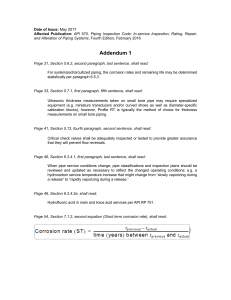

PROJECT TITLE DOCUMENT NO EPC PROYEK SENORO SELATAN SNS-Q-PR-10-037 DISCIPLINE REV : A QA/QC PAGE : 1 / 13 AREA ISSUED DATE N/A 21/05/2024 PROCEDURE BASED LINE THICKNESS INSPECTION PROCEDURE REVISION SHEET A REV 21/05/2024 DATE Issued For Review PURPOSE FDH DNY AGS PREPARED CHECKED APPROVED BY BY BY CTR BY DATE APPROVED BY JOB TOMORI DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 2 / 13 ISSUED DATE 21/05/2024 PROCEDURE TABLE OF CONTENTS 1. 2. FUNCTIONALITY ...................................................................................................................... 4 OBJECTIVE................................................................................................................................. 5 3. DEFINITION AND TERMS ....................................................................................................... 5 3.1 DEFINITION AND TERMS .................................................................................................................................................. 5 3.2 ABBREVIATIONS ................................................................................................................................................................ 5 4. REFERENCES ............................................................................................................................. 6 4.1 CODES, STANDARDS AND REFERENCES ......................................................................................................................... 6 4.2 COMPANY STANDARDS AND SPECIFICATION................................................................................................................ 6 4.3 INTERNATIONAL CODE & STANDARDS .......................................................................................................................... 6 5. GENERAL REQUIREMENTS ..................................................................................................... 6 6. TECHNIQUES OF THICKNESS MEASUREMENT READINGS ............................................... 7 7. 8. REPORTING AND DOCUMENTATION .................................................................................. 9 PERSONNEL QUALIFICATIONS AND INSTRUMENTS ......................................................10 9. ATTACHMENTS......................................................................................................................10 APPENDIX 1 - GENERAL GUIDELINE TO PERFORM BASE LINE THICKNESS MEASUREMENT ............................................. 11 APPENDIX 2 - UT BASE LINE INSPECTION FOR PIPING ........................................................................................................ 12 APPENDIX 3 - UT BASE LINE INSPECTION FOR PRESSURE VESSEL ..................................................................................... 13 DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : ISSUED DATE 21/05/2024 PROCEDURE REVISION SHEET REV DATE A 17-05-2024 PART OF REVISED DETAILS Issued For Review 3 / 13 DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 4 / 13 ISSUED DATE 21/05/2024 PROCEDURE 1. FUNCTIONALITY The Joint Operating Body Pertamina-Medco E&P Tomori Sulawesi (JOB Tomori) will develop further the Senoro gas field located onshore near the coast of Senoro-Toili Block on eastern arm of Sulawesi Island, Indonesia. There are two areas separated by conservation area of Bakiriang, Northern and Southern area. The initial development of Senoro fields consist of 3 (three) clusters, one Central Processing Plant (CPP) with 340 MMscfd capacity, one Export Terminal, a 30”-23.7 km sales gas pipeline, and Gas Metering Stations as “Existing Facilities”, in the northern area. JOB Tomori has completed the EPC of the North Senoro Facilities and developing South Senoro Project for maintaining its production level. South Senoro Project consists of Cluster area, flowline & Trunkline and Modification of existing CPP area. The new South Senoro clusters consist of three clusters, Cluster#3 (2 wells), Cluster#6 (4 wells) and Cluster#B (2 wells). The common design is flowlines and trunkline with some part offshore trunkline to transport the well fluids from the South clusters to the existing CPP Senoro. Figure 1.1 - Senoro Field, CPP and Pipeline in Senoro Toili Block DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 5 / 13 ISSUED DATE 21/05/2024 PROCEDURE 2. OBJECTIVE The objective of this document is to describes minimum requirement of Ultrasonic Test (UT) Base Line Thickness Measurement of all rigid pressure piping and pressure vessels systems prior the systems put on service during project phase. 3. DEFINITION AND TERMS 3.1 Definition and Terms Terms used in this document are defined as follows: COMPANY JOB PERTAMINA – MEDCO E&P TOMORI SULAWESI EPC COMPANY KSO TIMAS - PRATIWI Company selected by owner to perform the engineering SUPPLIER / detailed, procurement and construction Supplier / Vendor is defined as the company selected to supply VENDOR the equipment and service detailed in this specification. This is the entity having unit responsibility as defined in the industry codes and standards 3.2 Abbreviations ANSI American National Standards Institute ASME American Society of Mechanical Engineers ASTM American Society of Testing and Material ASNT American Society for Nondestructive Testing API American Petroleum Institute SS Stainless Steel DSS Duplex Stainless Steel QC Quality Control UT Ultrasonic Test TML Thickness Measurement Location DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 6 / 13 ISSUED DATE 21/05/2024 PROCEDURE 4. REFERENCES 4.1 Codes, Standards and References The following document shall be complied with, unless stated otherwise in this Standard specification. The latest editions and revisions of each code and/or specification, as of the contract document date, shall apply, unless otherwise specifically noted on the Contract Document or approved, in writing, by the Company. 4.2 Company Standards and Specification The latest revision of the Company Standard Specifications shall be used. TOMORI-SPE-P-ES-06- Project Quality Plan Q008 4.3 International Code & Standards Latest revision of International Code and Standard to be referred to: API 570 Piping Inspection Code: Inspection, Repair, Alteration, and Rerating of In-Service Piping Systems 5. API 510 Pressure Vessel Inspection Code: Maintenance Inspection, Rating, Repair, and Alteration API 581 Risk Based Inspection Base Resource Document GENERAL REQUIREMENTS 1) Baseline Thickness Measurement is required to ensure fabrication and construction accuracy and to provide MEPG data to monitor corrosion through the life of the component against specification and or manufacture data record. 2) The following guidelines define the requirements for obtaining baseline thickness measurements. The number of thickness measurements, locations, and required documentation are addressed in this Specification. 3) This procedure applicable for metallic piping (all size diameters) and pressure vessels, unless following conditions: a. Non-Metallic piping and nonmetallic pressure vessels / equipment’s. b. Metallic piping less than 2” diameter. DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 7 / 13 ISSUED DATE 21/05/2024 PROCEDURE 4) c. d. Chemicals tanks. SS/DSS Pipe Material e. Pump Casing. Permanent Inspection windows for insulated include personal protection equipment’s shall be made during installation refer to TML on the attached drawing with size 15x15 cm2. 5) 6. General guideline to perform base line thickness measurement, see appendix 1. TECHNIQUES OF THICKNESS MEASUREMENT READINGS The following techniques of wall thickness readings shall be undertaken on each piping component: Reference for 12 o’clock for piping is based on liquid / gas flow (please see detail reference on report sketch). Horizontal Pipes The top-most of horizontal pipes shall be point of 12 o’clock. Clockwise moving should face the direction where the flow coming from (ref. right-hand screw law). Figure 6 – 1 Radial rule on Horizontal pipes This rule is also applicable for angle-position pipes. Vertical Pipes Point of 12 o’clock on vertical pipes shall follow their adjacent upstream horizontal pipes. DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 8 / 13 ISSUED DATE 21/05/2024 PROCEDURE Figure 6 – 2 Radial rule on Vertical pipes Horizontal Equipment’s The following techniques of wall thickness readings shall be undertaken on each pressure vessel / equipment’s component: Reference for equipment is on name plate (please see detail reference on report sketch) Figure 6 – 3 Horizontal Components: Longitudinal and Radial orientation DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 9 / 13 ISSUED DATE 21/05/2024 PROCEDURE Vertical Equipment’s Reference for equipment is on name plate (please see detail reference on report sketch) Figure 6 – 3 Vertical Components: Longitudinal and Radial orientation 7. REPORTING AND DOCUMENTATION 1. A Baseline Thickness shall be generated from shop fabrication or construction drawings or isometric drawing to accurately record the thickness measurements. 2. All thicknesses shall be recorded on the report (see attachment) 3. Recorded minimum thickness shall have a mark indicating that the item was verified to be correct. Point of marking / tagging / naming for piping started from first point of piping using symbols and follow by clockwise should be marked on the isometric drawing. a. b. B mean Body of pipe E mean Elbow of pipe c. T mean Tee of connection d. C mean Cap e. R mean Reducer DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : 10 / 13 ISSUED DATE 21/05/2024 PROCEDURE 4. Every point component that has been measured in thickness shall be marked with a hollow round sticker (donut stickers) and should be maintained until handover to the Company. These measurement points will be the basis of the next baseline inspection by the Company Operation Plant to monitor its corrosion rate. 5. 8. Baseline Thickness harus dibuat dari gambar fabrikasi atau kontruksi atau gambar isometrik untuk mencatat pengukuran ketebalan secara akurat. PERSONNEL QUALIFICATIONS AND INSTRUMENTS 1. All inspection personnel performing the above activities shall be qualified for ASNT Level II - Thickness Measurements, refer to ASNT TC 1A. a. This includes all Subcontractor and Sub-supplier personnel performing the task. b. It is the responsibility of the Asset Integrity Representative to ensure that all personnel are qualified and have demonstrated their capability to use the UT c. instrument. Performance test for UT technician may require. NDT Contractor shall submit a written CV and copy of valid certificates to the Client / User upon request. 2. NDT contractor shall submit sample of Base Line Thickness Measurement plan, refer to manufacture / shop drawing for piping and equipment. 3. NDT Contractor shall submit manufacturer’s information on the instrument to be used by all UT-Thickness personnel in gathering this data to the Client / User for approval. Instrument calibration records shall be included in the submitted documents. a. On coated surfaces, the instrument and transducer will have the capability to disregard the thickness of the coating. b. On uncoated surfaces, a dual type of transducer or digital type instrument can be used but will require approval from the Purchaser prior to its use. 9. ATTACHMENTS Appendix 1 - General Guideline to Perform Base Line Thickness Measurement Appendix 2 - UT Base Line Inspection for Piping Appendix 3 - UT Base Line Inspection for Pressure Vessel DOCUMENT NO SNS-Q-PR-10-037 BASED LINE THICKNESS INSPECTION PROCEDURE REV : A HAL : 11 / 13 ISSUED DATE 21/05/2024 PROCEDURE Appendix 1 - General Guideline to Perform Base Line Thickness Measurement No Item Critical Part 12, 3, 6 & 9 clock 1 Piping Elbow 3 points at tee face Pipe Straight 12, 3, 6 & 9 clock Cap at least 4 points measured 2 Horizontal /vertical pressure vessel / drum All elbows, see Attachment 1 All tee joints, see Attachment 1 All piping joints, see Attachment 1 All caps, see Attachment 1 Reducer 12, 3, 6 & 9 clock All reducer, see Attachment 1 Shell 12, 3, 6 & 9 clock All pressure vessel, see Attachment 2 Head-1 (right side) 12, 3, 6 & 9 clock All pressure vessel, see Attachment 2 Head-2 (left side) 12, 3, 6 & 9 clock All pressure vessel, see Attachment 2 Nozzles TML = Thickness Measurement Location 12, 3, 6 & 9 clock All main outlet and inlet DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : ISSUED DATE 21/05/2024 PROCEDURE Appendix 2 - UT Base Line Inspection for Piping 12 / 13 DOCUMENT NO BASED LINE THICKNESS INSPECTION PROCEDURE SNS-Q-PR-10-037 REV : A HAL : ISSUED DATE 21/05/2024 PROCEDURE Appendix 3 - UT Base Line Inspection for Pressure Vessel 13 / 13