The Future of Heating with Open Coil and Tubular Technology!

advertisement

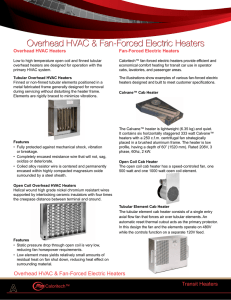

MAXIMIZING HEAT OUTPUT: THE BENEFITS OF OPEN COIL AND TUBULAR HEATERS! Introduction In the realm of industrial heating solutions, two prominent options stand out: open coil heaters and tubular heaters. Both play vital roles in various applications, each with its unique advantages. Understanding their benefits is crucial for maximizing heat output efficiently. UNDERSTANDING OPEN COIL HEATERS Open coil heaters, also known as resistance coil heaters, consist of an electrically conductive wire wound into a coil shape. These coils are typically made from alloys such as nickel-chromium (Nichrome) or iron-chromium-aluminum (FeCrAl), renowned for their high resistivity and durability. Key Features of Open Coil Heaters Versatility in applications Rapid heat transfer capabilities Cost-effective heating solution Easy to customize for specific requirements EXPLORING TUBULAR HEATERS MANUFACTURERS Tubular heaters Manufacturers, as the name suggests, feature a tube-like structure typically made of metals like stainless steel or Incoloy. Inside these tubes, a heating element, usually a resistance coil or a straight rod, generates heat when electricity passes through it. Advantages of Tubular Heaters i. Excellent uniform heating distribution ii. High-temperature capabilities iii. Corrosion resistance iv. Suitable for high-pressure environments Comparing Open Coil and Tubular Heaters When deciding between open coil and tubular heaters, several factors come into play. Understanding the differences helps in selecting the most suitable option for specific heating requirements. Heat Transfer Efficiency Open coil heaters are renowned for their rapid heat transfer capabilities. The exposed coil design allows for quick heating, making them ideal for applications requiring immediate heat output. On the other hand, tubular heaters provide uniform heating along their entire length, ensuring consistent temperature distribution. Customization and Versatility Open coil heaters offer greater flexibility in customization due to their coil design. Manufacturers can adjust parameters such as coil diameter, length, and spacing to tailor the heating element to specific applications. Tubular heaters, while less customizable in shape, excel in applications requiring precise temperature control and uniform heating. Durability and Longevity Both open coil and tubular heaters boast impressive durability. However, the choice of material and design can influence their longevity. Open coil heaters may be more susceptible to damage from physical stress or corrosive environments due to their exposed coil design. Tubular heaters, with their enclosed heating elements, offer enhanced protection against external factors, thus extending their lifespan. Applications of Open Coil and Tubular Heaters The versatility of open coil and tubular heaters makes them indispensable in various industries and applications. Open Coil Heater Applications i. HVAC systems ii. Industrial ovens and dryers iii. Packaging machinery iv. Plastic molding equipment v. Food processing industries vi. Tubular Heater Applications vii. Chemical processing viii. Oil and gas refineries ix. Pharmaceutical manufacturing x. Water heating systems xi. Automotive industry Conclusion In conclusion, both open coil and tubular heaters offer distinct advantages in maximizing heat output for diverse industrial applications. While open coil heaters excel in rapid heat transfer and versatility, tubular heaters provide uniform heating and durability. Understanding the specific requirements of each application is essential in selecting the most suitable heating solution. Source Blog:https://open.substack.com/pub/heatersandsensors/p/maximizi ng-heat-output-thebenefits?r=3npfnb&utm_campaign=post&utm_medium=web& showWelcomeOnShare=true