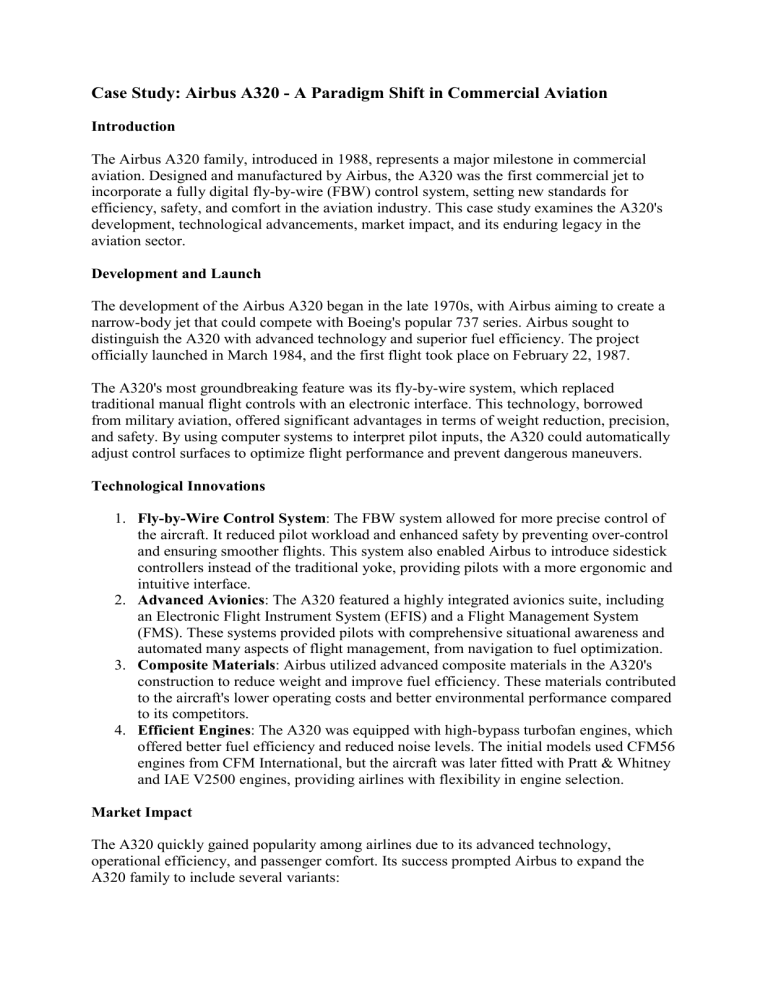

Case Study: Airbus A320 - A Paradigm Shift in Commercial Aviation Introduction The Airbus A320 family, introduced in 1988, represents a major milestone in commercial aviation. Designed and manufactured by Airbus, the A320 was the first commercial jet to incorporate a fully digital fly-by-wire (FBW) control system, setting new standards for efficiency, safety, and comfort in the aviation industry. This case study examines the A320's development, technological advancements, market impact, and its enduring legacy in the aviation sector. Development and Launch The development of the Airbus A320 began in the late 1970s, with Airbus aiming to create a narrow-body jet that could compete with Boeing's popular 737 series. Airbus sought to distinguish the A320 with advanced technology and superior fuel efficiency. The project officially launched in March 1984, and the first flight took place on February 22, 1987. The A320's most groundbreaking feature was its fly-by-wire system, which replaced traditional manual flight controls with an electronic interface. This technology, borrowed from military aviation, offered significant advantages in terms of weight reduction, precision, and safety. By using computer systems to interpret pilot inputs, the A320 could automatically adjust control surfaces to optimize flight performance and prevent dangerous maneuvers. Technological Innovations 1. Fly-by-Wire Control System: The FBW system allowed for more precise control of the aircraft. It reduced pilot workload and enhanced safety by preventing over-control and ensuring smoother flights. This system also enabled Airbus to introduce sidestick controllers instead of the traditional yoke, providing pilots with a more ergonomic and intuitive interface. 2. Advanced Avionics: The A320 featured a highly integrated avionics suite, including an Electronic Flight Instrument System (EFIS) and a Flight Management System (FMS). These systems provided pilots with comprehensive situational awareness and automated many aspects of flight management, from navigation to fuel optimization. 3. Composite Materials: Airbus utilized advanced composite materials in the A320's construction to reduce weight and improve fuel efficiency. These materials contributed to the aircraft's lower operating costs and better environmental performance compared to its competitors. 4. Efficient Engines: The A320 was equipped with high-bypass turbofan engines, which offered better fuel efficiency and reduced noise levels. The initial models used CFM56 engines from CFM International, but the aircraft was later fitted with Pratt & Whitney and IAE V2500 engines, providing airlines with flexibility in engine selection. Market Impact The A320 quickly gained popularity among airlines due to its advanced technology, operational efficiency, and passenger comfort. Its success prompted Airbus to expand the A320 family to include several variants: 1. A318 and A319: These shorter variants catered to airlines needing lower-capacity aircraft for regional routes. They offered the same technological benefits as the original A320 but with reduced seating capacity and range. 2. A321: The stretched variant, the A321, provided higher seating capacity and range, making it suitable for longer domestic and international routes. It quickly became popular for its versatility and cost-effectiveness. 3. A320neo: In response to increasing demand for more fuel-efficient aircraft, Airbus introduced the A320neo (New Engine Option) in 2016. The A320neo features more efficient engines, improved aerodynamics, and additional fuel-saving measures, resulting in significant reductions in fuel consumption and CO2 emissions. By 2020, the A320 family had become the best-selling commercial aircraft in history, with over 15,000 orders and more than 9,500 deliveries. Its widespread adoption was driven by its economic advantages, reliability, and the ability to meet the diverse needs of airlines around the world. Operational Efficiency and Safety The A320's operational efficiency has been a key factor in its success. Its advanced systems and materials contribute to lower fuel consumption and maintenance costs, providing airlines with a competitive edge. The aircraft's design also allows for quick turnaround times, further enhancing its appeal to operators. Safety has been a paramount concern for Airbus, and the A320's FBW system has played a crucial role in this regard. By preventing pilot errors and ensuring stable flight dynamics, the A320 has achieved an excellent safety record. Airbus continuously updates the aircraft's systems and software to address emerging safety challenges and improve performance. Environmental Impact The A320 family has set new benchmarks for environmental performance in commercial aviation. The introduction of the A320neo, with its more efficient engines and aerodynamic improvements, marked a significant step forward in reducing the carbon footprint of air travel. According to Airbus, the A320neo delivers a 15-20% reduction in fuel consumption and CO2 emissions compared to previous-generation aircraft. In addition to its fuel efficiency, the A320 family has been designed to minimize noise pollution. The quieter engines and optimized aerodynamics help reduce the noise footprint around airports, contributing to better community relations and compliance with stringent noise regulations. Challenges and Competition Despite its success, the A320 has faced challenges, particularly from its main competitor, the Boeing 737 series. Boeing has continuously updated the 737 to maintain its market position, leading to intense competition between the two aerospace giants. The Boeing 737 MAX, introduced as a direct competitor to the A320neo, has faced setbacks due to safety issues, but it remains a significant player in the narrow-body market. Airbus has also had to navigate various operational challenges, including supply chain disruptions, production delays, and evolving regulatory requirements. However, its commitment to innovation and customer satisfaction has enabled it to maintain its leadership position. Legacy and Future Outlook The Airbus A320 has left an indelible mark on the aviation industry. Its introduction of FBW technology revolutionized aircraft design and set new standards for safety and efficiency. The success of the A320 family has solidified Airbus's position as a leading aircraft manufacturer and paved the way for further advancements in aviation technology. Looking ahead, Airbus continues to innovate with the development of the A321XLR (Extra Long Range) and ongoing improvements to the A320neo family. These advancements aim to meet the evolving needs of airlines and passengers while addressing environmental concerns and regulatory requirements. Conclusion The Airbus A320 stands as a testament to the transformative power of innovation in aviation. Its pioneering technologies, operational efficiency, and market success have redefined the standards for commercial aircraft. As the aviation industry continues to evolve, the A320's legacy will endure, serving as a foundation for future advancements and a benchmark for excellence in aircraft design and performance.