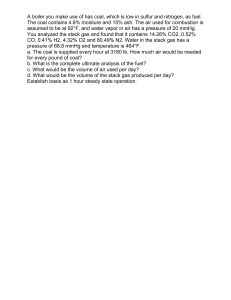

Plant Performance Report Semirara Coal: Effect on Boiler Operation and Economical Price Determination PPR-TSD-23-004 Prepared by: RB Del Rosario Date Created: Reviewed by: PC Licot, VH Panes Revision: Approved by: JV Diamante Date Approved: January 18, 2023 February 9, 2023 Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Date: February 9, 2023 To: Joel D. Ysip Plant Manager Revision: 0 Page: 2 of 17 Reynaldo E. Francisco Operations Manager Gary A. Algodon Supply Chain Manager Cc: Christian A. Sabigan Water Treatment Supervisor All Managers Subj: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Executive Summary Hardgrove Grindability Indices from COA suggest that Semirara coals (42.92 HGI) are harder and more erosive than Indonesian coals (51.78 HGI), as indicated by the former’s lower HGI and by the PSD measured at crusher upstream. The ash and silica content of Semirara coals (8.11% ash, 51.04% SiO2) is also higher than that of Indonesian coals (4.97% ash, 36.61% SiO2), increasing concentrations of erosive ash in the bed material. The 15.85% increase in average and 28.95% increase in maximum freeboard dP following the start of Semirara coal firing have accelerated boiler tube erosion due to the higher flue gas velocities and bed material concentrations in the upper furnace. Data show severe slagging and fouling potential of the Semirara coal sample. Although slagging should not be of concern, the decrease in finishing superheater and reheater desuperheater spray water quantities and the frequent localized overheating in the backpass indicate increased fouling rates. The higher total sulfur content of Semirara coals (0.57% S) than Indonesian coals (0.2% S) subjects the air preheaters to greater corrosion of cold end heating elements. Central composite design was used to analyze the effect of unit costs and average WESM price on the contribution margin difference between pure Indonesian coal firing and 2 Indo 1 Semirara coal firing, at fixed consumption rates, service and outage days, net load factor, and additional APMS and forced outage costs. Latest data suggest that 2 Indo 1 Semirara coal firing would match the contribution margin from pure Indonesian coal firing at Semirara coal prices of ~PHP 8,613.15/MT and ~PHP 9,392.49/MT in years 1 and 2, respectively. Findings and Analysis Effect of Semirara Coal on Boiler Tube Erosion In 2022, the plant has been troubled by three forced outages due to boiler tube leakage, two of which led to earlier than scheduled annual preventive maintenance shutdown. Following thorough research, it was determined that the use of Semirara coal since January 21 last year has significantly increased the rate of boiler tube erosion. Aside from the observed upswing in furnace freeboard differential pressure, two coal properties were analyzed: Hardgrove Grindability Index and ash content. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 3 of 17 Figure 1.1 Unit 3 boiler tube leakage at evaporator panel #6 ruptured tube. Photos by TSD Reliability. Recent literature on coal abrasiveness concludes that the abrasion index of coals increases for every increase in ash content and for every decrease in grindability (Alekhnovich et al., 2021). Presented in Figure 1.2 are the weighted average values of these properties for each coal mixture, showing decreasing coal quality and desirability as the percentage of Semirara coal increases. 60.00 51.78 48.83 50.00 45.87 42.92 40.00 30.00 20.00 10.00 4.97 6.02 7.06 8.11 Pure Indonesian 2 Indo, 1 Semirara Hardgrove Grindability Index 1 Indo, 2 Semirara Pure Semirara Ash Content (ADB), % Figure 1.2 Weighted average HGI and ash content per coal mixture The Hardgrove Grindability Indices (HGI) from the certificates of analysis (COA) suggest that Semirara coals (42.92 HGI) are harder and more erosive than Indonesian coals (51.78 HGI), as indicated by the former’s lower HGI and by the particle size distribution measured at the crusher upstream. In addition, the acceptable HGI range based on the coal supply evaluation criteria set by SCPC is 46-56 HGI. Although erosive metal loss decreases as furnace temperatures increase due to the softening of particles, the initial deformation temperatures of both Indonesian coals (1,212.15oC) and Semirara coals (1,093.51oC) are sufficiently high to resist the softening process. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 4 of 17 Table 1.1 PSD of Indonesian and Semirara coals last August 14, 2022 Mean Diameter Standard, mm D – 99 D – 50 D – 05 6.0 – 9.0 0.7 – 1.5 < 0.1 Indonesian: MV SL Rose (2) Sample Results, mm 0.9652 0.0406 Semirara: Barge Karangalan 2 (6) Sample Results, mm 1.3209 0.1046 The ash content of Semirara coals (8.11% ash) is also higher than that of Indonesian coals (4.97% ash). Coal abrasiveness increases proportionally with ash content due to the increase in the quantity of abrasive material such as aluminum, silicon, and iron oxide compounds, which have high particle hardness and thus provide greater kinetic energy upon impact, as stated in the aforementioned literature. These compounds are present in both Indonesian and Semirara coal ash in the form of alumina (Al2O3), silica (SiO2), and hematite (Fe2O3) as shown in Figure 1.3. Since no ash analyses are provided in the COA of Semirara coals, an independent coal analysis was conducted for Barge Karangalan 2 (8) samples in Masinloc Power Plant last September 9, 2022 to determine the composition of Semirara coal ash. Another study on the development of a predictive model for abrasion has clearly identified that both quartz, expressed as the combination of SiO2 and Al2O3 in this study, and ash content are the key predictors for abrasion (Bandopadhyay, 2010). 60.00 51.04 50.00 40.00 36.61 30.00 20.00 14.81 11.19 12.61 10.00 8.74 SiO2, % Al2O3, % Indonesian Coal Fe2O3, % Semirara Coal Figure 1.3 Weighted average percentages of alumina, silica, and hematite in coal ash Aside from the large quantity of erosive particles, another factor that accelerates erosion is high flue gas velocity, which increases the kinetic energy of the entrained particles as they strike the tube surfaces. Erosion must have been minimal on vertical tubes in a CFB boiler, where bed material flows parallel to the surfaces. However, any region inside the furnace where channeling or eddying of flue gas occurs is susceptible to erosion. Presented in Figure 1.4 are trends from January 1, 2021 to September 28, 2022, the date when the last boiler tube leakage occurred in Unit 3. The figure shows drastic increase in furnace freeboard differential pressures (dP) following the use of Semirara coal on January 21, 2022, which has escalated flue gas velocities and bed material concentrations in the upper furnace. At 150 ±1 MW, a 15.85% increase in average freeboard dP was observed, while the maximum freeboard dP surged by 28.95%. Unit 4 suffered the highest increase in average and maximum freeboard dP, yielding percent increase of 30.22% and 39.38%, respectively. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 5 of 17 Figure 1.4 Comparison among unit furnace freeboard dP The correlation between freeboard dP and coal mixture presented in Figure 1.5 is worth noting as it shows the general effect of Semirara coals on freeboard dP. The following data are the average freeboard dP observed at 150 ±1 MW from January 21, 2022 to September 28, 2022. 140.00 120.00 100.00 80.00 60.00 40.00 20.00 - 124.86 117.81 105.27 108.26 93.70 79.06 77.12 58.20 57.26 77.97 67.26 Unit 1 Unit 2 Pure Indonesian 83.53 2 Indo, 1 Semirara 85.83 Unit 3 1 Indo, 2 Semirara Unit 4 Pure Semirara Figure 1.5 Furnace freeboard dP in mmH2O vs coal mixtures Although it was Unit 4 which has experienced the greatest increase in freeboard dP, it was Unit 1 which encountered boiler tube leakages last May 29, 2022 and August 6, 2022, as well as Unit 3 last September 28, 2022. Summarized in Figure 1.6 are the number of days each unit was using each coal mixture from January 21, 2022 to September 28, 2022, and in Figure 1.7 are the actual consumptions and average coal mixtures during the said period, where it is evident that Units 1 and 3 have been the top Semirara coal consumers at 46.10% and 32.78%, respectively. This implies that the compounded effect of high freeboard dP and increased particle erosivity speeds up the rate of boiler tube erosion. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 6 of 17 200 154 140 150 118 111 100 50 81 46 23 28 48 57 63 41 6 0 Unit 1 Unit 2 Pure Indonesian 2 Indo, 1 Semirara Unit 3 1 Indo, 2 Semirara Unit 4 Pure Semirara Figure 1.6 Number of operating days per coal mixture 100% 219,918.55 326,133.43 302,930.12 315,556.72 137,959.69 147,747.63 138,517.57 Unit 2 Unit 3 Unit 4 80% 60% 40% 188,099.80 20% 0% Unit 1 Semirara Coal Consumption, MT Indonesian Coal Consumption, MT Figure 1.7 Average coal mixture per unit Comparative analysis on boiler tube erosion rates for Unit 1, which has the highest Semirara coal consumption, was conducted based on historical UTG data of tubes 3-7 and 169-172 recorded by TSD Reliability. During the 2021 APMS, it was observed that even after 18 months and 15 days of operation since the 2020 APMS, the thickness wastage was only 2.39 mm, yielding a 0.1292 mm/month erosion rate for pure Indonesian coal consumption. In addition, ceramic coating was applied on the furnace roof area during the 2021 APMS. Meanwhile, the unit experienced forced outage due to boiler tube leakage from the furnace roof last May 29, 2022, where tubes 3-7 and 169-172 were replaced. During the emergency shutdown, it was observed that after 9 months and 7 days of operation since the 2021 APMS, the thickness wastage was already 5.5 mm, yielding a 0.5957 mm/month erosion rate for 25.18% or 133,222.99 MT of Semirara coal consumption. The unit encountered yet another forced outage due to boiler tube leakage from the furnace roof side wall last August 6, 2022, days prior to its scheduled planned outage. During the 2022 APMS, it was observed that even after 1 month and 28 days of operation since the emergency shutdown, the thickness wastage was already 1.2 mm, yielding a 0.6207 mm/month erosion rate for 35.48% or 39,060.81 MT of Semirara coal consumption. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 7 of 17 Effect on Backpass Fouling and Air Preheater Corrosion As of January 18, 2023, the plant has 63 Semirara coal deliveries in total, all without ash and ultimate analyses provided in their COA. Being one of the only few references cited in ASME PTC 4-2008 due to their extensive use in the industry, the following analysis is based on formulas provided by The Babcock & Wilcox Company. Calculations were made using data provided in the COA of Indonesian coals and data gathered from the independent coal analysis for Barge Karangalan 2 (8) samples, and the resulting slagging and fouling indices presented in Table 1.2 show severe high temperature ash deposition potential of the Semirara coal representative. Table 1.2 Summary of calculated ash deposition indices Particulars Weighted Avg. Slagging Index Bituminous Ash Lignitic Ash Weighted Avg. Fouling Index Bituminous Ash Lignitic Ash A Lignitic Ash B Shipment year 2016 2017 2018 2019 2020 2021 2022 Indonesian Semirara 0.14 0.18 0.31 0.16 0.15 2245.46 2211.42 2215.47 2143.72 2229.02 2244.12 0.34 0.42 0.42 0.20 0.33 0.68 0.83 0.98 1.38 1.32 1.37 2.00 1.02 - 2285.02 1922.00 - 1.21 - 4.36 Fe2O3 > CaO + MgO Fe2O3 < CaO + MgO Fe2O3 > CaO + MgO Fe2O3 < CaO + MgO Fe2O3 < CaO + MgO CaO + MgO + Fe2O3 > 20% CaO + MgO + Fe2O3 < 20% Na2O Na2O <3 < 1.2 3-6 >6 1.2 - 3.0 > 3.0 Ash classification Ash deposition index formula S*(B/A) [(Max HT) + 4*(Min IDT)]/5 Na2O*(B/A) B = basic ash constituents (CaO + MgO + Fe2O3 + Na2O + K2O), % A = acidic ash constituents (SiO2 + Al2O3 + TiO2), % S = total sulfur on dry basis, % CaO = calcium oxide from ash analysis, % MgO = magnesium oxide from ash analysis, % Fe2O3 = ferric oxide from ash analysis, % Na2O = sodium oxide from ash analysis, % K2O = potassium oxide from ash analysis, % SiO2 = silicon dioxide from ash analysis, % Al2O3 = aluminum oxide from ash analysis, % TiO2 = titanium dioxide from ash analysis, % Max HT = higher of the reducing or oxidizing hemispherical temperatures, oF Min IDT = lower of the reducing or oxidizing initial deformation temperatures, oF Ash deposition potential classification Low Medium High Severe < 0.6 0.6 - 2.0 2.0 - 2.6 > 2.6 > 2450 2250 - 2450 2100 - 2250 < 2100 < 0.2 0.2 - 0.5 0.5 - 1.0 > 1.0 Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 8 of 17 Coal records were classified into two categories based on the chemical composition of their ash. Under bituminous ash are those with more Fe2O3 than the sum of CaO and MgO, while those with less Fe2O3 than the sum of CaO and MgO are categorized as lignitic ash. For the fouling index calculations, coals with lignitic ash were further classified into two subcategories, depending on whether the sum of the three compounds is greater or less than 20% by weight of ash. Weighted average total sulfur content, ash analysis, and ash fusion temperature data were then used in the provided formulas to determine the slagging and fouling indices. The initial deformation (IDT) and hemispherical (HT) temperatures of coal ash indicate the deposit surface temperature range where plastic slag, which is too viscous to flow and will continue to build in thickness, is likely to exist. Slagging therefore should not be of concern in the plant if furnace temperatures are maintained between the normal operating range of 850 oC to 950oC, which is well below the lowest recorded IDT and HT of 1023oC and 1041oC, respectively. Fouling on the other hand must be monitored as higher rates of ash deposition on convection heat absorbing surfaces are evident since Semirara coals were first utilized. Fouling occurs when volatile forms of sodium and potassium in the coal vaporize during combustion. As heat is absorbed and flue gas temperatures are lowered in the backpass, compounds formed from subsequent reactions between these alkali metals and sulfur in the flue gas condense on fly ash and form a layer of bonded deposits on tube surfaces. Presented in Figure 1.8 is an ash deposit sample dislodged from a finishing superheater upper tube last Unit 1 2022 APMS. Figure 1.8 Increased ash deposition on backpass tubes. Photos by TSD Reliability. Even without the calculated ash deposition indices, the observed increase in fouling may be directly associated with the increase in alkali content of coal ash. As presented in Table 1.3, the Semirara coal ash representative is beyond the 3% maximum acceptable alkali content and 1,170oC minimum acceptable IDT stated in the coal supply evaluation criteria, where it can also be noted that Na2O makes up the larger fraction of the alkali content. Table 1.3 Acceptable IDT and alkali content vs actual data Particulars IDT (Reducing) Alkali content (Na2O + K2O) Na2O content on dry basis K2O content on dry basis Acceptable Range > 1,170oC < 3% - Indonesian Coal 1,212.15oC 1.92% 1.21% 0.72% Semirara Coal 1,093.51oC 5.22% 4.36% 0.86% The requirements of the main and hot reheat steam temperature control system were used as an indication of fouling in the finishing superheaters and reheaters since the spray water flow rates of their respective desuperheaters reflect the changes in tube surface cleanliness. As presented in Figure 1.9, a decrease in spray water quantities was observed following the Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 9 of 17 start of Semirara coal consumption, which indicates somewhat lower steam temperatures due to the negative effect of tube fouling on efficient heat transfer. The notable downward trends can be especially observed in all units during the first few weeks of Semirara coal firing, where the plant was mainly in 1 Indo 2 Semirara operation. Figure 1.9 Low desuperheater spray water flow rates during high Semirara coal consumption Ash accumulations also result in unequal flue gas distribution and frequent localized overheating in the backpass, especially around the economizer #3 upper, which is being addressed directly with sootblowers. The sootblowing frequency was also increased to repress the higher fouling potential of Semirara coals, from once per shift when the plant was still in pure Indonesian coal firing to twice per shift or as necessary when mixed coal firing began. Certainly, variations in coal properties greatly affect sootblowing requirements in addition to unit load changes, furnace temperature fluctuations, and air flow conditions. Sootblower operation must therefore be continually assessed and reviewed based on changing operating parameters, as sootblowers are most effective in removing dry and loosely bonded deposits that occur in the early stages of fouling. In addition to increased fouling, Semirara coals also resulted in an increase in flue gas corrosivity. Due to the higher total sulfur percentage (ADB) of Semirara coals (0.57% S) than Indonesian coals (0.2% S), the air preheaters are subjected to greater corrosion of cold end heating elements as presented in Figure 1.10, and other structures along the flue gas path. About 0.25% to 1.5% of the sulfur dioxide (SO2) produced from coal combustion is converted to sulfur trioxide (SO3) as it reacts with oxygen in combustion air. SO3 then combines with moisture in the flue gas, forming sulfuric acid (H 2SO4) vapor. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 10 of 17 Figure 1.10 Corroded air preheater cold end heating elements. Photos by TSD Reliability. The H2SO4 vapor in the flue gas condenses on surfaces at temperatures below its acid dew point, which ranges from 121oC to 149oC. Summarized in Figure 1.11 are the average flue gas outlet and air inlet temperatures from January 21, 2022 to September 28, 2022, estimated to be equal to the cold end metal temperature of each unit at 150 ±1 MW. 160.00 141.42 140.00 136.82 120.00 136.70 135.43 100.00 84.94 80.00 60.00 82.52 59.48 57.83 58.13 57.68 40.00 53.93 52.90 82.53 82.04 52.77 52.99 20.00 Primary Air Inlet, °C Secondary Air Inlet, °C Unit 1 Unit 2 Flue Gas Outlet, °C Unit 3 Cold End Metal, °C Unit 4 Figure 1.11 Estimated cold end metal temperatures The air preheaters may be designed to operate with flue gas outlet and cold end metal temperatures below the acid dew point as the thermal efficiency gained offsets the additional maintenance costs, but these costs are most likely to escalate due to the effect of firing high-sulfur Semirara coals. Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 11 of 17 Figure 1.12 Significant increase in SO2 levels due to Semirara coal consumption Although SO2 is captured in the furnace by limestone, trends presented in Figure 1.12 show a significant increase in SO2 levels in 2022 due to the use of Semirara coals despite regular limestone injection. In addition, furnace temperatures above 899oC, as presented in Figure 1.13, lead to the dissociation of calcium sulfate (CaSO4) produced during the sulfation process, which reduces sulfur capture efficiency and promotes flue gas conditions ideal for greater cold end corrosion. Figure 1.13 Historical furnace temperature data Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 12 of 17 Although the amount of SO3 generated increases with increased oxygen in the flue gas, operational and design constraints highlight the evident disadvantage of using high-sulfur coals. First, excess air is supplied into the furnace in addition to the stoichiometric air quantity to ensure complete coal combustion. Second, the plant’s regenerative-type air preheaters have about 8% air ingress from the air side to the flue gas side by design, providing more oxygen and moisture for SO 3 and H2SO4 formation. At what price are Semirara coals economical? Due to the occurrence of boiler tube leakages in the units with the highest Semirara coal consumptions, along with the crucial findings in this report, it can be inferred that Semirara coals are detrimental to boiler operation. However, due to the significant difference between Indonesian and Semirara coal prices, a sensitivity analysis was conducted to determine the Semirara coal price where the projected decrease in operational cost can counter the projected outage costs. Table 1.4 General assumptions used in the sensitivity analysis Service days Planned outage days APMS extension days Forced outage days Case 1: Pure Indo 344 21 0 0 Year 1 Case 2: 2 Indo 1 Semirara 323.49 21 9 11.51 Case 1: Pure Indo 344 21 0 0 Year 2 Case 2: 2 Indo 1 Semirara 344 21 0 0 Presented in Table 1.4 are the two-year pure Indonesian coal firing and 2 Indo 1 Semirara coal firing operations investigated in this study. Case 1 assumes pure Indonesian coal firing for 344 days, with 21 days for APMS each year. Operational costs for both years are limited to the cost of Indonesian coals, silica sand, limestone, and demineralized water consumed, which are based on unit costs summarized in Table 1.5. Table 1.5 Latest unit costs from Finance and WTP Indonesian Coal, PHP/MT Semirara Coal, PHP/MT Silica Sand, PHP/MT Limestone, PHP/MT Demineralized Water, PHP/m3 Diesel Oil, PHP/L Unit Cost 7,933.92 6,968.47 7,062.14 1,964.29 86.25 58.20 Remarks Weighted average Indonesian coal price for December 2022 Weighted average Semirara coal price for December 2022 Gross delivered silica sand price as of December 31, 2022 Gross delivered limestone price as of December 31, 2022 Latest estimated demineralized water production cost Gross delivered diesel oil price as of December 31, 2022 Meanwhile, case 2 assumes 2 Indo 1 Semirara coal firing for 232.49 days in year 1, with 11.51 days of forced outage, 21 days for APMS, and 9 days of APMS extension due to the extent of boiler tube damage. The duration of forced outage was based on the actual Unit 1 emergency shutdown due to boiler tube leakage. Its anticipated occurrence was based on the projected 218.32 days of using 2 Indo 1 Semirara coal mixture prior to boiler tube leakage, estimated using the 133,222.99 MT of Semirara coal consumed by Unit 1 at 648.58 MT/day prior to tripping last May 29, 2022, and 147,747.63 MT for Unit 3 at 638.96 MT/day prior to tripping last September 28, 2022. Following the application of additional ceramic coating and thermal spray during the APMS, it was assumed that each unit would be capable of operating for 344 days in year 2, with 21 days for APMS. For the operational costs, included in both years are the costs of Indonesian and Semirara coals, lower silica sand consumption due to the higher ash content of Semirara coals, higher limestone consumption due to the higher sulfur content Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 13 of 17 of Semirara coals, and demineralized water consumed. On the other hand, outage costs in year 1 include the forced outage cost, start-up cost after the forced outage, and additional APMS cost. Presented in Table 1.6 are the differences in contribution margin between the two cases each year for one unit. Annual revenues were calculated using the corresponding service days, average forecasted net load factor of 94.9375% for 2023, net capacity of 134 MW, and average WESM price of PHP 7.38/kWh as of January 17, 2023. It was observed that the contribution margin difference changes by PHP 206,699.42 in year 1 and by PHP 219,802.66 in year 2 for every change in Semirara coal price by PHP 1.00. Table 1.6 Contribution margin differences in years 1 and 2 Year 1 Case 1: Pure Indo Case 2: 2 Indo 1 Semirara Year 2 Case 1: Pure Indo Case 2: 2 Indo 1 Semirara Revenue, PHP 7,751,194,516.80 7,289,117,796.19 Operational Cost, PHP 5,612,883,920.52 4,777,236,316.15 Outage Cost, PHP 0 33,616,483.81 Contribution Margin, PHP 2,138,310,596.28 2,478,264,996.23 339,954,399.96 Revenue, PHP 7,751,194,516.80 7,751,194,516.80 Operational Cost, PHP 5,612,883,920.52 5,080,078,134.90 Outage Cost, PHP 0 0 Contribution Margin, PHP 2,138,310,596.28 2,671,116,381.90 532,805,785.62 It is worth noting that 2 Indo 1 Semirara coal firing would still be more profitable by PHP 339.95M in year 1 despite the additional outage costs, and by PHP 140.40M even at equal coal prices. Moreover, 2 Indo 1 Semirara coal firing would still be more profitable by PHP 320.60M even at equal coal prices in year 2 due to the lower coal consumption as an effect of the Semirara coals’ higher gross calorific values. Although recent data show higher profitability from 2 Indo 1 Semirara coal firing, abrupt changes in prices highlight the need to determine the Semirara coal price that would match the contribution margins from the two cases, which could serve as a basis of a Semirara coal’s preferability for procurement. Figure 1.14 3D surface plots of the contribution margin difference regression models A central composite design was used to analyze the effect of the unit costs and the average WESM price on the contribution margin difference in both years, at fixed consumption rates, service days, outage days, net load factor, additional APMS cost, and forced outage cost. An experimental design space was created based on reasonable fluctuations in unit costs and average WESM price to develop regression models for contribution margin difference prediction, as presented in Figure Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 14 of 17 1.14. The ANOVA shows that all of the factors considered provide significant effect on the contribution margin difference in year 1 as indicated by their less than 0.05 p-values, thus their inclusion in the final regression model. Meanwhile, only the unit costs of coals, silica sand, and limestone affect year 2 contribution margin difference significantly. Table 1.7 Final regression equations in terms of actual unit costs and average WESM price Year 1 Contribution Margin Difference = Year 2 Contribution Margin Difference = Numerical Coefficient - 23027623.107973 + 286972.86024781 - 206699.44180238 + 898.01555844378 - 4041.668325282 + 1276.4608072227 - 124771.72047038 - 62969047.046626 206.99760523433 + 260571.53833224 - 219802.67361862 + 889.58732464283 - 4654.8923220849 * * * * * * * * * * * * * * Factor, Unit Indonesian Coal, PHP/MT Semirara Coal, PHP/MT Silica Sand, PHP/MT Limestone, PHP/MT Demineralized Water, PHP/m3 Diesel Oil, PHP/L Average WESM Price, PHP/kWh Indonesian Coal, PHP/MT Semirara Coal, PHP/MT Silica Sand, PHP/MT Limestone, PHP/MT The regression equations presented in Table 1.7 were used to calculate the Semirara coal prices that would yield no difference in contribution margin between the two cases. The latest available data suggest that 2 Indo 1 Semirara coal firing would match the contribution margin from pure Indonesian coal firing in year 1 at a Semirara coal price of ~PHP 8,613.15/MT and in year 2 at ~PHP 9,392.49/MT. Using the suggested Semirara coal prices in the calculations results in contribution margin differences of only PHP 28.74 and PHP 45.28 for years 1 and 2, respectively, proving the predictive power of the generated regression equations. Still, use the equations with caution, as these do not consider the effect of the other factors held constant on the contribution margin difference. Recommendations Item Action Responsible Group 01 Continue monitoring coal properties and assess other possible effects of varying coal quality on boiler operation. Finalize the feasibility study on coal blending strategies to evaluate the advantage of homogenized coal characteristics. TSD Performance 02 As the plant fully shifts to 2 Indo 1 Semirara coal firing after the Unit 4 2023 APMS, ensure that HGI, ash content, and other coal properties are within specifications. Acquire a third party to randomly conduct ash and ultimate analyses for Semirara coal deliveries. Procurement, Water Treatment 03 Continue the implementation of the boiler tube leak reduction program by applying additional thermal spray on the remaining critical areas such as the superheater panels. TSD Reliability 04 Maintain furnace freeboard dP around 75-100 mmH2O and ensure normal air flow rates and distribution to prevent high erosion rates in the upper furnace. Operations Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 15 of 17 References Alekhnovich, A.N., Artemieva, N.V., & Bogomolov, V.V. (2021). Definition and assessment of coal abrasivity. Power Technology and Engineering, 55(9). https://doi.org/10.1007/s10749-021-01326-y ASME PTC 4-2008. Fired Steam Generators Performance Test Codes. Bandopadhyay, A.K. (2010). A study on the abundance of quartz in thermal coals of India and its relation to abrasion index: Development of predictive model for abrasion. International Journal of Coal Geology, 84(1). https://doi.org/10.1016/j.coal.2010.08.005 Basu, P. (2006). Material issues. Combustion and gasification in fluidized beds. Taylor & Francis Group. Flynn D.J. (Ed.). (2011). Erosion. The NALCO guide to boiler failure analysis (2nd ed.). The McGraw-Hill Companies. Formosa Heavy Industries Corp. (2015). Circulating Fluidized Bed Steam Generator Instruction Manual. Indonesian and Semirara coals’ certificates of analysis (COA) PIR-TSD-22-014. Unit 1 Backpass Area: Dry Ice and Manual Scraping Cleaning Inspection. Tomei, G.L. (Ed.). (2015). Economizers and air heaters. Steam: Its generation and use (42nd ed.). The Babcock & Wilcox Company. Tomei, G.L. (Ed.). (2015). Fluidized bed combustion. Steam: Its generation and use (42nd ed.). The Babcock & Wilcox Company. Tomei, G.L. (Ed.). (2015). Fuel ash effects on boiler design and operation. Steam: Its generation and use (42nd ed.). The Babcock & Wilcox Company. Units 1-4 Distributed Control System (DCS) Unit 1 Ultrasonic Thickness Gauging (UTG) data Appendices Appendix A Pure Indonesian coal firing 1. Total Projected Operational Cost, PHP 5,612,883,920.52 1.1 Projected Cost of Coal Consumed MT/day Days PHP/MT PHP Indonesian Coal 2,044.90 344 7,933.92 5,581,084,244.72 MT/day based on the average daily feeder-based coal consumption of Unit 3 when in pure Indonesian coal firing and at least 95% net capacity factor 1.2 Projected Cost of Silica Sand Consumed MT/day Days PHP/MT PHP Silica Sand 5.74 344 7,062.14 13,937,176.24 MT/day based on the average daily formula-based silica sand consumption of Unit 3 when in pure Indonesian coal firing 1.3 Projected Cost of Limestone Consumed MT/day Days PHP/MT PHP Limestone 18.04 344 1,964.29 12,190,411.50 MT/day based on the average daily formula-based limestone consumption of Unit 3 when in pure Indonesian coal firing 1.4 Projected Cost of Demineralized Water Consumed m3/day Demineralized Water 191.17 Days 344 PHP/m3 86.25 PHP 5,672,088.08 Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Revision: 0 Page: 16 of 17 m3/day based on the average daily demineralized water consumption of Unit 3 Appendix B Year 1 of 2 Indo 1 Semirara coal firing 1. Total Projected Operational Cost, PHP 1.1 Projected Cost of Coal Consumed MT/day Indonesian Coal 1,287.42 Semirara Coal 638.96 4,777,236,316.15 Days 323.49 323.49 PHP/MT 7,933.92 6,968.47 PHP 3,304,263,165.68 1,440,378,564.86 4,744,641,730.54 MT/day based on the average daily feeder-based coal consumption of Unit 3 when in 2 Indo 1 Semirara coal firing and at least 95% net capacity factor 1.2 Projected Cost of Silica Sand Consumed MT/day Days PHP/MT PHP Silica Sand 3.15 323.49 7,062.14 7,198,457.04 MT/day based on the average daily formula-based silica sand consumption of Unit 3 when in 2 Indo 1 Semirara coal firing 1.3 Projected Cost of Limestone Consumed MT/day Days PHP/MT PHP Limestone 31.57 323.49 1,964.29 20,062,174.16 MT/day based on the average daily formula-based limestone consumption of Unit 3 when in 2 Indo 1 Semirara coal firing 1.4 Projected Cost of Demineralized Water Consumed m3/day Days Demineralized Water 191.17 323.49 m3/day based on the average daily demineralized water consumption of Unit 3 PHP/m3 86.25 2. Total Projected Outage Cost, PHP PHP 5,333,954.40 33,616,483.81 2.1 Projected Additional APMS Cost PHP 15,565,222.00 1,260,220.00 2,556,170.00 19,381,612.00 Additional Thermal Coating Additional Consumables Additional Fitters and Welders All figures are based on the actual Unit 3 2022 additional APMS cost from TSD Planning 2.2 Projected Forced Outage Cost Services Spare Parts OPEX 3,156,094.63 490,163.62 All figures are based on the actual Unit 1 June 2022 UMO OPEX from Finance Consumables - PHP 3,646,258.25 PHP/unit 7.38 86.25 58.20 PHP 2,634,807.60 228,038.96 7,261,713.52 2.3 Projected Start-up Cost after Forced Outage Feedback Power, MWh Demineralized Water, m3 Diesel Oil, liters Consumption 357.02 2,643.93 124,771.71 Document Code: PPR-TSD-23-004 Effective Date: February 9, 2023 Plant Performance Report: Semirara Coal: Effect on Boiler Operation and Economical Price Determination Silica Sand, MT Limestone, MT 56.19 34.23 Revision: 0 Page: 17 of 17 7,062.14 1,964.29 396,808.13 67,245.35 10,588,613.56 Feedback power based on the actual consumption last September 28-29, 2022 during Unit 3 tripping and last October 2628, 2022 during start-up Demineralized water based on the actual consumption last October 20-28, 2022 during Unit 3 start-up Diesel oil and silica sand based on the actual consumption last October 27-28, 2022 during Unit 3 start-up Limestone based on the actual consumption last October 28, 2022 during Unit 3 start-up Appendix C Year 2 of 2 Indo 1 Semirara coal firing 1. Total Projected Operational Cost, PHP 1.1 Projected Cost of Coal Consumed MT/day Indonesian Coal 1,287.42 Semirara Coal 638.96 5,080,078,134.90 Days 344 344 PHP/MT 7,933.92 6,968.47 PHP 3,513,729,267.11 1,531,688,024.02 5,045,417,291.13 MT/day based on the average daily feeder-based coal consumption of Unit 3 when in 2 Indo 1 Semirara coal firing and at least 95% net capacity factor 1.2 Projected Cost of Silica Sand Consumed MT/day Days PHP/MT PHP Silica Sand 3.15 344 7,062.14 7,654,786.54 MT/day based on the average daily formula-based silica sand consumption of Unit 3 when in 2 Indo 1 Semirara coal firing 1.3 Projected Cost of Limestone Consumed MT/day Days PHP/MT PHP Limestone 31.57 344 1,964.29 21,333,969.17 MT/day based on the average daily formula-based limestone consumption of Unit 3 when in 2 Indo 1 Semirara coal firing 1.4 Projected Cost of Demineralized Water Consumed m3/day Days Demineralized Water 191.17 344 3 m /day based on the average daily demineralized water consumption of Unit 3 PHP/m3 86.25 PHP 5,672,088.08