers should analyze HRSG performance at various cases and ensure that the plant performance is not impacted by the varying steam production in the HRSG. Supplemen tary firing of the HRSG, as well as steam and water injection in the gas turbine, may have to be considered to ensure steady steam production. Steam injection is becoming more widespread. In addition to controlling NO, emissions from the gas turbine combustor, it also increases the gas turbine power output as well as the HRSG output. This is due to the high er mass flow as well as the higher specific heat of the gas. In the Cheng cycle (3), for example, steam injection is significant, raising the amount of water vapor from 7% in uninjected units to 25%, with a corresponding increase in the gas turbine power output from 3.5 to about 5.5 MW. In summer months the gas turbine power output drops off, which may not be tolerable in some plants. Evaporative cooling or some other form of air cooling can be used in these plants to maintain a low and steady inlet air temperature to the compressor throughout the year. This results in a constant power output and steam generation, and HRSG performance in such units does not vary much with ambient temperatures. However, this option is economical only in large gas turbines exceeding, say, 50 MW capacity. Closing Closing thoughts Gas turbine HRSGs have different performance characteristics and construction features than conventional steam generators. By understanding these and relating them to conven tional steam generators, engineers can generate steam efficiently. The key points to remember are as follows. To determine steam generation from a given gas turbine, a HRSG simulation should be performed, because the HRSG exit gas temperature cannot be arbitrarily selected (as in a conventional steam generator). While evaluating HRSG steam flow, pinch and approach points should be selected in the un fired mode. Fired HRSGs are more efficient than unfired; hence, cogeneration plants are more efficient in the fired mode. Several options for im proving energy recovery in the HRSG should be evaluated. Multiple-pres sure steam generation should be considered to optimize energy recovery, particularly if high-pressure steam is generated. Since extended surfaces are widely used, an understanding of heat-transfer characteristics with finned tubes is desirable. Engineers often make the mistake of selecting a HRSG based on surface area alone, which can be misleading - more surface area does not always mean more heat transferred. And finally, HRSG simulation can help one evaluate plant operating data and compare it with design data. CHEMICAL ENGINEERING PROGRESS AUGUST 1996 • 14