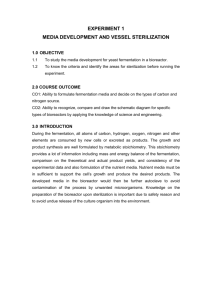

7L Bioreactor Preparation 7L Bioreactor Preparation and Operation 1 Safety .................................................................................................................................. 2 2 Goals of the experiment ...................................................................................................... 2 3 Background ......................................................................................................................... 2 4 Materials ............................................................................................................................. 4 5 Practical ............................................................................................................................... 5 6 Questions ............................................................................................................................ 9 1 Safety Page 1 of 9 7L Bioreactor Preparation 2 Please follow any safety instructions given by your trainer. Please tidy as you go. Clean up spills immediately as they pose slip/trip and fall risks. You will be using Isopropyl alcohol (IPA) at times during this practical, please dispose of materials that have come in-contact with IPA in the designated red bin. Please wear the correct PPE relevant to the area. When working with genetically modified organisms (GMOs), please dispose of any waste in the GMO bin (yellow bin with a green lid). Take care using sharp items such as scissors, tube cutters and cable tie tools. Electrolyte solution is a skin and eye irritant and gloves should be worn at all times when working with this solution. Goals of the experiment Trainees will work together to assemble a 7L autoclavable bioreactor and prepare it for operation. Trainees will identify the various instruments and components of the bioreactor and install as per procedure. The bioreactor will be connected to the control tower, media will be pumped in and the bioreactor will be inoculated. Samples will be collected to monitor the growth of the culture. 3 Background 3.1 Bioreactor Vessel The Applikon 7 litre jacketed bioreactor is a dished-bottom borosilicate glass autoclavable bioreactor with a stainless steel head-plate containing 17 various sized ports. The total volume of the glass container is 6.8L with a 5.4L maximum working volume. The aspect ratio for total volume is 2.2 and for the working volume it is 1.8. The control system consists of an ADI 1010 Bio Controller together with an ADI 1025 Bio Console and an ADI 1026 Gas Supply Unit. 3.2 Temperature Control The bioreactor is equipped with a silicone heating blanket which is wrapped around the vessel to maintain culture temperature-typically at 37C. This has a large heat transfer area to optimize heating. The temperature is monitored via a PT-100 temperature sensor which is inserted into the thermometer pocket of the head plate. The thermometer pocket should be filled with water or silicone oil in order to improve thermal contact between the culture and the probe. A recirculation heat exchanger is also fitting into the reactor for optimum temperature control during the process. This is supplied with chilled water. Working at elevated temperatures and using aeration of the culture might cause too much evaporation during the process (increase of nutrient concentration and decrease in volume); this can be prevented by using an air-outlet condenser. This reactor is fitted Page 2 of 9 7L Bioreactor Preparation with a stainless steel condenser supplied with chilled water recirculation and fitted with a vent filter. 3.3 Agitation The agitator in the glass bioreactor is a magnetically coupled stirrer assembly. This type of stirrer is especially designed for cell cultures and ensures no contamination from this site as there is no moving seal between the contents of the bioreactor and the external environment. A rushton impeller can be installed for bacterial fermentations or a marine impeller can be installed for mammalian cell cultures. The range of the impeller is from 0 to 1000rpm depending on the impeller in place. The operating range of the impeller is limited due to the potential damaging effect of the rotating impeller on the cell culture. The mammalian impeller has effective axial pumping capacity which ensures efficient mixing throughout the vessel. The aim of mixing is to obtain uniform conditions in the working volume of the bioreactor, in order to obtain an optimal mass transfer, to avoid gradients of any of the medium components, and to keep the microcarriers or cells in suspension. Baffles may also be used to increase the mixing efficiency (without baffles, the medium flow can become laminar, causing poor mixing efficiency and mass transfer). The baffles should be mounted near the reactor wall for optimum mixing performance. 3.4 Aeration Aeration into the reactor can be achieved through a porous sparger. In cell culture fermentations, high gas flow rates (causing shear forces) might damage the cells. To be able to meet the oxygen demand of the cells at lower gas flow, the exchange-surface must be increased. This can be achieved by using a porous sparge pipe. The sintered metal tip produces tiny air bubbles for optimum gas distribution. For higher culture with higher oxygen demand, a sterile gas stream can be sparged through the culture using an air-inlet pipe. This pipe can be applied when high gas flow rates are required, since this pipe causes hardly any pressure drop. The holes in this pipe are located at the bottom to make sure that medium will be driven out by the gas stream. Dissolved oxygen measurement is through a 12mm polarographic ADI dO2 sensor which is inserted through the head-plate. 3.5 Addition ports The bioreactor has several addition ports for media, cells and nutrient additions and a dip tube for taking samples. Addition ports for acid, base and antifoam solutions are also available. pH is monitored using an AppliSens sterilizable combined pressurized pH gel electrode with a silver/silver-chloride reference. A series of additional external pumps and pumps on the Bio Console are used to control additions of acid, base, antifoam and nutrient additions. Condenser Page 3 of 9 Addition port 7L Bioreactor Preparation Agitator Air filter on sample bottle DO probe Sample bottle pH probe Glass vessel Heating Jacket Silicone tubing Figure 1 7L Applikon bioreactor 4 Material Bioreactor Control Tower 7L Glass vessel and head plate 2L cell culture media 400mLs cell culture inoculum pH probe and buffer solutions pH 4 and pH7 Cable Tie tool Dissolved oxygen probe and electrolyte solution Waste beaker Lint free wipes Purified water in wash bottle Tube racks x2 6 headplate mill nuts Silicone tubing 70% IPA 0.2M vent filters KPC closed connectors Syringe Cable ties Tubing cutter Sampling assembly Addition bottles and assemblies Tyvek autoclave pouches Autoclave tape Tubing clamps Page 4 of 9 7L Bioreactor Preparation 5 Practical Exercise 1: Bioreactor Preparation Follow the steps below to prepare the bioreactor for autoclaving. The bioreactor will then be connected to the control system for operation. Bioreactor Vessel Preparation Ensure that the bioreactor is clean and dry Ensure the appropriate agitator assembly and impellers are mounted Inspect the top plate O-ring for any damage Place the head plate in position on the glass vessel Fasten the six mill nuts crosswise by hand Preparation of pH Probe Connect the pH probe to the pH probe cable On the Bio controller tower, press the pH button Press the calib. key Use the dial to scroll down to calibration and select with the calib. key Rinse the pH probe with DI water and then with buffer solution pH 7 Insert the PT100 temperature sensor and pH sensor into buffer solution pH 7 Press the start/stop key to measure temperature Press calib. to continue Use the dial to generate the value of the buffer (7.00) Press the Calib. Key Rinse the pH probe and PT100 with DI water and then with buffer solution pH 4 Place PT100 and probe in buffer solution pH 4 Use the dial to generate the value of the buffer (4.00) Press the calib. key Record slope of calibration Slope_____________ Record offset of calibration Offset____________ Press the setp. key twice to return to the main screen. Remove the pH probe and PT100 from the buffer solution and rinse with DI water Remove the cable from the pH probe and place the pH probe in the pH port in the head plate of the reactor and hand tighten Ensure the cap is on the probe Preparation of DO probe Page 5 of 9 7L Bioreactor Preparation Remove membrane cap from DO probe and add 1mL of electrolyte solution Replace membrane cap and rinse probe with DI water to remove any excess electrolyte Place DO probe into DO port on the headplate and screw into place Ensure top cap is on the probe Connect the Air Supply Attach silicone tubing from the sparger port to a 0.2m filter with tubing to reach the air supply on the gas supply unit Secure connections with cable ties where required Attachment of Cooling Tubing Attach cooling tubing to and from the condenser Attach cooling tubing to and from the heat exchanger Secure all connections with cable ties Preparation of Addition Bottles Prepare a 2L bottle for the addition of media with a KPC connector Prepare a 1L bottle for the addition of base with a KPC connector Prepare a 500mL bottle for the addition of inoculum with a KPC connector Connect addition lines to the bioreactor with KPC connectors Secure connections with cable ties where required Preparation of sampling assembly Attach sampling assembly to the bioreactor head plate Attach silicone tubing from the sampling assembly to the sampling port Attach a 0.2m filter and silicone tubing to the sampling assembly Secure all connections with cable ties Final Pre-autoclave checks Check vessel to ensure all connections and additions are in place and secure Clamp silicone tubing coming from the bioreactor where required Secure filters and KPC’s in an autoclave tyvek pouch Autoclave Bioreactor Remove bioreactor to equipment preparation room Place bioreactor in autoclave and autoclave as per SOP TRG-EQP-001 After the cycle is complete ensure the bioreactor has cooled before commencing with the next step Connecting to Control Tower Page 6 of 9 7L Bioreactor Preparation Connect the pH and DO probes to their relevant cables Ensure DO probe polarizes for 6 hours Connect the cooling tubes attached to the condenser to the control tower Connect the cooling tubes attached to the heat exchanger to the control tower Apply the heating jacket to the bioreactor Place the temperature probe in the port on the head plate Connect the air supply Exercise 2: Bioreactor Media Addition One bioreactor will be set up with media and cells. Work in the Biosafety cabinet to aseptically add prepared media addition bottle lid onto media supply bottle Follow the steps in the batch record to add media to one bioreactor. Media Addition Connect media bottle KPC to addition line KPC Place the silicone tubing through the peristaltic pump head Remove clamp Details Initial and Date Turn on pump Once the media transfer is complete stop the pump and re-clamp the tubing Turn on the agitator Turn on temperature control to 37oC Turn on pH Control and Airflow Allow equilibration overnight Calibrate the DO probe Exercise 3: Bioreactor Inoculation Work in the biosafety cabinet to aseptically sample from the inoculum bottle to confirm starting cell concentration and viability using the Vi-Cell cell viability analyser Calculate expected bioreactor concentration: Table 1. Calculations Expected Bioreactor Cell Concentration (cells/mL) Page 7 of 9 7L Bioreactor Preparation Work in the Biosafety cabinet to aseptically add prepared inoculum addition bottle lid onto inoculum supply bottle Follow the steps in the batch record to inoculate one bioreactor and take a sample. Inoculation Connect inoculum bottle KPC to addition line KPC Place the silicone tubing through the peristaltic pump head Remove clamp Turn on pump Once the inoculum transfer is complete stop the pump and re-clamp the tubing Sampling Details Initial and Date Details Initial and Date Wipe sample bottle with 70% IPA Insert 20mL syringe into the air filter outlet on the sample bottle and remove clamp Draw out the plunger on the syringe until the required volume of culture is in the sample bottle Push air back through the filter to ensure no culture is sitting in the sample line Re-clamp the tubing Using 70% IPA aseptically change the sample bottle with an autoclaved sample bottle Confirm bioreactor starting cell concentration and viability using the Vi-Cell cell viability analyser. Page 8 of 9 7L Bioreactor Preparation Table 2. 7L bioreactor cell concentration and viability Cell Concentration (cells/mL) Cell Viability (% viable) Practical Questions Question 1: Describe the purpose of the components of the 7L Applikon bioreactor listed in Figure 1. Question 2: Explain how pH is controlled in the bioreactor. Question 3: List and explain two different types of impellers often used in bioreactors. Question 4: During the preparation of the 7L bioreactor for autoclaving, why are lines not fully clamped before autoclaving? Question 5: Describe how aeration is achieved in the bioreactor. Page 9 of 9