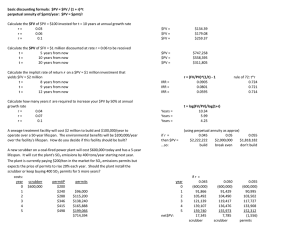

DEGREE PROJECT IN CHEMICAL ENGINEERING, SECOND CYCLE, 30 CREDITS STOCKHOLM, SWEDEN 2020­2021 Scrubbing of sulfur dioxide from secondary process gases in a copper smelter KTH Thesis Report Obiora Okolo KTH ROYAL INSTITUTE OF TECHNOLOGY SCHOOL OF ENGINEERING SCIENCES IN CHEMISTRY, BIOTECHNOLOGY AND HEALTH Author Obiora Okolo, okolo@kth.se School of Engineering Sciences in Chemistry, Biotechnology and Health KTH Royal Institute of Technology Host companies Boliden AB Metso Outotec Sweden AB Place for Project Skellefteå, Sweden Examiner Kerstin Forsberg, KTH Royal Institute of Technology Supervisors Jörgen Johansson, Boliden AB Olle Gunnarsson, Metso Outotec Sweden AB Abstract The processing industry is the largest source of sulfur dioxide (SO2 ) emissions in Sweden, which includes the non­ferrous metals industry. The copper smelter Boliden Rönnskär has an environmental permit to emit a maximum of 3500 tonnes of SO2 /year, a limit that the smelter has been close to in recent years. To reduce the SO2 emissions at Rönnskär, wet scrubbing (together with a bag filter for dust cleaning) has been proposed as a method for cleaning the SO2 ­bearing, intermittent tapping gases from the flash furnace. To find the optimal wet scrubbing technique for the purpose, wet scrubbing techniques based on the following reagents were investigated, evaluated and compared in this report: caustic soda, soda ash, peroxide, lime and zinc oxide. Measurements were also done on the secondary hood gases from the converters, which could make use of the remaining capacity in the scrubber. Further, tests were conducted on various process waters from other processes at Rönnskär, waters that could be reused in the scrubber. The scrubber techniques were then evaluated based on the input data and system requirements using simulation and design software as well as theoretical calculations. The results suggested that it is reasonable to clean secondary hood gases in the scrubber, as they contained approximately 280 tonnes of SO2 /year. This could be compared to the flash tapping gases that contained approximately 445 tonnes of SO2 /year. Among the scrubbers, the peroxide scrubber evolved as the most attractive technique due to its relatively low life cycle cost and due to its suitability with the leaching plant and the flash cooling tower process water. The other packed tower techniques, caustic soda and soda ash had the highest life cycle costs, mainly due to their high reagent costs. The soda ash scrubber, which was the cheaper of the two sodium­based scrubbers, could still be a suitable alternative due to its simplicity. The open spray towers had lower life cycle costs than the packed towers. However, the lime scrubber had several disadvantages that makes it an unsuitable alternative. In turn, the zinc oxide scrubber is a relatively under­researched and unproven technique, but should still be studied further as it could be integrated with the zinc smelting process at Rönnskär. The use of process waters in the scrubber would lead to a net reduction of process water to the process water treatment plant and would lead to reduced reagent costs if a stripper is installed to remove the SO2 from the process waters before entering the scrubber. Sammanfattning Processindustrin är den största källan för utsläpp av svaveldioxid (SO2 ) i Sverige, vilket även inkluderar icke­järnmetallindustrin. Kopparsmältverket Boliden Rönnskär har ett miljötillstånd som tillåter SO2 ­utsläpp på maximalt 3500 ton/år, en gräns som Rönnskär har legat nära under de senaste åren. För att minska svaveldioxidutsläppen på Rönnskär så har våtskrubbning (tillsammans med ett bagfilter för stoftrening) föreslagits som en metod för att rena de SO2 ­bärande och intermittenta tappgaserna från flashugnen. För att göra ett optimalt val av våtskrubberteknik för ändamålet, undersöktes, utvärderas och jämfördes våtskrubbningstekniker baserade på de följande kemikalierna i denna rapport: lut, soda, peroxid, kalk and zinkoxid. Mätningar gjordes också på sekundärhuvsgaserna från konvertrarna, som också kan användas i skrubbern då flashugnens tappgaser har ett fluktuerande flöde. Vidare gjordes tester på olika processvatten på Rönnskär, som skulle kunna återanvändas i skrubbern. Skrubbrarna utvärderades sedan baserat på indata och olika systemkrav med hjälp av simulerings­ och designprogram samt teoretiska beräkningar. Resultaten visade att det är rimligt att rena sekundärhuvsgaser i skrubbern, då de innehöll ca 280 ton SO2 /år. Detta kan jämföras med flashugnens tappgaser som innehöll ca 445 ton SO2 /år. Bland skrubbrarna, så utvecklade peroxidskrubbern sig till att vara den mest attraktiva tekniken på grund av dess relativt låga livscykelkostnader och dess lämplighet med både lakverket och flashkyltornsprocessvattnet. De andra teknikerna med packade torn, lut­ och sodaskrubbern, hade högst livscykelkostnader, huvudsakligen på grund av deras höga kemikaliekostnader. Sodaskrubbern, som var den billigare av de två natriumbaserade skrubbarna, skulle kunna vara lämplig ändå på grund av teknikens enkelhet. De öppna tornen hade lägre livscykelkostnader jämfört med de packade tornen. Dock så hade kalkskrubbern flera nackdelar som gör att den inte är ett lämpligt alternativ. Zinkoxidskrubbning har i sin tur inte studerats tillräckligt och är en relativt oprövad teknik, men den bör studeras vidare då den skulle kunna integreras med zinksmältningsprocessen på Rönnskär. Användningen av processvatten i skrubbern skulle leda till en nettominskning av processvatten till reningsverket. Det skulle även leda till minskade reagentkostnader ifall en stripper installeras för att ta bort SO2 från processvattnen innan de går in i skrubbern. Acknowledgements First and foremost, I would like to thank my supervisors Jörgen Johansson (Boliden) and Olle Gunnarsson (Metso Outotec) for providing me with guidance, support and expertise throughout my work, which has been invaluable for me. Further I would like to thank Robert Johansson, Peter Olsson and Kristoffer Renström at Boliden as well as Leif Skilling at Metso Outotec, for sharing their expertise throughout my work, but also for giving me the opportunity to write my master thesis at both companies in the first place. There were many other people who helped me at Rönnskär with various tasks and questions, who I would like to thank as well. I have really enjoyed my time at both companies and I believe that I have developed and learnt a lot. Thanks to all of you! Contents 1 Introduction 1 1.1 Aim and objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1.2 Boliden Rönnskär & Metso Outotec . . . . . . . . . . . . . . . . . . . . 2 1.3 Delimitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 Background 5 2.1 Overview of processes . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.1.1 Flash smelting and tapping . . . . . . . . . . . . . . . . . . . . . 5 2.1.2 Converting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.2 Processes at Boliden Rönnskär . . . . . . . . . . . . . . . . . . . . . . 7 . . . . . . . . . . . . . . . . . . . . . . . . 7 2.2.2 Process water treatment plant (RV1) and stripper . . . . . . . . 8 2.2.3 Leaching plant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.2.4 Process water sources . . . . . . . . . . . . . . . . . . . . . . . 10 2.3 Scrubber techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.3.1 SO2 absorption theory . . . . . . . . . . . . . . . . . . . . . . . . 10 2.3.2 Tower types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 2.3.3 Sodium­based scrubbing . . . . . . . . . . . . . . . . . . . . . . 13 2.3.4 Peroxide scrubbing . . . . . . . . . . . . . . . . . . . . . . . . . 14 2.3.5 Lime scrubbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 . . . . . . . . . . . . . . . . . . . . . . . . 16 2.2.1 Copper and gas flow 2.3.6 Zinc oxide scrubbing 3 Method 17 3.1 Input data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 3.1.1 Flash tapping gases and secondary hood gases . . . . . . . . . 17 3.1.2 Process waters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 3.1.3 Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.2 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.3 Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.4 Simulation and tower design . . . . . . . . . . . . . . . . . . . . . . . . 23 3.4.1 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 3.4.2 Tower design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 3.5 Cost analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 3.5.1 Operational costs . . . . . . . . . . . . . . . . . . . . . . . . . . 26 3.5.2 Capital investment cost estimation . . . . . . . . . . . . . . . . . 27 3.5.3 Life cycle costs and costs per unit reduction of SO2 emissions . 29 4 Results and analysis 30 4.1 SO2 from secondary hood gases . . . . . . . . . . . . . . . . . . . . . . 30 4.2 Base case scenario results . . . . . . . . . . . . . . . . . . . . . . . . . 30 4.2.1 Equilibrium temperatures . . . . . . . . . . . . . . . . . . . . . . 31 4.2.2 Water balances . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 4.2.3 Bleed compositions . . . . . . . . . . . . . . . . . . . . . . . . . 32 4.3 Tower design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 4.4 Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 4.4.1 Operational costs . . . . . . . . . . . . . . . . . . . . . . . . . . 35 4.4.2 Capital investment costs . . . . . . . . . . . . . . . . . . . . . . 36 4.4.3 Life cycle costs and costs per unit reduction of SO2 emissions . 37 4.5 Further analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 4.5.1 Process water . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 4.5.2 Minimum and maximum SO2 scenarios . . . . . . . . . . . . . . 39 4.5.3 Costs to obtain different removal efficiencies . . . . . . . . . . . 40 5 Discussion 42 6 Conclusions and future work 46 Bibliography 48 A Tower design figures 53 B Life cycle costs and costs per unit reduction of SO2 emissions (10 % WACC) 55 Acronyms FGD ­ Flue gas desulfurization RV1 ­ The process water treatment plant at Rönnskär NaOH ­ Caustic soda Na2 CO3 ­ Soda ash BAT ­ Best available technology BAT­AEL ­ BAT­associated emission levels L/G ratio ­ Liquid­to­gas ratio WACC ­ Weighted average cost of capital Chapter 1 Introduction Sulfur dioxide (SO2 ), a colorless gas with a sharp odor, has an acidifying effect on the environment which harms both plants and animals. For humans, it may affect the respiratory tract and lung function, as well as cause eye irritation. The processing industry is the largest source of SO2 emissions in Sweden. This is due to the use of sulfur­containing fuels and raw materials. [42]. In the non­ferrous metals industry, the emissions originate from the processing of metal sulfides such as chalcopyrite (CuFeS2 ) sphalerite ((Zn,Fe)S) and galena (PbS) [40]. Emissions of SO2 are regulated on UN, EU and Swedish national level ([42]; [41]), which affects the non­ferrous metals industry in different ways. The copper smelter Boliden Rönnskär has an environmental permit from the Swedish environmental court to emit 3500 tonnes of SO2 /year from 2019 and onwards, which is a reduction from a previous permit to emit 4500 tonnes of SO2 /year. Since the new permit was introduced, Rönnskär has been close to the emissions limit. There are also plans for an increased copper production in the coming years, which would be associated with increased SO2 emissions. To create a margin to the new emissions limit, the company has identified the possibility of reducing the SO2 emissions from the flash furnace’s tapping gases. This is as they are easily accessible and as they contain a large share of the SO2 emissions at Rönnskär. The SO2 reduction is to be conducted through the use of a wet scrubber, in which the SO2 is absorbed from the flue gases through various techniques. As the flash tapping gases are released in an intermittent pattern, periodically there will be capacity in the scrubber to take in other process gases as well. An example of gases 1 CHAPTER 1. INTRODUCTION that could be added to the scrubber are the gases from the secondary hoods, which are the process gases that the primary hood of the converter does not have capacity for. Today, the flash tapping gas and the secondary hood gas streams go through a bag filter and a stack and reach the atmosphere without any reduction of SO2 . Installing a scrubber would free up capacity in the bag filter, leading to reduced levels of SO2 in the tapping area and in the converter aisle, which is positive from a working environment perspective. 1.1 Aim and objectives The aim of the project is to investigate, evaluate and compare different scrubbing techniques to reduce the SO2 emissions from the flash furnace’s tapping gases. To reach the aim, the following objectives will have to be fulfilled: • Compile input data about the flash tapping gases. • Investigate if it is reasonable to take in secondary hood gases into the scrubber. • Perform simulations on and design of the different scrubber techniques. • Perform cost analysis on the different scrubber techniques. • Account for how the scrubbers are integrated into and affect Rönnskär’s other processes. 1.2 Boliden Rönnskär & Metso Outotec This thesis report was conducted together with Boliden AB and Metso Outotec Sweden AB. Boliden were mainly involved in input data collection and process integration, while Metso Outotec were mainly involved in the simulation and design of the scrubber techniques. Practical work was performed at Boliden’s copper smelter site, Rönnskär. The Rönnskär site is located in Skelleftehamn in the municipality of Skellefteå while the local Metso Outotec office is located in Skellefteå in the same municipality. Boliden is a metal company with its own mines and smelters that supplies base and precious metals through the mining of ore and the production and delivery of metals to the industry. Boliden has operations in Sweden, Finland, Norway and Ireland [5]. The Rönnskär site is mainly a copper smelter, but other non­ferrous metals are 2 CHAPTER 1. INTRODUCTION also produced. The plant receives copper concentrates from its own mines (in the Boliden area and from Aitik) and from external suppliers. Rönnskär is Boliden’s biggest production unit [4]. Metso Outotec provides technologies, end­to­end solutions and services for the minerals processing, aggregates, metals refining and recycling industries globally [24]. Metso Outotec is a merger between Metso Minerals and Outotec, which was established on the 1/7/2020 [23]. 1.3 Delimitations As Boliden Rönnskär is a site with many processes that are integrated in a complex system (see Figure 2.2.1), many of the scrubber techniques affect other parts of the site. The calculations however only focused on the scrubbers themselves as well as on the incoming process waters, the stripper and the process water treatment plant. Implications on other relevant operations at Rönnskär were only part of the analysis and discussion and were not included in any calculations. Further, there are many methods to abate SO2 from gas streams including using a cleaner fuel, using a sulfur recovery unit and the use of end­of­pipe treatment methods like flue gas desulfurization (FGD), biological technologies and electron beam irradiation [13]. However, in this study only FGD systems were studied. This decision was made based on a pre­study that was conducted by Boliden. Among the FGD systems, only wet scrubbers were evaluated. This is as wet scrubbers have a higher removal efficiency than dry and semi­dry scrubbers [43] and as dry and semi­dry scrubbers have mainly been applied for low sulfur content process gases at high temperatures in the coal industry [25]. Other system requirements were set based on Boliden’s pre­study and based on legislation, which are presented in Section 3.2. In a screening process, five wet scrubbers were selected for the evaluation in this report. These are scrubbers based on the following reagents: caustic soda, soda ash, peroxide, lime and zinc oxide. These scrubbers were selected due to the following reasons: • The caustic soda and soda ash scrubbers were selected due to their simplicity and technical maturity. They also produce a liquid effluent, which can be treated further at Boliden’s process water treatment plant. 3 CHAPTER 1. INTRODUCTION • The peroxide scrubber was selected as it is a proven technique. It was also chosen as it had potential synergies with the leaching plant. • The zinc oxide scrubber was selected due to its possible suitability with the zinc smelting at Rönnskär. • The lime scrubber was selected due to its relatively low reagent cost. Other types of scrubbers were not considered due to their costs, removal efficiency, complexity or the fact that the technique was not used on a commercial scale. More information about the chosen scrubber techniques will be presented in Section 2.3. In the cost analysis, the operational cost only included the reagent costs and the costs for running the pumps and the fan. The costs included in the capital investment cost are presented in Section 3.5.2. 4 Chapter 2 Background In this chapter a general overview is given of flash smelting, flash tapping and converting together with a presentation of the relevant processes at Boliden Rönnskär. Further, the scrubber techniques are presented by describing their operating principles, their advantages and disadvantages and by giving examples of industrial plants using the scrubber in question. SO2 absorption theory and different tower types used for wet scrubbing are also presented. 2.1 Overview of processes In this section a general overview of flash smelting and tapping as well as converting is given. 2.1.1 Flash smelting and tapping Flash smelting is the most common process for copper (Cu) matte smelting. In the flash furnace copper­iron­sulfur (Cu­Fe­S) concentrate reacts with oxygen gas (O2 ) continuously. This leads to oxidation of the concentrate’s Fe and S, heat evolution and melting of the solids. Flash smelting results in [38]: • Molten Cu­Fe­S matte with ∼60 % Cu, which is fed to the converters. • Molten iron­silicate slag with 1­2 % Cu, which after treatment for Cu recovery only contains a minor fraction of the Cu input. 5 CHAPTER 2. BACKGROUND • Hot dust­laden off­gas containing 30­50 vol.­% SO2 , which can be further treated for sulfuric acid (H2 SO4 ) production. The matte and slag are tapped through water­cooled holes embedded in the furnace walls. The holes typically have a 60­80 mm diameter. The tapping is only partial as 0.5 m deep reservoirs for matte and slag respectively are maintained in the furnace. During steady­state operation the tapping of matte is done on a scheduled basis or when it is needed in the converter. Tapping of slag is also done on a scheduled basis or when it reaches a specific level in the furnace [38]. Tapping leads to SO2 emissions around the furnace, especially on the matte side that contains more sulfur [33]. 2.1.2 Converting In the converter the Cu from the matte, containing approximately 60 % Cu, is oxidized into molten blister copper that contains approximately 99 % Cu. Similarly to the flash smelting, the converting also produces molten iron­silicate slag and SO2 ­containing off­gas. The converting occurs through the oxidation of Fe and S from the matte with oxygen­enriched air. [38]. Converting occurs in two stages, where the first one is the slag­forming stage (slag blow) in which primarily Fe and S are oxidized to ferrous oxide (FeO), magnetite (Fe3 O4 ) and SO2 . Silica flux is added to form a liquid slag with the Fe oxides. The slag­forming stage is done when the Fe in the matte has been lowered to about 1 %. The slag is separated from the remaining matte, which now mainly consists of impure molten white metal (Cu2 S) [38]. The second stage is copper making (copper blow), when the S in the white metal is oxidized to SO2 . Cu is not noticeably oxidized until almost all S is oxidized, which leaves the produced blister copper with low levels of both S and O (0.001­0.03 % S and 0.1­0.8 % O). The copper blow is terminated when copper oxide begins to appear [38]. The matte is charged to the converter in several steps. Each step is followed by the slag blow and slag being poured from the converter before new matte is charged. This leads to accumulation of Cu in the converter until there is sufficient molten white metal (250­300 tonnes) for the copper blow. The blister copper is poured from the converter into ladles and is transported to the anode casting for further refining [38]. 6 CHAPTER 2. BACKGROUND The converter off­gas is collected by a primary hood that should fit as closely as possible over the converter mouth. The off­gas entering the primary hood contains between 8­ 10 vol.­% SO2 [38]. Outotec primary hoods capture over 95 % of the SO2 from the converting process [6]. The secondary hood collects SO2 ­bearing gas that is not captured by the primary hood [38]. Too much SO2 in the secondary hood during normal operation is an indication of the primary system being insufficient and in need of modification. Secondary hoods handle secondary gases such as emissions from [6]: • rolling in and out the converter. • charging the converter in both filling and blowing position. • tapping matte, slag and blister copper. • parked ladles. Secondary hoods are important for a safer and cleaner working environment. They also extend equipment lifetime due to less dust exposure [6]. 2.2 Processes at Boliden Rönnskär In this section the copper production process at Rönnskär and a few other processes of interest for this project will be presented. 2.2.1 Copper and gas flow In Figure 2.2.1 the various processes at Boliden Rönnskär are included. The copper flow (in orange) represents the set of processes that are involved in the processing of Cu. The Cu concentrate goes through either the flash furnace or the electric smelting furnace while the Cu­containing electronic waste goes through the E­kaldo plant. Secondary raw material, which contains copper, enters the electric smelting furnace as well. The next step from both furnaces and the E­kaldo plant is the converter, where the blister copper is produced. The plant has three converters, which are more or less identical, of which two are in operation simultaneously. During normal operation, one 7 CHAPTER 2. BACKGROUND Figure 2.2.1: Operations at Boliden Rönnskär. cycle is completed in one of the converters before the other one begins its cycle. Each cycle takes around 8 hours. Figure 2.2.1 also shows the gas flow (in black) which represents the SO2 ­dense (7­40 vol.­% SO2 ) primary gas flows from the furnaces, the Kaldo plant, the converter aisle (the primary hood gases) and a fluidized bed roaster. But there are also other low SO2 ­ bearing gases that are not included in the figure such as the flash tapping gases and the gases entering the secondary hood, which are of main interest in this report. The gases that do not enter the primary hood of the converter (less than 1 %) either rise towards the converter aisle ceiling or enter the secondary hood where they are transported to a bag filter. The flash tapping gases are transported to the same bag filter before they both exit through a stack. 2.2.2 Process water treatment plant (RV1) and stripper The process water treatment plant (RV1) is designed for 200 m3 water/h and handles 160 m3 water/h on average, of which 110 m3 /h is process water from Rönnskär’s different processes. The flow rate is expected to increase with different expansions 8 CHAPTER 2. BACKGROUND planned at Rönnskär. Most of the current process waters come from gas treatment processes such as scrubbers, cooling towers, WET­ESPs etc., but also from other processes such as the electrolysis plant. These waters contain various concentrations of SO2 and H2 SO4 making the incoming water to RV1 acidic (pH 1­2). All of the process water that comes to RV1 goes through a stripper. The stripper is a packed tower, where air is used to remove SO2 from the process water. The SO2 from the stripper is then mixed with the concentrated SO2 gases entering the sulfuric acid plant. The average volumetric flow and SO2 concentration of the incoming process water are both above the correspondent values that the stripper is designed for, leading to an average removal efficiency of 90% instead of the 95 % that it should remove [36]. Green liquor, a dissolved smelt of mainly sodium carbonate (Na2 CO3 ) and sodium sulfide (Na2 S), is used to precipitate metals and arsenic at RV1, but can also react with other compounds such as SO2 . How much SO2 that is left in the process water after the stripping determines how much additional green liquor that is consumed when the water reaches RV1. SO2 dissolved in the incoming process water reacts with the active precipitation chemical in green liquor, sulfide (S2− ), to form elementary sulfur (S0 ) which reacts further with SO2 and water to form thiosulfate (S2 O2− 3 ). The reactions are the following [36]: 2 S2–(aq) + SO2(aq) + 4 H+(aq) S0(s) + SO2(aq) + H2O(l) 3 S0(s) + 2 H2O(l) (2.1) S2O32–(aq) + 2 H+(aq) (2.2) With a higher removal efficiency in the stripper, less SO2 would end up at RV1 consuming green liquor. Around half of Boliden’s green liquor costs can be attributed to the poor function of the stripper. Further, high SO2 levels in the incoming water result in working environment issues for the staff at RV1 [36]. The scrubber bleeds consist of both sulfites and sulfates. The sulfites turn into SO2 at low pH values and consume green liquor at RV1 while the sulfates do not need to be treated before being discharged into the sea. Sulfates are therefore not a problem for RV1. Any H2 SO4 that reaches RV1 is neutralized using caustic soda (NaOH). 9 CHAPTER 2. BACKGROUND 2.2.3 Leaching plant A new leaching plant is being built at Rönnskär where hazardous waste from the own production is being reprocessed to reduce the amount of waste ending up in a deep repository while the yield of already mined ore increases [14]. The leaching plant process will consist of a multi­stage leaching process. Input chemicals will mainly consist of H2 SO4 (70­76 %) from the H2 SO4 production at Rönnskär, green liquor and NaOH. The estimated use of H2 SO4 (70­76 %) is around 1.3 m3 /h (11 000 m3 /year) and the plant is expected to be in operation 340 days/year. 2.2.4 Process water sources The two process water that were evaluated for reuse as make­up water in the scrubber originate from the clinker scrubber and the flash cooling tower. The clinker scrubber is a caustic soda scrubber used to remove halogens and SO2 from gases from the zinc clinker process. The flash cooling tower, cools the flash smelting off­gases from around 65 ◦ C to 25 ◦ C and is then taken to the remaining steps of the sulfuric acid production. The compositions and other properties of both the clinker scrubber process water and the flash cooling tower process water are presented in Section 3.1.2. 2.3 Scrubber techniques In this section, SO2 absorption theory and the different scrubber techniques that were evaluated in this report are presented. 2.3.1 SO2 absorption theory Removal of SO2 from flue gases occurs in three steps [17]: 1. SO2 is absorbed into water droplets. 2. The dissolved SO2 reacts with an alkaline species. 3. The reaction product is removed. When the liquid reaches its saturation limit of SO2 , the mass transfer rates are in equilibrium and no additional SO2 can be removed. Therefore it is important to design 10 CHAPTER 2. BACKGROUND and operate the scrubbers so that saturation conditions are not reached, which is done by providing sufficient liquid or by a chemical reaction that prevents the dissolved SO2 from returning to the gas phase [17]. Many commercial gas absorption processes involve chemical reactions in the liquid phase [25]. The reaction between SO2 and the alkaline solutions is, based on decades of studies, assumed to be instantaneous. Instead it is the mass transfer that is considered the limiting and most important step [26, 43]. Absorption of SO2 in water is a pH­dependent process and the pH of the liquid decreases as it approaches saturation. Therefore, the removal efficiency is a function of the liquid’s pH. Scrubbers are operated at pH levels above 5.5 and preferably between 6.0 and 6.5 to avoid mass transfer limitations. The pH levels are maintained by continually adding alkali to react with SO2 and therefore there is no significant equilibrium limit of the absorption when the liquid’s pH is above 5.5 [17]. The alkalinity in wet scrubbers keeps the following two equilibrium reactions progressing to the right [39]: SO2(g) + H2O(l) H2SO3(aq) (2.3) The sulfurous acid (H2 SO3 ) further disassociates to form bisulfites or sulfites [39]: H2SO3(aq) HSO3–(aq) + H+(aq) SO3–2(aq) + 2 H+(aq) (2.4) Although a higher gas temperature leads to a lower absorption rate and vice­versa [26], for wet scrubbing systems, the inlet gas temperature is mainly important with respect to the construction materials in the scrubber. Due to the long contact time between gas and liquid in the scrubber, the temperature of the outlet gas is close to the adiabatic saturation temperature which is reached through vaporization of the liquid [17]. 2.3.2 Tower types Packed towers and open spray towers are the two most common contactors used to facilitate the absorption in wet scrubbing. 11 CHAPTER 2. BACKGROUND Packed tower A packed tower is a column filled with packing material that provides a large surface area for the contact of liquid and gas [26]. A countercurrent flow is preferred, making the most diluted gas to be in contact with the cleanest scrubbing liquid [43]. A packed tower normally consists of a tower shell, mist eliminator, liquid distributor, packing material and a packing support. Both structured and random packings are used for scrubbers and are mainly made of metal or plastic. Metallic packings are not suitable for corrosive flue gases, while plastic packings are not suitable for high temperatures. Ideally, the packing’s life time will be as long as the tower’s lifetime, but in adverse environments it can be shorter due to corrosion, fouling and/or breakage [26]. The size of a packed tower is mainly affected by the gas velocity. When the diameter of the tower is decreased, the gas velocity increases. At some point the velocity becomes so high that it restricts the downward flow of the liquid. The liquid starts to accumulate at the so called loading point, in which the pressure drop starts to increase and the mixing between phases decreases. Increasing the gas velocity further passed the loading point leads to the liquid filling the void space in the packing completely which in turn leads to substantial increase in pressure drop and minimal mixing between phases. This is called flooding and has to be avoided [18]. Advantages with packed towers are that they can reach high removal efficiencies and that they have relatively low water consumption requirements. Disadvantages include risk of fouling and clogging and extensive maintenance of the packing material. Installation, operational and wastewater disposal costs may also be higher for packed towers compared to other types of contactors [26]. Soda­based scrubbers normally use packed towers [9]. Open spray tower In open spray towers, the liquid is injected into the tower through a spray distribution system, where it comes in contact with the flue gas that flows in the opposite direction [26]. The towers are completely open and have no internal components except for the spray nozzles and connecting piping [17]. This makes them simple to operate and maintain and they also have lower pressure drops than packed towers. However, compared to other scrubbers they have lower mass transfer, leading to lower removal efficiencies for gases of lower solubility. To reach higher removal efficiencies they 12 CHAPTER 2. BACKGROUND require higher water circulation rates [26]. Lime scrubbers are typically open spray towers, due to the risk of scaling and plugging in a packed column [9, 12]. 2.3.3 Sodium­based scrubbing Among sodium­based scrubbers, the most common systems use aqueous solutions of either caustic soda (NaOH) or soda ash (Na2 CO3 ) as reagents to absorb SO2 . They both produce a clear liquid solution with a high pH and can be used interchangeably in most scrubbers. Caustic soda dissolves in water to create the scrubbing solution through the following reaction [39]: Na+(aq) + OH–(aq) + H2O(l) NaOH(s) + H2O(l) (2.5) For soda ash, the scrubbing solution is created through the following reactions [39]: Na2CO3(s) + H2O(l) 2 Na+(aq) + CO3–2(aq) + H2O(l) (2.6) HCO3–(aq) + OH–(aq) (2.7) CO3–2(aq) + H2O(l) Both soda ash and caustic soda scrubbers produce a mixture of sodium sulfite (Na2 SO3 ), sodium sulfate (Na2 SO4 ) and sodium bisulfite (NaHSO3 ). The proportions of the different compounds depends on the pH and the degree of oxidation. The overall reactions with SO2 are [39]: SO2(g) + 2 Na+(aq) + 2 OH–(aq) SO2(g) + 2 Na+(aq) + 2 OH–(aq) + 1 O2(g) 2 SO2(g) + Na+(aq) + OH–(aq) Na2SO3(aq) + H2O(l) (2.8) Na2SO4(aq) + H2O(l) (2.9) NaHSO3(aq) (2.10) 13 CHAPTER 2. BACKGROUND As the systems have a relatively simple design, they require relatively little space. Further, scaling and plugging risks are small and the power consumption is low due to a low liquid­to­gas flow ratio [21]. Another advantage is that the sodium­ based scrubbers produce an aqueous solution instead of a slurry, which simplifies the operation of the scrubber [15]. Caustic soda scrubbers tend to be slightly more expensive than soda ash scrubbers and the cost of caustic soda also fluctuates more than other reagents due to a high market demand [39]. The costs for the sodium­ based reagents are in general higher than for the reagents in lime­based scrubbers [17, 39]. The liquid effluent from sodium­based scrubbing may create disposal problems at some locations and has to be treated before it is discharged into any watercourse [39]. At the Freeport McMoRan Miami smelter a large 2 300 000 Nm3 /h scrubber, using 20 % caustic soda as reagent, is used to treat converter aisle fugitives and anode off­gas [16]. Caustic soda is otherwise typically sold as a 50 % solution [39]. 2.3.4 Peroxide scrubbing In peroxide scrubbing, SO2 is removed through the following reaction with hydrogen peroxide (H2 O2 ): SO2(g) + H2O2(aq) H2SO4(aq) (2.11) The Peracidox ® scrubber is one of the patented scrubber techniques using H2 O2 , owned by Metso Outotec, to remove residual SO2 from dilute off gases. In this process, scrubbing is achieved through direct contact in a packed tower, where the hydrogen peroxide reacts with SO2 in the first chamber and then overflows to a second chamber. The exiting 50 % H2 SO4 is either recycled to a sulfuric acid plant or sold as a by­product if a market exists [9]. The concentration of the outgoing H2 SO4 will be approximately the same as the concentration of the incoming H2 O2 in a peroxide scrubber (Personal communication with Leif Skilling, 15/2/2021). 14 CHAPTER 2. BACKGROUND Metso Outotec lists the following benefits with the Peracidox ® process [2]: • No additional chemicals (H2 SO4 as product, no wastewater or residues). • Low opacity. • High removal efficiency. • High reliability. • Low investment cost. • High flexibility with respect to variations in SO2 content of the gas. Disadvantages with the Peracidox ® process include a relatively high reagent cost and the relatively low strength of the resulting H2 SO4 solution [9]. 2.3.5 Lime scrubbing Wet scrubbing systems based on lime and limestone are the most popular commercial FGD systems [25]. In fact, they are used in over 90 % of all FGD systems in the United States [34]. In lime scrubbers, the flue gas is scrubbed with calcium hydroxide (Ca(OH2 )) which is formed when quicklime (CaO) reacts with water. The slurry is pumped into an open spray tower where the SO2 is absorbed into the droplets of the slurry, which leads to several chemical reactions that can be simplified as [25]: CaSO3 · 1 3 H2O(s) + H2O(l) 2 2 (2.12) 1 3 1 H2O(s) + H2O(l) + O2(g) 2 2 2 CaSO4 · 2 H2O(s) (2.13) SO2(g) + Ca(OH)2(s) + H2O(l) CaSO3 · The product in Reaction 2.13. is gypsum (CaSO4 * 2 H2 O) that can be sold if it is clean of impurities and if a market exists. Advantages of lime­based scrubbers include that they are simple, use a widely available and inexpensive reagent and that they produce a potentially usable product (gypsum). Disadvantages include high capital costs [25] and the risk of calcium compounds accumulating in recirculating loops causing scaling [12]. Also, lime­based scrubbers can be adversely affected by rapid changes in concentration [9] and operate poorly below 60 ◦ C (Personal communication with Olle Gunnarsson, 14/1/2021). 15 CHAPTER 2. BACKGROUND 2.3.6 Zinc oxide scrubbing Zinc oxide (ZnO) reacts with water to create zinc hydroxide (Zn(OH)2 , which reacts with the SO2 through several reactions to form zinc sulfite (ZnSO3 ) and zinc sulfate (ZnSO4 ). These reactions can be simplified as [19]: SO2(g) + Zn(OH)2(s) ZnSO3(s) + 1 O2(g) 2 ZnSO3(s) + H2O(l) (2.14) ZnSO4(aq) (2.15) Zinc oxide scrubbing is suitable at a zinc smelter as the ZnO reagent can be obtained from the fuming plant and the clinker furnace. The resulting ZnSO3 and ZnSO4 can be processed further before they are reintroduced as raw material in the zinc smelting process. As the zinc scrubber takes reagent from and later reintroduces the products to the zinc smelting process, the scrubber has no reagent cost. ZnO has limited solubility in water, making it the rate limiting step for the overall reaction with SO2 . This leads to several problems [19]: • Scaling and blockage of the equipment occurs easily. • To ensure a high removal efficiency the liquid­to­gas ratio needs to be increased, leading to high energy consumption. • Poor buffering ability of pH in ZnO solution and low absorptive capacity. Organic additives such as citric acid can be used to increase the absorption rate and SO2 removal efficiency, but also to prevent scaling and corrosion [19]. DynaWave, who have installed zinc oxide scrubbers at zinc smelters in Belgium and Australia, have tackled the low dissolution rate and achieved higher removal efficiencies than other zinc oxide scrubbers by using a reverse jet nozzle. The nozzle is used to create an intense mass and energy transfer region, where the flue gas is quenched and the SO2 is transferred to the liquid [10, 11]. 16 Chapter 3 Method In this chapter a description is given of how the different parameters were acquired, chosen or calculated. First the input data regarding the gas streams, process waters and costs are presented. Then the system requirements and scenarios are presented which the calculations, simulations and design were based on. Finally the set of methods used for the cost analysis are presented. 3.1 Input data Most of the input data were collected from existing process data at Boliden. For some processes and parameters, additional measurements or tests were conducted. 3.1.1 Flash tapping gases and secondary hood gases Data regarding the flash tapping gases from the flash furnace were collected from Boliden’s existing process data regarding volumetric flows, temperatures and SO2 concentrations. The data used to calculate the average slag tapping and average matte tapping values as well as the minimum and maximum SO2 scenario values for the flash tapping gases were based on process data from the 24/9/2020 as well as from the period 13/11/2020 ­ 17/11/2020. There were no data regarding the secondary hood gases, which is why continuous measurements were conducted between 16/12/2020 ­ 21/12/2020 to monitor the volumetric flow, SO2 concentration and temperature. The results during the period 17 CHAPTER 3. METHOD Figure 3.1.1: Volumetric flow and SO2 concentration of the flash tapping gases during the 24/9/2020. 16/12/2020 ­ 17/12/2020 were used to calculate the values in Table 3.1.2. This is, as it was only during these two days when the operations followed a normal pattern. The average values of the different flow parameters of the flash tapping gases are listed for matte tapping and slag tapping periods in Table 3.1.1. The fan is constantly running at the matte tapping area while a damper is opened during slag tapping periods leading to a higher volumetric flow. It should be noted that the matte tapping values in Table 3.1.1 represent the whole period with lower volumetric flows, not only the period when matte tapping actually occurs. In Figure 3.1.1 it can be seen how the SO2 concentration peaks during matte tapping. The figure also shows the fluctuating volumetric flow rate. The average values for slag tapping were used in the base case scenario, which will be presented in Section 3.3. Table 3.1.1: Average values of different flow parameters of the flash tapping gases. Slag tapping (base case scenario) 3 Volumetric flow (Nm /h) 138 800 Temperature (◦ C) 38 SO2 (ppm) 175 Parameter Matte tapping 49 100 37 245 The average values of the different flow parameters for the secondary hood gases are listed during forced ventilation (for example during charging of material into converter) in Table 3.1.2. Figure 3.1.2 shows that the majority of the highest SO2 concentration values coincide with the forced ventilation into the secondary hood. This is logical, as one of the reasons for pulling gas into the secondary hood is to reduce the 18 CHAPTER 3. METHOD Table 3.1.2: Average values of different flow parameters of the secondary hood gases. Forced ventilation 3 Volumetric flow (Nm /h) 109 800 Temperature (◦ C) 28 SO2 (ppm) 270 Parameter Remaining operation time 31 000 45 90 Base case scenario 111 200 38 125 Figure 3.1.2: Volumetric flow and SO2 concentration of the secondary hood gases in converter 3 during the period 16/12/2020­17/12/2020. SO2 level in the converter aisle. Figure 3.1.2 also shows how often the forced ventilation occurs. As the measurements on the secondary hood gases were only conducted on one secondary hood (on converter 3), it was assumed that similar flow properties would be present in the other converter in operation. Average SO2 and temperature values were calculated for the secondary hood gases in the base case scenarios (see Table 3.1.2) in which secondary hood gas was pulled to fill up the remaining scrubber capacity (250 000 Nm3 /h ­ 138 800 Nm3 /h = 111 200 Nm3 /h). These averages include both the forced ventilation and the remaining operation time periods. The values in the minimum and maximum SO2 scenarios were based on ten minute averages. This is as the gas streams are likely to be mixed in the transport towards the scrubber. The minimum SO2 scenario consists of the minimum volumetric flow rate from two secondary hoods (29 000 Nm3 /h from each secondary hood) and the volumetric flow during matte tapping. The minimum SO2 levels approach zero at times, but were set to 5 ppm for some reagent to be consumed. The values of the flow parameters in the minimum and maximum SO2 scenarios are presented in Table 3.1.3. 19 CHAPTER 3. METHOD Table 3.1.3: Values of different flow parameters in the minimum and maximum SO2 scenarios for the flash tapping gases and secondary hood gases. Minimum SO2 scenario Volumetric flow (Nm3 /h) Temperature (◦ C) SO2 (ppm) Maximum SO2 scenario Volumetric flow (Nm3 /h) Temperature (C) SO2 (ppm) Flash tapping gas Secondary hood gas 49 300 19 5 58 000 27 5 140 000 49 340 110 000 74 3480 3.1.2 Process waters Two process waters were evaluated for reuse as make­up water in the scrubber. This is as there was an ambition to use process water from existing processes at Rönnskär to avoid an additional water load to RV1 that already works close to maximum capacity. Table 3.1.4: Properties of the clinker scrubber process water and the flash cooling tower process water. Parameter Clinker scrubber water Flash cooling tower water Fluorides (mg/l) Chlorides (mg/l) Dry matter (mg/l) SO2 (g/l) H2 SO4 (g/l) pH Temperature (◦ C) Volumetric flow (m3 /h) 760 1.8 540 4.4 ­ 8.9 30 19 155 <0.1 10 18.9 8.1 1.1 25 3 The process water data is from ten measurements on the clinker scrubber process water (between September 2019 and January 2021) and four measurements on the flash cooling tower process water (between November 2020 and January 2021), which are presented in Table 3.1.4. The H2 SO4 value in the flash cooling tower process water is based on nine separate measurements between March 2020 and March 2021. The temperature and flow rate for the clinker scrubber process water were obtained from zinc smelting staff at Rönnskär in February 2021 while the same values were obtained from existing process data for the flash cooling tower process water during the same 20 CHAPTER 3. METHOD month. In Table 3.1.4 it can be seen that the clinker scrubber process water is alkaline and has high values of fluorides, chlorides and dry matter while the flash cooling tower process water is acidic and has high SO2 and H2 SO4 concentrations. The latter also has a smaller volumetric flow and temperature compared to the clinker scrubber process water. 3.1.3 Costs Reagent costs Typical reagent costs are listed in Table 3.1.5. The zinc oxide scrubber has no reagent cost as it is obtained from the zinc smelting process at Rönnskär. Table 3.1.5: Reagent costs. Reagent Cost (SEK/tonne) Caustic soda (50 weight­%) 2450 Soda ash 2450* Lime (quicklime) 1150** Peroxide (49 weight­%) 2900 Zinc oxide 0 Green liquor 800 * Including 125 SEK/tonne for emissions rights. ** Including landfill cost of 235 SEK/tonne. Equipment costs The costs for the tower and the tower internals were rough estimates with some input from Olle Gunnarsson from Metso Outotec. The pump capital costs were based on cost indexes in a report by the National Energy Technology Laboratory (NETL) of the U.S. Department of Energy [20] while the fan and mixing tank capital costs were based on Peters et al. [35]. The bag filter and the belt filter (for the open spray towers) were not included in the cost calculations. The exchange rates used for the equipment cost calculations were 8.37 SEK/$ and 10.03 SEK/€. The remaining capital investment costs were estimated using the method in Section 3.5.2. 21 CHAPTER 3. METHOD 3.2 System requirements A few requirements were set for the scrubbing systems. As Boliden is regulated based on total SO2 emissions (3500 tonnes/year), it is of interest to scrub as much SO2 as possible for a reasonable cost. However, there is also a removal efficiency regulation set by the EU commission when a unit for SO2 removal is installed. Wet scrubbers are one of three techniques that are seen as the best available technique (BAT) for reducing SO2 emissions from primary and secondary copper production. The BAT­associated emissions levels (BAT­AEL) for SO2 emissions to air from a wet scrubber following primary copper production is 350 mg/Nm3 [8] on a daily average. Boliden targets to have a margin to the BAT­AEL. Additionally, there were a few parameters that were fixed and decided based on Boliden’s pre­study. One of these was the capacity of the scrubber which was set to 250 000 Nm3 /h. This is based on expected future flash furnace production that includes both increased tapping and simultaneous tapping of slag and matte. It was also decided that dust will be abated with a bag filter before the scrubber. The bag filter will be designed to emit 1 mg/Nm3 , but should guarantee that the emissions do not exceed 2 mg/Nm3 . 3.3 Scenarios The scrubber techniques were evaluated in different scenarios. First, five base case scenarios were created based on the different reagents: caustic soda, soda ash, peroxide, lime and zinc oxide. In these base case scenarios, the removal efficiency was set to 90 % and clean industrial water of 10 ◦ C was used. The average values during slag tapping were used for the flash tapping gases (see Table 3.1.1). The remaining gas to fill up the capacity (250 000 Nm3 /h) was taken from the secondary hood gases whose values for the different parameters in the base case scenarios are listed in Table 3.1.2. From these scenarios, results regarding the water balances, energy balances as well as the sizes and compositions of the bleeds were obtained. It should be noted that the base case scenarios are not averages of the volumetric flows, temperatures or SO2 concentrations for the flash tapping gases and the secondary hood gases. Instead they represent one of the most probable operating modes when using both gas streams in the proposed scrubber. 22 CHAPTER 3. METHOD Further the use of the two process waters was evaluated. This was done by analyzing how they affect both the scrubber and processes downstream of the scrubber. The process water analysis was based on the make­up water need in the base case scenarios. For the scrubbers that had the most promising results in the base case scenarios and in operation with the process waters, a sensitivity analysis was conducted in which the minimum and maximum SO2 scenarios (see Table 3.1.3) as well as the costs to obtain different removal efficiencies were studied. The minimum and maximum scenarios had the same removal efficiency (90 %) and used the same clean industrial water of 10 ◦ C as in the base case scenarios. 3.4 Simulation and tower design The scenarios were studied using the simulation software METSIM, the design software Rapsody and theoretical calculations. METSIM is a general­purpose process simulation software designed to perform mass and energy balances in complex processes [22] while Rapsody is a software for the design of packed columns [37]. 3.4.1 Simulation For the packed towers, the equilibrium temperature was first obtained in METSIM for the maximum SO2 scenario, where the liquid flow rate was based on a liquid­to­ gas (L/G) ratio value from the literature (see Table 3.4.2). The obtained equilibrium temperature was then used to design the packed tower in Rapsody, in which a more suitable L/G ratio was chosen. This new L/G ratio was then plugged back into METSIM, in which it was used for the simulation of all scenarios. For the open spray towers, the L/G ratio was based both on literature references and Metso Outotec’s experience. The sizes of the make­up water flow rates were decided by adding together the water evaporated in the scrubber and the bleeds. While the evaporated water was obtained directly from METSIM, the bleeds were calculated using the solubilities of the scrubbing products that are listed in Table 3.4.1. The bleed sizes were calculated in this way to avoid precipitation of the scrubbing products. The tabulated solubility values are at various temperatures, but were the values encountered in the literature that are the closest to the operating temperatures of the scrubbers. 23 CHAPTER 3. METHOD Table 3.4.1: Solubilities of the products in the different scrubbers. Solubility (g compound/g water) Temperature (◦ C) Reference Caustic soda & soda ash Na2 SO3 0.31 25 Na2 SO4 0.28 25 Peroxide H2 SO4 * ­ Lime CaSO3 0.000043 18 CaSO4 * 2 H2 O 0.0020 20 Zinc oxide ZnSO3 0.0015 25 ZnSO4 0.56 25 * Soluble at all concentrations and temperatures. [30] [29] [31] [7] [28] [27] [32] As the reaction products of the lime and zinc oxide scrubbers are practically insoluble (except ZnSO4 ), belt filters were used to dewater parts of the slurries and to obtain bleeds that are 30 % solid. The peroxide scrubber bleed contains a 49 % H2 SO4 (based on the input 49 % H2 O2 ). Bisulfites, such as sodium bisulfite, were not included in the calculations and analyses. 3.4.2 Tower design A packed tower and an open spray tower were designed based on the maximum SO2 scenario, to ensure that the scrubber is always able to clean 90 % of the SO2 . Only one design for each type of tower was designed due to similar flow properties of the packed tower scrubbers (caustic soda, soda ash and peroxide) and the open spray tower scrubbers (lime and zinc oxide). The towers consist of several parts. The top of the towers consists of a liquid/slurry distributor, a gas outlet and a liquid/slurry inlet. The packing section consists of the packed bed and the support grid for the packed towers while the reactive zone in the open spray towers does not have any internal components. The bottom of the towers includes the gas inlet and the liquid/slurry outlet. The tower diameter for the packed towers was obtained from Rapsody and was decided based on many design parameters which include packing type and size, flooding factor, gas velocity, liquid load and pressure drop. The parameters mentioned above need to 24 CHAPTER 3. METHOD have specific values or fall within specific ranges that were based both on the literature and personal communication with Olle Gunnarsson. These common values/ranges are listed for both packed and open spray towers in Table 3.4.2. Table 3.4.2: Common values/ranges for various packed tower and open spray tower parameters. Common values/ranges Packed tower L/G ratio (L/m3 ) [18] Gas velocity (m/s) Operating pressure drop (kPa/m packing) Total operating pressure drop (kPa) Flooding factor (%) [18] Liquid load (m3 /m2 /h) Tank residence time (min) Open spray tower L/G ratio (L/m3 ) [18] Gas velocity (m/s) Total operating pressure drop (kPa) Residence time (reactive zone) (s) Tank residence time (min) 0.2­5.4 2­2.5 0.1­0.2 1.5 50­75 20 5 2.2­12.7 3­4 1 3­4 2 The height of the packing determines the removal efficiency and is decided with the following formula [18]: Z = HT U × N T U (3.1) where Z is the height of the packing, NTU is the number of transfer units and HTU is the height of a transfer unit. The HTU and the NTU were both obtained from Rapsody. The tank height was calculated based on the tank residence time and the calculated tower diameter. The gas inlet size was based on a 15 m/s velocity for the incoming gas flow and the 250 000 Nm3 /h capacity. The section above the gas inlet has a height that is 50 % larger than the gas inlet height which is to allow the gas to be well distributed before reaching the packing/reactive section. 0.5 m height is added to the bottom of the tower to compensate for the pump(s) being unable of pumping water from the absolute bottom part of the tower. Heights for the remaining parts of the tower were decided when all the heights mentioned above were decided. 25 CHAPTER 3. METHOD 3.5 Cost analysis The costs included the operational costs and the capital investment costs. These costs were later used to calculate the life cycle costs and the costs per unit reduction of SO2 emissions. 3.5.1 Operational costs The operational costs include the reagent costs as well as the pump and fan power costs. The reagent costs were calculated based on the yearly reagent consumption which in turn were based on the SO2 emissions during October 2019 ­ September 2020 for the flash tapping gases and 16/12/2020 ­ 21/12/2020 for the secondary hood gases. The size of these emissions is presented in Table 4.1.1 in the Results section. A 5 % surplus of reagent was used to ensure that the desired removal efficiency was reached and that an alkaline environment was maintained in the alkaline scrubbers. The pump power costs were based on the shaft pump power which is calculated using the following formula: P = qρgh (3.6 × 106 )η (3.2) where P is the shaft pump power (kW), q is the flow (m3 /h), ρ is the density of the fluid (kg/m3 ), g is the acceleration of gravity (m/s2 ), h is the differential head (m) and η is the pump’s efficiency. The packed towers uses one pump that transports the liquid from the bottom of the tower to the liquid distributor. The open spray towers uses three pumps of equal size to transport the liquid to three different heights 2 meters apart from each other. The utilization rate of the pumps in the open spray towers was assessed to be 2/3 of the maximum capacity due to the fluctuating volumetric flows and SO2 concentrations of the incoming gas streams. Further, the liquid was assumed to drain down in the packed towers while it is sprayed into the open spray towers which requires an additional 10 m head. The fan power costs were based on the fan power which is calculated using the following formula: P = dp × q η (3.3) 26 CHAPTER 3. METHOD where P is the power used by the fan (kW), dp is the total pressure increase by the fan (kPa), q is the gas volume flow delivered by the fan (m3 /s) and η is the fan’s efficiency. As previously shown in Table 3.4.2 the pressure drop for the packed towers and the open spray towers were estimated to be 1.5 kPa and 1.0 kPa respectively. The electricity cost was set to 0.45 SEK/kWh while the efficiency was set to 0.7 for both the pumps and the fan. 3.5.2 Capital investment cost estimation In this section, the set of methods used for estimating the capital investment costs are presented. The capital cost estimates were study estimates, which are based on major items of equipment which have a probable accuracy of estimate up to ± 30 %. A study estimate is important for determining whether a proposed project should be given further consideration or for comparison with alternative designs [35]. In Table 3.5.1 the items that are needed for a new facility and that were included in the calculations are listed. Table 3.5.1: Fixed­capital investment items for a chemical process [35]. Directs costs Indirect costs Delivered equipment Delivered­equipment installation Instrumentation and controls Piping Electrical systems Buildings (including services) Yard improvements Service facilities Land Engineering and supervision Legal expenses Construction expenses Contractor’s fee Contingency The delivered equipment costs were calculated using cost indexes, scaling and the data and references presented in Section 3.1.3. The costs of the remaining fixed­capital investment items were estimated using ratio factors based on the delivered equipment cost. These methods are presented below. 27 CHAPTER 3. METHOD Cost index As prices could change with time due to changes in economic conditions, cost indexes are used to update cost data applicable at a previous date to costs that are representative of conditions today [35]. The present cost is calculated through the following formula: Present cost = Original cost × Index value at present Index value when original cost was obtained (3.4) The Chemical Engineering Plant Cost Index (CEPCI) has been used since 1963, by professionals in chemical process industry to adjust process plant construction costs from one period to another [1]. The values used in this report are presented in Table 3.5.2. Table 3.5.2: Chemical Engineering Plant Cost Index (CEPCI) values [3]. Year CEPCI 1998 390 2002 396 2019 608 Scaling If the two pieces of equipment are not of the same size, the capacity has to be adjusted. The following formula can be used to predict the cost of a piece of equipment by using the cost of a similar piece of equipment [35]: Cost of equipment A = Cost of equipment B × X 0.6 (3.5) where X is the capacity ratio between the two pieces of equipment [35]. Cost components When the delivered equipment cost is determined, the other components of the capital investment cost can be estimated by using ratio factors between the capital investment items and the delivered equipment cost. This method is commonly used for study 28 CHAPTER 3. METHOD Table 3.5.3: Percentages of the delivered equipment cost for fluid processing plants [35]. Percentage of the delivered equipment cost (%) Direct costs Delivery of purchased equipment 10* Installation of purchased equipment 60* Instrumentation and controls (installed) 36 Piping (installed) 68 Electrical systems (installed) 15 Buildings (including services) 18 Yard improvements 10 Service facilities (installed) 6* Indirect costs Engineering and supervision 33 Construction expenses 41 Legal expenses 4 Contractor’s fee 22 Contingency 44 Working capital (15 % of TCI**) ­ * Percentage of purchased equipment. ** TCI ­ Total capital investment. estimates with an expected accuracy of ± 20 to 30 % [35]. In Table 3.5.3 the ratio factors are presented as percentages of the delivered equipment cost. 3.5.3 Life cycle costs and costs per unit reduction of SO2 emissions The life cycle costs includes the previously presented capital investment costs and operational costs, but also the cost of capital. A WACC (weighted average cost of capital) rate of 6 % was used in the calculations, which has previously been found reasonable for environmental investments at Rönnskär by Swedish authorities. The same calculations were also done for a 10 % rate which is a normal WACC for an investment in the production environment at Rönnskär (Personal communication with Peter Olsson, 4/2/2021). The economic lifetime was assumed to be 10 years and the capital investment costs were assumed to be paid at equal installments over the economic lifetime. Further, it was assumed that the economic lifetime is the same for all components of the scrubbers. 29 Chapter 4 Results and analysis 4.1 SO2 from secondary hood gases In Table 4.1.1 it can be seen that the potential SO2 from the secondary hood gases is significant and amounts for around 39 % of the SO2 that could be removed. As the flash tapping gases are expected to emit 780 tonnes of SO2 /year in the future, the total SO2 emissions from the flash tapping gases and the secondary hood gases would amount to 1060 tonnes/year, of which 26 % would be secondary hood gases. Table 4.1.1: SO2 emissions from the flash tapping gases and the secondary hood gases. The emissions are based on the period October 2019 ­ September 2020 for the flash tapping gases and for the period 16/12/2020 ­ 21/12/2020 for the secondary hood gases. Gas SO2 emissions (tonnes/year) Flash 445 Secondary hood 280 Total 725 4.2 Base case scenario results In this section, all the tabulated values are in the cases where only sulfates are produced in the reaction between SO2 and the reagent. The base case scenarios were based on process data from the 24/9/2020 as well as from the period 13/11/2020 ­ 17/11/2020 for the flash tapping gases and from the period 16/12/2020 ­ 17/12/2020 for the 30 CHAPTER 4. RESULTS AND ANALYSIS Table 4.2.1: Reagent consumption in the base case scenarios. Reagent (kg/h) NaOH (50 weight­%) Na2 CO3 H2 O2 (49 weight­%) CaO ZnO 260 170 115 90 130 secondary hood gases. The reagent consumption in the base case scenarios is listed in Table 4.2.1. 4.2.1 Equilibrium temperatures The equilibrium temperatures in the base case scenarios (see Table 4.2.2) do not vary much. The variations that are observed are associated with the differences in reaction enthalpies for the different reactions as well as the different water balances in the scrubbers. It can be noted that the lime scrubber’s equilibrium temperature is far below 60 ◦ C, which is needed for the lime scrubber to operate properly. Table 4.2.2: Equilibrium temperatures in the base case scenarios. Scrubber Equilibrium temperature (◦ C) Caustic soda & Soda ash Peroxide Lime Zinc oxide 20 23 19 20 4.2.2 Water balances The water balances are presented in Table 4.2.3. The bleeds were based on the solubilities in water for the caustic soda, soda ash and zinc oxide scrubbers meaning that a bleed and make­up smaller than the listed minimum values would lead to precipitation. For the peroxide scrubber the bleed was adjusted so that a 49 % H2 SO4 was produced and for the lime scrubber it was based on the belt filter that produces a 30 % solid. The reaction between Na2 CO3 and water in the soda ash scrubber is endothermic (31 400 kcal/h in the base case scenario) which makes the resulting NaOH/CO2 ­ solution cold (smaller than 0 ◦ C). To heat the mixture to at least 4 ◦ C, 38 kW heating of 31 CHAPTER 4. RESULTS AND ANALYSIS Table 4.2.3: Water balances in the base case scenarios if only sulfates were produced. Scrubber Evaporation Minimum bleed (m3 /h) (m3 /h) Minimum water added (m3 /h)* Caustic soda & Soda ash 2.76 0.78 3.54 Peroxide 2.32 0.23 2.55 Lime 2.90 0.57 3.47 Zinc oxide 2.68 0.45 3.13 * Includes both the make­up water and water from the reagent solutions. the tank is needed. The heating costs are included in the operational cost for the soda ash scrubber presented in Section 4.4.1. Another way to keep the temperature above 4 ◦ C would be to add the make­up water and an additional 2 m3 water/h to the reagent mixing tank. The latter option would also result in a larger bleed. The caustic soda and soda ash scrubbers require a minimum bleed of 0.63 m3 /h if all of the SO2 would be converted into Na2 SO3 . A belt filter is used for the lime scrubber as the bleed based solely on the solubility of CaSO4 would have been at least 160 m3 /h, which is unreasonably large. If only CaSO3 was formed, the bleed based on the solubility would be as large as 4660 m3 /h, while it is 0.47 m3 /h using the belt filter. As the zinc oxide scrubber produces ZnSO3 , it would require a belt filter as in the lime scrubber. This is because if only ZnSO3 was produced in the reaction between Zn(OH)2 and SO2 , the bleed based on the solubility would be 150 m3 /h. Using a belt filter that produces the same 30% solid as in the lime scrubber to separate the ZnSO3 , results in a bleed of 0.53 m3 /h. The biggest risk of accumulating impurities is in the peroxide scrubber as it has the smallest bleed. 4.2.3 Bleed compositions In Table 4.2.4 the bleed compositions for all base case scenarios are presented. The bleed for the caustic soda and soda ash scrubbers end up in RV1, the lime scrubber bleed ends up in a landfill (as the produced gypsum is not pure enough) and the zinc oxide scrubber bleed is reintroduced into the zinc smelting process. The peroxide bleed primarily ends up in the leaching plant, but as it is only in operation 340 days per year there has to be alternative solutions. 32 CHAPTER 4. RESULTS AND ANALYSIS Table 4.2.4: Bleed compositions in the base case scenarios. The rows with sulfites/sulfates represent the extreme cases were only sulfites or only sulfates were produced. Mass flow rate (kg/h) Caustic soda H2 O (l) NaOH (aq) Na2 SO3 (aq)/Na2 SO4 (aq) Soda ash H2 O (l) NaOH (aq) Na2 SO3 (aq)/Na2 SO4 (aq) CO2 (aq) Peroxide H2 O (l) H2 O2 (aq) H2 SO4 (aq) Lime H2 O (l) Ca(OH)2 (s) CaSO3 *0.5 H2 O (s)/CaSO4 *2 H2 O (s) Zinc oxide H2 O (l) Zn(OH)2 (s) ZnSO3 (s)/ZnSO4 (aq) 740 5 190/220 700 5 190/220 0.1 150 0.02 150 470 5 200/250 420 5 200/230 The alternative solutions are (in order): • Mixing the peroxide bleed into the sulfuric acid plant. • Not using the scrubber (the gases go through the converter filter where no SO2 is removed). • The peroxide bleed goes to RV1 where the H2 SO4 consumes NaOH. The bleed of the peroxide scrubber consists of a 49 % H2 SO4 , which is directly linked to the reagent H2 O2 with the same concentration. This can be compared to the 70­76 % used at the leaching plant. However, as the required H2 SO4 at the leaching plant (2300 kg/h) is many times larger than the scrubber’s bleed (300 kg/h), the bleed can be introduced to the leaching plant even though it has a lower concentration. 33 CHAPTER 4. RESULTS AND ANALYSIS 4.3 Tower design The design parameters for the packed towers are listed in Table 4.3.1 and the design is presented in Figure A.0.1 in Appendix A. The packing used is a 50 mm polypropene Hiflow ® ring with a void fraction of 94 % and a surface area of 90 m2 /m3 . The flooding factor is below the values found in the literature, but was chosen to have a reasonable liquid load and operating pressure drop. The design parameters for the open spray towers are also listed in Table 4.3.1 while the design is presented in Figure A.0.2 in Appendix A. An L/G ratio at the upper end of the values found in the literature was chosen for the open spray towers, as this was assessed to be needed to reach similar removal efficiencies as in the packed towers. Table 4.3.1: Tower design parameters for the packed towers and the open spray towers. Packed tower Packing Liquid flow rate (m3 /h) Volumetric L/G ratio (L/m3 ) Gas velocity (m/s) Flooding factor (%) Operational pressure drop (mbar/m) Packed height (m) Tank residence time (min) Tank volume (m3 ) Tank height (m) Open spray tower Liquid flow rate (m3 /h) Volumetric L/G ratio (L/m3 ) Gas velocity (m/s) Residence time (s) Height reactive section (m) Tank residence time (min) Tank volume (m3 ) Tank height (m) Hiflow plastic 50­6 770 2.5 2.2 40 1.9 4 5 65 2.2 4000 12.7 3 3 9 2 130 5.1 The heights of the other tower parts are listed in Table 4.3.2 while the tower dimensions are listed in Table 4.3.3. The latter table shows that even though the packed towers have a slightly larger diameter, the open spray towers have a larger volume due to their height. 34 CHAPTER 4. RESULTS AND ANALYSIS Table 4.3.2: Heights of other tower parts (the same for both packed and open spray towers). Part of the tower Height (m) Distance top ­ liquid distributor Distance liquid distributor ­ packing Distance gas inlet ­ packing Diameter gas inlet Distance gas inlet ­ tank 2 0.5 3.75 2.5 0.3 Table 4.3.3: Tower dimensions of the packed tower and the open spray tower. Packed tower Diameter (m) 7.0 Height (m) 15.2 3 Volume (m ) 590 Open spray tower 6.1 23.1 680 4.4 Costs The costs were based on the SO2 emissions during the period October 2019 ­ September 2020 for the flash tapping gases and the period 16/12/2020 ­ 21/12/2020 for the secondary hood gases. 4.4.1 Operational costs The reagent costs are listed in Table 4.4.1 and are as previously for the cases where only sulfates are produced. Table 4.4.1: Reagent costs for the different scrubber techniques. Scrubber Cost per year (SEK) Caustic soda Soda ash Peroxide Lime Zinc oxide 4 190 000 2 790 000 2 150 000 690 000 0 For the sodium­based scrubbers, the actual reagent cost is higher as the sulfites that are produced consume green liquor at RV1. If the whole bleed consists only of Na2 SO3 (190 kg/h) then 10 % of it would go to RV1 (90 % removed in the stripper) where it consumes 50 kg/h green liquor to the cost of 40 SEK/h (350 000 SEK/year). 35 CHAPTER 4. RESULTS AND ANALYSIS If the peroxide scrubber bleed would go to RV1 instead of going to the leaching plant or the sulfuric acid plant, the costs would increase with 6 440 000 SEK/year due to the use of caustic soda when H2 SO4 is neutralized at RV1. In Table 4.4.2 it can be seen that the pump power is much higher for the open spray towers due to a higher liquid flow rate, but also due to the extra power needed to spray in the recirculating slurry (as opposed to the packed towers where the recirculating liquid drains down from the liquid distributor). On the contrary the packed towers have slightly higher fan power costs due to the higher pressure drop in the packed towers. A cost of 150 000 SEK/year is added for the 39 kW heating in the soda ash scrubber. Table 4.4.2: Pump and fan power cost for the packed tower and open spray tower. Pumps Required shaft pump power (kW) Electricity per year (kWh) Cost per year (SEK) Fan Fan power (kW) Electricity per year (kWh) Cost per year (SEK) Packed tower Open spray tower 38 330 000 150 000 297 2 600 000 1 170 000 187 1 640 000 740 000 125 1 090 000 490 000 From Table 4.4.3 it can be concluded that the sodium­based scrubbers have the highest operating costs, while the open spray towers (lime and zinc oxide) have the lowest operating costs. Table 4.4.3: Total operating costs for the different scrubber techniques. Scrubber Total operational costs per year (SEK) Caustic soda Soda ash Peroxide Lime ZnO 5 080 000 3 830 000 3 040 000 2 350 000 1 660 000 4.4.2 Capital investment costs In Table 4.4.4 it can be seen that the purchased equipment costs are higher for the open spray towers due to a slightly larger tower volume and the larger pumps. This leads to 36 CHAPTER 4. RESULTS AND ANALYSIS the open spray towers having higher total capital investment costs which are presented in Table 4.4.5. Table 4.4.4: Purchased equipment costs for the packed tower and the open spray tower. Column shell Internals Pumps Fan Mixing/storage tank Total purchased equipment Packed tower costs (SEK) Open spray tower costs (SEK) 9 630 000 1 240 000 330 000 770 000 120 000 12 090 000 10 180 000 570 000 1 190 000 770 000 120 000 12 830 000 Table 4.4.5: Total capital investment costs for the packed tower and the open spray tower. Packed tower costs (SEK) Purchased equipment 12 090 000 Delivery of purchased equipment 1 210 000 Installation of purchased equipment 7 250 000 Instrumentation and controls (installed) 4 790 000 Piping (installed) 9 040 000 Electrical systems (installed) 1 990 000 Buildings (including services) 2 390 000 Yard improvements 1 330 000 Service facilities (installed) 730 000 Engineering and supervision 4 390 000 Construction expenses 5 450 000 Legal expenses 530 000 Contractor’s fee 2 930 000 Contingency 5 850 000 Working capital 8 450 000 Total capital investment 68 420 000 Open spray tower costs (SEK) 12 830 000 1 280 000 7 700 000 5 080 000 9 590 000 2 120 000 2 540 000 1 410 000 770 000 4 660 000 5 790 000 560 000 3 100 000 6 210 000 8 960 000 72 600 000 4.4.3 Life cycle costs and costs per unit reduction of SO2 emissions The costs in Table 4.4.6 include the previously presented operating costs and capital investment costs as well as the cost of capital. The results show that the sodium­ based scrubbers have the highest costs even if only sulfates were formed. The peroxide scrubber is the second cheapest if the bleed goes to the leaching plant, while it is the 37 CHAPTER 4. RESULTS AND ANALYSIS most expensive if the bleed goes to RV1. The same results for a 10 % WACC can be found in Table B.0.1 in Appendix B. Table 4.4.6: Life cycle costs and costs per unit reduction of SO2 emissions for a 6 % WACC during the 10 year economic lifetime. Caustic soda Only sulfates formed Only sulfites formed Soda ash Only sulfates formed Only sulfites formed Peroxide To leaching plant To RV1 Lime Zinc oxide Life cycle costs (SEK) Costs per unit reduction of SO2 emissions (SEK/kg reduction of SO2 emissions) 138 000 000 141 000 000 21 22 125 000 000 129 000 000 19 20 117 000 000 182 000 000 118 000 000 109 000 000 18 28 18 17 4.5 Further analysis In the further analysis, the use of process waters was evaluated for the different scrubbers. A sensitivity analysis, including the minimum and maximum SO2 scenarios as well as studying the costs to obtain different removal efficiencies, was conducted for the soda ash and peroxide scrubbers which were considered to have the most promising results. 4.5.1 Process water If process waters are used as make­up water in the scrubbers, an increased reagent use and cost is required to react with the SO2 in the process waters. As 90 % of the SO2 from the process waters would have been removed in the stripper, the green liquor use at RV1 reduces with 10 % when the process waters are used in the scrubber instead. This reduction does not occur if only sulfites are formed in the sodium­based scrubbers as the sulfites also consume green liquor at RV1. Further, the flash cooling process water contains H2 SO4 , which has to be neutralized in the alkaline scrubbers (all except the peroxide scrubber in which H2 SO4 is the product). The costs associated with the clinker scrubber process water and the flash cooling tower process water are presented in Table 4.5.1 and 4.5.2 respectively. The results in the tables are based on the data in 38 CHAPTER 4. RESULTS AND ANALYSIS Table 3.1.4 and represent the cases where only sulfates are formed in the scrubbers. The results show that the costs for removing SO2 are high for many scrubbers, while the costs are lower for neutralizing H2 SO4 in the scrubbers than at RV1. The latter is as all the scrubbers have cheaper reagents than the caustic soda that is used at RV1 for neutralizing H2 SO4 (expect the caustic soda scrubber). Table 4.5.1: Costs of using clinker scrubber process water in the scrubber. Scrubber SO2 removal cost (SEK/year) Caustic soda 790 000 Soda ash 540 000 Peroxide 330 000 Lime 130 000 Zinc oxide 0 Green liquor cost Total at RV1 (SEK/year) (SEK/year) ­ 60 000 ­ 60 000 ­ 50 000 ­ 60 000 ­ 50 000 730 000 480 000 280 000 70 000 ­ 50 000 Table 4.5.2: Cost of using flash cooling tower process water in the scrubber. Scrubber Caustic soda Soda ash Peroxide Lime Zinc oxide SO2 removal cost (SEK/year) 3 210 000 2 210 000 1 340 000 530 000 0 Green liquor cost at RV1 (SEK/year) ­ 240 000 ­ 250 000 ­ 200 000 ­ 240 000 ­ 220 000 H2 SO4 removal cost (SEK/year) 950 000 650 000 0 160 000 0 NaOH cost at RV1 (SEK/year) Total (SEK/year) ­ 950 000 ­ 980 000 ­ 770 000 ­ 960 000 ­ 880 000 2 970 000 1 630 000 370 000 ­ 510 000 ­ 1 100 000 4.5.2 Minimum and maximum SO2 scenarios The amount of Na2 CO3 added in the soda ash scrubber and 49 % H2 O2 added in the peroxide scrubber in the minimum SO2 scenarios were 2.4 kg/h and 1.6 kg/h respectively while they were 2370 kg/h and 1550 kg/h respectively in the maximum SO2 scenarios. Tables 4.5.3 and 4.5.4 show the equilibrium temperatures, water balances and bleed compositions for the soda ash scrubber and the peroxide scrubber. In the maximum SO2 scenario, the soda ash scrubber has a bleed size that would imply a significant load on RV1 while the H2 SO4 in the peroxide scrubber bleed has to be of a higher concentration in the maximum SO2 scenario if it is to be used in the leaching plant. The size of the peroxide bleed is also larger than what is used in the leaching plant. 39 CHAPTER 4. RESULTS AND ANALYSIS Table 4.5.3: The equilibrium temperatures and water balances in the minimum and maximum SO2 scenarios for the soda ash scrubber and for the peroxide scrubber. Soda ash Peroxide Minimum SO2 scenario Equilibrium temperature (◦ C) 13 13 3 Evaporation (m /h) 0.6 0.6 Minimum bleed (m3 /h) 0.1 0.006 3 Minimum water added (m /h)* 0.7 0.6 Maximum SO2 scenario Equilibrium temperature (◦ C) 31 39 3 Evaporation (m /h) 7.0 5.5 Minimum bleed (m3 /h) 8.9 3.1 3 Minimum water added (m /h)* 15.9 8.6 * Includes both the make­up water and water from the reagent solutions. Table 4.5.4: Bleed composition in the minimum and maximum SO2 scenarios for the soda ash scrubber and for the peroxide scrubber. The rows with sulfites/sulfates represent the extreme cases were only sulfites or only sulfates were produced. Minimum SO2 scenario Maximum SO2 scenario mass flow rate (kg/h) mass flow rate (kg/h) Soda ash H2 O (l) NaOH (aq) Na2 SO3 /Na2 SO4 (aq) CO2 (aq) Peroxide H2 O (l) H2 O2 (aq) H2 SO4 (aq) 80 0.1 2.2/2.4 0.0001 8350 70 2210/2490 20 3 0.000006 0.2 2200 36 2080 4.5.3 Costs to obtain different removal efficiencies Table 4.5.5: Cost differences between different removal efficiencies and the 90 % removal efficiency for the soda ash scrubber and peroxide scrubber. The changes in operational costs for the peroxide scrubber are in parenthesis in the last column. Removal efficiency (%) Change in packing height (m) Change in capital cost (SEK) 99 95 90 85 80 1.6 0.5 0 ­ 0.3 ­ 0.5 5 730 000 1 790 000 0 ­ 1 070 000 ­ 1 790 000 Change in soda ash scrubber operational cost (peroxide scrubber) (SEK) 280 000 (220 000) 160 000 (120 000) 0 ­ 160 000 (­ 120 000) ­310 000 (­ 240 000) 40 CHAPTER 4. RESULTS AND ANALYSIS At 91.2 % removal efficiency, the SO2 emissions are below the BAT­AEL (350 mg SO2 /m3 ) at all times, including the maximum SO2 scenario used in this report. Table 4.5.5 shows the cost differences for various removal efficiencies for the soda ash and peroxide scrubber. For removal efficiencies of 95 % and 99 % the costs increase with 2 % and 6 % respectively compared to the 90 % removal efficiency, while for removal efficiencies of 85 % and 80 % the costs decrease with 1 % and 2 % respectively compared to the 90 % removal efficiency. 41 Chapter 5 Discussion As the flash tapping occurs intermittently, part of the study was to investigate if the secondary hood gases could be taken into the scrubber to make use of the remaining capacity of the scrubber when flash tapping does not occur. The results show that the potential is high as at least 280 tonnes of SO2 /year could be cleaned from the secondary hood gases, which is also a significant amount in relation to the SO2 from the flash tapping gases. As emissions regulations have been and keep getting more stringent, Rönnskär has a possibility of creating an even bigger margin to the 3500 tonnes of SO2 emissions/year permit. And as previously stated, taking in secondary hood gases into the scrubber improves the working environment in the converter aisle. However, the use of secondary hood gases in the scrubber would imply an increased cost for piping as the converters are further away from the location of the proposed scrubber than the flash furnace. Controlling the two secondary hoods in operation in addition to the flash tapping would also make process control more complex. The two latter issues have not been investigated in this report. The sodium­based scrubbers have the highest operational costs, which could be even higher depending on the share of Na2 SO3 in the bleeds. The simplicity of the sodium­ based scrubbers could still make the soda ash, which is the cheaper of the two, worth considering. As the incoming gas streams have approximately the same concentrations of oxygen as ambient air, the maximum amount of Na2 SO3 is oxidized to Na2 SO4 in the scrubbers. To get a more precise cost estimate of the sodium­based scrubbers the equilibrium between sulfites and sulfates needs to be studied. 42 CHAPTER 5. DISCUSSION The peroxide scrubber is compatible with the flash cooling tower process water as it does not need to neutralize the H2 SO4 as in the other scrubbers. This is an advantage as it removes the neutralization cost of the flash cooling tower process water at RV1 without any added reagent cost. The peroxide scrubber also works well with the fluctuating flow of the incoming gas streams. The bleed from the peroxide scrubber was a H2 SO4 solution between 0.006­3.1 m3 /h. In the minimum and base case scenarios (0.23 m3 /h) the contribution was small compared to the total 70­76 % H2 SO4 used in the leaching plant (1.3 m3 /h on average) making the exact concentration of the bleed less important. However, in the maximum scenario the bleed size is larger (3.1 m3 /h) than the average need at the leaching plant which would require it to have the same concentration as the H2 SO4 used in the leaching plant. The excess bleed would also require intermediate storage or to be taken to the sulfuric acid plant. Another issue is that the leaching plant is only expected to operate 340 days/year during which the bleed has to be taken somewhere else. Due to the high cost of neutralizing the H2 SO4 in the peroxide scrubber in RV1, mixing the peroxide bleed into the sulfuric acid plant or pausing the use of the scrubber should be the alternative solutions considered before taking it to RV1. Yet another issue is that the peroxide bleed is the smallest among the scrubbers, meaning that it has the biggest risk of accumulating impurities from the various gas and water streams. If the peroxide bleed is to be used at the leaching plant, this would require a new pipeline to transport the H2 SO4 from the scrubber. The two latter issues have not been investigated in this report. The scrubbers operate at relatively low temperatures (13­39 ◦ C) which is positive for the solubility of SO2 in water. However, the temperatures are far from the optimal temperature range for the lime scrubber. Other disadvantages for the lime scrubber are the fluctuating flow rates and SO2 concentrations of the incoming gas streams and that Rönnskär preferred not to produce non­regenerative solid scrubbing products. Considering the disadvantages and the fact that the life cycle costs for the lime scrubber are higher than for the peroxide scrubber and only slighter lower than for the soda ash scrubber, it is unlikely that the lime scrubber is to be selected. The zinc oxide scrubber process is interesting as it has no reagent costs, which also gives the scrubber the lowest life cycle costs. The cost of treating the ZnSO3 and ZnSO4 before reintroducing it to the zinc smelting process is unknown and should be estimated if the zinc oxide technique is chosen for the proposed scrubber. It is also unknown which of the insoluble ZnSO3 or the soluble ZnSO4 is preferred as a product from the scrubber, 43 CHAPTER 5. DISCUSSION as this depends on the cost and feasibility of the treatment methods. There is limited literature regarding the zinc oxide scrubber, but as previously mentioned, there are a few zinc oxide FGD systems in operation from who Rönnskär could learn more. Especially regarding the issue of ZnO having low solubility in water. The bleed streams are all approximately 1 m3 /h in the base case scenarios which is a minor contribution when comparing it to the 160 m3 /h that RV1 handles on average and the 200 m3 /h that it is designed for. The maximum bleed values of, for instance, the soda ash scrubber (8.9 m3 /h) would however have a considerable impact. The use of process waters in the scrubbers has the advantage that the water load to RV1 decreases due to the evaporation in the scrubbers. The net reduction is even bigger if the bleed does not go to RV1 at all which is the case for the peroxide scrubber. The SO2 content in the process water leads to an increase in the reagent consumption and cost. In the meanwhile, the stripper currently removes 90 % of the SO2 that enters it. Therefore using process water in the scrubber leads to increased costs for Rönnskär as most of the SO2 would have been removed in the stripper for a much lower cost. Therefore, it is recommended to install a new stripper before the scrubber to remove the SO2 before it enters the scrubber to reduce reagent costs. On the other hand, neutralizing the H2 SO4 of the flash cooling tower process water in the scrubber instead of in RV1 leads to cost reductions as all scrubber reagents (except NaOH) are cheaper than the NaOH used for neutralizing H2 SO4 in RV1. This makes the flash cooling tower process water suitable for the proposed scrubber. However, it should be noted that the flash cooling tower only provides the scrubber with approximately 3 m3 process water/h, which would not be enough, for example, in the maximum cases where a larger amount of water is needed in the scrubber. In these cases, the process water would have to be used together with other water. Another process water that was not studied in this report is the flash scrubber process water, which contains less SO2 and more H2 SO4 than the flash cooling tower process water. From what has been learnt in this report, this process water could be interesting to study further to achieve even more cost reductions, especially with the peroxide scrubber. Based on the reasoning above, the clinker scrubber process water, that has a pH in the alkaline range, should not be used in the scrubber. Instead, it should go straight towards RV1 where it contributes in neutralizing the other process waters that are mainly acidic. The clinker scrubber process water is also high in fluorides and has 44 CHAPTER 5. DISCUSSION some chlorides, which means that there would be a risk of scaling and corrosion in the scrubber. Another disadvantage that the clinker scrubber process water has, is that the clinker furnace is located further away from the location of the proposed scrubber than the flash cooling tower, which would lead to higher piping costs. A removal efficiency of 91.2 % would be needed to have emissions below the BAT­AEL at all times, including the maximum SO2 scenario. As the BAT­AEL is stated as a daily average, Rönnskär has to evaluate how often the SO2 emissions will be close to the values in the maximum SO2 scenario in the future. Based on the data used in this report a 90 % removal efficiency would be enough to comply with the BAT­AEL, but it has to be monitored if this will be the case in the future as well. 45 Chapter 6 Conclusions and future work The aim of the project was to evaluate various scrubber techniques to remove SO2 from the flash tapping gases at Boliden Rönnskär. First, it was concluded that including the secondary hood gases in the scrubber was a suitable alternative to make use of the scrubber’s capacity and to reduce SO2 emissions further. Among the scrubbers, the peroxide scrubber evolved as an attractive alternative due to its suitability with the leaching plant and the flash cooling tower process water. It also had the lowest life cycle costs of the packed towers. The sodium­based scrubbers were the most expensive mainly due to their high reagent costs. However, due to the simplicity of the sodium­based scrubbers, the soda ash scrubber might still be worth considering. The open spray towers had the lowest operational costs, due to their low reagent costs, but also the highest capital costs. The lime scrubber had several disadvantages that made it unsuitable for the process gases and waters in question, while the zinc oxide scrubber had the issue of zinc oxide’s low solubility in water. As the zinc oxide scrubber had the lowest life cycle cost and could be integrated with the zinc smelting process, it should be investigated further. The use of process water in the scrubbers lead to a net reduction of process water to RV1 due to evaporation in the scrubbers. Further, it was cheaper (equally expensive for the caustic soda scrubber) to neutralize H2 SO4 in the scrubbers than in RV1, while it was more expensive to take care of SO2 in the scrubber compared to stripping. Therefore it is recommended to use the flash cooling tower process water in the scrubber together with a stripper unit before the scrubber to minimize the reagent costs. 46 CHAPTER 6. CONCLUSIONS AND FUTURE WORK For future work it is proposed to: • Perform a complete analysis of metals in the process gases and waters to evaluate the risk of scaling and corrosion. • Study the flash scrubber process water as it could reduce reagent costs even more than the flash cooling tower process water. • Study the process control of the different process gases and waters. • Study the sulfite/sulfate equilibrium to obtain more precise operational costs, if any of the sodium­based scrubbers or the zinc oxide scrubber is preferred. 47 Bibliography [1] Access Intelligence. The Chemical Engineering Plant Cost Index. https://www. chemengonline.com/pci-home. [Online; accessed 30­December­2020]. [2] Albrecht, Jan. “Revamp and Upgrade Possibilities in Sulphuric Acid Plants”. In: Procedia Engineering 138 (2016), pp. 184–198. DOI: 10.1016/j.proeng.2016. 02.076. [3] Bailie, Richard C., Whiting, Wallace B., Shaeiwitz, Joseph A., Turton, Richard, and Bhattacharyya, Debangsu. Analysis, Synthesis, and Design of Chemical Processes. eng. 1st ed. Pearson, 2018. ISBN: 9780134177403. [4] Boliden. Boliden Rönnskär. https : / / www . boliden . com / operations / smelters/boliden-ronnskar. [Online; accessed 5­November­2020]. [5] Boliden. Operations. https : / / www . boliden . com / operations. [Online; accessed 5­November­2020]. [6] Brännström, Per and Hedlund, Lennart. “Environmental improvements for Peirce­Smith converters with Outotec’s converter hood technology for primary and secondary gas capture”. In: Base Metals Conf. 2013, pp. 139–150. [7] Chemical Book. Calcium sulfite. https : / / www . chemicalbook . com / ChemicalProductProperty_EN_CB5874682.htm. [Online; accessed 12­February­ 2020]. [8] Cusano, Gianluca, Rodrigo Gonzalo, Miguel, Farrell, Frank, Remus, Rainer, Roudier, Serge, and Delgado Sancho, Luis. “Best available techniques (BAT) reference document for the non­ferrous metals industries”. In: Integrated Pollution Prevention and Control (2017). 48 BIBLIOGRAPHY [9] Davenport, William G., King, Matthew J., Rogers, Brian, and Weissenberger, Arne. “Sulphuric Acid Manufacture”. In: Southern African Pyrometallurgy 2006 International Conference. The Southern African Institute of Mining and Metallurgy, Johannesburg, South Africa. 2006, pp. 1–16. [10] DuPont. DynaWave ® case study no. 52 Zinc oxide reagent for SO2 reduction. https://cleantechnologies.dupont.com/fileadmin/user_upload/Editor/ CleanTechnologies / documents / PDFs / 53 - CASE - STUDY - 2012 - 07 - DuPont MECS-DynaWaveCS.pdf. [Online; accessed 2­November­2020]. 2012. [11] DuPont. Mecs ® DynaWave ® case study no. 54, Sulfuric acid plant tailgas scrubbing using zinc oxide. https : / / cleantechnologies . dupont . com / fileadmin/user_upload/Editor/CleanTechnologies/documents/PDFs/54DuPont-MECS_DynaWaveCS.pdf. [Online; accessed 2­November­2020]. 2015. [12] Emerson. Lime/Limestone Wet Scrubbing System for Flue Gas Desulfurization. https: / / www . emerson . com / documents / automation / application - data - sheet lime-limestone-wet-scrubbing-system-for-flue-gas-desulfurizationrosemount-en-68458.pdf. [Online; accessed 5­November­2020]. 2014. [13] Hanif, Muhammad Adli, Ibrahim, Naimah, and Jalil, Aishah. “Sulfur dioxide removal: An overview of regenerative flue gas desulfurization and factors affecting desulfurization capacity and sorbent regeneration”. In: Environmental Science and Pollution Research 27 (2020). DOI: 10.1007/s11356-020-091914. [14] Hifab. Environmental impact assessment (EIA) ­ regarding a leaching plant för F1/K1­dust etc. at Boliden Rönnskär’s industrial area (in Swedish). https: / / www . boliden . com / globalassets / operations / smelters / ronnskar / miljotillstand/bilaga- d_mkb_lakverket- ronnskar_180219.pdf. [Online; accessed 5­November­2020]. 2018. [15] IDC Technologies. Flue gas desulfurization. http : / / www . idc - online . com / technical _ references / pdfs / chemical _ engineering / Flue _ Gas _ Desulfurization.pdf. [Online; accessed 5­November­2020]. [16] Jones, D.M., Brandt, R., Nanda, A., and Piatkiewicz, A. “Environmental Upgrade at the Freeport McMoRan Miami Smelter”. In: Copper 2019, Vancouver, Canada. 2019. 49 BIBLIOGRAPHY [17] Joseph, Gerald T. and Beachler, David S. “415: Control of Gaseous Emissions”. In: Student Manual, US EPA, Research Triangle Park, NC (2000). [18] Joseph, Gerald T. and Beachler, David S. “Scrubber systems operation review”. In: APTI Course SI C 412 (1998). [19] Li, Gao, Li, Yuan, and He, Jun. “Intensifying effects of zinc oxide wet flue gas desulfurization process with citric acid”. In: Journal of Environmental Chemical Engineering 7 (2018). DOI: 10.1016/j.jece.2018.102831. [20] Loh, H., Lyons, Jennifer, and White, Charles. “Process Equipment Cost Estimation, Final Report”. In: (2002). DOI: 10.2172/797810. [21] Marsulex Environmental Technologies. Sodium hydroxide. http://www.met. net / wet - fgd - technologies - sodium - carbonate . aspx. [Online; accessed 5­ November­2020]. [22] METSIM International. Increase Your Production with METSIM. https : / / metsim.com/. [Online; accessed 2­November­2020]. [23] Metso. Metso Outotec och Neles. https://www.metso.com/se/metso-outotecoch-neles/. [Online; accessed 5­November­2020]. 2020. [24] Metso Outotec. About Metso Outotec. https://www.mogroup.com/company/. [Online; accessed 5­November­2020]. [25] Miller, Bruce. “Formation and Control of Sulfur Oxides”. In: 2017, pp. 467–506. ISBN: 9780128113653. DOI: 10.1016/B978-0-12-811365-3.00009-0. [26] Mussatti, David C. EPA Air Pollution Cost Control Manual: 6th edition. eng. 2002. [27] National Institute of Standards and Technology. Zinc sulfite. https://srdata. nist . gov / solubility / IUPAC / SDS - 26 / SDS - 26 - pages _ 271 . pdf. [Online; accessed 12­February­2020]. [28] National Library of Medicine. Calcium sulfate. https://pubchem.ncbi.nlm. nih.gov/compound/Calcium-sulfate. [Online; accessed 12­February­2020]. [29] National Library of Medicine. Sodium sulfate. https : / / pubchem . ncbi . nlm . nih.gov/compound/Sodium-sulfate. [Online; accessed 12­February­2020]. [30] National Library of Medicine. Sodium sulfite. https : / / pubchem . ncbi . nlm . nih.gov/compound/Sodium-sulfite. [Online; accessed 12­February­2020]. 50 BIBLIOGRAPHY [31] National Library of Medicine. Sulfuric acid. https://pubchem.ncbi.nlm.nih. gov/compound/Sulfuric-acid. [Online; accessed 12­February­2020]. [32] National Library of Medicine. Zinc sulfate. https://pubchem.ncbi.nlm.nih. gov/compound/Zinc-sulfate. [Online; accessed 12­February­2020]. [33] Nelson, L.R. and Hundermark, R.J. “The tap­hole ­ key to furnace performance”. en. In: Journal of the Southern African Institute of Mining and Metallurgy 116 (2016), pp. 465–490. ISSN: 2225­6253. [34] Papiya, Roy and Sardar, Arghya. “SO2 Emission Control and Finding a Way Out to Produce Sulphuric Acid from Industrial SO2 Emission”. In: Journal of Chemical Engineering Process Technology 06 (2015). DOI: 10 . 4172 / 2157 7048.1000230. [35] Peters, Max S., Timmerhaus, Klaus D., and West, Ronald E. Plant design and economics for chemical engineers. Vol. 4. McGraw­Hill Companies, 2003. [36] Renström, Kristoffer. “CSK­stripperns reningsgrad samt påverkan på Reningsverkets grönlutsförbrukning 2019­2020”. In: (2020). [37] RVT Process Equipment. Rapsody ™. https://www.rvtpe.com/global/en/ news-media/software. [Online; accessed 30­December­2020]. [38] Schlesinger, Mark E., Sole, Kathryn C., and Davenport, William G. Extractive Metallurgy of Copper. eng. 5th ed. London: Elsevier, 2011. ISBN: 9780080967899. [39] Schnelle, Karl B. and Brown, Charles A. Air pollution control technology handbook. eng. Mechanical engineering handbook series. Boca Raton, FL: CRC Press, 2002. ISBN: 0­8493­9588­7. [40] Söderman, Tom. Garpenberg. https : / / www . boliden . com / globalassets / investor- relations/reports- and- presentations/capital- markets- day/ 2011/cmd/5- garpenberg- an- introduction- tom- soderman- mine- managergarpenberg.pdf. [Online; accessed 5­November­2020]. 2011. [41] Swedish Environmental Protection Agency. Facts about SO2 in Air (in Swedish). http : / / www . naturvardsverket . se / Sa - mar - miljon / Klimat - och - luft / Luftfororeningar/Svaveldioxid/. [Online; accessed 5­November­2020]. 51 BIBLIOGRAPHY [42] Swedish Environmental Protection Agency. Sulfur dioxide (SO2). https : / / utslappisiffror . naturvardsverket . se / en / Substances / Other - gases / Sulfur-dioxide/. [Online; accessed 5­November­2020]. [43] Valle­Zermeño, Ricardo del, Formosa, Joan, and Chimenos, Josep Maria. “Wet flue gas desulfurization using alkaline agents”. eng. In: Reviews in chemical engineering 31.4 (2015), pp. 303–327. ISSN: 0167­8299. 52 Appendix A Tower design figures Figure A.0.1: Packed tower design. Figure A.0.1 and Figure A.0.2 show the tower designs of the packed towers and open spray towers respectively. The figures of both towers are drawn to scale, while the equipment outside the tower (pumps, fans etc.) are not. 53 APPENDIX A. TOWER DESIGN FIGURES Figure A.0.2: Open spray tower design. 54 Appendix B Life cycle costs and costs per unit reduction of SO2 emissions (10 % WACC) Table B.0.1: Life cycle costs and costs per unit reduction of SO2 emissions for a 10 % WACC during the 10 year economic lifetime. Reagent Caustic soda Only sulfates formed Only sulfites formed Soda ash Only sulfates formed Only sulfites formed Peroxide To leaching plant To RV1 Lime Zinc oxide Life cycle costs (SEK) Costs per unit reduction of SO2 emissions (SEK/kg reduction of SO2 emissions) 150 000 000 154 000 000 23 24 138 000 000 141 000 000 21 22 130 000 000 194 000 000 131 000 000 122 000 000 20 30 20 19 55