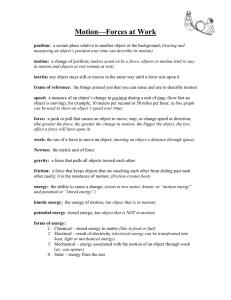

Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 DOI: 10.59081/njte.18.1.005 EFFECT OF MOISTURE CONTENT ON SOME SELECTED MECHANICAL PROPERTIES OF FARO 44 AND 57 VARIETY OF RICE (PADDY AND DEHUSKED) Moses Mazza1,2*, Lawan Garba Abubakar2, M. Hamisu Muhammad3, OlaosebikanLayi Akangbe2, Bala Gambo Jahun2, Mohammed Aminu2, Abubakar Abdulkarim Jilima4, Danlad Drambi Usman2, Suleiman Haruna5 1 Department of Agricultural Engineering, National Cereals Research Institute, Badegi, P.M.B. 8 Bida, 912101, Nigeria 2 Department of Agricultural and BioresourceEngineering, Abubakar Tafawa Balewa University, P.M.B. 0248, Bauchi, Nigeria 3 Department of Mechanical and Production Engineering, Abubakar Tafawa Balewa University, P.M.B. 0248, Bauchi, Nigeria 4 Department of Agricultural and Environmental Engineering, Modibbo Adama University, Yola, P.M.B 2076, Yola, Adamawa State, Nigeria 5 Department of Agricultural and Bioenvironmental Engineering, Federal Polytechnic P.M.B.0231, Bauchi *Corresponding author email: mosesmazza@gmail.com Telephone: +2348032913213 Abstract The mechanical properties of rice are among the most important parameters for designing and development of a rice milling machine, destoning machine as well as materials handling. The objective of the study was to determine the mechanical (angle of sliding and internal frictions) properties of (FARO 44 and FARO 57) paddy and dehusked at three different moisture content (5, 10 and 15%) moisture content dry basis. These properties were determined using Funnel and Baker technique and shear box apparatus respectively. The results showed that, angles of internal friction were at least 15.2°, on the average within the moisture ranges tested however, 35° angles were also obtained. Angles of sliding friction ranged between 40° - 50°. This study concludes that moisture content and variety affect the engineering property; angle of internal friction is useful in the determination of lateral and horizontal stress in the silo for grain storage. Keywords: rice varieties, form, mechanical properties, and moisture content 1. INTRODUCTION Rice (Oryza sativa) belongs to the grass family of Gramineae, it is among the major sources of carbohydrate, more than half of the human race regard and consume rice as their staple food [1]. It is highly valued and competitive commodity in the world trade over a decade’s [2 and 1]. Oryza sativa is the dominant species followed by Oriza glaberrima and is regarded as the third most popular crop after wheat and maize in world crop production [3 and 4]. More than four (4) billions of world population depends on rice as their major source of calories [3]. Information on the physical and mechanical properties of the agricultural products is an important tool for designing equipment for the purpose of planting, harvesting, dehulling, drying, handling and storage therefore, static coefficient of friction of seeds (rice) against different materials, angle of repose, hardness, true and bulk densities are among the properties that are considered 49 “physical” by researchers as per seed [5]. These variables are central in classification of seeds and in the design of machines for processing or analyzing the behavior of the products in handling or grading [6]. They are central because they give technical information to the designer on what are the basic “inputs” for their design. All mechanical properties of seeds are dependent on the moisture content. They respond either in increasing or decreasing angle of sliding friction and angle of internal friction as the moisture content varies. The initial moisture content is determined by subjecting seeds to oven drying (either air or vacuum) at temperatures between 80oC to 130oC for 8hrs to 24hrs by [7]. [8] stated that in order to design a harvesting, conveying and processing equipment, it is necessary for the determination of physical and mechanical properties of grains [9] studied the effect of moisture content on the physical properties for Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 three Egyptian paddy rice varieties, they recorded the increase occurring in seed sphericity (S) due to the increase of moisture content .Cereal-grain kernel densities have been of interest in breakage susceptibility and hardness. [10 and 11] reported that various physical properties of green beans (Phaseulus aureus L.) were evaluated as a function of moisture content in the range of 8.39 to 33.40% db. The static coefficient of friction is used to determine the angle at which chutes must be positioned to achieve consistent flow of materials through the chute. Mechanical properties of rice is very important in the design of rice processing machine, milling machine, and destoning machine Frictional coefficient and angle of repose influence the flow of rice materials in machine and outlets. Flow ability of materials which is characterized by the angle of repose and the coefficient of friction on a particular surface determined the type of handling system and its components [12]. According to [13] have reported an increase in moisture content was found to increase the linear dimensions, mass of 100 seeds, surface area, apparent volume, true volume, arithmetic mean diameter, effective geometric diameter, sphericity, angle of repose, porosity and static coefficient of friction while bulk density and true density decreased with increase in moisture content. The purpose of this study was to determine the effect of moisture content on the mechanical properties of FARO44 and FARO57 rice which is the most common rice variety grown in Nigeria. Therefore, machine designers and engineers can utilize this information for future design of equipment related to rice seed, specifically FARO44 and FARO57variety. 2. MATERIALS AND METHODS The materials used in this research includes Hot air oven, angle of repose apparatus galvanized steel and mild steel, Shear box apparatus, FARO 44 and FARO 57 both paddy and dehusked. Experimental Design: A random sampling technique was carried out, two variety, two form, three. For angle of sliding friction; 2x2x3x3=36 experiment and angle of internal friction; 2x2x3x3=36, total 36+36 =72 experiment. 2.1 Moisture content determination The moisture contents of the samples were determined using the procedure reported by [14]. 50 DOI: 10.59081/njte.18.1.005 The sample were oven dried at 130±3oC for 2 hours, the weight loss of the samples was recorded and the moisture contents in percentage were determined in dry basis using Equation (1) [15] 𝑊 −𝑊 𝑀𝐶𝑑𝑏 = 100 × [ 𝑎𝑊 𝑏] … (1) 𝑏 Where: 𝑀𝐶𝑑𝑏 is Moisture content, dry basis, % 𝑊𝑎 is Weight of water in the sample, g 𝑊𝑏 is Weight of dry matter in the sample, g 2.2 Determination of Angle of sliding friction. The coefficient of friction of the seeds is equal to the tangent of the angle of internal friction for the material [6], this was determined on plywood, glass and galvanized steel surfaces using a tilting table. The angle of inclination of the table to the horizontal at which samples started sliding was measured with the protractor attached beside the inclined plane apparatus and used in Equation (13) to calculate the static coefficient of friction] and reported by [14] 𝜇 = tan 𝛼 ... (2) Where: 𝜇 𝑖𝑠 𝑠𝑡𝑎𝑡𝑖𝑐 𝑐𝑜𝑒𝑓𝑓𝑖𝑐𝑒𝑛𝑡 𝑜𝑓 𝑓𝑟𝑖𝑐𝑡𝑖𝑜𝑛 𝛼 𝑖𝑠 𝑎𝑛𝑔𝑙𝑒 𝑜𝑓 𝑡𝑖𝑙𝑡 𝑖𝑛 𝑑𝑒𝑔𝑟𝑒𝑒𝑠 (Angle internal friction) of 2.3 Determination of Angle of Internal friction. While there's no single ISO standard specifically for the angle of internal friction of grains, ISO 178924:2017 provides a framework for determining shear strength parameters, including the angle of internal friction grains, direct shear test Shear box apparatus was used to determine the shear stress of the rice at different moisture content. The normal stress (𝜎), Apparent cohesion (C) and the shear stress at failure (𝜏) were determined and used Coulomb’s equation (3) to determine the angle of internal friction. 𝜏 = 𝐶 + 𝜎 tan ∅ ... (3) Where: 𝜏 = shear strength of the rice (KN/m2) 𝐶 = Apparent cohesion of the rice (KN/m2) 𝜎 = normal stress on the plane of rupture (KN/m2) ∅ = angle of internal friction (degree) Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 DOI: 10.59081/njte.18.1.005 3. Results and discussion Results of the analysis of variance carried out on the data generated in the laboratory on mechanical properties of paddy and dehusked forms of Faro 44 and Faro 57 rice varieties at 5, 10 and 15% product moisture contents in dry basis are provided in Table 1. Only form, moisture content and the interaction between variety and form had significant influence on the angle of sliding friction of rice grains on galvanized steel surface and it is in-line with the findings by [16] to have reported the sliding friction increases with increase in moisture content on galvanized steel when the same property was determined on mild steel surface, only form and moisture were observed to be the important influence parameters responsible for observed variations in angle of sliding friction of the grown rice varieties on mild steel surface. Table 1: ANOVA on effects of Rice variety, Rice form and moisture content on mechanical properties Source of variation Property Angle of sliding friction (on galvanized steel), θsfg (°) Angle of sliding friction (on mild steel), θsfm (°) Variety 0.34 Form <0.001 Moistur e 0.012 Variety X Form <0.001 0.019 <0.001 0.012 0.067 Variety X Moistur e 0.924 Form X Moistur e 0.583 Variety X Form X Moistur e 0.374 0.552 0.917 0.71 Probability (p) values less than 0.05 indicate significance, at the 5% level and p values less than 0.01 indicate significance at the 1% level; where p values are greater than 0.05, observed effects are not significant statistically. Table 2: Main effects of influence factors on some properties of rice Property Angle of internal friction, (°) Moisture content (%, dry basis) Variety Faro 44 Form Faro 57 Dehusked Paddy 5 10 15 24.00 17.30 26.08 15.17 24.25 20.25 17.38 Angle of sliding friction (on galvanized 43.67a 44a 41.5b 46.17a 43.25b 43.67b 44.58a steel), 𝜃𝑠𝑓𝑔 (°) Angle of sliding friction (on mild steel), 47.44a 46.5b 45.78b 48.17a 46.25b 46.92ab 47.75a 𝜃𝑠𝑓𝑚 (°) Means comparison is restricted within factor subsets and is property-wise. Values with the same alphabets are not significantly different, statistically. increased to 20.25° as moisture content was lowered to 10%. When moisture content was further lowered to 5%, mean value of the angle of internal friction increased to 24.25°, this concurred with [17] that with decrease in moisture content, the angle of internal friction increases. In Figure 1, a comparison of angles of internal friction of the two varieties and forms of rice. Useful empirical relationships for estimating angles of internal friction of the two varieties of rice in paddy and dehusked forms, as a function of moisture content of the produce determined using the method of least squares are presented in table 3 3.1 Effects of Influence Factors on Angles of Internal Friction The angles of internal friction of the two varieties of rice used in this study were determined for paddy and dehusked grains at the indicated product moisture contents. Angle of internal friction of the Faro 57 variety (17.3°) was significantly lower than that of Faro 44 which was 24°. Mean angle of internal friction of paddy forms of the two rice varieties was 15.17° while that of dehusked rice was 26.08°. Evidently, as the moisture contents of the varieties of rice used decreased, mean values of the angles of internal friction increased; angle of internal friction was 17.38° at 15% product moisture content but 51 Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 Angle of internal friction (°) Faro 44 Paddy Faro 57 Paddy DOI: 10.59081/njte.18.1.005 Faro 44 Dehusked Faro 57 Dehusked Figure 1: Effect of moisture content on angle of internal friction 40 35 30 25 20 15 10 5 0 4 9 14 Moisture content (%) 19 Table 3: Dependence of angle of internal friction on moisture content Variety Faro 44 Paddy M2 -0.1360 M 2.0600 C 27.40 R2 1.0000 Faro 44 Dehusked -0.2840 4.4000 5.00 1.0000 Faro 57 Paddy 0.4520 -10.8800 76.10 1.0000 Faro 57 Dehusked 0.0580 -0.1300 9.00 1.0000 of angles of sliding friction may be had using the empirical forms fitted to the dataset using the method of least squares. These relationships are presented in Table 4. 3.2 Effects of Influence Factors on Angles of Sliding Friction As to the angle of sliding friction, on galvanized steel these angles were the least for dehusked forms of Faro 44 as they ranged between 40° 41°. This was followed by angle of sliding friction of dehusked Faro 57 rice on galvanized steel which ranged between 42° - 43°. The angle of sliding friction of paddy forms of Faro 57 ranged in values between 45° - 46.3° while those of paddy forms of Faro 44 ranged in values between 46° - 48° degrees on galvanized steel surface. These angles approximate the angles of repose of these varieties of rice in the indicated forms and at the stated moisture conditions. Graphical comparison of these was done in Figure 2. It may be seen that the dehusked forms presented with smaller angles of sliding friction than paddy forms of both varieties. Within the limits of moisture levels investigated, estimates Angle of sliding friction (°) 60 50 40 30 Faro 44 Paddy Faro 44 Dehusked Faro 57 Paddy Faro 57 Dehusked 20 10 0 4 9 14 Moisture content (%) Figure 2: Effect of moisture content on angle of sliding friction on galvanized steel 52 19 Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 DOI: 10.59081/njte.18.1.005 Table 4: Dependence of angle of sliding friction (on galvanized steel) on moisture content M 0.2000 C 44.667 R2 0.7500 Faro 44 Dehusked 0.1000 39.667 0.7500 Faro 57 Paddy 0.1333 44.333 1.0000 Faro 57 Dehusked 0.1000 41.333 0.7500 Variety Faro 44 Paddy M2 Angles of sliding friction were much larger for the stated forms of the two varieties of rice on mild steel than they were on galvanized steel, and they ranged in values between 45° - 47° for dehusked forms of Faro 44 and 45° - 46° for dehusked forms of Faro 57 on mild steel. Angles of sliding friction of paddy forms of Faro 44 ranged between 48° - 50° while those for paddy forms of Faro 57 ranged from 47° - 48° on mild steel, this agreed with the range given by [18] they found the range to be 46° - 49° for paddy, and 45° - 48° for dehusked rice. Comparing these results (Figure 3), it may be seen that angles of sliding friction were smaller for dehusked forms but larger for paddy forms. Regression equations by which these angles may be estimated within the limits of the test moisture contents are presented in table 5. These angles not only approximate the angles of repose for these products at the indicated conditions on the test surfaces but also are directly proportional to the coefficients of sliding friction of the grains of rice on these surfaces. Faro 44 Paddy Faro 57 Paddy Faro 44 Dehusked Faro 57 Dehusked Angle of sliding friction (°) 51 50 49 48 47 46 45 44 4 9 14 Moisture content (%) Figure 3: Effect of moisture content on angle of internal friction on mild steel Table 5: Dependence of angle of sliding friction (on mild steel) on moisture content M 0.2 C 47.000 R2 1.0000 Faro 44 Dehusked 0.2 43.667 0.7500 Faro 57 Paddy 0.1 46.333 0.7500 Faro 57 Dehusked 0.1 44.687 0.7500 Variety Faro 44 Paddy M2 53 19 Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 DOI: 10.59081/njte.18.1.005 4. Conclusion Angles of internal friction were at least 15.2°, on the average. Within the moisture ranges tested however, 35° angles were also obtained. Angles of sliding friction ranged between 40° - 50° with change in moisture contents. According to the [19 and 6] agreed that the moisture content of rice has an effect on mechanical properties, angle of internal friction increases significantly from 10% to 20% moisture content. Increase in moisture content led to an increase in cohesion which agreed with [19]. In this study, some designrelated mechanical properties of two varieties of rice commonly grown in Nigeria were determined using standard laboratory techniques and following standards recommended in literature. The friction properties determined were as follows: [3] Food and Agriculture Organization of the United Nations (FAO). (2003). World rice trade dynamics and rice price volatility. https://www.fao.org/marketsand-trade/commodities/rice/rmm/en/ [4]Food and Agricultural Organization (FAO), (2012). World Rice Production. Www.wikipadia [5]Bande YM, Adam NM, Azmi Y, Jamarei O (2012) Determination of selected physical properties of Egusi melon (Citrullus colocynthis lantus) seed. J Basic Appl Sci. 8: 257 – 265. [6]Awad M., Osama F., Wael F., Wael E. B., Mohsen E., Walied E. F. and Mahmoud O. (2022). A combined machine for collecting and chopping rice straw. 1. Angles of sliding friction fall within the range of 40°- 50°. 2. Angles of internal friction occur within the range of 15.2° - 35°. [7] American Society of Agricultural and Biological Engineers (ASABE) S352.2 (2018). Moisture Measurement— Unground Grain and Seeds. American Society of Agricultural and Biological Engineers, St. Joseph. These results may only be employed for operations to be carried out within the range of moisture contents employed for their determination. [8] Zareiforoush1 H, Hosseinzadeh1 B, Adabi1 M.E, Motavali1 A (2011). Moisture-dependent physical properties of paddy grains Journal of American Science, 2011;7(7) page 175-182. REFERENCES [1] International Rice Research Institute (IRRI). (2023). Rice: Production, trade, and consumption trends. http://books.irri.org/RT12_1_content.pd f [9]Zareiforoush, M., Komarizadeh, M. H., & Khoshtaghaza, M. H. (2021). Effect of moisture content on some physical properties of paddy grains. Journal of Agricultural Science and Technology, 23(3), 349-359. [10]Mujumdar, A. S. (2014). Physical properties of grains. In Handbook of post-harvest operations and processing (pp. 75-120). CRC Press. [2]Mohidem, N. A., Hashim, N., Shamsudin, R., & Che Man, H. (2022). Rice for Food Security: Revisiting Its Production, Diversity, Rice Milling Process and Nutrient Content. Agriculture, 12(6), 741. https://www.mdpi.com/20770472/12/6/741: https://www.mdpi.com/20770472/12/6/741 54 Nigerian Journal of Tropical Engineering Vol. 18 No. 1 |ISSN: 1595-5397| Apr. 2024 DOI: 10.59081/njte.18.1.005 [11]Nimkar P.M. and Chattopadhyay P.K. PH—Postharvest Technology: Some physical properties of green gram. Journal of Agricultural Engineering Research, (2001), vol. 80, no. 1, pp. 183–189. DOI: https://doi.org/10.1006/jaer.2000.0664 [17] Petal N. S., Jagan, K. S., Sinha, J. P. & Kumar A. (2013). Physical Properties of Basmati Varieties of Paddy Rice. Journal of Agricultural Engineering. 50(4). [18] [12] Solaf A. E., Mahmoud A., Fatma A. E., Mokhtar C. and Mahmoud O. (2022). Influence of operating parameters on the milling quality of long-grain white rice. INMATEH - Agricultural Engineering, 68(3), 669–680. Jafar M. & Javad K. (2022). Simultaneous Measurement of Rice Grain Friction Coefficient and Angle of Repose using Rotary Cylinder [19] Kajuna S.T.A.R and . Rugenga E. (1998). Relationship between the Angle of Repose and Angle of Internal Friction for Agricultural Granular Materials: Agricultural Engineering and Land Planning Department : Tanzania Journal of Agricultural Sciences 1(2): 187 [13]Abdul-Rasaq A. Adebowale & Lateef O. Sanni &Hameed O. Owo & Olayinka R. Karim (2010). Effect of variety and moisture content on some engineering properties of paddy rice. Journal of Food Sci Technology (September–October 2011) 48(5):551–559DOI 10.1007/s13197-010-0173 [14] Gheorghe V., Gabriel, A. C. P., Elena, M. S., Bianca, S. Z. (2010). Aspects Regarding the Determination of the Moisture Content of Cereal and Granular Materials with Apparatus with Infrared Radiations. Faculty of Biotechnical Systems Engineering, Biotechnical Systems Department [15]Kabutey, A., Herak, D., Choteborsky, R., Mizera, Č., Sigalingging, R., & Akangbe, O. L. A. (2017). Oil point and mechanical behaviour of oil palm kernels in linear compression. International Agrophysics, 31(4), 427434. doi:10.1515/intag-2016-0055 [16] Abdulrasaq, A. A., Lateef O. S., Hameed O. O., & Karim O. R. (2011). Effect of Variety and Moisture Content on Some Engineering Properties of Paddy Rice. Journal of Science and Technology. 55