2-Theoretical and experimental investigation of impinging jet ventilation and comparison with wall displacement ventilation

advertisement

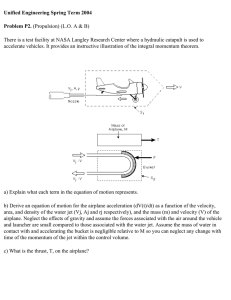

Building and Environment 37 (2002) 1329 – 1342 www.elsevier.com/locate/buildenv Theoretical and experimental investigation of impinging jet ventilation and comparison with wall displacement ventilation T. Karimipanaha , H.B. Awbib; ∗ a Air Innovation AB, Sweden b Indoor Environment and Energy Research Group, Department of Construction Management and Engineering, The University of Reading, Reading RG6 6AW, UK Received 2 August 2001; received in revised form 1 October 2001; accepted 18 October 2001 Abstract This paper focuses on evaluating the performance of a new impinging jet ventilation system and compares its performance with a wall displacement ventilation system. Experimental data for an impinging jet in a room are presented and non-dimensional expressions for the decay of maximum velocity over the 0oor are derived. In addition, the ventilation e2ciency, local mean age of air and other characteristic parameters were experimentally and numerically obtained for a mock-up classroom ventilated with the two systems. The internal heat loads from 25 person-simulators and lighting were used in the measurements and simulations to provide a severe test for the two types of ventilation systems. In addition to a large number of experimental data CFD simulations were used to study certain parameters in more detail. The results presented here are part of a larger research programme to develop alternative and e2cient systems for room ventilation. ? 2002 Elsevier Science Ltd. All rights reserved. Keywords: Impinging jet ventilation; Displacement ventilation; Classroom ventilation; Air jets; Room air movement; CFD 1. Introduction Although the traditional mixing systems have poor ventilation e2ciency and are less energy e2cient, they still occupy a large portion of the market. When displacement ventilation (DV) was <rst introduced almost three decades ago, it seemed at the time to be a promising ventilation concept due to its high ventilation e2ciency and strati<cation principle. In DV systems, cool air supplied at low level is entrained by plumes rising from heat sources in the room. To create an e=ective ventilation system in the occupied zone, there should be a balance between the momentum in the supply air and thermal (buoyancy) forces due to heat sources. In this low momentum displacement 0ow, the buoyancy forces created by heat sources have a tendency to take over and thus often causing poor ventilation e2ciency in some zones of the room [1]. Another disadvantage of a displacement system is that it can only be used for cooling and is not suitable for winter heating. To overcome this problem new systems like ceiling mounted textile bag supply and down-to-0oor impinging supply have been developed, see Ref. [2]. A new method of air distribution known as the Air Queen (AQ) has been developed in Sweden, which is based on impinging jet ventilation (IJV) [3]. This method is based on the principle of supplying a jet of air with high momentum downwards onto the 0oor. As the jet impinges onto the 0oor it spreads over a large area causing the jet momentum to recede but still has a su2cient force to reach long distances. Unlike the DV system which “0oods” the 0oor with supply air, the resulting 0ow from an IJV is a very thin layer of air over the 0oor. This method has the advantages of both the mixing and displacement ventilation systems without known disadvantages. Impinging jet ventilation has lower momentum than mixing and higher momentum than wall displacement ventilation (WDV), i.e. when the air terminal unit is wall mounted at low level. Although higher momentum than WDV, IJV produces a similar 0ow <eld and has, therefore, promising applications [2,4]. 2. Properties of impinging jet ∗ Corresponding author. Tel.: +44-118-931-6786; fax: 44-118-9313856. E-mail address: h.b.awbi@reading.ac.uk (H.B. Awbi). The impingement of a turbulent jet on a 0at plate (wall) has been widely studied with di=erent con<gurations. In all 0360-1323/02/$ - see front matter ? 2002 Elsevier Science Ltd. All rights reserved. PII: S 0 3 6 0 - 1 3 2 3 ( 0 1 ) 0 0 1 1 7 - 2 1330 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 Nomenclature (The International system of units (SI) is used throughout this paper) Aout Supply outlet area (m2 ) Ci Inlet contaminant concentration (ppm) Co Outlet contaminant concentration (ppm) IJV Impinging jet ventilation (dimensionless) To Outlet temperature (◦ C) Ti Inlet temperature (◦ C) U Air velocity in radial direction (m=s) Uo Air velocity at supply outlet (m=s) Jet centreline velocity (m=s) Uc Umax Maximum air velocity at di=erent positions from 0oor (m=s) WDV Wall displacement ventilation (dimensionless) d Supply outlet diameter (m) h Impingement height from 0oor level (m) early investigations, the prediction of the momentum 0ux follows the same procedure as in a classical boundary layer. The impinging jet is an interesting test case due to its di=erent 0ow regions (i.e. the potential core region, the free jet region, the impinging or 0ow de0ection region and the wall jet region). Some early and recent investigators have also studied the free and impinging jet phenomena. Beltaos and Rajaratnam [5] provided detailed results for the impingement region and enlarged the scope of the results which were available in the free jet and wall jet regions. Gutmark et al. [6] presented an experimental study of the turbulent structure on the centre-line of a two-dimensional impinging jet. They pointed out that the impingement of the jet is not a=ected by the presence of the plate over 75% of the distance between the nozzle and the plate and also the turbulent properties of the jet change from their equilibrium level close to the impingement region. The impinging jet is somewhat similar to a stagnation 0ow in which an in<nite stream impinges on a <nite body. In our investigation we used the impinging jet con<guration shown in Fig. 1. The 0ow <eld is divided into three regions, see also Ref. [5]: (i) a free jet region, (ii) the impingement region and (iii) the wall jet region. There are also transitional zones between these regions. The numerical analysis and development of impinging 0ows have received large attention, not because of their simplicity, but due to the presence of di=erent 0ow regions. However, the result from the analysis may depend on the turbulence model used. A jet approaching a plate will at some distance from the plate begin to “feel” the presence of the plate. For example the mean velocity on the centre line is similar to a free jet up to some distance and then decreases (faster) to the zero Supply air0ow rate (m3 =s) Radial distance from the jet impingement point to measuring point (m) x0 Radial distance from the jet impingement point to the virtual origin (m) y Vertical distance from 0oor (m) y1=2 The height from 0oor corresponding to half of the maximum air velocity (m) Ventilation e=ectiveness for contaminant rec moval (%) Ventilation e=ectiveness for heat distribution= t removal (%) DV Displacement ventilation PMV Predicted mean vote PPD Predicted percentage of dissatis<ed (%) r Radius of supply outlet (m) qv x value at the impingement point, see Fig. 2. The distance from the plate where the centre line velocity starts to deviate from the free jet curve is taken as the location of the end of the free jet region and the beginning of the impingement region. From the <gure one can see that the e=ect of the plate is felt when the distance from the plate is ¡ 0:14h, which is in agreement with the results obtained by Bealtos and Rajaratnam [5]. Fig. 1. Impinging jet con<guration. T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 1331 The resulting empirical relation based on the measured Umax at di=erent distance (x) in the radial direction, can give a basis for use of impinging jet supply system. 3.1. Methodology and test conditions Fig. 2. Decay of centre line velocity with di=erent impingement heights (d = 25 mm). 3. Impinging jet ventilation system A test method has been developed for impinging jet supply devices, which is based on the radial impinging jet theory, see Ref. [7]. It was based on the assumption that the velocity distributions on the impinging surface have the same pro<les as the wall jet region illustrated in Fig. 3. Independent tests show that the radial velocity (U ) in the y-direction with di=erent radial distances from the origin give a similar velocity pro<le described in dimensionless form, see Ref. [8]. Using these similarity criteria, the following proportionality relation is obtained: Umax x log ˙ log √ ; (1) Uo Aout where Umax is the maximum velocity in radial direction for a speci<c point located at horizontal distance x from origin (impingement point), Uo is supply velocity and Aout is the supply outlet area. Velocity <eld measurements were carried out in a test room (“classroom”) at the Centre fQor Built Environment in GQavle, Sweden. The supply device “Air Queen” model AQ-D54=24 was used in the tests. Two impingement heights of 300 and 950 mm were studied, see Fig. 4(a). The aim of velocity measurements was to establish a basis of dimensioning physical parameters for design purposes of the impinging jet supply. This was to investigate the variation of the maximum air velocity on the 0oor with the jet outlet velocity and to establish the vertical height above the 0oor where this maximum occurs as this will be important for draught considerations. The tests were also aimed to show the in0uence of impingement height on the 0ow pattern over the 0oor. The supply air0ow rate was regulated by a variable speed fan and the supply temperature was set according to the cooling load in the test room. The room temperature was kept constant by cooling the room walls. The air0ow was measured by an ori<ce plate. During the tests an air0ow of 150 l=s, supply temperature of 18◦ C and a room temperature of 21:5◦ C were used, see Ref. [7] for further details. For supply heights of h = 950 and 300 mm, velocities were conducted at 12 measuring points with di=erent distances (x) and 3 angles from the impingement point, see Fig. 4(b). At each measuring point the traversing for velocity was carried out from the 0oor up to 300 mm with 10 mm between traversing intervals. At each point in the traversing interval, 480 samples were recorded for a sampling interval of 0:5 s to give the mean velocity at that point. Fig. 3. Radial jet impinging on a 0at plate. 1332 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 Fig. 4. A plane view of test facility with measuring points. All dimensions in metres. The following measuring instruments were used in the tests: • Air velocity measuring instrument of type Swema Air 300 with hotwire anemometer of type CTDA. • Micromanometer of type Alnor MP3 KDS (pressure measurement for supply duct). • Temperature measuring instrument of type Mitec AT30 with thermistor. The measuring errors were estimated to be: Supply air0ow (ori<ce) Room temperature Supply temperature Air temperature in the jet Air velocity ±4%. ±0:5 K. ±0:5 K. ±0:2 K. ±0:05 m=s. The measured parameters for the two cases considered were: Supply height 950 mm Supply air0ow rate, qv = 0:15 m3 =s. 2 Supply √ outlet area, Aout = 0:094 m ⇒ characteristic value Aout ≈ 0:30 m. Supply air velocity at outlet, Uo = 1:60 m=s. Supply height 300 mm Supply air0ow rate, qv = 0:15 m3 =s. 2 Supply √ outlet area, Aout = 0:117 m ⇒ characteristic value Aout ≈ 0:34 m. Supply air velocity at outlet, Uo = 1:29 m=s. The reason for varying the supply outlet area and the velocity in the two chosen heights was because the extended noise damping cover of supply duct in the case with supply height of 300 mm was missing. 3.2. Test results The results from these tests are given in Figs. 5 –10. The equation in Fig. 6 shows a best line <t through the measured values. This is used to calculate the jet spread rate, i.e. 0.081 in the equation and also the virtual origin which is −0:34. The same procedure is repeated for other angles, see Figs. 8 and 10, which show the di=erence in the jet spread and the location of virtual origin for the two angles. The di=erences obtained are due to the vicinity of the wall and the entrained air into the jet boundaries for the measuring cases with 30◦ and 90◦ which leads to a higher spread rate, 0.081 and 0.074, respectively. These values are very close to the wall jet spread rate obtained by Karimipanah [3]. For the 60◦ case the jet spread rate is as low as 0.067, see Fig. 8 and the con<guration in Fig. 4. For the later case, the con<nement e=ects are less important and the jet seems to be almost una=ected by the walls. 3.3. Empirical equations The empirical equations for each angle given below show how the maximum velocity varies with distance from the supply device as a function of supply area and outlet velocity. The equations have been derived from the data in Figs. 5 –10. −1:52 x ◦ Angle 30 Umax = 3:38Uo √ ; (2) Aout −1:19 x Angle 60◦ Umax = 2:66Uo √ ; (3) Aout −1:10 x ◦ √ Angle 90 Umax = 2:45Uo : (4) Aout T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 1333 Umax U0 3 2.5 2 1.5 1 U max = 3.3784 U0 x A out -1.5202 0.5 0 1 7 5 3 9 11 13 15 x A out Fig. 5. Decay of maximum velocity for angle 30◦ and supply height of 950 mm. y1/2 x Aout 0.90 0.80 y1/2 0.70 = 0.081 x Aout x Aout + 0.0278 0.60 0.50 0.40 0.30 0.20 0.10 -1.00 0.00 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 x Aout -0.10 Fig. 6. The rate of spread of the jet for angle 30◦ and supply height of 950 mm. The absolute values for the distance of the virtual origin are also determined from the <gures for each angle. The following relations show the spread of jet with distance from the supply jet centreline and the distance of the virtual origin for angles of 30◦ ; 60◦ and 90◦ . It is shown in Figs. 6, 8 and 10 that the virtual origin is always downstream of the jet centreline. x0 ◦ Angle 30 (5) √A = |0:34|; out x0 = |1:90|; Angle 60◦ √ (6) A out x0 = |0:95|: Angle 90◦ √ (7) A out 3.4. Discussion of results The distance (x) form the impingement point up to the actual measuring point gives the best parameter for dimensionless representation of the experimental data. The results show that velocities for di=erent angles considered are somewhat di=erent. Although the largest velocities occur for angles of 60◦ and 90◦ , the velocities for these two angles at the same measuring points are almost the same. The small variations are due to measuring errors. The lower velocities for angle 30◦ are due to the damping e=ect of the adjacent wall. Since the aim is to produce dimensionless correlations that can be used for selecting impinging jet devices the results 1334 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 Umax U0 3.00 2.50 2.00 1.50 Umax = 2.6571 U0 x -1.1881 Aout 1.00 0.50 0.00 1.00 3.00 5.00 7.00 9.00 11.00 13.00 x 15.00 Aout Fig. 7. Decay of maximum velocity for angle 60◦ and supply height of 950 mm. y1/2 x A out 0.80 0.70 0.60 0.50 0.40 0.30 y1/2 = 0.0671 x 0.20 x Aout + 0.1273 Aout 0.10 -2.00 0.00 -1.00 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 x Aout -0.10 Fig. 8. The rate of spread of the jet for angle 60◦ and supply height of 950 mm. for angle 90◦ , which gives somewhat higher values, will be used for this purpose. Thus, if one considers a maximum velocity at a speci<c distance from the supply device, it is clear that the value at the same distance for other directions may be lower than that for 90◦ . Based on this assumption, the equation for the maximum velocity at a distance x from the jet centreline is −1:10 x : (8) Umax = 2:45Uo √ Aout The exponent for an ideal case should be −1:0. However, due to friction losses and entrainment of the room air into the jet and also because the jet momentum cannot be conserved in a con<ned enclosure, a value of −1:10 is obtained from measurements. Concerning the supply device height above the 0oor, the results show that the velocity pro<les for both 300 and 950 mm supply heights are almost the same. The marginal di=erence in the maximum velocities is probably due to the smaller supply area in the case with h=950 mm which gives somewhat higher outlet velocity. A higher supply outlet velocity results in a higher momentum and can a=ect the jet velocity spread over the 0oor. Therefore the height of the supply outlet has no signi<cant in0uence on the velocity pro<les over the 0oor, but small in0uences on the ventilation e2ciency [4]. T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 1335 Umax U0 3 2.5 2 1.5 U max = 2.4476 U0 x Aout -1.0977 1 0.5 x 15 Aout 0 1 7 5 3 9 11 13 Fig. 9. Decay of maximum velocity for angle 90◦ and supply height of 950 mm. y1/2 x Aout 0.9 0.8 y1/2 = 0.0744 x 0.7 Aout + 0.0705 Aout 0.6 0.5 0.4 0.3 0.2 0.1 0 -2 -1 0 1 2 3 4 5 6 7 8 9 10 x Aout -0.1 -0.2 Fig. 10. The rate of spread of the jet for angle 90◦ and supply height of 950 mm. 4. Application to a classroom A test room of 8:4 × 7:2 × 3 m3 and 25 person-simulators, placed in the room to represent a teacher and 24 students, was used for evaluating the performance of the IJV system. A climate chamber attached to the room was used to simulate extreme winter and summer conditions, see Fig. 11. The heat output from the person-simulators were 2375 and 525 W was considered for lighting giving a total cooling load of 2900 W (48 W=m2 ). In all tests the air 0ow rate was 10 l=s per person and the supply air temperature was kept constant at 15◦ C. The outdoor temperature was kept at −21◦ C to simulate winter conditions and at +25◦ C to simulate summer conditions. However, only results for the summer condition are presented here. Results from tests under winter conditions can be found in Ref. [4]. Two types of air supply devices have been evaluated; one is based on the IJV principle and the other on the WDV concept. The devices were tested by measuring the air temperature, air velocity and air quality (local mean age of air) in the occupied zone. The room area was divided into 12 zones and a stand placed in the middle of each zone was used to measure 1336 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 Fig. 11. Plan view of the classroom with supply positions. All dimensions in metres. Fig. 12. Velocity vectors in a horizontal plane 10 cm from 0oor and age of air contours in a vertical plane: (a) wall displacement ventilation; (b) impinging jet ventilation. the required quantities at di=erent heights. The local mean age of air was measured by using the tracer gas decay technique at 1:2 m above 0oor. Further details can be found in Refs. [2,4]. To assess the e=ectiveness of the two ventilation systems for measurements and CFD simulations, well-known parameters given below are used [9]. Ventilation e8ectiveness for heat distribution or removal ( t ): This is similar to a heat exchanger e=ectiveness and is de<ned by t = T o − Ti : TR − Ti (9) Ventilation e8ectiveness for contaminant removal ( c ): This is a measure of how e=ective the ventilation system is in removing internally produced contamination. It is de<ned by C o − Ci : (10) c= CR − Ci In Eqs. (9) and (10), T is temperature (◦ C), C is the contaminant concentration in parts per million (ppm), the subscripts i and o refer to inlet and outlet, respectively, and ( R) represents the mean value for the occupied zone (to a height of 1:8 m). The values of t and c is dependent on the method of room air distribution, room characteristics, heat and contaminant sources, etc. T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 1337 22.5 22 21.5 Temprature [oC] 21 20.5 20 19.5 IJV CFD IJV measured WDV CFD WDV measured 19 18.5 18 0.01 0.09 0.42 0.74 0.89 1.19 1.50 2.07 2.38 2.46 2.61 2.85 Height [m] Fig. 13. Mean temperature pro<les for two ventilation systems. 0.3 IJV CFD IJV measured WDV CFD WDV measured Mean velocity [m/s] 0.25 0.2 0.15 0.1 0.05 0 0.01 0.09 0.42 0.74 0.89 1.19 1.5 2.07 2.38 2.46 2.61 2.85 Height [m] Fig. 14. Mean velocity gradients for two ventilation systems. In addition, expressions for the predicted percentage of dissatis<ed (PPD) and predicted mean vote (PMV) are used here and these are de<ned in Ref. [10]. 5. CFD calculations The CFD program VORTEX [11] has been used to predict the air0ow properties in the classroom. This program has been developed for the simulation of air0ow, heat transfer, mean age of air distribution, PPD and PMV in enclosures. The code uses the standard – turbulence model and has been developed for ventilation research, which may be more suitable for ventilation simulations than the more general-purpose codes. In the simulations, the measured mean temperatures of the six room surfaces have been used as boundary conditions. The number of nodes used were 49 × 39 × 37 giving a resolution of 0:17 m in the horizontal plane and 0:081 m in the vertical direction. The distance from the 0oor of the impinging jet outlet was 0:90 m in both the measurements and the CFD simulations. 6. Results from CFD and measurements in classroom Fig. 12(a) and (b) shows the air 0ow patterns from the CFD results for the two supply methods at a height of 10 cm from the 0oor. Although, the air supply velocity of 1338 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 0.25 Mean velocity [m/s]. 0.2 0.15 0.1 0.05 IJV measured IJV CFD WDV measured WDV CFD 0 0.00 1.05 3.15 5.25 7.35 8.00 Distance from window, x[m] Fig. 15. Predicted and measured mean velocity distribution in a horizontal plane 10 cm above the 0oor for two ventilation systems. 30 IJV CFD WDV CFD 25 PPD [%] 20 15 10 5 0 0.01 0.09 0.42 0.74 0.89 1.19 1.5 2.07 2.38 2.46 2.61 2.85 Height [m] Fig. 16. Predicted PPD pro<les for two ventilation systems. 1:56 ms−1 in the case of IJV was much higher than in the displacement ventilation case the velocity close to the 0oor decays very rapidly and it is only quite large at a short distance from the jet impinging point on the 0oor. The spread of the impinging jet over the 0oor produces a velocity near the 0oor which is similar in magnitude to that of the displacement ventilation system. However, the 0oor layer in this case is much thinner than that in the case of the WDV. The temperature gradients for the two cases are shown in Fig. 13. The agreement between the measurements and CFD simulations are good. The recommended temperature gradient of 3 K or less is achieved. The mean velocity gradients are shown in Fig. 14. Except for heights up to 15 cm above the 0oor the velocities are much lower than 0:15 m=s for both cases, indicating a comfortable environment. The velocity distribution over a horizontal plane 10 cm above the 0oor (see Fig. 11) is plotted in Fig. 15. Only the wall displacement system shows a tendency for a velocity higher than the recommended maximum of 0:15 m=s closed to the walls. Fig. 16 shows the PPD. One can see from the <gure that in a large portion of the room PPD is below 10% for both systems and this is acceptable for such large heat loads [10]. T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 1339 1.8 1.6 ε i [-] 1.4 Normalised mean age 1.2 1 0.8 0.6 WDV measured WDV CFD IJV measured IJV CFD 0.4 0.2 0 1 2 3 4 5 6 7 8 9 10 11 12 Measuring point number Fig. 17. Predicted and measured normalised local mean age of air pro<les at the breathing zone (1:2 m above 0oor) for two ventilation systems. 25 WDV measured WDV CFD IJV measured IJV CFD 24 Temprature [oC] 23 22 21 20 19 1 2 3 4 5 6 7 8 9 10 11 12 Measuring point number Fig. 18. Predicted and measured local mean temperature pro<les at the breathing zone (1:2 m above the 0oor) for two ventilation systems. The normalised mean age of air (i.e. the local age divided by that at the exhaust) is shown in Fig. 17 for all the measuring points at a height of 1:2 m above the 0oor (breathing zone level). There is some agreement between the WDV and the IJV results at some of the points but not at others. This may be due to the di=erence between the momentum in the two systems and its interaction with the local buoyancy forces. The CFD results show similar trends to measurements. The temperature and velocity pro<les at all measuring points 1:2 m above the 0oor (breathing zone) are shown in Figs. 18 and 19. Both systems show good temperature distributions but the WDV gives higher values. Considering the velocity <eld for both cases one can see that the velocities are very low and there is little tendency to draught risk. A general consideration of all the parameters studied show that both systems can handle the extreme situation they have been exposed to with some small di=erences between them. The predicted contaminant removal e=ectiveness ( c ), was 140% for WDV and 130% for IJV indicating the ability 1340 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 0.16 0.14 WDV measured WDV CFD 0.12 Mean velocity [m/s] IJV measured 0.1 IJV CFD 0.08 0.06 0.04 0.02 0 1 2 3 4 5 6 7 8 9 10 11 12 Measuring point number Fig. 19. Predicted and measured local mean velocity pro<les in breathing zone (1:2 m above the 0oor) for the two ventilation systems. Fig. 20. Smoke visualisation of impinging jet ventilation. of both systems to remove the contaminants in an e=ective way. The corresponding value of the predicted ventilation e=ectiveness for heat distribution for the two cases was 1421 and 142 respectively, which again indicates a high and very close value for the two systems. The PMVs were −0:63 and −0:61, respectively, which are slightly less than −0:5 that is suggested by Fanger [10] to be acceptable. Fig. 20 shows four sequences of smoke visualisation for an impinging jet supply device. One can see that when the jet reaches the heat source (sitting person) a plume forms and due to su2cient momentum the jet continues along the 0oor. This is the advantage of impinging jet ventilation compared to a displacement system, in which case the 0ow sometimes has insu2cient momentum to continue pass the heat source and its totally consumed by the plume. Similar types of impinging jet supply devices (Air Queen) have been installed in di=erent buildings, e.g. schools, of<ces, industrial buildings, etc. The device is similar in looks to a duct and is mounted onto a wall. It supplies air downward to the 0oor and contaminated air is exhausted from ceiling level. Four applications of impinging jet ventilation in Sweden are shown in Fig. 21(a) – (d). One of these T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 1341 Fig. 21. Practical applications of impinging jet ventilation: (a) System 3R international factory in Stockholm; (b) Heavy metal industries in Fagersta; (c) StrQomsbro school in GQavle; (d) Swedish taxes o2ce in Stockholm. represents an installation in a school, one in an o2ce building and two in industrial buildings. Fig. 21(a) shows an installation of impinging jet supply in System 3R International, which was installed to replace displacement devices in a building where precision instruments=tools are manufactured. When displacement ventilation was used there were many complains from the workers and after their re- placement with impinging jet systems no compliment was reported. Fig. 21(b) shows IJV installed in a factory for heavy metal industry. Fig. 21(c) shows the application in the StrQomsbro School in GQavle and Fig. 21(d) is in the Swedish Taxes O2ce in Stockholm. Since installing the impinging jet ventilation system in all these buildings no complains have yet been reported. 1342 T. Karimipanah, H.B. Awbi / Building and Environment 37 (2002) 1329–1342 Another advantage of impinging jet ventilation is that the duct itself has a sound damping e=ect, which reduces aerodynamic noise at the supply terminal. Lars Berthilson (VVESS Consulting AB, GQavle), Per-Johan Q Ohlsson, Johan Kostakis and Orjan Josefsson for their valuable contribution to this work. 7. Conclusions References The results presented in this paper have shown that a 0oor level air distribution can handle a full room heat load in an acceptable manner. Although both the WDV and the IJV systems show similar tendencies, some small di=erences in their performance were observed. Because of the better balance between buoyancy and momentum forces the IJV system shows slightly better mean age of air and velocity distributions. The experiments show that after a short distance from the impinging region and due to the damping e=ect of the 0oor, the jet velocities have decreased to an acceptable level. Furthermore, the IJV system can also be used for both heating and cooling purposes. In this paper we have evaluated the IJV system under certain conditions which are by no means exhaustive. Therefore, this new system may need further studies by ventilation researchers and designers to fully understand its performance under various conditions experienced in practice. [1] Etheridge D, Sandberg M. Building ventilation: theory and measurement. UK: Wiley, 1996. [2] Karimipanah T, Sandberg M, Awbi HB. A comparative study of di=erent air distribution systems in a classroom. In: Awbi HB, editor. Air distribution in rooms: ventilation for health and sustainable environment. Proceedings of the ROOMVENT 2000, Vol. 2. Oxford: Elsevier, 2000. p. 1013–8. [3] Karimipanah T. Turbulent jets in con<ned spaces. Ph.D. thesis, Royal Institute of Technology, Sweden, 1996. Q Thermal comfort and air quality in a [4] Kostakis J, Josefsson O. classroom. B.Sc. thesis, University College of GQavle, 1999 (in Swedish). [5] Beltaos S, Rajaratnam N. Plane turbulent impinging jets. Journal of Hydraulic Research 1973;11:29–59. [6] Gutmark E, Wolfshtein M, Wygnanski I. The plane turbulent impinging jet. Journal of Fluid Mechanics 1978;88(Part 4):737–56. [7] Berthilson L, Ohlsson PJ. Down-to-0oor Impinging Jet supply device—air exchange e2ciency. B.Sc. thesis, University College of GQavle, 1997 (in Swedish). [8] Rajaratnam N. Turbulent jets. Amsterdam: Elsevier, 1976. [9] Awbi HB. Energy e2cient room air distribution. Renewable Energy 1998;15:293–9. [10] Fanger PO. Thermal comfort. New York: McGraw-Hill, 1972. [11] Gan G, Awbi HB. Numerical simulation of the indoor environment. Building and Environment 1994;29(4):449–59. Acknowledgements The authors gratefully acknowledge Prof. Mats Sandberg, Leif Claesson (in BMG, GQavle), Mr Bengt Svensson and