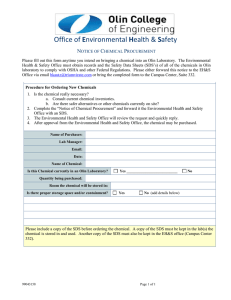

NAME: DATE: Score COURSE(Year & Section): CLASS SCHEDULE: MODULE 10: CHEMICAL SAFETY ACTIVITY Instruction: 1. Match the pictograms below with the corresponding hazards. Classify this hazard as physical, health or environmental hazard? 18 points (Example: 1. e-physical hazard) 1. 2. 3. 4. 5. 6. 7. 8. 9. Hazard Classification of Hazard _______ _______ _______ _______ _______ _______ _______ _______ _______ __________________ __________________ __________________ __________________ __________________ __________________ __________________ __________________ __________________ 2. Read and review each of the 16 sections in the sample SDS given on pages 246-259. Below are the questions about SDS. Write the appropriate LETTER that corresponds to your answer on the space provided before the number. (2 points each, 22 points total) _____1. Who is responsible for obtaining or developing a safety data sheet (SDS) for each hazardous chemical they produce? a. Employers b. Employees c. Manufacturers d. Distributors _____2. Which sections of the SDS are mandatory and must be included? a. Sections 1-5 and 11 b. Sections 2-12 and 15 c. Sections 2-11 and 14 d. Sections 1-11 and 16 _____3. In which SDS section would you be directed not to flush a chemical down drainage systems? a. Section 3. Composition/Information on Ingredients b. Section 4. First Aid Measures c. Section 5. Firefighting Measures d. Section 6. Accidental Release Measures _____4. In which SDS section would you be cautioned not to get the chemical in your eyes, on skin, or on clothing? a. Section 6. Accidental Release Measures b. Section 7. Handling and Storage c. Section 8. Exposure Controls d. Section 9. Physical and Chemical Properties _____5. In which SDS section would you be informed of signs and symptoms of overexposure? a. Section 9. Physical and Chemical Properties b. Section 10. Stability and Reactivity c. Section 11. Toxicological Information d. Section 12. Ecological Information _____6. In which SDS section is the chemical possibly designated a hazardous waste according to Federal regulations? a. Section 13. Disposal Considerations b. Section 14. Transport Information c. Section 15. Regulatory Information d. Section 16. Other Information _____7. In which SDS section would European Union (EU) risk and safety phrases be listed? a. Section 13. Disposal Considerations b. Section 14. Transport Information c. Section 15. Regulatory Information d. Section 16. Other Information _____8. After you are aware of significant new information about a specific chemical, how soon must you add it to the SDS? a. Within 3 months b. 9 months c. Up to 1 year d. 2 years _____9. The wholesale distributor must do each of the following EXCEPT _____. a. providing a SDS within 30 days of the employer purchase b. providing the SDS at the time of purchase by the employer c. providing a SDS upon request by the employer d. posting a "SDS Available" sign or otherwise informing the employer _____10. Where may the safety data sheets be kept when employees travel between workplaces during a shift? a. May be kept anywhere b. Must be in the cab of the truck c. May be kept at the primary workplace facility d. Must be filed in a computer 11. SDS stands for _____________________________________________________ NAME: DATE: COURSE(Year & Section): CLASS SCHEDULE: Score CHEMICAL SAFETY CASE STUDY (QUIZ) Stuy and analyze the case regarding chemical safety. Based on the given facts, analyse the cause of ths accident and fill out the Causal Analysis table. After your assessment, as a safety officer, what would be your recommendations and learning points regarding this case. CASE: CONTACT WITH HYDROFLOURIC ACID DURING DECOMMISSIONING OF PRESSURISED TANK Description of Incident: Liquefied propane with traces of hydrofluoric (HF) acid was passed through a pressurised tank for treatment. The tank contained solid potassium hydroxide which is being consumed during the treatment had to be periodically replaced. A process technician was isolating the tank to replace the potassium hydroxide. After depressurising the tank, he connected a rubber hose from the nitrogen gas supply valve to the utility connector valve of the tank to initiate nitrogen purging. He then opened the utility connector valve without verifying that the tank had been fully depressurised. The rubber hose burst and contents from the tank gushed out. The technician suffered severe chemical burn injuries. Photographs showing the burst rubber hose used to connect the tank utility connector valve to the nitrogen gas supply valve. 1. Utility connector valve. 2. Nitrogen gas supply valve. 3. Rubber hose. 4. Utility connector. 5. Utility connection valve. 6. Burst rubber hose with its quick coupling. POSSIBLE CAUSES AND CONTRIBUTING FACTORS WORKER • The worker opened the valve located at the bottom of the tank to depressurise the tank. However, this method caused the sludge to choke the pipeline and hinder the depressurising process. • The worker failed to ensure complete depressurisation of the tank before opening the bottom valve. • The worker wore a lower-class HF suit which did not provide sufficient protection for the task in the event of a chemical splash. • He proceeded to purge the tank without authorisation from his supervisor. MANAGEMENT • Safe work procedures have not been documented specifically for tank decommissioning. • The management failed to ensure that the workers wore the appropriate class of chemical protective suit. CAUSAL ANALYSIS Evaluation of loss Type of contact Immediate cause(s) Basic Cause(s) Failure of Occupational Safety and Health Manaagement RECOMMENDATIONS AND LEARNING POINTS