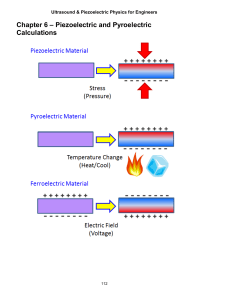

Journal Pre-proof Activation of ferroelectric implant ceramics by corona discharge poling Magnus Rotan, Mikalai Zhuk, Julia Glaum PII: S0955-2219(20)30528-8 DOI: https://doi.org/10.1016/j.jeurceramsoc.2020.06.058 Reference: JECS 13385 To appear in: Journal of the European Ceramic Society Received Date: 31 January 2020 Revised Date: 19 June 2020 Accepted Date: 21 June 2020 Please cite this article as: Rotan M, Zhuk M, Glaum J, Activation of ferroelectric implant ceramics by corona discharge poling, Journal of the European Ceramic Society (2020), doi: https://doi.org/10.1016/j.jeurceramsoc.2020.06.058 This is a PDF file of an article that has undergone enhancements after acceptance, such as the addition of a cover page and metadata, and formatting for readability, but it is not yet the definitive version of record. This version will undergo additional copyediting, typesetting and review before it is published in its final form, but we are providing this version to give early visibility of the article. Please note that, during the production process, errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain. © 2020 Published by Elsevier. Activation of ferroelectric implant ceramics by corona discharge poling Magnus Rotan, Mikalai Zhuk, Julia Glaum* Department of Materials Science and Engineering, Norwegian University of Science and Technology, Trondheim, Norway Address: K2-102, Sem Sælands vei 12, 7034 Trondheim, Norway -p Phone: +47 73593983 ro of *corresponding author: Julia Glaum, e-mail address: julia.glaum@ntnu.no Abstract re Ferroelectric ceramics show great potential for medical implants to augment bone regeneration and lP improve implant fixation. To induce an overall piezoelectric response prior to implantation, a clean, contact-less and non-line-of-sight electrical poling method is preferred to allow poling of arbitrarily na structured scaffolds without the need for electrodes or insulating liquids. A feasibility study was conducted on the use of corona discharge, which is a contact-less poling method operating in air, to piezoelectrically activate (Ba,Ca)(Zr,Ti)O3 (BCZT), (K,Na)NbO3 (KNN) and commercial Pb(Zr,Ti)O3 (PZT) ur ceramics. While both PZT and BCZT are readily poled by the corona technique, KNN requires a high Jo electric field and an extended poling period to activate its piezoelectric potential. Comparing the poling characteristics of samples with and without electrodes revealed that the same degree of poling can be achieved. These results highlight that corona discharge is a feasible method to pole piezoelectric ceramics intended for biomedical applications. Keywords: Piezoelectric ceramics, Biomedical application, Corona discharge poling 1. Introduction The unique property of ferroelectric materials – their ability to transform a mechanical deformation into an electric signal and vice versa – is exploited in many applications, ranging from ultrasound devices to buzzers in mobile phones [1]. As many types of cells are sensitive to electric stimulation, increasing research efforts are put into the development of piezoelectric scaffolds and implants that could supply such charges at a certain location in vivo without the need for an external power source. The development of surface charges can either be achieved through ultrasound stimulation or simply ro of through the mechanical load applied by the body itself, e.g. during walking. Such devices might enhance the lifetime of implants by increasing the adhesion between natural tissue (e.g. neural or bone cells) and artificial material, thus reducing the recovery time and health care cost following a -p surgical intervention [2,3]. re When considering new materials for in vivo applications, it is essential that they are non-toxic. In the past decade, due to legislation and restriction on the use of hazardous elements, large effort has been lP put into finding acceptable replacements for the commercially used lead-based piezoelectric materials [4-8]. Among these, BaTiO3- and (K,Na)NbO3-derivatives appear to be the most promising [2, 8-14]. na Apart from toxicity concerns, the materials must express a macroscopic piezoelectric response to be able to generate a net surface charge during mechanical straining. After sintering, the ferroelectric ur domains of a polycrystalline ceramic are randomly oriented and need to be aligned by a sufficiently high electric field for the material to exhibit a macroscopic piezoelectric coefficient. In industrial Jo fabrication, this step is conducted in a heated oil bath, where the oil prevents dielectric breakdown of the surrounding medium [1]. However, for biomedical applications, it is crucial to avoid any foreign substances that are not biocompatible as this would jeopardize the livability of the implant and would ultimately be toxic to the body. Furthermore, complex shapes necessary to meet the design specifications of implants introduce challenges for poling by the conventional procedure where two oppositely charged electrodes are needed in order to create an electric field. Exploring alternatives that yield sufficiently high piezoelectric coefficients while operating in air, preferably without electrodes and being applicable for non-flat surfaces are therefore of interest. In this study, the potential of utilizing corona discharge to pole ferroelectric ceramics intended for biomedical applications was investigated. Corona discharge poling (CDP) is a non-contact method that allows the alignment of ferroelectric domains by application of a large electric field extending between a sharp tip electrode and a grounded plate on which the piezoelectric sample is placed. In this process ro of a secondary, effective field arises across the sample as ions are produced around the corona electrode and led onto the sample surface. Two lead-free ferroelectric ceramic systems – (Ba,Ca)(Zr,Ti)O3 and (K,Na)NbO3 - were compared to a commercial Pb(Zr,Ti)O3 (PZT) ceramic. Polarization (P), strain (S) -p and piezoelectric coefficient (d33) hysteresis loops were determined to distinguish the characteristics of the three compositions and to establish a basis for comparison with samples poled by the corona re technique. To investigate the influence of sample surface electrodes on the piezoelectric and compared. Experimental na 2. lP characteristics established during CDP, samples with and without deposited electrodes were poled For the synthesis of Ba0.9Ca0.1Zr0.1Ti0.9O3 (BCZT), powders of BaCO3 (99.98%; Sigma Aldrich), CaCO3 ur (99.0%; Sigma Aldrich), TiO2 (99.99%; Sigma Aldrich) and ZrO2 (99.978%, Alfa Aeasar) were dried and mixed in stoichiometric amounts prior to milling for 24 hours in 96% ethanol using 5mm zirconia balls Jo as grinding media. Powders were then dried, sieved (250 µm sized mesh) and further pressed into 25 mm diameter disks applying 40 MPa in a uniaxial press. Disks were calcined in a cylindrical zirconia crucible with a half-closed lid placed in a chamber furnace at 1300 °C for 2 hours using 350 °C/h and 400 °C/h as heating and cooling rate, respectively, before crushing them and repeating the milling, drying and sieving procedure. The final samples were achieved by pressing the calcined powder uniaxially into 10 mm diameter disks at 100 MPa before sintering. Sintering was done in Pt crucibles covered with an alumina lid leaving a 1-2 mm gap at 1400 °C for 6 hours partially covered in a bed of sacrificial powder using the same heating and cooling rate as for the calcination. Raw spray pyrolyzed K0.5Na0.5NbO3 (KNN) powder (CerPoTech, Norway) was milled for 24 hours in 100% ethanol before drying and calcination in an alumina crucible at 650 °C for 5 h using 180 °C/h and 600 °C/h as heating and cooling rate, respectively. Subsequently, the powders followed the same preparation procedure as the one for BCZT. Pressed pellets were sintered completely covered in a bed of sacrificial powder in alumina crucibles with an almost closed lid (1-2 mm gap). Sintering was ro of executed at 1125 °C for 2 h using 300 °C/h and 600 °C/h as heating and cooling rate, respectively. Sintered pellets of both BCZT and KNN were ground from both sides down to approx. 1 mm thickness using P1200 grit SiC paper and cleaned in an ultrasonic bath using ethanol for 10 minutes before they -p were dried at 100 °C for 24 h. re Commercially available PIC151 PZT (10 mm diameter, 1 mm thickness; PI Ceramics, Germany) were received both with co-fired silver electrodes and without. Samples without electrodes were polished lP with P1200 grit SiC paper to achieve the same surface roughness as the other two compositions prior to corona poling. na For micrograph imaging samples of all three compositions were polished down to 1 µm finish using diamond spray followed by different etching procedures for each material. BCZT was chemically ur etched in a of solution deionized water and 37% hydrochloric acid (1:1 ratio) for 30 s and subsequently thermally etched at 1300 °C for 5 min using 600 °C/h as heating and cooling rate. KNN was only Jo thermally etched at 1070 °C for 7 min using 600 °C/h as heating and cooling rate. PZT was solely chemically etched for 15 s in a solution of deionized water and hydrochloric acid (1:19 ratio) with 5 drops (≈ 0.25 ml) of hydrofluoric acid added. The densities of BCZT and KNN were measured according to the Archimedes principle using ISO5017:2013 [15]. Micrographs of the grain microstructure of the samples were obtained using a Zeiss Ultra 55 scanning electron microscope (SEM) (Carl Zeiss AG, Germany). Grain size measurements were performed following a linear intercept method using the Lince software (Lince 2.4.2, Ceramics Group, TU Darmstadt, Germany). At least 100 intersections were measured for the three compositions and expressed as mean value and standard deviation. Gold electrodes were deposited on the BCZT and KNN samples on each side of the pellet. The deposition was conducted in 0.1 bar Argon atmosphere for 1 min using Edwards S150B sputter coater ro of (Edwards, UK). An in-house corona discharge single tip electrode setup similar to the one described by Waller et al. was utilized to pole the samples [16]. The point electrode was a cylindrical copper needle (28 mm in -p length and 5 mm in diameter) with a conical ending of 8 mm length and capped with a hemispherical re tip with a radius of curvature of 150 µm. A schematic of the corona setup is given in Figure 1. An IKA C-MAG HP4 hotplate (IKA®-Werke GmbH & Co. KG, Germany) was used to heat the samples and a K- lP type thermocouple (PeakTech Prüf- and Messtechnik, Germany) was used to verify the equilibrium temperature of the sample surface prior to poling. The poling was conducted in a single step ramp-up na of the DC voltage using less than 1 s to reach the setpoint for BCZT and PZT, whereas 3 s was used for KNN. After poling, the specimens were removed from the hotplate and placed on a room temperature ur steel plate for quick dissipation of heat. The piezoelectric coefficient d33 of the corona poled samples was measured by the direct method on Jo a YE2730A d33 -meter (Sinocera Piezotronics Inc., China) applying 0.25 N at 100 Hz. Each sample was measured on both sides and the average of the absolute value was noted. Samples poled without electrodes were coated with gold electrodes prior to d33 -measurements. The polarization and strain hysteresis loops were recorded at 1 Hz using a TF Analyzer 2000 (aixACCT, Germany). The piezoelectric coefficient d33, determined by the converse effect, was measured using the TF Analyzer’s small signal capacitance versus voltage (CV) function. The small signal frequency was 1000 Hz, and the vibration amplitude 3 V/mm for PZT and BCZT, 30 V/mm for KNN. 3. Results 3.1 Microstructure Scanning electron micrographs of PZT, BCZT and KNN are displayed in Figure 2 with their respective ro of characteristics given in Table 1. For PZT, a dense and homogeneous microstructure can be observed. The BCZT ceramic exhibits the largest grain size of all three compositions and its relative density underlines the dense microstructure observed in the micrograph. Large grain size and high density are -p quite common for solid state synthesized BCZT [17, 18]. KNN reveals a much smaller average grain size compared to the other two compositions, however, some abnormal grain growth is observed as well, lP re which is commonly reported for this system [19, 20]. 3.2 Ferroelectric hysteresis loops na Polarization and strain as a function of electric field alongside their respective d33 loops are given in Figure 3 for all compositions. Measurements were performed at selected temperatures below the ur individual Curie temperatures (Table 2). All compositions exhibit well-developed hysteresis loops although with different appearances. Selected characteristics are extracted and plotted in Figure 4. Jo The commercial PZT ceramics exhibit the highest remanent and maximum polarization, the highest maximum and remanent strain as well as the highest piezoelectric response at room temperature (Figure 3 a)-c)). The main characteristics of these hysteresis loops are stable up to at least 80 °C, whereas at 200 °C a considerable reduction in the coercive field, maximum and remanent polarization and negative strain is seen. In contrast to that, the remanent piezoelectric coefficient is persistent at this temperature (Figure 3 c)). Compared to PZT, BCZT exhibits a rather small coercive field that is stable in the measured temperature range (Figure 3 d)-f)). The remanent polarization is about a third of that of PZT at room temperature and continuously decreases with increasing temperature. The remanent piezoelectric coefficient demonstrates an increase at 50 °C followed by a slight decrease at 70 °C. This observation can be explained by the presence of a phase transition around 55 °C giving rise to more rotational freedom of the electric dipoles [22-24]. KNN required the highest electric field to reach polarization saturation and in addition exhibits the ro of lowest strain and the lowest piezoelectric coefficient of the three compositions (Figure 3 g)-i)). The coercive field decreases only slightly within the measured temperature range, whereas the maximum and remanent polarization increase. -p The characteristic shape of the polarization loop becomes more rounded as the temperature increases, which can be rationalized by an increase in leakage current. These leakage currents might re contribute to the development of the asymmetric appearance of the strain hysteresis loops with lP increasing temperature through charge accumulation. The remanent piezoelectric coefficient of KNN increases slightly with temperature and reaches a maximum around 200 °C, which can be associated 3.3 na with the known phase transition from orthorhombic to tetragonal crystal structure [7]. Corona discharge poling ur The impact of corona discharge poling on the achieved piezoelectric coefficient depends on several parameters: voltage, corona electrode distance, radius of the electrode tip, sample thickness, Jo temperature and time under the corona [25, 26]. To evaluate the influence of the different variables and to optimize the poling procedure for the individual material systems investigated, a wide parameter space was investigated (Table 2). It is well known that poling is facilitated at higher temperatures due to increased domain wall mobility. A set of temperatures in the range up to the Curie temperature was therefore selected for the study [27-30]. For BCZT a poling temperature of 80 °C was deemed too close to TC as large scattering was observed in the obtained d33 values and hence 70 °C was chosen as the highest temperature. KNN, having a high coercive field and a relatively high TC, proved hard to pole leaving a limited parametric exploration space. 330 °C was chosen as a limit for the highest temperature. Additionally, a high voltage in combination with a short corona electrode distance, required the voltage to be ramped slower compared to BCZT and PZT (in 3 s up to the maximum voltage as opposed to < 1 s for the other compositions) to avoid instant sparking from the corona electrode. ro of Corona discharge poling was performed on pristine PZT (co-fired silver electrodes), BCZT and KNN (both with sputtered gold electrodes) and the measured d33 (determined by the direct method) as a function of the applied voltage during poling is shown in Figure 5. The average value taken from three -p separate specimens is plotted with standard deviation. Concerning PZT, d33 increases with increasing poling voltage for all temperatures (Fig. 5 a)), periods re (Fig. 5 b)), and corona electrode distances (Fig. 5 c)) before leveling at a maximum of 610 pC/N. For lP samples poled at 200 °C (Fig. 5 a)), the maximum d33 is less than for those poled at 80 °C and 22 °C. As expected, the piezoelectric coefficient increases with increasing time under the corona (Fig. 5 b)) and with decreasing distance between specimen and corona electrode (Fig. 5 c)). For the highest na voltages, a high surface charge sometimes resulted in discharges in the form of sparks. However, the ur samples showed no physical sign of a dielectric breakdown post poling. For BCZT, a small reduction in d33 was observed in the first few seconds after inserting each sample Jo into the d33- meter. It has been reported that the piezoelectric performance of BCZT is quite susceptible to mechanical loading and already low forces can lead to some reduction of the piezoelectric coefficient [33]. For consistency, readings were, therefore, taken 10 s after insertion. The results are plotted in Figure 5 d) and e). BCZT reaches saturated d33 values already after 1 min at 20 kV both for low and high temperatures. An increase in standard deviation is observed at 15 and 20 kV demonstrating little difference between samples poled at room temperature and at 70 °C. No significant difference is seen for 1-, 3- and 5- minutes poling at 70°C and 15 kV or above (Fig. 5 e)). 4. Discussion 4.1 Corona discharge poling vs. traditional poling ro of As the switching of ferroelectric domains is a stochastic process with the probability for a distinct switching event increasing with time and electric field applied [34-38], poling in general is expected to be more efficient for longer poling times and higher fields applied. While the piezoelectric coefficient -p of all compositions follows these trends (Figure 5), there are distinct differences due to the variation in the poling dynamics related to their inherent properties. BCZT, having the smallest coercive field of re the three, requires the shortest time and the lowest field to reach polarization saturation. KNN on the lP other hand requires high field, short electrode distance and long time to pole due to its higher resistance towards ferroelectric switching as expected by the high coercive field. na While the general dependencies between the poling parameters and the developed piezoelectric coefficients are similar for samples poled via corona discharge and via conventional poling, ur achievement of the saturated poling state happens on different time scales. For the two techniques, a comparison of the time dependency of the polarization development is difficult because longer time Jo is required to build up the effective electric field acting on the samples in the CDP method. For all the samples investigated, the hysteresis loops obtained in the conventional way show that saturated polarization was achieved during a single loop measurement, which means that ferroelectric switching occurred within ¼ of a second at their respective maximum electric fields (Fig. 3). However, the effective field acting on the samples during CDP is more difficult to predict. For PZT, fully polarized samples were obtained after 60 s for sufficiently high voltages indicated by the plateau reached in the measured d33 values (Fig. 5). An estimate of the electric field that is experienced by the samples and its development over time during corona poling can be made by comparing the present data to those of Zhukov et al. who investigated the development of polarization for PZT as a function of time and applied field in a conventional electrode-wired configuration [34]. The d33 values of PZT poled by corona discharge at different voltages, 80 °C and 5 cm distance (Fig. 5 b)) are normalized (d33/d33,max, with d33,max being the highest values for each composition in Fig. 5 b)) and plotted together with the normalized data of Zhukov (d33/d33-max) in Figure 6. It should be noted that from Figure 3, it was ro of observed that the coercive field at 80 °C is essentially the same as at room temperature where the data of Zhukov were recorded. Samples that were poled under the corona at 6 kV do not show any piezoelectric response even after 5 min and it can be argued that the accumulated surface charge was -p not sufficient to produce a field in the range of the composition’s coercive field (0.93 kV/mm). Using the same argument, at 10 kV, the charge accumulates to a surface potential creating a field between re 0.7 and 0.8 kV/mm in the time frame of 1-5 minutes demonstrating a rather slow build up at this corona potential. After 3 min at 20 kV the effective field has clearly exceeded the coercive field and lP saturation in the polarization is reached. In this range, however, the exact surface potential is hard to estimate as all potentials above the coercive potential lead to saturation of d33 after 1 minute. na The polarization loops in Figure 3 a) and d) suggest that leakage currents during poling are low for both PZT and BCZT. It is therefore reasonable to assume that charges are accumulated in a similar way ur and, hence, similar surface potentials are obtained during the corona charging of the two compositions. Because the coercive field for BCZT is much lower than for PZT, the saturation Jo polarization is reached in an even shorter time as seen in Figure 5 e). However, considering the low coercive field, one would expect that the corona would produce saturated polarization and a leveling in the d33 at even lower voltages than what is observed. For example, as in the argument above, 1 minute at 10 kV resulted in an electric field of at least 0.7 kV/mm over the sample. The coercive field of BCZT at this temperature is approximately 0.13 kV/mm (Fig. 4 b)), meaning that the poling field is more than five times the coercive field. This should be more than sufficient to pole the BCZT ceramics to saturation. It has, however, been recognized that the poling mechanism in BCZT is somewhat different from PZT and that the temporal development of domain realignment is of a slower character [37, 38]. Higher fields are therefore necessary to achieve saturated polarization in short times for BCZT. In the case of KNN it was expected that poling would be more difficult compared to PZT and BCZT due to its higher coercive field. In addition to that, the polarization loops in Figure 3 give evidence of a significant leakage current during electric field application, indicating that the surface does not ro of accumulate sufficient charge during corona poling in order to create a field strong enough to fully polarize the samples within 30 minutes. This is supported by the observation that even at the highest voltage applied, no dielectric breakdown of the air around the sample was observed. The dielectric -p strength of air is reported to be around 3 kV/mm in atmospheric conditions [35] and for PZT and BCZT, prolonged corona charging resulted in timely sequenced sparks going between the sample surface re and the ground plate. For poling of KNN this was not observed, neither at high temperatures nor for preliminary low- and intermediate- temperature experiments. It should be noted that other factors lP such as air density, humidity and shape of electrode also influence the breakdown potential of air, but these factors were consistent for all experiments conducted. Electroded vs. non-electroded samples na 4.2 ur For the purpose of biomedical implantation, implants should contain as few foreign substances as possible to prevent unwanted side effects. Omitting the steps of electrode deposition from the Jo manufacturing process would reduce this risk and also the cost of production. For these reasons, the possibility to pole piezoelectric implants without the need for electrodes is of high interest. The present results show that PZT, BCZT and KNN all display approximately the same piezoelectric performance whether the samples were poled with or without electrodes using the corona discharge method (Table 3). While in the conventional procedure the electric charges are distributed through the highly conductive electrodes giving rise to a homogeneous electric field throughout the sample disks, for non-electroded and highly insulating ceramics, charges deposited on the surface have low mobility, which hinders the formation of a uniform surface potential. The corona process must therefore make sure that charges are deposited in a uniform manner to ensure proper poling of the whole specimen. Extensive research has been carried out on the corona discharge method in order to describe the electric field surrounding the corona tip, the charge transport, current density profiles, surface potentials and ro of discharge currents for different setups [26, 40-43]. In the early work of Warburg, it is described that the current density in both positive and negative point-to-plane coronas is distributed over the plane according to what is now known as the Warburg distribution [40]. Figure 7 presents the Warburg distribution as calculated for different applied voltages and 5 cm corona electrode distance. It is -p obvious that for using sample disks with a radius of 0.5 cm as used in the present study, a uniform re distribution of charges across the surface is established, which is in line with our observation that electroded and non-electroded samples exhibit the same piezoelectric performance after poling. For lP practical applications, however, where larger samples or non-flat surfaces need to be poled, care must Conclusion ur 5. na be taken to assure a uniform surface potential. Two piezoelectric material systems, BCZT and KNN, that have received much attention for their Jo potential as active implant materials, were compared to commercial PZT. While both PZT and BCZT are readily poled by the corona technique, KNN was found to be more reluctant and thus a high electric field and an extended period of time had to be used to achieve a decent piezoelectric response. This difference in poling behavior is attributed to the high coercive field as well as the significant conductivity of the KNN samples studied, which hindered the proper development of an electric field across the samples. Comparing the piezoelectric response between electroded and non-electroded samples poled by the corona technique, led to the conclusion that under the experimental conditions used, electrodes are not needed to achieve optimal piezoelectric performance. This work shows that the corona technique can be successfully employed to pole lead-free piezoelectric ceramics without the use of electrodes or insulating liquids, which makes it a very promising tool in the context of biomedical applications. Declaration of interests The authors declare that they have no known competing financial interests or personal relationships ro of that could have appeared to influence the work reported in this paper. Acknowledgements -p This work was funded by The Research Council of Norway under the FRINATEK project, with grant no. re 250098. Dr. James Roscow from the Department of Mechanical Engineering at University of Bath, UK is kindly acknowledged for his input on the corona discharge setup. Birgitte Sofie Karlsen from Sintef lP Industry, Norway is acknowledged for chemical etching of PZT for micrograph imaging. Y.A. Genenko, References S.J. Rupitsch, Piezoelectric Sensors and Actuators: Fundamentals and Applications, Top. ur [1] na Technical University Darmstadt, Germany is acknowledged for helpful discussions. Jo Mining, Metall. Mater. Eng. (2018) 559. DOI:10.1007/978-3-662-57534-5 [2] J. Jacob, N. More, K. Kalia, G. Kapusetti, Piezoelectric smart biomaterials for bone and cartilage tissue engineering, Inflamm. Regen. 38 (2018) 2. DOI:10.1186/s41232-018-0059-8 [3] A.H. Rajabi, M. Jaffe, T.L. Arinzeh, Piezoelectric materials for tissue regeneration: A review, Acta Biomater. 24 (2015) 12–23. DOI:10.1016/j.actbio.2015.07.010 [4] J. Rödel, W. Jo, K.T.P. Seifert, E.M. Anton, T. Granzow, D. Damjanovic, Perspective on the development of lead-free piezoceramics, J. Am. Ceram. Soc. 92 (2009) 1153–1177. DOI:10.1111/j.1551-2916.2009.03061.x [5] J. Rödel, K.G. Webber, R. Dittmer, W. Jo, M. Kimura, D. Damjanovic, Transferring lead-free piezoelectric ceramics into application, J. Eur. Ceram. Soc. 35 (2015) 1659–1681. DOI:10.1016/j.jeurceramsoc.2014.12.013 [6] J. Koruza, A.J. Bell, T. Frömling, K.G. Webber, K. Wang, J. Rödel, Requirements for the transfer of lead-free into application, J. DOI:10.1016/J.JMAT.2018.02.001 [7] Mater. 4 (2018) 13–26. ro of piezoceramics J.-F. Li, K. Wang, F.-Y. Zhu, L.-Q. Cheng, F.-Z. Yao, (K,Na)NbO3 -Based Lead-Free Piezoceramics: -p Fundamental Aspects, Processing Technologies, and Remaining Challenges, J. Am. Ceram. Soc. 96 [8] re (2013) 3677–3696. DOI:10.1111/jace.12715 Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, [9] lP Lead-free piezoceramics, Nature. 432 (2004) 84–87. DOI:10.1038/nature03028 J.P. Ball, B.A. Mound, J.C. Nino, J.B. Allen, Biocompatible evaluation of barium titanate foamed na ceramic structures for orthopedic applications, J. Biomed. Mater. Res. Part A. 102 (2014) 2089–2095. DOI:10.1002/jbm.a.34879 B. Tandon, J.J. Blaker, S.H. Cartmell, Piezoelectric materials as stimulatory biomedical and scaffolds for bone repair, Acta Biomater. 73 (2018) 1–20. Jo materials ur [10] DOI:10.1016/J.ACTBIO.2018.04.026 [11] B. Liu, L. Chen, C. Shao, F. Zhang, K. Zhou, J. Cao, D. Zhang, Improved osteoblasts growth on osteomimetic hydroxyapatite/BaTiO3 composites with aligned lamellar porous structure, Mater. Sci. Eng. C. 61 (2016) 8–14. DOI:10.1016/j.msec.2015.12.009 [12] W. Chen, Z. Yu, J. Pang, P. Yu, G. Tan, C. Ning, Fabrication of Biocompatible Potassium Sodium Niobate Piezoelectric Ceramic as an Electroactive Implant, Materials. 10 (2017) 345. DOI:10.3390/ma10040345 [13] P. Yu, C. Ning, Y. Zhang, G. Tan, Z. Lin, S. Liu, X. Wang, H. Yang, K. Li, X. Yi, Y. Zhu, C. Mao, Bone- inspired spatially specific piezoelectricity induces bone regeneration, Theranostics. 7 (2017) 3387– 3397. DOI:10.7150/THNO.19748 [14] K.K. Poon, M.C. Wurm, D.M. Evans, M. Einarsrud, R. Lutz, J. Glaum, Biocompatibility of Appl. Biomater. (2019) jbm.b.34477. DOI:10.1002/jbm.b.34477 [15] ro of (Ba,Ca)(Zr,Ti)O3 piezoelectric ceramics for bone replacement materials, J. Biomed. Mater. Res. Part B ISO 5017:2013, Dense shaped refractory products — Determination of bulk density, apparent D. Waller, T. Iqbal, A. Safari, Poling of Lead Zirconate Titanate Ceramics and Flexible re [16] -p porosity and true porosity, International Organization for Standardization, 2013. Piezoelectric Composites by the Corona Discharge Technique, J. Am. Ceram. Soc. 72 (1989) 322–324. [17] lP DOI:10.1111/j.1151-2916.1989.tb06125.x P. Wang, Y. Li, Y. Lu, Enhanced piezoelectric properties of (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 lead-free na ceramics by optimizing calcination and sintering temperature, J. Eur. Ceram. Soc. 31 (2011) 2005– 2012. DOI:10.1016/j.jeurceramsoc.2011.04.023. J. Hao, W. Bai, W. Li, J. Zhai, Correlation Between the Microstructure and Electrical Properties ur [18] Jo in High-Performance (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 Lead-Free Piezoelectric Ceramics, J. Am. Ceram. Soc. 95 (2012) 1998–2006. DOI:10.1111/j.1551-2916.2012.05146.x. [19] A.B. Haugen, F. Madaro, L.P. Bjørkeng, T. Grande, M.A. Einarsrud, Sintering of sub-micron K0.5Na0.5NbO3 powders fabricated by spray pyrolysis, J. Eur. Ceram. Soc. 35 (2015) 1449–1457. DOI:10.1016/j.jeurceramsoc.2014.11.011. [20] J.G. Fisher, S.J.L. Kang, Microstructural changes in (K0.5Na0.5)NbO3 ceramics sintered in various atmospheres, J. Eur. Ceram. Soc. 29 (2009) 2581–2588. DOI:10.1016/j.jeurceramsoc.2009.02.006. [21] PI Piezoelectric Ceramic Products - Fundamentals, Characteristics and Applications, PI_CAT125E_R3_Piezoelectric Ceram. (n.d.). static.piceramic.com (accessed June 10, 2020). [22] Y. Tian, L. Wei, X. Chao, Z. Liu, Z. Yang, Phase transition behavior and large piezoelectricity near the morphotropic phase boundary of lead-free (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 ceramics, J. Am. Ceram. Soc. 96 (2013) 496–502. DOI:10.1111/jace.12049 W. Liu, X. Ren, Large piezoelectric effect in Pb-free ceramics, Phys. Rev. Lett. 103 (2009) 1–4. ro of [23] DOI:10.1103/PhysRevLett.103.257602 [24] D. Damjanovic, A morphotropic phase boundary system based on polarization rotation and K. Adamiak, P. Atten, Simulation of corona discharge in point-plane configuration, J. re [25] -p polarization extension, Appl. Phys. Lett. 97 (2010) 062906. DOI:10.1063/1.3479479 [26] lP Electrostat. 61 (2004) 85–98. DOI:10.1016/j.elstat.2004.01.021 P. Atten, K. Adamiak, B. Khaddour, J.-L. Coulomb, Simulation of corona discharge in configurations with a sharp electrode, J. Optoelectron. Adv. M. 61 (2004) 85-98. [27] na https://old.joam.inoe.ro/arhiva/pdf6_3/Atten.pdf A.B. Kounga, T. Granzow, E. Aulbach, M. Hinterstein, J. Rödel, High-temperature poling of B. Li, M.C. Ehmke, J.E. Blendell, K.J. Bowman, Optimizing electrical poling for tetragonal, lead- Jo [28] ur ferroelectrics, J. Appl. Phys. 104 (2008) 24116. DOI:10.1063/1.2959830 free BZT–BCT piezoceramic alloys, J. Eur. Ceram. Soc. 33 (2013) 3037–3044. DOI:10.1016/J.JEURCERAMSOC.2013.05.032 [29] H. Du, W. Zhou, F. Luo, D. Zhu, S. Qu, Z. Pei, An approach to further improve piezoelectric properties of (K0.5Na0.5)NbO3-based lead-free ceramics, Appl. Phys. Lett. 91 (2007) 202907. DOI:10.1063/1.2815750 [30] B. Li, J.E. Blendell, K.J. Bowman, Temperature-Dependent Poling Behavior of Lead-free BZT- BCT Piezoelectrics, J. Am. Ceram. Soc. 94 (2011) 3192–3194. DOI:10.1111/j.1551-2916.2011.04758.x [31] D.S. Keeble, F. Benabdallah, P.A. Thomas, M. Maglione, J. Kreisel, Revised structural phase diagram of (Ba0.7Ca0.3TiO3)-(BaZr0.2Ti0.8O3), Appl. Phys. Lett. 102 (2013) 92903. DOI:10.1063/1.4793400 [32] J. Ravez, C. Broustera, A. Simon, Lead-free ferroelectric relaxor ceramics in the BaTiO3-BaZrO3- CaTiO3 system, J. Mater. Chem. 9 (1999) 1609–1613. DOI:10.1039/a902335f [33] M.C. Ehmke, J. Daniels, J. Glaum, M. Hoffman, J.E. Blendell, K.J. Bowman, Reduction of the ro of piezoelectric performance in lead-free (1-x)Ba(Zr0.2Ti0.8)O3-x(Ba0.7Ca0.3)TiO3 piezoceramics under uniaxial compressive stress, J. Appl. Phys. 112 (2012) 0–5. DOI:10.1063/1.4768273 [34] S. Zhukov, Y.A. Genenko, H. von Seggern, Experimental and theoretical investigation on -p polarization reversal in unfatigued lead-zirconate-titanate ceramic, J. Appl. Phys. 108 (2010) 014106. M. Vopsaroiu, J. Blackburn, M.G. Cain, P.M. Weaver, Thermally activated switching kinetics in second-order phase transition ferroelectrics, lP [35] re DOI:10.1063/1.3380844 Phys. Rev. B. 82 (2010) 024109. DOI:10.1103/PhysRevB.82.024109 S. Zhukov, Y.A. Genenko, O. Hirsch, J. Glaum, T. Granzow, H. von Seggern, Dynamics of na [36] polarization reversal in virgin and fatigued ferroelectric ceramics by inhomogeneous field mechanism, S. Zhukov, Y.A. Genenko, M. Acosta, H. Humburg, W. Jo, J. Rödel, H. von Seggern, Polarization Jo [37] ur Phys. Rev. B. 82 (2010) 014109. DOI:10.1103/PhysRevB.82.014109 dynamics across the morphotropic phase boundary in Ba(Zr0.2Ti0.8)O3−x(Ba0.7Ca0.3)TiO3 ferroelectrics, Appl. Phys. Lett. 103 (2013) 152904. DOI:10.1063/1.4824730 [38] S. Zhukov, M. Acosta, Y.A. Genenko, H. von Seggern, Polarization dynamics variation across the temperature- and composition-driven phase transitions in the lead-free Ba(Zr0.2Ti0.8)O3−x(Ba0.7Ca0.3)TiO3 ferroelectrics, J. Appl. Phys. 118 (2015) 134104. DOI:10.1063/1.4932641 [39] D. Xiao, Dielectric Strength of Atmosphere Air, in: Springer, Berlin, Heidelberg, 2016: pp. 149– 194. DOI:10.1007/978-3-662-48041-0_6 [40] E. Warburg, Charakteristik des Spitzenstromes, in: Handb. Phys. Vol. 14, Springer, Berlin, 1927: pp. 154–155. [41] R.A. Moreno, B. Gross, Measurement of potential buildup and decay, surface charge density, ro of and charging currents of corona‐charged polymer foil electrets, J. Appl. Phys. 47 (1976) 3397–3402. DOI:10.1063/1.323199 [42] M. Goldman, A. Goldman, R.S. Sigmond, The corona discharge, its properties and specific uses, J.E. Jones, A theoretical explanation of the laws of Warburg and Sigmond, Proc. R. Soc. London. re [43] -p Pure Appl. Chem. 57 (1985) 1353–1362. DOI:10.1351/pac198557091353 Jo ur na lP Ser. A Math. Phys. Eng. Sci. 453 (1997) 1033–1052. DOI:10.1098/rspa.1997.0058 Figure 1. Schematic diagram of the corona discharge poling setup. For the present study a negative lP re -p ro of polarity was set to the tip electrode. na Figure 2. Scanning Electron Micrographs of the polished and etched surfaces of PIC151 PZT, Jo ur Ba0.9Ca0.1Zr0.1Ti0.9O3 and Ka0.5Na0.5NbO3. ro of -p Figure 3. Polarization, strain and d33 hysteresis loops of PZT (a), (b) and (c), BCZT (d), (e) and (f) and Jo ur na lP re KNN (g), (h) and (i). ro of -p re lP Figure 4. Remanent polarization (a), coercive electric field (b), and small remanent signal d33 (c) as a Jo ur na function of temperature extracted from the hysteresis loops in Fig. 3. ro of -p re Figure 5. d33 of PZT (a), (b) and (c), BCZT (d) and (e) and KNN (f) after corona discharge poling at Jo ur na lP different voltages, temperatures, times and corona electrode distances. Figure 6. Normalized d33 values of corona discharge poled PZT samples compared to the data of Zhukov et al. [34]. The measured data of Zhukov is reproduced with lines and labeled with arbitrarily set ro of markers to guide the reader. -p Figure 7. Current density distribution according to the Warburg law calculated for 5 cm corona Jo ur na lP re electrode distance [34, 36]. Table 1. Average grain size and density for PZT, BCZT and KNN ceramics. Densities are given in absolute values as well as relative density calculated from extracted lattice parameters of their respective powder X-ray diffraction patterns (not shown). Densities are given as an average of 5 samples. Composition Grain size (m) Density/ Relative density (gcm-3 / %) PZT 7±2 7.80 [21] / N.A. BCZT 22 ± 6 5.59 ± 0.05 / 95.5 KNN 3.6 ± 0.6 4.15 ± 0.04 / 92.1 Temperature Voltage (°C) (kV) 6, 10, 15, 20, 22, 80, 200 25, 30 6, 10, 15, 20, 22, 70 25 1, 3, 5 BCZT 1, 3, 5 KNN 1, 3, 5, 10, 330 15, 30 30 4, 5, 7 5 250 [1] 90 [31, 32] 2.3 420 [7] re PZT Corona electrode distance TC (cm) (°C) -p Sample Time (min) ro of Table 2. Parameter space investigated for PZT, BCZT and KNN on corona discharge Sample Time Temperature (min) (°C) lP Table 3. Piezoelectric coefficient d33 of PZT, BCZT and KNN poled by corona discharge. Stated values PZT 3 70 20 5 595 ± 11 587 ± 3 BCZT 3 70 20 5 440 ± 22 421 ± 20 30 330 30 2.3 53 ± 17 43 ± 28 are an average of 15 samples except for PZT and KNN without electrodes, which are an average of 5. na ur Jo KNN Voltage Corona (kV) distance (cm) electrode d33 with d33 without electrodes electrodes (pC/N) (pC/N)