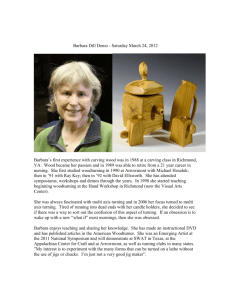

AS THE (SUSTAINABLE!) CORK TURNS • USING A PROFILE GAUGE • HERE’S THE SCOOP! AMERICAN WOODTURNER Journal of the American Association of Woodturners June 2024 vol 39, no 3 • woodturner.org VISCERAL SIMPLICITY: THE BOLD WORK OF RUBEN VAN DER SCHEER MARIA VAN KESTEREN: VARIATIONS ON A THEME THE LIFE-INSPIRED CREATIONS OF RON GERTON GLorinBrückin GALLERY Conques-sur-Orbiel, France When I discovered woodturning as a way of creating and conveying stories, it immediately became apparent to me to include different materials along with wood. I wanted to study the narrative potential that could arise from such combinations—especially because I don’t like leaving the wood alone. Materials such as copper, zinc, or stone—already part of my daily life as a plumber—have gradually found their way into my work. Initially, my creations were in the realm of everyday objects such as boxes, trays, and candlesticks. But then my work evolved to include sculptures, often spherical shapes with natural or Nordic influences. The addition of hammered metal increasingly became the guiding principle of my explorations, always with the aim of giving the illusion that the metal is hidden under the wood. Follow Lorin on Instagram, @lorinbruckin. Brick, 2021, Elm (turned and burnt), worn pieces of terracotta brick eroded by river current, earth/oil joint mixture, oil, 10" (25cm) diameter Column, 2024, Century-old oak barn beam, shale, earth/oil joint mixture, oil finish, 12" × 8" × 8" (30cm × 20cm × 20cm) Sous la Croute (Under the Crust), 2023, Ash burl (burnt and carved), red wine stain, hammered and heated copper inserts, 6" (15cm) diameter American Woodturner June 2024 GALLERY Cévennes, 2020, Cedar (turned and burnt), stone, oil, 9½" (24cm) Cévennes is a tribute to my native region in the South of France. It is a mountainous area where people have altered the landscape by building terraced walls with shale to cultivate the land. Crack, 2022, Wood, hammered zinc from old gutters, earth/oil joint mixture, copper, oil finish, 8" (20cm) diameter Boule de Canton Cuivre (Copper Canton Ball), 2022, Ash burl, hammered copper, oil, pigment, 7" (18cm) diameter (Left) Oak Runes, 2020, Oak, zinc, 6¼" (16cm) diameter (Right) Runes, 2020, Wood, zinc, 6¼" (16cm) diameter The Runes series, comprising turned wood spheres adorned with zinc inserts, is my personal interpretation of the Viking runes engraved on Scandinavian stelae. woodturner.org 1 Dedicated to providing education, information, and organization to those interested in woodturning American Woodturner (ISSN 0895-9005) is published bimonthly by: American Association of Woodturners 222 Landmark Center, 75 5th St W Saint Paul, MN 55102-7704 Periodicals postage paid at Saint Paul, MN, and at additional mailing offices. POSTMASTER: Send address changes to American Woodturner, AAW 222 Landmark Center, 75 5th St W Saint Paul, MN 55102-7704 Inside This Issue June 2024 vol 39, no 3 F E AT U R E S Using a Profile Gauge 20 Terry Martin demonstrates the usefulness of this handy accessory. the Scoop! (No Special Chucks Needed) 22 Here’s Using a wood scoop you made yourself to measure out the morning coffee is an ever-satisfying ritual. Bill Kram shows how to make them without the need for a specially made chuck. office: 651-484-9094 toll free: 877-595-9094 email: memberservices@woodturner.org website: woodturner.org gallery website: galleryofwoodart.org Executive Director Marketing and Communications Director Curator Jennifer Newberg Accent Light with Open-Segmented Base 26 “Galaxy” Rolland “Kip” Stratton shows a simple approach to open Matt Brubaker Tib Shaw AAW BOARD OF DIRECTORS segmenting to create a lovely accent piece that makes a hand-blown glass orb really shine. Designs with CAD Before Turning 32 Visualize Using reputable software that can be acquired free of charge, President Vice President Treasurer Secretary Mike Summerer Ron Day Chuck Lobaito Linda Britt Board Members Jay Brown Sally Burnett Kimberly Winkle KC Kendall Reid Zimmerman Smoke a Bowl (Literally)! 34 Instructor Beth Ireland shares her discovery that turned John Hill Jean LeGwin Dale Larson David Wahl Margaret Lospinuso Louis Vadeboncoeur the (Sustainable!) Cork Turns 36 As Yes, cork grows on trees and is a sustainable resource. It is Board of Advisors Yearly General membership in the American Association of Woodturners is $74 and includes a subscription to American Woodturner. Dues for international members are equivalent to USA amounts before exchange rates are applied. All electronic-journal memberships are $60 yearly or USA equivalent. Send dues to: American Association of Woodturners 222 Landmark Center 75 5th St W St. Paul, MN 55102-7704 USA Ron Giordano shows the benefits of designing with CAD, including a link to a free CAD tutorial download. items can be embellished using a meat smoker. also an excellent material for turning, by Scott Hendricks. Life-Inspired Creations of Ron Gerton 41 The Drawing from work experience and an appreciation for nature, Ron Gerton creates surprising works using a variety of materials, by Jerry Johnson. 46 Visceral Simplicity: The Bold Work of Ruben van der Scheer Dedicated to experimenting with simple forms and materials, Dutch woodturner Ruben van der Scheer achieves elevated results, by Steve Loar. Or join online at woodturner.org Printed in the USA by Quad/Graphics, West Allis, WI © 2024 American Association of Woodturners van Kesteren: Variations on a Theme 52 AMaria snapshot of this widely influential Dutch turner who mentored Ruben van der Scheer, by art historian Thimo te Duits. 2 American Woodturner June 2024 woodturner.org EDITORIAL Journal of the American Association of Woodturners A SSO C I AT I O N N E W S 4 Editor’s Note 6 Apply for an AAW Grant 6 Call for Joshua Friend 4 President’s Letter Demonstrators: AAW Symposium 2025 Mike Summerer 5 AAW’s 39th Annual International Woodturning Symposium 7 Join the AAW Legacy Society 7 Our Heartfelt Thanks, Portland Symposium Sponsors and Exhibitors! 6 2025 POP ARTIST SHOWCASE OPPORTUNITY Creative Woodturning Projects, by Richard Findley @ 12 SkillsUSA Utah Holds Third-Annual High School Woodturning Contest 14 AAW WIT Wig Stand Initiative— One Year Later 15 Calendar of Events 16 Tips GALLERY 1 Gallery Lorin Brückin 71 Advertising Index Joshua Friend editor@woodturner.org Editorial Advisors Betty Scarpino Terry Martin Jean LeGwin Journal Production Plaid Moose Creative Linnea Overbeck Art Director Production Management Woodturning Don McIvor FUNdamentals editormcivor@woodturner.org. EDITORIAL SUBMISSIONS Send article ideas to: editor@woodturner.org For tips on article submission and photography requirements, visit tiny.cc/AWsubmissions*. MEMBER SERVICES For address changes or journals damaged or lost in the mail: Contact the AAW office at memberservices@woodturner.org or call 651-484-9094 or 877-595-9094 (toll free). Index to previous articles: Download a free complete American Woodturner index (PDF format) at tiny.cc/AWindex*. WO O DT U R N E R SCH AT T E R 8 From the Editor’s Inbox 10 Tips for Selling Tools 11 Book Review: American Woodturner 54 Members’ Gallery Bruce L. Jones William A. Clark, III Scott Wishart Chuck Goldstein John Sisak Perry Balog To order back issues: Order past issues of American Woodturner at tiny.cc/AWbackissues* or call 651-484-9094 or 877-595-9094 (toll free). ADVERTISERS For rates and specifications, contact: Ewald Consulting Erica Nelson 763-497-1778 • erica.nelson@ewald.com Betsy Pierre 763-295-5420 • betsy.pierre@ewald.com While the AAW is supported in part by advertisers, sponsors, and exhibitors, it does not endorse any product featured or advertised in this journal, nor does the AAW assume responsibility for the content of individual ads. DIVERSITY STATEMENT The AAW strives to cultivate an organization built on mentorship, encouragement, tolerance, and mutual respect, thereby engendering a welcoming environment for all. To read AAW’s full Diversity Statement, visit tiny.cc/AAWDiversity* A NOTE ABOUT SAFETY COVER Cover: Ruben van der Scheer, Wall Shelf of Ideas Back cover: Daniel Michalik An accident at the lathe can happen with blinding suddenness; respiratory and other problems can build over years. Take appropriate precautions when you turn. Safety guidelines are published online at tiny.cc/turnsafe*. Following them will help you continue to enjoy woodturning. *Web address is case sensitive. woodturner.org 3 A N A SSO C I AT I O N N E W S NEWS Editor’s Note Ever wondered where ideas for content for AAW publications come from? Of course, as your editors, Don McIvor and I come up with topics based on our own observations and experience as longtime woodturners. But also, very often we receive incredibly useful ideas from you, the woodturning community. Since we can’t possibly attend all woodturning events and be aware of everything everywhere, you are our eyes and ears out there in the field. We routinely receive messages suggesting that a certain woodturner be profiled in the journal or that a certain technique or project be included. As active AAW members and readers of both this journal and Woodturning Fundamentals, you are well positioned to influence the content. And by doing so, our publications become a more accurate reflection of current needs and trends in our field. AAW publications are by woodturners and for woodturners. So please don’t hesitate to reach out with your ideas for content. —Joshua Friend From the President Continuous improvement for woodturners How do we “grow” in woodturning? When I started out, I produced a few small plates without knowing good technique by current standards. I assumed the tools were sharp, and would remain sharp, since they came from the factory that way. After spending several weeks scraping my way to success, I decided my next woodturning project would be a chess set. Several months later, I finished the project, and it is unique in having twenty-four pawns, about sixteen of which look similar. The set is still in the family, in the possession of a grandson, who is an excellent chess player. After a few decades in this avocation, I have developed modest skills and can produce a platter or bowl (with sharp tools and good technique) in a fraction of the time those early projects took. Frequently, however, I seize upon a new idea from my imagination, a demonstration, or the instant gallery at a chapter meeting or symposium. Once I start that new project, I learn things—about myself, my impatience, the wood, and the tools. Afterwards, I feel that I am a better turner, and my next effort includes a new perspective and an improved skill set. The AAW, in its print, online, and inperson programs, seeks both to educate and entertain. Our presentations intend to demonstrate good, safe technique and to inspire. Particularly for our Annual International Symposium, we do not expect attendees to spend their discretionary dollars for a series of basic classes that can be more effectively delivered locally, in person with a mentor, or at a local chapter event. Having said that, we know that our most effective demonstrators, even when teaching a complex process, show good fundamentals as well. What, then, is our role as “experienced” woodturners in furthering our art, craft, and organization? Are you pushing your creative limits? Are you demonstrating at your local chapter meetings? Are you sharing a new technique (or tool) at the “show and tell” table? Are you writing informative articles for our Woodturning Fundamentals publication? When was the last time you invited a new turner to your shop for a mentoring session? Our community I have just returned from a regional woodturning event in Upstate New York (Totally Turning). As always, I am struck by the sense of community, sharing, and enthusiasm for our woodturning group. I was able to connect with leaders of chapters, talk with both beginning and experienced woodturners, and even reconnect with a former colleague 4 in my non-woodturning profession who is now a woodturner. This event is part of a larger woodworkers gathering with instant galleries for all forms of work with wood. In my opinion, these cross-fertilization opportunities are worth pursuing. Portland AAW Symposium As you read this, we will have completed another International Symposium, this time in Portland, Oregon. Registration exceeded our targets, and the event featured incredible demonstrators, wood artists, and exhibitors. As always, this success was due to the hard work and involvement of over 100 volunteers, both for the Symposium itself and in support of all of the committees, staff, and ad hoc groups who assisted with the event in the background. We are grateful for their efforts. All year long, many hands make light work, and I hope you will consider volunteering your time and talent, if not to the AAW then perhaps at the local level for your chapter. Even mentoring a new turner in your own shop helps fulfill our mission to increase awareness of our avocation. Keep turning, Mike H. Summerer President, AAW Board of Directors American Woodturner June 2024 A SSO C I AT I O N N E W S 2025 AAW International Woodturning Symposium Join Us in Saint Paul, Minnesota June 12-15, 2025 AAWSYMPOSIUM.ORG woodturner.org 5 A N2025 POP ARTIST SHOWCASE OPPORTUNITY A SSO C I AT I O N N E W S NEWS Application deadline: August 1, 2024 Each year the Professional Outreach Program (POP) showcases two wood artists at the AAW’s Annual International Symposium. They are either experienced artists who have made significant contributions to the woodturning field but have not received appropriate recognition, or emerging artists who have the potential to make significant contributions to the field. The two selected artists give two demonstrations each and participate in a panel discussion of their work led by David Ellsworth. Artists receive a complimentary Symposium registration; a featured display in the Special Exhibitions area; demonstration and panel compensation; three days of lodging at the AAW host hotel, and up to $300 in travel expenses. Artist applications are invited for the 2025 AAW Symposium in Saint Paul, Minnesota, June 12-15, 2025. Applications will be juried by the POP committee. The application deadline is August 1, 2024. See online application at tiny.cc/Calls. The 2024 POP Showcase Artists Heather Marusiak (Manhattan, Kansas) and Kevin Jesequel (Portland, Oregon) were the POP Showcase Artists featured at the 2024 AAW Symposium in Portland, Oregon. Apply for an AAW Grant AAW Grants are available to individuals, chapters, schools, and non-profit organizations. Examples include but are not limited to outreach programs and/or events to encourage youth and underrepresented populations (women, minority, disabled, etc.) to learn and pursue woodturning, support of existing or developing unique woodturning programs, educational workshops or class participation, professional development opportunities, chapter projects, etc. In addition to monetary awards, up to ten mini-lathe packages are available for award each year. Regular AAW Grants are awarded on a bi-annual basis. To be eligible, applications must be received by December 31 for grants given January through May, and by May 31 for June through December. However, Women in Turning (WIT) grants and others for under-represented populations, events, and exhibitions are awarded quarterly. Find detailed grant descriptions and application information at tiny.cc/aawgrants. If you have questions, please contact the AAW office by calling 877-595-9094 or emailing memberservices@woodturner.org. Call for Demonstrators: AAW Symposium 2025 Photo: Andi Wolfe The AAW’s 39th Annual International Symposium will be held in Saint Paul, Minnesota, June 12-15, 2025. To apply to be a demonstrator, visit tiny.cc/Calls between May 1 and August 1, 2024. For more information, call the AAW office in Saint Paul at 651-484-9094 or email memberservices@woodturner.org. Roberto Ferrer gives the thumbs up during one of his rotations at the 2023 AAW Symposium in Louisville, Kentucky. 6 American Woodturner June 2024 A SSO C I AT I O N N E W S Join the AAW Legacy Society When you think about what will happen to your belongings after you’re gone, it is natural to think about the people and organizations that have meant something to you. If you have been a member of the American Association of Woodturners (AAW) during your lifetime and believe in our mission, you can ensure we will continue to make a positive difference far into the future. You can support future woodturners and secure the AAW’s future by leaving a gift in your will or trust. This makes sense, especially if you have assets that would be subject to capital gains tax if given to others. By donating these assets to the AAW, you won’t pay capital gains tax, and you can deduct their current value from your income tax. You can easily include a bequest in your will or trust, and it is flexible: • It does not affect your finances during your lifetime. • It is private, not disclosed until after your passing. • You can change it any time before your death. After setting up your bequest, let us know so we can welcome you into the AAW’s Legacy Society, a group of special individuals who have made provisions for the AAW in their estate plans. —Joe Dickey, Fundraising Committee Specify an amount or percentage You can specify a certain amount or a percentage of what is left in your estate after other expenses. Generally, giving a percentage allows for more flexibility in your long-term planning. Your gift is deductible for federal estate tax purposes, and there is no limit on the deduction. Plus, it is often exempt from state inheritance taxes. Sample Bequest Language Simple bequest language that you can provide to your estate attorney might read like this: “I give, devise, and bequeath [specific dollar amount, or percentage of estate] to the American Association of Woodturners, a nonprofit organization located at 75 5th Street W, 222 Landmark Center, Saint Paul, MN 55102 USA [Tax ID: 45-3809279], for its general purposes.” Our Heartfelt Thanks, Portland Symposium Sponsors and Exhibitors! 2024 AAW International Symposium Sponsors: Thank you to the many vendors who filled the tradeshow in Portland, Oregon, this year: Cousineau Wood Products Crown Hand Tools Easy Wood Tools Howard Products, Inc. JPW Industries/Powermatic/JET Lyle Jamison Woodturning, LLC MDI Woodcarvers Supply Rikon Woodcraft Airbrushing Wood Arrowmont School of Arts and Crafts Branches to Bowls, Ltd. Carter and Son Toolworks Clapham’s Beeswax Products, Ltd. Clark’s Art Beyond ClubExpress, a division of Lumaverse Technologies Craft Supplies USA Curt Theobald Studios D-Way Tools Easy Inlay EZ Jigs - Chefwarekits FedEx Gallery Hardwoods Gilmer Wood Company Hunter Tool Systems Joshua Salesin JPW Industries/JET/Powermatic Kallenshaan Woods A Special Thank You to JPW Industries JPW Industries, makers of Powermatic and JET lathes, continued its legacy with the AAW as the donor of the 2024 Symposium raffle lathe in Portland, Oregon. The company was also a key sponsor of our Learn to Turn Youth Program as well as demonstration rooms during the Portland Symposium. woodturner.org Lucid Woodturners/XTool Lasers Lyle Jamieson Woodturning, LLC Matt’s Wood, Inc. MDI Woodcarvers Supply Milwaukie Hardwoods, LLC Niles Bottle Stoppers Oregon State University Peke Safety Planet Plus, Ltd. Robert Sorby, Ltd. Robust Tools Rockler Woodworking & Hardware Stainless Bottle Stoppers Stuart Batty Tools Teknatool USA Trent Bosch Tools Woodturner PRO Woodturners Smocks Woodturning Magazine GMC Publications, Ltd. 7 WO O DT U R N E R SCH AT T E R CHATTER @ FROM THE EDITOR’S INBOX I have raspberries growing in the garden, so I turned wood colanders to rinse them. First, I turned the bowls, then drilled the drain holes. I found stainless steel grommets at the hardware store and used gel cyanoacrylate (CA) glue to secure them in each hole. I used varnish as a finish, and the colanders are holding up well to normal use and hand-washing in warm soapy water. —Tim Heil, Minnesota Send emails to editor@woodturner.org On February 11, 2024, members of the Yellowstone Woodturners (Billings, Montana) watched and cheered during the Chiefs/49ers Super Bowl game, but on the Friday before that, we cheered and had a bowl of soup at a different kind of “Souper Bowl.” Our club’s 2023 goal was to turn 100 bowls and donate them to Angela’s Piazza (angelaspiazza.org) for their annual fundraiser. Angela’s Piazza is a community organization that aids domestic violence survivors and their families. Each year they hold their own “Souper Bowl” when they invite local supporters to purchase a bowl of soup donated by local restaurants and then send the satisfied diners home with a wood bowl turned by our club or a ceramic bowl made by local craftspeople. Our club’s donation of turnings gave every turner, beginner or pro, the opportunity to “let the chips fly” and contribute to humanity. —Richard Vande Veegaete, Yellowstone Woodturners The Cumberland Woodturners (Crossville, Tennessee) prides itself on giving back to the community by utilizing special projects and events. In 2023, we continued to team up with the Dogwood Exchange, Village Green, and the first National Bank as sales locations for Christmas ornaments and turned art projects. We are happy to report that last year we broke our past ornament and art sales record by selling more than 750 custom ornaments and generating more than $16,000 in total sales. We consider our Christmas ornament program and turned art projects as club hallmarks and are proud to donate all proceeds to local community charities. The 2023 recipients from those sales were House of Hope and Kids on the Rise, which help hundreds of kids in need throughout the year. Club challenges To support our outreach efforts, our club offers special turning challenges to our members. We turn art projects and sell them at our local arts festivals with all proceeds going to local charities. We challenge club members to make boxes for Beads of Courage, a national organization that provides milestone beads for children who are going through medical treatments. Boxes turned by our club members serve as vessels that children can use as a special place to store these meaningful beads. Members of the Cumberland Woodturners also make wig stands for both children and adults suffering from hair loss during cancer treatments. This year, 2024, marks the fifteenth year the Cumberland Woodturners has served our community with projects dedicated to sporting local charities. For more information, including how to join us, visit cumberlandwoodturners.com. —Thomas Neckvatal, President, Cumberland Woodturners Representatives from House of Hope and Kids on the Rise receive funds generated and donated by the Cumberland Woodturners. 8 American Woodturner June 2024 WO O DT U R N E R SCH AT T E R The Ohio Valley Woodturners Guild (OVWG) recently donated nearly forty Beads of Courage (BoC) boxes to Cincinnati Children’s Hospital. This is a well-established program with the OVWG, going back many years. In the BoC program, boxes are donated to young patients undergoing various medical treatments for which they receive commemorative beads. The children use the boxes to hold the beads, as they meet certain milestones in their treatment process. To encourage contributions of turned boxes, our Guild has conducted an annual BoC box contest. Many members are regular contributors. Two young members of the Guild committed that the first thing they would turn each month is a BoC box. BoC boxes lovingly made by OVWG members. To learn more about donating boxes to Beads of Courage, including important guidelines and instructions for woodturners, visit beadsofcourage.org/bead-bowls. —KC Kendall, Ohio Valley Woodturners Guild OVWG member David Wright leads the club’s BoC initiative. My wife wanted a better way to store her necklaces, so she could retrieve one without getting them tangled. I thought about a solution where I could turn something for her. I have been making wig stands for cancer patients and wondered if I could make a necklace holder from a wig stand. I evenly spaced sixteen small screw hooks around the edge of the top and found that the necklaces hang nicely from these hooks. Then it occurred to me that I could include the necklace hooks with the wig stands we donate to cancer patients. I decided to drill the holes in the wig stand and include the hooks in a separate bag, along with a note that informs the recipient that the screw hooks can be threaded into the holes after the stand is no longer being used to hold a wig. Voila! Now it is a necklace holder! —James Andersen, Wisconsin The Cumberland Woodturners (Crossville, Tennessee), along with Theresa Hess and Sally Neckvatal, sponsored an ornamentpainting activity using a recently developed memory-ornament package. This ornament package was recommended by club member Jake Niedling to be offered for sale during our annual Christmas ornament project. The packages contained all necessary painting materials plus some decal embellishments and several ornaments turned by members of the Cumberland Woodturners. Theresa and Sally put the package to the test with a gathering of twelve girls who are members of Theresa’s granddaughter’s soccer team. The paint-a-thon, including lunch, was a rousing success. The Cumberland Woodturners continues to seek projects that provide opportunities for members to be more involved and connected with our community. All proceeds from ornament sales are donated to local charities. —Thomas Neckvatal, President, Cumberland Woodturners woodturner.org Prepackaged ornament-decorating kits, including turned ornaments, helped the Cumberland Woodturners involve community members in charitable fundraising. 9 WO O DT U R N E R SCH AT T E R CHATTER Tips for Selling Tools Jeff King Photos by Dennis Belcher. Following are some tips for woodturners who, for whatever reason, have decided it is time to reduce their collection of woodshop tools. They are largely based on the recent experiences of members of the Wilmington Area Woodturners Association, an AAW chapter in North Carolina. No doubt, readers will think of ideas to supplement these tips; this article is merely intended to prompt you to think and plan ahead, so you can be better prepared when your tool sale is on the horizon. Plan ahead 1. A sale held indoors, ideally in your shop, will reduce the chore of having to move and display all of your items outside. And an outdoor/driveway sale might necessitate scrambling if the weather takes a turn for the worse. 2. While many woodturners are retired and have the flexibility to attend a sale almost any day and time, new and younger members may not have that same flexibility. A weekend sale reduces this concern. 3. The availability of on-street parking at the site, especially if you intend to hold just a one-day sale, must be considered, particularly if heavy tools/machines need to be transported to vehicles. Also, street Plan ahead to avoid parking issues. and driveway parking can quickly run out. Conducting a day-long series of thirty-minute sales sessions, for maybe ten buyers at each session, will eliminate an overflow crowd all at one time. However, if a buyer chooses a time later in the day, or is assigned one, they may find the items they wanted have already been sold. That will be disappointing for them, particularly if they traveled a long way to the sale. 4. Folding tables are an easy place to display tools, whereas placing them on the ground or floor is much less desirable and can create a tripping hazard. 5. Have one or more extension cords available so prospective purchasers can plug in and safely try electric tools before purchasing. 6. You may want to put a sign, such as “WOODTURNERS TOOL SALE” curbside at your location to help buyers find you. 7. Understand that the actual sales price of used tools will likely not come close to the original price you paid for them. Before pricing the tools in the sale, determine whether your goal is to have nothing left at the end of the sale or to maximize revenue. A helpful rule of thumb is that used tools can Have power available so buyers can test electric tools. 10 be priced at 50% of the current price of a comparable new item. Adjust this percentage based on the condition of the tool and the primary goal of the sale. Also, expect that no matter how reasonably you have priced your items, some prospective purchasers may attempt to negotiate further. Decide ahead of time how you will handle this scenario—know your bottom line. 8. Some buyers may show up well before the sale starts to increase their chances of getting what they want to buy. Decide ahead of time how (or whether) you will accommodate them. A “to do” list 1. Prepare an inventory of your sale items, including brand names, model numbers, tool capacities in inches (as appropriate), horsepowers, voltages, and prices, for inclusion in a comprehensive list for publication ahead of the sale. If your club can publish your sale items (either in a newsletter or on their website), make the list “emailable” and include photos. 2. Clean your tools as best you can. People may show up ahead of the starting time to get first dibs on certain items. Decide ahead of time how you will accommodate them. American Woodturner June 2024 WO O DT U R N E R SCH AT T E R 3. Plug in and test any electric tools to ensure they operate. 4. Locate and plan to provide to the purchaser any owner’s manual or instructions that came with the tools. 5. If you have many items, label each one with an inventory number and a price. Several sizes of adhesive stickers for this purpose are available at any of the local office supply stores. 6. Cash may be the simplest way to make a sale, but if you trust the person offering a check, that is your choice. If it is to be a cash-only sale, have a supply of various denominations on hand. Price items in even dollar amounts to avoid the need for coins. 7. Arrange to have help during your tool sale. The availability of a family member or friend to finalize sales and Mark each sale item with an inventory number and price. Be sure to have sufficient smaller bills on hand to make change. collect payment will leave you, the owner, free to answer questions for other prospective buyers. 9. If your sale will be held in a confined space, such as a one- or two-stall garage, try to arrange your tables and tools so that prospective buyers can inspect them and move through your display in a free-flowing manner. Locate related items together—such as sandpaper and sanding tools, electric drills and drill bits, and routers and router bits. 8. Have on hand or remind buyers to bring sturdy shopping bags and/or cardboard boxes to move their purchases to their vehicle. If you are selling a heavy piece of equipment, have on hand or ask buyers to bring a two-wheeled cart, hand truck, or some extra help. —Jeff King, Wilmington Area Woodturners Association Book Review: Creative Woodturning Projects, by Richard Findley, Guild of Master Craftsman (GMC) Publications, 2024, 160 pages, paperback Richard Findley’s first book, Turning Decorative Bowls, was reviewed in the October 2023 AW (vol 38, no 5, page 9). Based on the same premise—addressing a challenge set by the editor of Woodturning magazine—Creative Woodturning Projects has greater appeal for two reasons. Content The book’s projects are true to its title: creative. Most are small and ideal as gift items for family and friends. There are two examples of jewelry—a heartshaped pendant and ring—that would be appreciated by any recipient. One section is devoted to games, including woodturner.org a handsome chess set, and another to boxes, none of which align with the usual mental image of box. A bread board with incised letters would be ideally suited for slicing a baguette at the table, although devious crumbs could hide in the incised letters. The book concludes with a 3" (8cm) globe on a stand that permits pyrography of any version of the world you want— antipodeans can turn it upside down. Like in the bowls publication, Findley tells how he tackled each project by means of images and text. A seasoned turner could readily follow along, with the proviso that patience and practice make perfect. to encourage a novice. The projects are exciting and inspiring, with end results that are a testament to the pleasure and practicality of woodturning. While making a cryptex is, by no means, easy, the satisfaction in its completion would build confidence and commitment to the lathe. Potential Creative Woodturning Projects is recommended as a contemporary woodturning how-to book that includes a “Tools of the Trade” chapter that would help a newbie decide what is essential for the workshop. As with Findley’s previous book, you can support the maker/author by purchasing signed copies via his website, turnersworkshop.co.uk. The book, in itself, would be an ideal present for an established turner or —D Wood 11 WO O DT U R N E R SCH AT T E R CHATTER SkillsUSA Utah Holds Third-Annual High School Woodturning Contest Photos by Alan Peck. The third-annual SkillsUSA Utah High School Woodturning Contest was held March 29, 2024. Nine contestants participated, representing five schools from five school districts. The primary goals of SkillsUSA are to help students build leadership and workplace skills. As a result, preparing for the state contest requires SkillsUSA Utah 2024 Woodturning Contestants (left to right): back row: Griffin Burnham, Isaac Loser, Chance Roberts; center row: Benjamin Tuttle, Andrew Jensen, Lincoln Zacaharias; front row: Asher Anderson, Jaelie Adams, Porter Avery. All fifty states have a SkillsUSA association, director, and annual competition, but currently only Utah holds a state-level woodturning competition. significant effort beyond making a turned project. Contestants were judged in five categories—project design, project quality, interview, portfolio notebook, and written test. The quality of the turnings and portfolio notebooks submitted were excellent and represented significant creativity, initiative, and work. Each of the three winners submitted work that was very nicely done and performed well in all five judging categories. Student prizes and contest judges were provided by Craft Supplies USA (Provo) and Woodcraft (Sandy). Several individuals, including members of the Timp Woodturners Association (Provo, Utah), donated their time to serve as judges and assistants to make the contest run smoothly. Nathan Pickett (SkillsUSA Utah State Director), Savannah Costello (SkillsUSA Utah State Site Director), and Jared Massic (Woodturning Cluster Chair) were particularly supportive and helpful. About SkillsUSA SkillsUSA is a national career and technical student leadership organization with more than 380,000 members. It sponsors over 100 different competitions (see sidebar). All fifty states have a SkillsUSA association, director, and annual competition, but currently only Utah holds a state-level woodturning 1st Place, Maple Harbor, by Porter Avery, Tooele High School, Josh Warren (teacher) 3rd Place, Sun Kissed, by Chance Roberts, Tooele High School, Josh Warren (teacher) 2nd Place, Three-Legged Chair, by Asher Anderson, Brighton High School, Paul Otterstrom (teacher) 12 American Woodturner June 2024 WO O DT U R N E R SCH AT T E R competition. It is hoped that in 2025 there will be SkillsUSA woodturning competitions held in additional states and that eventually woodturning competitions will be held in states throughout the country at the national level. If you are interested in organizing a SkillsUSA woodturning competition in your state, please contact Kip Christensen at kc@learningturning.com. Display Bowl, by Lincoln Zacaharias, Brighton High School, Paul Otterstrom (teacher) More on SkillsUSA To learn more about SkillsUSA, visit the following links: • SkillsUSA main website: skillsusa.org • SkillsUSA State Association Directors: skillsusa.org/who-we-are/leaders-and-partners/association-directors • SkillsUSA List of Competitions: skillsusa.egnyte.com/dl/B7UvDZ4E9e Maple Magic, by Griffin Burnham, Tooele High School, Josh Warren (teacher) Function or Form/Nesting Dolls, by Benjamin Tuttle, Timpview High School, Cameron Whatcott (teacher) Rolling Pin, by Jaeli Adams, Dixie High School, Arissa Ward (teacher) Fruit Burl Bowl, by Isaac Loser, American Fork High School, Sandon Ellefson (teacher) woodturner.org Cherry Chair, by Andrew Jensen, Brighton High School, Paul Otterstrom (teacher) 13 WO O DT U R N E R SCH AT T E R CHATTER AAW WIT Wig Stand Initiative—One Year Later As part of a WIT wig stand initiative, members of the Tennessee Association of Woodturners (both female and male) collaborated with students from Covenant School and the folks at Tri Star Medical Center. Women in Turning (WIT) is a program of the AAW that brings together women worldwide who share a passion for woodturning. WIT is dedicated to encouraging and assisting women in their pursuit of turning by sharing A selection of WIT-initiative wig stands from the Minnesota Woodturners Association monthly challenge project. Photo: Linda Ferber ideas, information, and processes to further their skills and creativity. WIT programming provides a platform to connect women, embracing all backgrounds and differences in celebration of equity and inclusion. WIT Liaisons Genae Johnson turns a wig stand spindle/post during a Cape Cod Woodturners WIT gathering. Photo: Robin McIntyre Club officers help engage women in their local club by supporting a WIT Liaison—a point person in the club, either female or male, who works within the group to bring women together and also engages in the larger WIT Liaison community. Since early 2022, WIT Liaisons have been meeting online every six to eight weeks to share ideas, insights, and concerns and to problem-solve and build community. They also connect via the WIT Liaison online community, sharing information and ideas. The WIT Wig Stand Initiative Cape Cod Woodturners’ Deb Chase shares her embellishment talents on a wig stand top. Photo: Don Chase In late 2022, New Jersey’s Atlantic Shore Woodturners Club Liaison Susan Chiarello presented the idea to launch a national WIT project to make wig stands. Wig stands have been crafted by other clubs over the years, but this was to be specifically a WIT initiative. The wig stands are donated to local partnering organizations that are giving away free wigs to those in need. The partners may be hospitals, oncology clinics, cosmetology programs, or other organizations that 14 support people undergoing (most often) cancer treatment. Almost all of us—our families, friends, and communities—have been touched by cancer, so this project resonates with people on a personal level. After a few months of gathering and organizing resources for distribution, production, an introductory letter, and photos by Robin McIntyre, Jean LeGwin, and the WIT Committee, the AAW WIT Wig Stand Initiative was launched in March 2023. The response has been widespread. WIT groups and entire woodturning chapters have jumped on the bandwagon and have produced 541 wig stands to date. These creations of talent and TLC are treasured by their recipients, who are having to endure a tough time in their lives. It would be wonderful if there was no ongoing need for these wig stands, but unfortunately the need continues. Join us on this journey. To see all of the resources in our initiative—the what, why, and how, plus distribution materials—visit the WIT Calls, Projects & Grants webpage at tiny.cc/WITInfo (URL is case-sensitive). Let’s keep a good thing moving forward! Many thanks to all who have donated their time and talents to this community project. —Robin McIntyre, WIT Liaison Coordinator and Cape Cod Woodturners WIT Liaison American Woodturner June 2024 WO O DT U R N E R SCH AT T E R Calendar of Events Send event info to editor@woodturner.org. Ausust issue deadline: June 15. England October 4–6, 2024, Association of Woodturners of Great Britain (AWGB) 18th International Woodturning Seminar, Yarnfield Park Training and Conference Centre, Staffordshire. Demonstrators to include Mick Hanbury, Simon Hope, Margaret Garrard, Jason Breach, Kade Bolger, David O’Neill, Yann Marot, Jan Hovens, Neil Joynt, and Rolly Munro. For more, visit awgbwoodturningseminar.co.uk. Ireland October 12, 13, 2024, Irish Woodturners Guild (IWG) Seminar, Tullamore Court Hotel, Tullamore, County Offaly. Demonstrators to include Emmet Kane, Derek Weidman, Chris Parker, Nikos Siragas, and Roberto Cecconello. For more, visit iwg.ie. Colorado September 27–29, 2024, Rocky Mountain Woodturning Symposium, The Ranch Larimer County Events Center, Loveland. Demonstrators to include Jean-François Escoulen, Dale Larson, Rudolph Lopez, Jacques Vesery, Kimberly Winkle, Michael Anderson, Christian Brisepierre, Linda Ferber, Joe Fleming, Chris Hoehle, Vinny Luciani, Randall Olander, Doug Schneiter, and Chip Siskey. Symposium to include hands-on learning, tradeshow, instant gallery, and auctions. For more, visit rmwoodturningsymposium.com. Illinois August 2–4, 2024, Turn On! Chicago Woodturning Symposium, Crowne Plaza Hotel, Northbrook. Demonstrators to include Stuart Batty, Roberto Ferrer, Greg Gallegos, Keith Gotschall, Kristen LeVier, Laurent Niclot, Elizabeth Weber, Rob Wallace, Jeff Hornung, and Kurt Wolff-Klammer. Live rotations, instant gallery with People’s Choice award, WIT meeting, banquet/auction, and tradeshow. For more, visit turnonchicago.com and follow us on Instagram, @turnonchicago. September 26–28, 2025, Segmented Woodturners Symposium, Crowne Plaza woodturner.org Hotel, Northbrook. The only symposium fully dedicated to segmenting. Save the date for next year; details to come. For more, visit segmentedwoodturners.org. Minnesota Multiple 2024 exhibitions, AAW’s Gallery of Wood Art, Landmark Center, Saint Paul: • May 19–September 1, 2024: Art from the Lathe—Selected Works from the AAW Permanent Collection • September 8–December 29, 2024: Common Roots (AAW’s 2024 member exhibition) • Ongoing: Touch This!; Around the Hus—Turning in Scandinavian Domestic Life; She’s Tops! Selections from the Linda Ferber Collection; vintage and historic lathes and turned items For more, visit galleryofwoodart.org or email Tib Shaw at tib@woodturner.org. Montana September 20–22, 2024, Yellowstone Woodturners Symposium, Roaring 20s Club House, Billings. Featured demonstrator/ instructor will be Michael Roper, whose sessions will be geared toward both beginners and experienced turners. For more, visit the Yellowstone Wood Turners Facebook page or email Sam Angelo (samandcheryle@gmail. com) or Roger Kesler (rogerkesler@msn.com). Pennsylvania February 9–September 15, 2024, Experiencing Form: Phil Brown and the Museum’s Residency Artist Alumnae, Museum for Art in Wood, Philadelphia. An exhibition of bowls and sculpture initiated by the late Phil Brown and completed by the residency alumni. For more, visit museumforartinwood.org. Hancock, Greg Gallegos. Featuring Friday night meet & greet demonstrator presentations, Women in Turning meeting, vendor room, silent auction, raffle, instant gallery, and a hands-on room with tips and tricks from professionals. For more, visit mawts.com. Texas August 23–25, 2024, SWAT (Southwest Association of Turners) annual symposium, Waco Convention Center, Waco. Demonstrators to include Stuart Batty, Sammy Long, Kurt Hertzog, Kirk DeHeer, Jason Breach, Beth Ireland, and Laurent Niclot. Registration includes lunch each day, vendor tradeshow, and instant gallery. For more, visit swaturners.org. Virginia November 2, 3, 2024, Virginia Woodturners, Inc., biennial symposium, Expoland, Fishersville. Headline artists include Donna Zils Banfield, Trent Bosch, JoHannes Michelsen, Kristin LeVier, Andi Wolfe, Bob Rotche, Nick Agar, Joe Fleming, Barry Gross, Jeff Hornung, Linda Ferber, Willie Simmons, and Steve Schwartz. Forty-six demonstrations, large vendor tradeshow, instant gallery. For more, visit virginiawoodturners.com. Washington October 19, 2024, Northwest Washington Woodturners’ 12th-annual all-day demo, A Day with Keith Gotschall, Anacortes First Baptist Church, Anacortes. Full-day demonstration including bowl-turning techniques and turning a stool. Deli lunch provided, and classes will also be available. For more, visit nwwwt.org, email questions to info@nwwwt.org, or call Charley Drake at (425) 785-2994 or Rod Parker at (480) 338-3395. September 20–22, 2024, The Mid Atlantic Woodturning Symposium, Lancaster Marriott Hotel and Convention Center, Lancaster. Featured demonstrators to include Stuart Batty, Alan Lacer, Keith Gotschall, Carol Hall, Mark 15 WO O DT U R N E R SCH AT T E R TIPS Tips Share your turning ideas! If we publish your tip, we’ll pay you $35. Email your tips along with relevant photos or illustrations to editor@woodturner.org. —Joshua Friend, Editor Toolrest jig for off-center work Making certain repeating patterns using an offset jig, such as the Joyner offset jig, requires you to place the tool in the exact same spot on a toolrest multiple times. To aid in this process, I made a jig that attaches to my Robust box toolrest. You can see my diamond-pointed carbide tool just fits in the slots in the jig I made, providing consistent alignment (Photo 1). The bottom of the wood jig has a narrow lip, which, when pressed up against the metal toolrest, helps to keep the jig square to the toolrest. I also make use of the metal post in the Robust toolrest by having a hole in the wood jig. These two features are all that I need to keep the jig in place during use (Photos 2, 3). When positioning the toolrest, make sure to leave enough room for the offset jig to be removed so you can change the offsets (Photo 4) without having to move the toolrest. Depending on the pattern you are making, you may end up moving the toolrest or making use of an additional slot on the plywood jig once the first set of patterns is made. —Byron Patterson, Wisconsin, AAW member since 2020 1 2 3 Drop-on chainsaw scabbard My chainsaw is always sitting around somewhere in my studio. The chain teeth are razor sharp, so I like to keep a chainsaw scabbard over them to avoid getting cut accidentally. Commercially available scabbards are designed to slip on/off the end of the bar. I found installing and removing them to be more difficult than necessary, which meant I didn’t use a scabbard consistently. I solved the problem by making my own scabbard that just slips down over the bar. It is easy to install and remove. I made the drop-on scabbard out of ¼"- (6mm-) thick plywood with ¾"- (19mm-) square spacers on the top and front. I painted it red and yellow to make it easy to find. —Carl Ford, New York, AAW member since 2001 4 Lathe-mounted abrasive disk It’s impossible to carve bone and soft metals with any accuracy using a handheld angle grinder. But if you mount an angle grinder disk inboard (as shown) and lock a horizontal platform into the banjo, accurate carving of a hand-held workpiece is possible. —Mike Darlow, New South Wales, Australia, AAW member since 1986 16 American Woodturner June 2024 WO O DT U R N E R SCH AT T E R Bed ways-mounted workstation Since my best dust collection is located at my lathe, I am forever doing much of my sanding there, whether sanding turnings or other pieces. Not only is balancing work on the ways tricky, but it’s too easy to drop a workpiece on the floor. So using scraps laying around the shop, I created a new, stable sanding and work platform at the lathe. First, I used wood glue and a brad nailer to fasten a 1½" × 2½" (38mm × × 6cm) piece of pine to a 17" × 27" (43cm × 69cm) piece of scrap plywood. The pine piece fit nearly perfectly between the bed ways of my lathe without my having to do any significant trimming (Photo 1). This piece not only stabilizes the plywood work surface but also allows me to move the workstation left or right. Next, to give the plywood platform a non-skid surface, I glued rubberized shelf lining to the plywood using a spray adhesive (Photo 2). Finally, to make the workstation really stable, I attached four powerful rare-earth magnets to the underside of the plywood using epoxy. Since the magnets have a total pulling force of over 20 pounds, they keep everything in place while I’m working. However, the magnets aren’t so strong that I can’t easily remove the workstation when I need to put it away. —Rich Sabreen, Connecticut, AAW member since 2015 1 Cake tester aids in centering faceplate When attaching a faceplate to a bowl blank, I like to get it centered to reduce wobble and to maximize the bowl size. My faceplate has an opening diameter of 1½" (38mm), so if you center it by eye, there is quite of bit of room for error. To center it more precisely, I turned a small “plug” with a diameter just shy of 1½" and drilled a small hole through the center of it, just big enough for a cake tester. To center the faceplate, I drill a small hole in the center of the bowl blank about ⅛" (3mm) deep. I then “pin” the plug to the center of the blank with the cake tester and drop the faceplate over the cake tester and plug. After attaching the faceplate with screws, the cake tester and plug will easily drop out. And since cake testers are inexpensive, you won’t need to borrow one from the kitchen! —Michael Mullen, New York, AAW member since 2021 2 Sandpaper rack The “secret” to achieving a finely polished finish is to sand through the grits to, say, 600 grit. If I start with 150 grit, I then sand with 180, 240, 320, 400, and 600. This process is much more efficient if you use a sandpaper rack. The one shown is about 20" (50cm) tall, 16½" (42cm) wide, 6" (15cm) deep. Its top shelf is at a height of about 12" (30cm), which is 4" (10cm) higher than my lathe’s center height. The rack’s features include the following: • The square bar at the top is rotatable so that four different series of grits can be labeled on it. • The top “shelf” holds triple-folded quarter sheets, which are used to sand the workpiece. • The top shelf’s vertical dividers are supported on dowels so that shavings fall through. • The top shelf is high enough for the turner to safely reach over the rotating workpiece to remove and replace triplefolded quarter sheets. • The bottom shelf holds unfolded quarter sheets and is positioned high enough to clear the top of the lathe’s banjo. —Mike Darlow, New South Wales, Australia, AAW member since 1986 woodturner.org 17 WO O DT U R N E R SCH AT T E R TIPS Vary bevel sizes on double-bevel scrapers The most important part of a doublebevel scraper (commonly known by the more technical term, negativerake scraper) is the edge, and because the bevels don’t touch the wood, their only purpose is to create the included angle of that edge. The included angle can be as small as you want, but too acute will mean it goes blunt very quickly. There are many reasons you might have different angles, such as the hardness or abrasiveness of the wood you are working, or how often you prefer to sharpen. Once you have decided on the angle you want, the best way is to divide the angle in two and that will be the angle your grinder toolrest should be set at (Photo 1). 1 An internet search will show that many turners sharpen the upper and lower bevels to the same length, which means the edge will be in the middle of the tool thickness, but that is not the most efficient way to sharpen these tools. When I shape such scrapers, I complete the bevel on the bottom first, so it looks like a conventional scraper, and then I turn it over and create only a tiny bevel on the top, as little as 0.1" (2.5mm) wide (Photos 2, 3). I only need one final pass on the lower bevel to create the “hook” on the upper bevel and I am good to go. The advantage is that when I sharpen, I need to touch up only the bottom bevel. When the small bevel on the top gets too narrow, I sharpen it to its former 0.1" width 2 3 and because the upper and lower bevel angles are the same, I don’t need to adjust the grinder toolrest. I only need to do that about every tenth time I sharpen. The edge is the same as with equal bevels, but I have kept the edge nearer to the top of the tool, so there is more support from below. If you already have a double-bevel scraper with equal bevels, sharpen only the bottom bevel for a while and eventually you will arrive at the same result, and you can decide for yourself if you will keep it that way. Photo 4 shows just how well the tool works, and this is with very hard Australian hairy oak. —Terry Martin, Queensland, Australia, first joined the AAW in 1996 4 Boring holes with a cross-slide vise Dowel centers wasteblock If you need to bore holes of specific and constant diameter, you can use a cross-slide vise. The one shown in Photo 1 is inexpensive and amply accurate. You have to pack the cross-slide vise up so that the cutting takes place at lathe-axis height. The cutter shown held in the vise is an unhandled detail gouge, with the blade sharpened out-cannel; it leaves a better surface than a scraping cutter would. For deep small-diameter holes, swap to an in-cannel-sharpened gouge (Photos 2, 3). —Mike Darlow, New South Wales, Australia, AAW member since 1986 When I glue a wasteblock to a bowl blank, I do two things. First, I drill a shallow hole in the center of the wasteblock and the bowl blank (labeled A and B, respectively, in Photo 1). Next, I spread glue between the bowl blank and wasteblock and keep them aligned using a dowel inserted into the corresponding holes. The final step is to use the drill press as a clamp while the glue dries (Photo 2). —Tim Heil, Minnesota, AAW member since 2001 2 1 Ready to increase the diameter of the hole in an Osage orange workpiece using a gouge clamped between the vise jaws. 3 A bowl gouge sharpened in-cannel. 1 18 2 American Woodturner June 2024 WO O DT U R N E R SCH AT T E R Needle-tip applicator bottle for CA glue I bought these needle-tip applicator bottles at Hobby Lobby, and they are great for applying cyanoacrylate (CA) glue without getting it in unwanted places. The needle on the bottle allows me to get close to, for example, a crack in the wood that needs to be filled, giving me greater accuracy. I keep the needle cap that comes with the bottle off, as using it actually causes the needle to clog. The uncovered needle doesn’t clog very often, but if it does, I just soak it in acetone for a few minutes and I am ready to go again. —Terry Butler, Arkansas, AAW member since 2022 Leveling bolts as sanding disk mandrel I used leveling bolts and foam to make a sanding disk holder, or mandrel. (The traditional purpose of leveling bolts is to thread them onto the ends of table legs for easy leveling adjustment.) Start by cutting foam disks slightly wider than the flat of the leveling bolt. Next, use double-sided carpet tape to affix the foam to the leveling bolt. I cut rounds of sandpaper to fit over the foam, then use more double-sided tape to hold the sanding disk to the foam pad. —Tim Heil, Minnesota, AAW member since 2001 Steel rod mandrel Years ago, I took a class in which we turned twig pots. In preparation for the class, the instructor asked us to get a ¾" (19mm) drill bit with a #2 Morse taper. We turned twig pots and drilled the center with this drill bit to accept a glass tube. Then, when we were ready to complete the bottom of the twig pots, we used the drill bit as a mandrel to reverse-mount the work. We installed the drill bit directly in the headstock spindle, then mounted the workpiece on the drill bit using the hole we had drilled. I have used this mounting method many times since then. However, one limitation is that pushing sideways on the drill bit could make the Morse taper come loose. Likewise, mounting the drill bit in a drill chuck with a Morse taper could cause the same problem; drill chucks and Morse tapers are not made for side pressure while being held from one end only. Holding a steel rod of appropriate diameter in a collet chuck is one alternative that I have used woodturner.org successfully. But while I was preparing to give a demonstration for our club on turning twig pots, I realized that only two club members own collet chucks. I wanted to present a holding method that I knew would be accessible for most turners. We ended up using a length of steel rod driven into a piece of wood that had been turned with a chucking tenon to fit in a four-jaw chuck. To make this jig, be sure to drill a hole just slightly smaller than the rod you intend to use. The goal is to get a press fit with no glue/epoxy required. For the steel rod, I bought cold-rolled zinc-coated ½" (13mm) steel rod from Home Depot, which requires a 31⁄64" hole for a good fit in the wood. During the demo, our club members were impressed by how rapidly I reverse-mounted, turned, and sanded the bottom of the twig pot I had made. —Leon Olson, Utah, AAW member since 2010 A steel rod press-fit into a hole in a piece of wood held in a chuck can serve as a reliable mandrel. Blue painter’s tape will take up any slack to achieve a good fit of the twig pot. The hole drilled in a twig pot fits on the steel rod mandrel, providing access to the bottom of the workpiece. For maximum safety, use tailstock support until the final passes. 19 Using a Profile Gauge T here are different kinds of profile gauges, and the type that is used by woodturners is a contour profile gauge. These gauges use a set of captive pins to copy a shape so it can be transferred to a piece of wood. It is a very quick way of copying what would otherwise require a very complex set of measurements. My oldest profile gauge is made of metal, as shown in Photo 1. It is very reliable because once you set it, it is very hard to accidentally change the profile. The newer plastic ones are easier to set, but it’s quite easy to accidentally change the setting if you bump it. Reproduce an existing shape I was recently asked to turn a large number of small wooden holders for desk compasses. It wasn’t a complicated shape, but they all had to be exactly the same (Photo 2). I used my 5" (13cm) profile gauge on the sample I was given to establish the shape of the top. Sometimes, if you just press the whole gauge down on the Terry Martin shape to be copied, the “fingers” spread apart, so it is better to push them down one at a time with a fingernail to get an accurate impression (Photo 3). Once the profile gauge was set, I had to be careful not to bump it too hard. I used a chuck to mount a square blank that I had cut slightly larger than the diameter of the finished piece. I then drilled the hole for the compass with a Forstner bit in a chuck held in the tailstock. When I made the first one, I bored the hole in small increments until it was the right depth for the compass, then noted how many turns of the tailstock handle it took to reach that depth. That made it quickly repeatable without need for measuring. After that I made a flat cut from left to right to create the shoulder of the body, just like the outside of a bowl. Once I reached the edge of the square, I knew I had the exact diameter, which is repeatable for every piece. As I refined the cut for the shoulder and the small bevel that leads into the hole, I stopped and checked the shape against the profile gauge (Photos 4, 5). After I had turned all the tops of the compass holders, I proceeded to turn the bottoms. I used a small chuck with the jaws expanded into the hole to reversemount each workpiece for turning the base. I again used the gauge to copy the profile of the base of the sample. When I had completed fifty of them and lined them up for applying a finish, there were no discernible differences in the shape, thanks to my profile gauge. After the finish dried, it needed only a small amount of silicon inside to hold the compasses and the job was complete. Line up curves Another way a profile gauge can be of great help for woodturners is when you want to carve feet on a bowl. A common method is to turn a ring on the base of the bowl, mark the positions of the feet, and then remove the wood between the feet. The problem is that when you are cutting the curve on the underside of the bowl, it is difficult to know if the Gauge a completed project Profile gauges 2 1 The author’s three profile gauges. The plastic ones are 5" and 10" (13cm and 25cm) wide. A sample desk compass the author was commissioned to copy in multiples. He uses a profile gauge to take a physical record of the shape to be duplicated. 20 3 American Woodturner June 2024 F E AT U R E Confirm the shape 4 Before sanding, the author verifies the shape of the top of the compass holder using the profile gauge, making additional cuts as needed. The same process is used for the bottom of the piece. 5 curve matches inside and outside of the foot ring. If you get it wrong, the difference of the curves will be very obvious after you have removed the wood between the feet, and you might have to do more turning to blend the curve. There are several ways to make a bowl with a ring that will later be carved to create feet. If the ring is small enough, it can temporarily double up as the spigot, or chucking tenon, that is used for remounting to turn the inside of the bowl. In that case, the curves inside and outside of the ring can be matched up while you are still shaping the whole underside, and once the bowl has been hollowed, you can proceed directly to carving the feet. In the process, you can remove all evidence that the ring was used as a spigot. However, if the bowl is large and the ring is too wide to be used as a spigot, then a spigot needs to be turned inside the foot ring for remounting. In this case, the bowl will need to be reverse-mounted after hollowing to remove the spigot. In either case, a simple way to make the curve consistent is to use a profile gauge. I turned a red cedar bowl that was 8" (20cm) in diameter with a 3½" (9cm) foot ring and a small spigot inside the ring. I reverse-mounted it when the bowl’s interior was completed and removed the spigot (Photo 6). As I approached what I thought was a good curve, I constantly checked by pushing the profile gauge onto the wood so that it copied the curve on both sides of the ring. After removing the gauge from the bowl and holding it at eye level, I could see if the curves lined up and was able to make small cuts until they matched (Photos 7, 8). Confirm the curve 7 6 A bowl is reverse-mounted on plate, or jumbo, jaws to allow full access to the base. The author has removed the chucking tenon that was inside the foot ring and now strives for a continuous curve flowing down the bowl and through the foot. Then I removed the wood between the legs with a combination of a small flexible saw and a carbide cutter in a flexible shaft. With careful sanding, I removed all signs that there had been a ring there (Photo 9). Profile gauges have many possible applications for woodturners, particularly if you do production runs, so why not give them a try? Terry Martin is a woodturner and writer working in Ipswich, Australia. Visit his website, terrymartinwoodartist.com, or contact him at tmartin111@bigpond.com. Carve the feet 8 The profile gauge confirms that the curve inside the foot continues perfectly from outside the foot. woodturner.org The goal: a continuous curve 9 With the proper curve established, the author carves away most of the ring, leaving just the finished feet. 21 HERE’S THE SCOOP (NO SPECIAL CHUCKS NEEDED) Bill Kram T urned kitchen utensils are a pleasure to make and a joy to use. The personal touch of the maker— you—also gives them special meaning as a gift. Turning scoops was the theme of an August 2012 American Woodturner article by Mike Peace, “Donuts and Coffee: A Small, Versatile Chuck Lets You Turn Scoops” (vol 27, no 4, page 43). This article had a special appeal for me, as it showed how to make a coffee scoop that could be used each day for my morning coffee routine. I thought this would be a nice replacement for my generic plastic measuring scoop. The 2012 article starts with directions for the construction of a complex donut chuck. The author acknowledges that you will probably spend more time making the chuck than turning your first scoop. This method is presented in several published articles and in internet videos, too. One drawback, besides its complexity and time involved, is its restriction to just one scoop size per donut chuck. Blank layout Draw the scoop’s shape directly onto the turning blank. A centerline (A) runs along the top surface and down the ends. Line B represents the center height of the side view and is positioned ½" down from the top surface. 1 22 After thinking about this and wondering if I could avoid spending the time making the chuck, an idea came to mind for another method of construction. I believe it is simpler and more convenient, as it uses no special jig at all—just a large wood faceplate—and allows for any size scoop to be made. As with other methods of turning a one-piece scoop, the blank has to be mounted in two separate orientations on the lathe. One position is for turning the bowl of the scoop, and the second is for turning the handle. The method I have adopted reverses the steps from other approaches I have seen: the bowl is hollowed first and then the piece is spindle-turned to completion. Prepare the blank For a coffee scoop measuring 1 tablespoon, start with a blank of dry, straight-grained wood about 2" (5cm) square and 6" (15cm) long. Photo 1 shows a blank with a 5"- (13cm-) long scoop drawn onto it, including spindle features. Start by drawing a centerline down the length of the blank on American Woodturner June 2024 F E AT U R E the top surface, and, using a square, extend it across the ends. Then draw lines across the ends of the blank and down the sides ½" (13mm) down from the top surface. Center-punch the line intersections on the ends; these will be your mounting centers. Draw the outline of the scoop on the side and on the top of the blank. For a 1-heaping-tablespoon-sized scoop, the bowl should be 1¾" (44mm) outside diameter (OD) and 1½" (38mm) inside diameter (ID). The bowl top opening is cut to 1¼" (32mm) to account for the curvature of the scoop. Mount the blank, 1st orientation A simple wood or medium-density fiberboard (MDF) faceplate disk is used for the first mounting of the scoop blank. The disk diameter can be 10" (25cm) or larger. I fastened a counterweight block to the disk to help reduce vibration. The counterweight shown in Photo 2 measures 2" square by 3" (8cm) long, which has proved sufficient for a good balance. Position the scoop blank on the faceplate with the tailstock pressing against the center point of the bowl. Then fasten the blank to the faceplate using beads of hot-melt glue (Photos 2, 3). Only a few spot beads are needed for a secure mount; a continuous line of hot-melt glue is not needed and would make removal of the blank unnecessarily difficult. As an alternative, it is also possible to hold the scoop blank in a four-jaw scroll chuck. See Alternate Holding Method sidebar. Attach blank to faceplate 2 With the workpiece held in place with tailstock pressure, the author uses beads of hot-melt glue to fasten it in place. For better holding results, use a hot-melt glue gun with a 60-watt or higher rating. Note the short counterweight block, which helps to balance the turning and reduce vibration. 3 Alternate Holding Method – Splines If you don’t want to make a dedicated faceplate disk for mounting the work, you can also mount the blank in a scroll chuck. To give the chuck something to grab onto, you’ll need to either glue a separate spline to the blank bottom or form a spline from the blank itself, which would entail starting with a thicker workpiece (Photo a). In either case, I center the splines by trimming them on a table saw, running both sides along the fence to cut the same amount off of each side (Photo b). The spline thickness is matched to the chuck opening. (a) A spline, either added by way of glue (top) or formed out of the original blank (bottom), provides a way of holding the blank in a chuck for hollowing. a (b) Alternating passes on a table saw centers the spline b Prepare for hollowing Hollow the bowl Define the top edge, or rim, of the bowl with a parting tool to a depth of about ⅛" (3mm) (Photo 4). Make two cuts with a thin-blade tool to define both the OD and ID of the bowl’s opening. Drill a depth-indicator hole using a ⅜" (6mm) bit held in a drill chuck mounted in the tailstock (Photo 5). Drill the hole 1" (25mm) deep. woodturner.org 4 With the tailstock removed, use a thin parting tool to define in OD and ID of the bowl’s rim. 5 Drill a depth-indicator hole. A tape marker on the bit limits the depth to 1". 23 Start hollowing the bowl with a spindle gouge. I used a ½" gouge, making push cuts to the bowl’s bottom. Then, using a back cut, the bowl sides can be cut to a spherical shape. Complete the hollowing with a round nose scraper (Photos 6-8). As you hollow the bowl, check the depth periodically with the side outline marking for reference (Photos 9, 10). Finally, confirm the inside shape using a half-round template cut to 1½" OD (Photo 11). Sand the inside of the scoop’s bowl. Remove the blank from the mounting disk using a small chisel to cut the hot-melt glue beads and pry it off (Photos 12, 13). Hollow the bowl 6 7 The author uses a spindle gouge and round nose scraper to hollow the bowl of the scoop. 8 Confirm depth and shape 9 10 A simple shopmade jig comprising a piece of wood and a dowel is used to gauge the depth of the bowl. Holding it against the side view drawing on the blank accurately shows the progress. 11 A half-round template is used to confirm the interior curve. Remove blank from faceplate A chisel will break away the hot-melt glue spots and pry the workpiece from the faceplate disk. 12 13 24 American Woodturner June 2024 F E AT U R E Mount in spindle orientation 14 Dark lines are added to indicate where to cut away waste wood. The bowl’s rim is darkened as a visual aid while it is spinning. Mount the blank, 2nd orientation Trim the blank on a bandsaw to remove waste material, which will facilitate the turning to finished form. Draw cutlines on the blank to guide the bandsaw cuts. Also, mark the top edge, or rim, of the bowl with a black felt pen, as shown in Photo 14. This will serve as a guide when shaping the bowl. The trimmed blank is now ready for mounting between centers (Photo 15). It is important that the tailstock live center be positioned exactly on the centerline of the bowl 15 The bandsaw-trimmed scoop mounted between centers, ready for turning. for the wall thickness to be uniform. Take trial cuts to check for center position, and adjust the live center’s horizontal location as needed. Start turning the bowl area, using the intermittent “ghost image” from the black edge as a visual guide for a uniform sphere (Photo 16). Continue rough-turning to form the handle and bowl shapes, and then complete the turning to the final shape (Photos 17, 18). Sand the handle and part the work from the lathe. The little end nubs can be sanded off with a rotary sanding disk mounted in a drill chuck held in your lathe’s headstock spindle. Sand the top edge of the bowl to remove the black markings. If the two side edges of the bowl are not quite equal, small adjustments can be made by rotating the scoop to sand the thinner edge slightly (Photo 19). Bill Kram is a retired electrical engineer who worked for General Electric in New York, Oklahoma, and New Hampshire. He currently lives in Sun City West, Arizona, and is a member of AAW, the Arizona Woodturners, and the Prescott Area Woodturners. Bill has been an active turner for more than twenty years. Refine surfaces 18 With the bowl fully shaped, the author completes the scoop’s handle. woodturner.org 16 The darkened bowl rim serves as a visual aid as the author shapes a sphere for the bowl’s exterior. Shape handle 17 Shape bowl’s exterior 19 A handy sanding tip! Mount a sanding disk in a drill chuck held in your lathe’s headstock spindle. 25 “GALAXY” ACCENT LIGHT -with- OPEN-SEGMENTED BASE Rolland K. Stratton Mount top to pressure plate 1 2 The top is temporarily affixed to a wood faceplate using double-sided carpet tape. Tailstock pressure helps to form a good bond. 26 T he first time I incorporated light in my woodturning was when my son gave me some stained glass for Father’s Day, along with a quick lesson in cutting it. I designed a stack-laminated bowl with a segment ring that featured the stained glass as “portals,” and a votive light placed inside the completed bowl lit up these accent windows beautifully. More recently, I was inspired by the recent deepspace photos from NASA’s James Webb Space Telescope and a trip to the Corning Museum of Glass in American Woodturner June 2024 F E AT U R E Shape top, form chucking recess 3 4 5 The top is shaped and a temporary chucking recess, or mortise, is formed. Corning, New York. Seeing these things led me to create a stack-laminated, open-segmented, bowl with a tapered opening at the top to hold a 4" (10cm) handblown glass orb with globs and lines of colored glass inside. After experimenting with light sources, I found that a small puck, or push, light had enough power to push light through the bowl’s side openings and up through the globe. And with that, my own “galaxy” was formed. Start at the top I started with a piece of maple 7½" (19cm) in diameter with a chucking tenon. Mounted in my chuck, this served as a faceplate, or “pressure plate,” which I flattened and sanded. To this, I add two pieces of doublesided carpet tape (Photo 1). I started with the piece that would become the top, which holds the glass orb—a piece of white oak 6¼" (16cm) in diameter and 1¼" (32mm) thick. After cutting it round on the bandsaw and sanding both flat surfaces on my bench sander, I pressed it onto the doublesided tape, aligning it using my tailstock live center in the center mark left from my compass (Photo 2). The tailstock pressure presses the wood into the tape and supports the work during turning. Apply finish and remove top Reverse-mount top, form foundation rim Now the top is reversemounted using the recess and chuck jaws in expansion mode. The wide flat rim will serve as the foundation for the segments used in the stack lamination. 7 6 woodturner.org Prior to removing the top with a drywall knife, the author applies a Danish oil finish. I then shaped and shear-cut the outer design of this top piece. Using the long point of a skew point, I marked the outer edge and depth of a mortise in the bottom of the blank. Using a small bowl gouge, I hollowed most of the mortise opening (Photos 3-5). Finally, I removed the tailstock and cut the mortise to its final shape. Note that making cuts that press the workpiece into the tape (toward the headstock) is safer than cuts that might pull it away. After sanding through the grits and applying Danish oil, I removed the top from the glue strips using a small drywall skimming blade (Photos 6, 7). 8 27 Add first segment layer I remounted the turned top using the mortise as a chucking recess, expanding my chuck jaws into this recess. I then hollowed the center of the top to about ⅞" (22mm) depth, leaving a 1"- (25mm-) wide rim as a foundation for attaching the open segments. Make certain this outer rim is truly flat. After sanding this side through the grits, I oiled the small dish shape in the center (Photo 8). Applying finish at this stage protects that area of the wood from any glue that might drip and leave a stain. However, there should be no oil on the rim, where you will glue the first layer of segments. I had cut and prepared a variety of segments for my artistic palette. The segments were all ¼" (6mm) thick , ⅞" wide, and 1⅞" (48mm) long on the top outside corners. These were cut at a 10-degree angle on my table saw sled. I had separate containers for segments of bloodwood, cherry, purpleheart, sapele, walnut, ash, oak, butternut, canarywood, and pau grandis. I like to be playful when creating designs, often trying out a variety of unglued rings to several levels and rearranging pieces in a variety Mark for segment placement 9 10 The author uses a clock-making template (from Klockit) to mark off segment locations and an inside ledger line. of patterns before selecting my final wood colors and patterns. I placed a paper clock-making template on top of the foundation rim to mark lines where the twelve segments would be glued. I then added a ledger line with a compass by scribing a circle around the inside edge of the rim (Photos 9, 10). This helped me to accurately align the inner edge of the segments at the first level as I glued them in place (Photo 11). Add layers progressively I carefully checked that my chosen segments were in the correct order throughout the gluing process. After selecting each piece, I sanded away any torn grain and ensured all pieces were dust-free. I decided to repeat the base pattern on each of the additional layers (for a total of nine segment layers). Except for using the marked edge lines for the first level, the subsequent pieces were carefully placed by eye, and I made final adjustments to the segment openings before the glue set up (Photo 12). In this design, each subsequent level was added to the right of the existing segments, giving the bowl a swirling, or stairstep, pattern. Glue on 1st three layers 11 12 An assortment of precut segments in various wood species is a color palette, with which the author chooses a pattern for the open stack lamination. 28 13 The first three layers are arranged and glued. Pressure is applied via a weight and flat board. American Woodturner June 2024 F E AT U R E I used a small paintbrush to apply a light layer of glue to each segment where it would make contact with the segment below it. I experienced no glue squeeze-out. My workbench has a cardboard cover, so I don’t need to scrape the old glue off of its maple top, and it also protects my designs from being marked by the hardwood. I placed a thin board with a weight on top over the glued segments until the glue had dried (Photo 13). This and every subsequent level was carefully sanded and cleaned before the next level was glued on. I used a flat sanding board to level each segment layer while the piece was still in the chuck. After gluing the first three levels, I mounted the work on the lathe using the chuck once again in expansion mode and added a pressure plate held in place with tailstock pressure. This plate would support the outer cut and make turning the outside a much safer process. I cut the outer profile I wanted and gave it a final shear-cut (Photos 14-15). I removed the pressure plate and carefully turned the inside of the open-segment rings. A progressive approach keeps the cutting close to the uppermost levels, so I didn’t have to reach deeply into the bowl. I used a bowl gouge to turn the inside levels at 1200 rpm, which is the same lathe speed I used on the outside. Especially on the inside, make very light cuts. I cut toward the chuck to avoid the possibility of a pull cut catching a layer and blowing the segments apart. Using this process of turning three levels at a time also helped me to know exactly where my ½" (13mm) bowl wall was located, so I could adjust the placement of the woodturner.org Turn 1st three layers 14 15 The work thus far is mounted on the lathe with a pressure plate applied with tailstock pressure. Both the outside profile and inside are turned, the inside using push cuts toward the chuck. Turn 2nd three layers 16 17 After the next three layers are glued onto the assembly, the work is returned to the lathe and turned both outside and in. Glue on last set of layers 18 19 At the workbench, the last three layers are glued on, continuing the stepwise pattern. Again, the weight and flat board provide gluing pressure. 29 next segments to create the developing shape I desired. The width of these segments provided enough material for me to change the shape of the design on the fly. My bowls are playful in color selection and shape, and they are not rigorously engineered. I glued the next three levels using the same procedure. I adjusted the placement of the segments to create the desired shape of the design. The emerging bowl was returned to the lathe after the third level was added. As before, I turned that level using the safety pressure plate held in place by the tailstock, then removed the pressure plate to access and shape the inside. The final shaping cut and then a series of shear-cuts blended the six levels (Photos 16, 17). After sanding the top level flat and true, I returned the piece to my workbench to add the final three layers using the same gluing process (Photos 18, 19). I returned to the lathe to turn the final segment layers, outside and in, using a freshly sharpened gouge (Photos 20, 21). After each section was turned, I was careful to clean all dust and shavings from the piece in preparation for the next gluing. Turn last set of layers 20 21 Now with nine segment layers assembled, the work is returned to the lathe and turned outside and in. Add the base I decided that the tenth and final ring would be a solid ring from figured white oak to match the top. This last ring would become the actual base of the piece. I cut the solid base ring to the right diameter to match the outside of the last segment ring and mounted it on the pressure plate with double-sided tape, pressing it tight using tailstock pressure. I trued its outer edge, cut and sanded the disk’s surface, and cut an inner circle with a sharp parting tool, which resulted in a 1" solid ring (Photo 22). I removed the ring from the plate with the drywall blade and confirmed its placement on the last segment ring (Photo 23). After checking again that the ring’s surface was true, I placed a light layer of glue on top of each of the nine segments, centered it on the ring aligned with the grain orientation of the top, and added a weight until the glue was dry (Photo 24). I then mounted the work back in the chuck and shaped the final solid ring to complete the base (Photos 25, 26). Open the top To reverse-mount the work in order to make the opening in the top, I Turn and part base ring 22 Material for the base ring is affixed to the wood faceplate using strips of doublesided tape and tailstock pressure. The author uses a parting tool to form the base ring. Glue base ring to segment assembly 23 The ring is dry fit on the turned segment assembly. 24 The author glues the segment assembly onto the base ring using weights for gluing pressure. 30 American Woodturner June 2024 F E AT U R E returned the pressure plate to the chuck, sanded away any excess remains from the previous use of tape, and blew away any dust. This time I added three pieces of double-sided tape, because the wall of the design’s base was thin with a limited area for the tape to hold it. Using the centering mark on the top for alignment, I pressed the piece squarely into the doublesided tape with the point of the tailstock live center. There was room to make the initial cuts of the tapered edge with the tailstock in place. I used the old mortise, or recess, as the outer edge for holding the glass orb. At 200 rpm, I carefully cut the required angle into the mortise. I alternated cutting the outer edge with removing material from the center, which helped to prevent a catch. As this cutting pattern was repeated, a small nub emerged under the live center point. I continued to remove material until I was almost through the opening. I finally removed the tailstock and used a very sharp thin parting tool to complete the cut. The center wood popped out without binding (Photos 27, 28). Using the glass orb I had acquired, I Turn base ring 25 confirmed the angle of my tapered opening (Photo 29). Thin cuts can be made if adjustments are necessary. I then sanded all surfaces of the tapered opening and top and applied Danish oil to the outside of the segments and into all the openings, wiping away any excess. Using the drywall skimming knife again, I carefully removed the work from the three pieces of doublesided tape. At the workbench, I applied more Danish oil to the inside of the form. Open the top 27 After the finish had dried, I placed the lit puck light under the turned base and topped it with the glass orb. I love standing back, turning off the lights, and seeing the beauty of inner galactic space! Rolland “Kip” Stratton grew up before TV. He was allowed to play in his dad’s woodshop and now practices playful “what if-ness” in design and tool use. He teaches in his home shop, never charges for time and materials, and takes students without regard for race, age, or gender self-identification. Confirm fit of glass orb 28 The work is once again mounted on the wood faceplate using double-sided tape and tailstock pressure, this time with the thicker top on the tailstock side. Making careful cuts and keeping the tailstock in place for as long as possible, remove the center wood to create an opening in the top. woodturner.org 26 The base ring, which here looks like a bowl rim, is turned outside and in, and the author blends the new material with the previously turned layers with careful cuts. For the inside cuts without tailstock pressure, be sure to make cuts in the direction of the chuck. 29 The author holds up the 4" glass orb to check for a well-seated fit. Adjust as needed with light cuts. 31 Visualize Designs with CAD Before Turning C AD (computer-aided design) is the use of computers to design 2D and 3D models of real-world objects. Although CAD has gained in popularity among woodworkers for designing flat-work items such as bookshelves and tables, the use of CAD for woodturning has not received much attention. There are several CAD programs on the market. I use Fusion 360 CAD software from Autodesk (V.2.0.18961) to test various design ideas such as shape, grain direction, wood choice, and finishes before turning the item at the lathe. If I design pieces on the fly at the lathe, my impromptu results can be arbitrary and unappealing. However, if I design with CAD beforehand, my results are more aesthetically pleasing. Once I finalize a design, I print dimensioned drawings and use calipers to transfer those dimensions to the actual turning. For example, Photo 1 shows a photorealistic CAD model of a lidded vase, and Free CAD Software Available Online! There is currently a free version of Autodesk’s Fusion 360 CAD software available for personal, non-commercial use for both Windows and Macintosh operating systems. Check it out at autodesk.com/products/fusion-360/personal. CAD model vs. actual turned piece 1 A CAD model of a vase (left) compares closely to the author’s actual turned work (right). All elements of the design were fully visualized via CAD prior to turning. 2 Shape: designing progressively From left to right, the first, second, and third proposed CAD designs of a finial. The one at far right was the chosen design. 3 4 5 32 Ron Giordano Photo 2 shows the actual turned vase. Using CAD, I adjusted the shape, wood choice, and decorative features of the vase until I was pleased with the design prior to actual turning. CAD allows me to focus 100% on design during the modeling stage and 100% on execution during the turning stage. I find this singular focus per stage improves both the design and execution of my turnings. Visualize design options The design elements of shape, wood selection, and grain orientation can be explored using CAD. Although design is a personal choice, it’s helpful to look at other people’s designs to understand the elements and proportions that make them pleasing to your eye. From that learning, you can develop your own design aesthetic. Shape CAD can be used to progressively improve the shape of turned objects. For example, Photo 3 shows the initial design of a finial which is poorly shaped and unbalanced. The second version (Photo 4) is an improvement with a more interesting bulb but still ungainly. The third version (Photo 5) is more sophisticated and, with continued refinement, will be ready to turn. Wood selection A nice feature of CAD is that the wood species can be easily changed to visualize the design and improve the appearance of the turning. The modeled vase in Photo 6 lacks contrast, interest, and harmony. The second model (Photo 7) is better; the wood choices are more coordinated, the silver pins complement the silver top, and the black bands set-off the middle ring nicely. I can now go to the lathe and focus solely on the technical aspects of American Woodturner June 2024 F E AT U R E cutting the wood since the design has already been established. The use of CAD for woodturning has not received much attention. Grain orientation CAD can also be used to visualize the grain pattern on a turning, depending on the pith location. For example, CAD models can show the distinctive grain patterns for an endgrain vase with the pith at the center (Photo 8), a facegrain vase with the pith intersecting the side (Photo 9), and a facegrain vase with the pith just above the top edge (Photo 10). Although experienced turners are aware of these patterns, it is still instructive to visualize and rotate these models to mentally associate how the location of a vase within a log determines the resulting grain pattern. Visualize wood choice 6 7 Two CAD designs allow for full consideration of wood species. At left, a plain-looking vase and at right, an improved design showing the effect of figured wood and wellcoordinated features. Visualize grain orientation Modeling basics There are three key steps in creating a CAD model. First, a 2D sketch of the profile is made (Photo 11); second, the profile is revolved around the turning axis to create a 3D model (Photo 12); and third, the wood appearance is specified (Photo 13). To help you get started, I’ve made a detailed tutorial on making a simple vase using CAD. See the sidebar for download details. Give it a try. It’s fun! Ron Giordano is a retired chemical engineer who lives in Granger, Indiana. He enjoys making both flatwork and turned items. He learned the basics of CAD several years ago from his son. Ron’s work can be seen on his website, rongiordano.com; on Instagram, @ron_giordano_woodworking; and on YouTube, @onemorecut7749. Downloadable Fusion 360 Tutorial! Ron Giordano has created a detailed and illustrated tutorial on the use of Fusion 360 CAD software to help you get started successfully. Download the tutorial PDF from the AAW website. Log on and visit tiny.cc/AWextras or scan the QR code. woodturner.org 8 9 10 12 13 CAD renderings showing the effects on grain of pith placement. Endgrain form with pith at center (left); facegrain form with pith intersecting side (middle); and facegrain form with pith above the rim (right). CAD process 11 CAD renderings derive from a simple process. Begin with a sketch of your desired shape or curve in 2D profile. That 2D shape is used to create a 3D object to which you can apply the appearance of wood grain or other color. 33 SMOKE A BOWL (LITERALLY)! Beth Ireland D uring my years of teaching the eight-week Turning Intensive at The Center for Furniture Craftsmanship (CFC) in Rockport, Maine, several fun activities that enhance camaraderie have become tradition. My favorite (for those who are not vegetarian) is smoking a variety of meats using the wood chips and shavings generated during wet bowl week. On that day, we light the fire at 8:00 a.m. and keep it going until 5:00 p.m., at which point our class enjoys a potluck dinner together. An idea from ceramics I have always felt that experiences equal creative ideas. While teaching at Peters Valley School of Craft (Layton, New Jersey), I have been able to visit the ceramics studio’s firing of their anagama kiln and talk to the participants. Anagama is a wood-firing process. When the participants put their clay bowls in the anagama kiln for a multiple-day firing, they have no idea how the surface MORE ON THE CFC! What’s New in Woodturn ing Instructio n? F E AT U Joshua Friend To learn more about O woodturning and craft at The Center for Furniture Craftsmanship, use the AAW’s Explore! search tool to find these valuable resources. Log on at woodturner.org! • “What’s New in Woodturning Instruction?” by Joshua Friend, October 2013 AW (vol 28, no 5, page 33) • “Book Review: Why We Make Things and Why It Matters: The Education of a Craftsman by Peter Korn [CFC’s founder], June 2014 AW (vol 29, no 3, page 11) Center for Photo: Mark Furniture Juliana Craftsmans hip, Rockport, Maine ver the past twenty years, the Center woodturn for Furniture ers are older Craftsmanship (retired) hobbyists, and (CFC) in Rockport, not surprisin Maine, has The Beth the available gly most built a solid Ireland connec tion in the of instructio reputaThe intensive developm n caters to market. Many tion ent of fine woodturn craftsman that furniture professional ship. Not ing course CFC will ers, after one to sit on cover many at rels, Peter gaining enough woodturnhis laufacets of becomKorn, CFC’s ing a profession generate experience, founder and utive director, al turner. income by execan accompli Beth teaching is expandin onstratin shed profession Ireland, offering in g the school’s g for the hobbyist and dem- the woodturn al, will be instructo by becomin ing instructio market, not r. To get a school is not g dedicated better undern. The But standing new practition of the Korn’s vision ing—it routinely to teaching woodturn ers. course, I caught significance of this employs an demographics. goes beyond the new list of faculty. up with Beth impressiv Purchase e But beginnin at SUNY icated professio He maintains that , where she 2014, students g in January dedwas the artist will the appropria nal turners who possess residence. It doesn’t in 12-week intensive be able to take a new take long te stand that build relationsh skills and who can woodturn she is an inspired to undergeared toward ing course ips with architect who, as Korn profession teacher designers puts it, makes al turning. course will s, , and custom The that you can cover a broad you believe builders have the opportun achieve curriculum including ity to thrive anything architectu , her optimism . I found and economi creatively ral work; produccontagiou tion technique cally. s. Beth got her s for faceplate, I wanted to and endgrain start in carpentry spindle, see than thirty work; furniture shop in action, CFC’s woodturning more years ago nents; milling compoand is no so to hard work with other stranger month comprehe I visited while the and long woodwor machines nine- Her productio king nsive furniture for stock preparatio abilities are students were n runs. program and joinery; obvious. Her n, forming, doing their teacher is sharpenin goal as a one week woodturn not just to g; tool-maki and business of ing. The facility impart the ng; skills needed practices. specific sive, with As such, the for predefine course represents twelve Oneway is impresshe intends d projects; 1640 lathes for students, to typical woodturn a bold departure from plus one for W Othe Osatisfactio D T U Rhelp N Estudents R S C experienc H AT T E R demonstr ing instructio purposes. e n ation A course I witnessed n. problem solving,of creativity through specifical Stephen Gleasner teaching the ly geared a career in so they can furniture toward what they woodturn students spindle create turning skills, envision. ing? This my interest. One of her piqued such as beads, class projects Demogra first pommels coves, and phically, is tool-mak , which are most ing that stock ing, emphasiz likely furniture tools tend projects (Photos to be useful in to create stock end products, 1, 2). woodturn and er.org grinds) increase custom tools (and possibilit ies. Book Review: Why We Make Things and Why It Matters: The Education of a Craftsman by Peter Korn, David R. Godine Publisher, 2013, 200 pages Someone once described Peter Korn as a smart man. After reading his new book, Why We Make Things and Why It Matters: The Education of a Craftsman, I consider that an understatement. Twenty years ago, Korn founded the Center for Furniture Craftsmanship (CFC) (AW, vol 28, no 5), organized it as a nonprofit school, and strategically placed himself within the institution to ensure its ongoing success and his own employment, doing what he loves. On the surface and taken as isolated events, those actions sound simply like good career moves, but in the context of his new book, they represent the culmination of a life punctuated by serious health issues, supported by a persistent love of craft, and open to continually reinventing himself. Unlike Korn’s first book, Working With Wood: The Basics of Craftsmanship (Taunton Press), his new book is not instructional, unless considered existentially; How to Make a Good Life could well be its sub-subtitle. The overt theme is that the act of making objects, with conscious investment of self, fulfills the human spirit. Korn parallels that narrative with the inspirational story of how he crafted his own life, giving the book depth. Korn asks big questions framed in broad contexts: What gives objects meaning? How and why do we create those objects? He also discusses the nature of identity and selfhood and how objects inevitably result from a confluence of factors, deftly placing the discussion into historical context. For those involved in creative work— woodturning, furniture making, pottery, glasswork, writing—Korn’s initial thesis is not an untold secret. He notes early in the text that students who attend CFC “do not invest time, money, and effort traveling to Maine to cut dovetails with hand tools because they need hardwood benches, which are the introductory-class projects. What lures them is the hope of finding a deeper meaning by learning to make things well with their own hands.” The act of creating is fulfilling and nourishing and makers undergo change in the process: We are the maker and the object being made. Creative activity is a vehicle for self-transformation. Korn is skilled at voicing concepts that many makers and consumers only know intuitively: Objects are the material expression of ideas and values, whether art, craft, or mass-produced. He shines a Arrowmont Purchases Historic Campus Arrowmont School of Arts and Crafts is pleased to announce the school’s Board of Governors has purchased its historic campus in Gatlinburg, Tennessee, from the Pi Beta Phi Fraternity for Women. “We are grateful to those who have made it clear that they believe in Arrowmont’s future as much as they value its rich history,” says Arrowmont’s executive director Bill May. Key donors to purchase the campus are the City of Gatlinburg, Sevier County, the Windgate Charitable woodturner.org Foundation, and numerous individual donors including the Arrowmont Board and staff. Gifts ranged from $3.5 million to $5. “All levels of giving are important,” May adds. “It’s the heartfelt donation of $5 from a retiree or teenage woodturner that helps convince municipalities like the City of Gatlinburg—which contributed $3.5 million—or foundations like Windgate—which contributed a matching grant of $2.25 million—that spotlight on the designing and 33 making of objects to remind us they are the result of a multitude of decisions on Photo: Mark the part of the LeFavor maker, inevitably influenced by his or her existence in a particular time and place. (And you thought it was just a refrigerator!) Offering these kernels of truth that reside outside of our everyday awareness makes Korn’s book a rewarding read. The ideas in Why We Make Things are perceptive and well informed. The tone is erudite, yet accessible to thoughtful readers. Korn had already proven himself as a furniture maker, designer, teacher, writer, and administrator. With this insightful and well-crafted book, he has risked and gained more as an author, and in doing so offers a roadmap toward a fulfilling life. —Joshua Friend Tim Yoder’s Woodturning Show Returns Tim Yoder, star of Woodturning Workshop, is back with a new, bi-weekly show called Woodturning With Tim Yoder. Viewers can watch the half-hour episodes at popularwoodturning.com. their larger contributions are necessary, justified and well spent.” The American Association of Woodturners was born on the front porch of Arrowmont’s dining hall 27 years ago. That shared history has been vital and important to both organizations, and benefits a growing international community of woodturners. For more information about Arrowmont or to view 2014 workshop offerings, visit arrowmont.org. 11 RE will turn out. The results depend on temperature and placement in the kiln. I thought about this a lot and realized how similar the process is to smoking meat, where the charcoal goes in a side box (heat source) and the meat (or any object being smoked) goes on the rack. At the far side opposite the side box is a vent pipe (Photo 1). By opening and closing the vents near the coals, you can control the air flow over the coals, which ultimately controls the temperature. The smoke vent also has a cap that can be opened and closed in unison with the coal vent to move the heat and smoke across whatever you have placed on the rack. The items closer to the side box cook quicker, whereas items closer to the vent pipe at the other end cook slower, with a lower temperature and, importantly, longer exposure to the smoke. I had first tried smoking a woodturned bowl in the meat smoker a couple of years ago. The first one came out a beautiful brown. I periodically rotated the bowl to expose all sides to the smoke being drawn to the vent pipe. The interior of the bowl remained its natural wood color, as the smoke could not cross over its surface. Moving the exterior surface of the bowl every half hour toward the smoke gave a nice even dark brown on the surface. The smoke is controlled by whatever you put on the coals. During the 34 woodturning intensive, we usually turn maple or cherry during bowl week, as those are wood species local to Maine. We collect the chips and shavings, trying not to pick up any unwanted debris from the floor. We then put the shavings into a bucket of water (Photo 2). After the initial lighting of the fire, we put a handful of lump charcoal on the fire in the smoke box every half hour all day and add wet chips to keep the smoke constant. The smoke adds flavor to the meat and, as I had discovered, color to anything on the rack. By opening the vent on the vent pipe, you can pull the smoke through the smoker. I have found over the years that items near the vent pipe get the most color (Photo 3). Mask to create patterns My prior experience with fabric batiking made me aware of the idea of achieving a pattern by putting something to resist the color from being added to an object (like masking during painting). I tried different resist, or masking, materials and finally came to furnace tape. It stands up to heat and does not leave residue on the wood surface after it is peeled away. Whatever areas of the wood you cover with the furnace tape remain the wood’s natural color, and all exposed areas are colored by the smoke. As you might imagine, this technique offers lots of creative possibilities (Photos 4, 5). American Woodturner June 2024 F E AT U R E I like to use this method on maple, as it results in a very noticeable color contrast. Some students tried the method on cherry and were also happy, but with a more subtle outcome. During this last winter session, everyone tried making one. We cut out designs from the furnace tape and stuck them to the surface of our turned bowls before adding them to the meat smoker. Considerations Our bowls were turned wet and had air-dried for two weeks before smoking. I have also tried this technique on kilndried wood with the same success. I have made multiple elliptical bowls that were created by cutting apart and gluing the two sides of a bowl back together. See Beth Ireland’s AW February 2022 article, “Make an Elliptical Vessel” (vol 37, no 1, page 26). When smoking glued items, I add some kind of mechanical fastener such as a spline, rivet, or even sewing, as most glues are sensitive to heat (Photo 6). The coloring effect takes place only on the surface of the wood. If you sand it, the new color will be removed. However, it does take protective finishes very well. I have used polyurethanes and also waxes on smoked surfaces. My students had a lot of fun exploring this technique. So, the next time you’re having a cookout, try smoking a bowl to see what creative results you can achieve! Color bowls in a meat smoker 1 A typical meat smoker, with a coal (or heat) box, smoke chamber, and vent pipe at the far end. woodturner.org 3 Woodturned items are added to the upper rack in the smoke chamber, positioned near the vent pipe for maximum smoke exposure. Mask areas with furnace tape (4) Prior to smoking their bowls, the author’s students applied shapes cut in furnace tape to create masked patterns. 4 5 (5) Any area covered by the furnace tape remained the wood’s natural color, and all exposed areas were colored by the smoke. The smoke adds flavor to the meat and, as I had discovered, color to anything on the rack. Take caution with glued items To learn more about The Center for Furniture Craftsmanship, visit woodschool.org. Beth Ireland, a professional architectural woodturner and sculptor with more than thirty years of experience, lives and works in St. Petersburg, Florida. She teaches the two-month Turning Intensive at The Center for Furniture Craftsmanship in Maine, as well as workshop classes at major craft centers around the country. For more, visit bethireland.net. 2 The author’s students collect their wood shavings and chips after wet-turning bowls and soak them in water before using them to flavor the meat in the smoker. Wood glues are generally sensitive to heat, so take care if you intend to try this technique on any turnings that have been glued together, such as these elliptical bowls. The author suggests reinforcing glue joints with mechanical fasteners. 6 35 Photo: Daniel Michalik A cork oak tree in a protected forest in central Portugal called Companhia das Lezírias, April 2022. AS THE (SUSTAINABLE!) CORK TURNS Scott Hendricks I have enjoyed woodturning for more than forty years and have worked with many species of wood, but I had never turned cork. In fact, I had never heard of using cork as a turning material until Peters Valley School of Craft in Layton, New Jersey, offered a weekend class on the subject, taught by Daniel Michalik. I jumped at the opportunity. About cork In preparation for the class, I did a little research. The primary source of cork is the bark of the cork oak tree (Quercus suber), which grows primarily in countries along the Mediterranean Sea. I learned that Portugal produces 70% of the world’s cork. Portugal practices sustainable forest management to protect and grow their forests. The cork oak has a thick outer bark that protects it from temperature fluctuations, droughts, and brush fires. The bark is soft, fire resistant, buoyant, lightweight, rot resistant, and impermeable to liquids (Photo 1). The bark is stripped from trees that are at least twenty-five years old. These mature trees can have their bark harvested every nine years. This stripping actually 36 promotes the tree’s growth and prolongs its life; in fact, cork oaks can grow for 300 years. Once harvested, the bark/cork is washed, boiled, and flattened, making it softer and easier to work with. The average cork thickness is approximately 2" (5cm) (Photo 2). The primary product is bottle corks, which are punched from the cork bark (Photo 3). After the bottle corks have been cut out, the cork scraps are ground into ¼" (6mm) pieces, as shown in Photo 4, and are mixed with a binder, placed in large molds, heated in ovens, and pressed into workable blocks. American Woodturner June 2024 F E AT U R E The finished blocks can be made into a variety of products, such as flooring, craft projects, bulletin boards, etc. Cork is an excellent insulator against temperature and sound and is frequently used in building construction throughout Europe. As buildings are renovated or demolished, the reclaimed cork is repurposed (Photo 5). Up to 10% of recycled cork is added to virgin cork to increase the production yield. There are primarily two types of cork: hard and soft. The difference derives from the manufacturing process. Dimensionally, a block of hard cork weighs 130 lbs. (60kg), while a block of soft cork the same size weighs 65 lbs. (29.4kg), or one-half the weight of hard cork. From the tree 1 Examples of cork bark without and with the outer layer intact (left and right, respectively). 2 The average cork bark thickness is approximately 2" after it is stripped from the tree. From scraps to usable blocks The Peters Valley class At the start of our class at Peters Valley, on display were three large blocks of cork, cork circles, along with different examples of cork turnings. The large blocks were soft cork, while the cork circles were cut from a block of hard cork. The large blocks of cork each had lines marked on them, indicating where each block would be cut into six smaller pieces on a bandsaw (Photo 6). Each student in the class was given a piece and coached on the types of projects we could turn. Most of the students had previous turning experience and this showed in their finished projects. Mounting cork on the lathe Our first step in turning the cork was to determine the best way to mount it on the lathe. Similar to normal wood—cork is actually a type of wood—it can be mounted via a spigot (chucking tenon), mortise, jam chuck, or faceplate. When contemplating how to secure the piece on the lathe, remember that cork compresses much more woodturner.org 3 4 After bottle corks are punched from the cork oak bark, the scraps are ground into small pieces and pressed into workable blocks. Cork is sometimes reclaimed from renovation or demolition projects and then repurposed. Some recycled cork is added to virgin cork during the manufacturing process to increase production yield. 5 than wood, which presents unique considerations. In fact, I learned that after being crushed under a pressure of 14,000 pounds per square inch (PSI), cork will regain 90% of its original size in twenty-four hours. Class materials Spigot, or chucking tenon The spigot approach failed for several students since the chuck jaws expanded to just 2" (5cm), limiting the diameter of the spigot. This was inadequate to hold the soft cork. 6 Class materials included blocks of both soft and hard cork, as well as rounds. 37 Attempts to the save the spigots with cyanoacrylate (CA) glue were not successful since the spigot was then out of alignment with the turning. Therefore, use large spigots to support the piece. Hard vs. soft cork Mortise, or recess A mortise, or recess for accepting the chuck jaws in expansion mode, can be a successful solution so long as the shoulder is sufficiently wide and deep to support the piece being turned. 7 8 The bowl on the left was turned from hard cork, while the bowl on the right was turned from soft cork. Due to differences in density, hard cork weighs about twice the weight of soft cork. Jam chuck Depending on the piece being turned, a jam chuck can be a good solution since the pressure is compressing the cork. Faceplate The standard faceplate we were using at Peters Valley—2½" to 3" (6cm to 8cm) in diameter—was expanded via a plywood wasteblock fastened to the faceplate. This allowed for the attachment screws to be placed farther apart, ensuring a secure attachment to the cork workpiece. The screws should penetrate the cork by at least 1½" (38mm). gouges and skews. The material cuts quickly and smoothly. With sharp tools, there is virtually no tearout. The hard cork supports more turned detail such as beads in the piece, but soft cork not as much. I tried a spiral/texturing tool to see what would happen. When I pressed the tool into the hard cork, I observed the cork compressing. As soon as I removed the tool, the intended texture design was gone. Protect yourself from the dust Vacuum chuck I experimented with the use of a vacuum chuck and found it very successful for reverse-mounting a bowl to remove the spigot. Turning cork When turning cork, very sharp tools are essential, but with sharp tools, the hard cork cuts easily. With soft cork, more care must be taken so as not to cut too deeply. Cork doesn’t have grain like regular wood, so it is uniform throughout. There is no need to worry about sidegrain vs. endgrain. Cork turns easily with conventional woodturning tools such as 9 Conventional woodturning tools work very well on cork, but don’t expect the long shavings you might get from regular wood. Turning and sanding cork produces a fine dust, so be sure to use adequate dust collection and personal protection equipment (PPE) to protect your lungs. 38 There was no mark left in the cork. This was due to the elasticity of the cork. I experienced the same results with the soft cork. The bowls pictured in Photos 7 and 8 were turned in our class. The bowl in Photo 7 was made from hard cork, while the bowl in Photo 8 was made from soft cork. Although it may be difficult to see the difference in the photos, the hard cork has a tighter composition, allowing for cleaner cuts and finer detail elements. Although these bowls are about the same size, the hard cork bowl weights almost twice as much. This is a result of the density of the hard cork vs. the soft. A hot wire was used to embellish the hard cork bowl with burn lines. When turning and sanding cork, serious dust protection is in order. Cork dust is fine and unlike the dust produced when turning conventional wood; there are no long shavings (Photo 9). Both hard and soft cork sand very easily, and 220-grit sandpaper yields a smooth surface. When I experimented with higher grits, it was difficult to see a significantly smoother result. This appears to be due to the granular structure of both cork types. Cork can be left unfinished, stained, or painted. For the hard American Woodturner June 2024 F E AT U R E cork bowl in Photo 7, I tried Danish oil on it, but the oil soaked in rapidly and just darkened the bowl. With the soft cork bowl shown in Photo 8, I sprayed three coats of semigloss polyurethane and did not see any significant difference—no sheen. Only after applying two coats of shellac did I begin to see a sheen developing on the bowl. I suspect if I used shellac as the first two coats, followed by the polyurethane, it would have yielded a glossier finish. Alcohol-based stain worked, as well. However, cork does not have to be finished and can be used outdoors with no impact on the cork. Class projects Ours was an introductory class and most participants had some turning experience, though none of us had turned cork. Turning cork is fun, and project ideas are limited only by one’s imagination. Photos 10-13 show some examples of the participants’ turnings. Our creativity resulted in a grooved bowl, a cork stool with ash legs, a chess piece, and a wine cooler. Other turnings (not shown in photos) included a mallet, cork stoppers for handblown glass vessels, a lidded bowl, a high stool with a cork seat, and various bowls. Aquiring cork for turning Cork is sold by the block, and you can select it based on your intended project. Keep in mind cork can be laminated with wood glue to create larger turning blanks, and the glue lines are virtually invisible after turning. The material can be turned surprisingly thin and still have strength, and it is suitable for indoor or outdoor use. Note that price can be a factor, with a block of hard cork measuring 6½" thick, 37" long, and 25" wide costing around $360 and soft woodturner.org Class projects 10 A grooved bowl by the class instructor, Daniel Michalik (left), and a stool with a cork seat, made by Janine Wang. 11 Class projects 12 13 A chess piece and wine cooler, both made by the author. cork somewhat less than that for a similarly sized piece (as of October 2023). If you have difficulty finding cork, it can be ordered from our class instructor Daniel Michalik. Find him on Instagram (@danielmichalik) and send him a direct message (DM). Or you can learn more at Daniel’s website, danielmichalik.com. The cork is shipped directly to you from a warehouse in Wisconsin. Scott Hendricks has been a woodturner for more than forty years and is a member of the Watergap Woodturners, an AAW chapter in northwestern New Jersey. He lives on his farm in Blairstown, New Jersey, with his wife, two dogs, four cats, ten alpacas, and three French geese. Along with turning wood, he grows hay for the livestock. Email Scott at hendricks9903@gmail.com. 39 WORKS IN CORK BY DANIEL MICHALIK Photos courtesy of the artist. Bacia Grande, 2014, Cork, 10" × 25" (25cm × 64cm) Heavy Bowl, 2019, Cork, 3½" × 11½" (9cm × 29cm) Totem Vessel Trio, 2019, Cork, Each: 10" × 7½" (25cm × 19cm) Dual Bowls, 2018, Cork, Each: 3" × 8 ½" (8cm × 22cm) Cork with milk paint Praia – Sky and Sea, 2010, Cork, milk paint, Each: 6" × 12" (15cm × 30cm) 40 American Woodturner June 2024 F E AT U R E The Life-Inspired Creations of RON GERTON Jerry Johnson T he multimedia creations of Washington State’s Ron Gerton reside in many private collections and museums. The broad range of his inspired artwork derived from both his personal interests and professional expertise, a story recounted here to explain some of the amazing works from this talented artist. Engineering and art Ron humbly worked his way through college as a checker in a grocery store and graduated with a degree in mechanical engineering. Out of necessity and to earn extra money, he rebuilt automotive engines and transmissions in high school and during college. He was the first person in his family to go to college, and this was a remarkable feat that would prove much more difficult with today’s high tuition rates. From 1969 to 1975, Ron worked in Pearl Harbor, Hawai‘i, as a nuclear engineer, refueling and overhauling nuclear submarines. He worked there as a civilian employee for the Navy, and after six years, he and his family moved to Richland, Washington, where he worked for twenty-eight years as a nuclear engineering manager. At first glance, engineering and art may seem like polar opposites. A career in engineering doesn’t leave a lot of spare time, yet Ron enjoyed hiking with his children and occasionally they would find agates, which they collected and tumble-polished. His daughter asked if he could figure out woodturner.org Emerging Vessels, 2008, Curly koa, curly maple, birch, laser-cut maple scraps, laser-cut black plastic, art poster segments, 36" × 24" × 4½" (91cm × 61cm × 11cm) how to make jewelry out of some of her favorite agates, so Ron learned how to work wax and cast the gems into gold jewelry. That turned out to be easy for him, and he went on to teach jewelry casting at the local community college for more than twenty years. After Ron’s wife and daughter had accumulated enough jewelry, they wanted something to keep it in. Ron made jewelry boxes out of curly Koa he had brought back from Hawai‘i. During this time, he also learned how to restore the antique furniture they had acquired. While hiking, Ron would find contorted pieces of sagebrush, which reminded him of the bonsai plants they had seen in Hawai‘i. Sagebrush is a very weak material, so Ron decided to cast pieces of it in metal. He built a bronze casting system and began casting the sagebrush in bronze. He then decided to weld several of the pieces together to form sculptures. Wood and bronze Ron Gerton became interested in woodturning in the early 1990s, 41 Casting sagebrush in bronze Pieces of dried sagebrush are used to create wood/wax forms that are then encased in a ceramic shell into which molten bronze is poured. A Tree Runs Through It, 2005, Western bigleaf maple burl, cast bronze, polyurethane, 4' × 3' × 3' (1.2m × 91cm × 91cm) when a friend introduced him to the craft. He soon purchased a Nichols lathe so that his daughter could have an activity while home from college for the summer. She made several nice bowls and vessels, and shortly after she returned to college, Ron started to work with the lathe himself. In a short time, he was hooked on woodturning and quickly mastered the turning of very large hollow vessels. He became so immersed in woodturning that in 1997 he became a founding member of the Mid-Columbia Woodturners, an AAW chapter in Kennewick, Washington. Soon Ron started to incorporate his turned wood vessels into his cast bronze sculptures and showed them at AAW Symposia and other conferences. As time progressed, his wood and bronze artworks became more complex. A 2005 piece, A Tree Runs Through It, was made from Western bigleaf maple burl. These burls tend to have voids as they form, sometimes from bark inclusions. Ron used these natural voids to allow part of the bronze casting to run through the inside of the wood vessel and emerge from the opening that he had created for hollowing. Bronze casting is a very time-consuming process. First, Ron has to find a suitable section of dried sagebrush for his artwork. The pieces of sagebrush Ron finds are usually too large for a single casting, so he cuts them up and makes several smaller castings. The process starts by adding many wax sprues (channels) and vent lines. Once the wax is in place, the whole assembly is coated with a ceramicand-sand slurry to form a shell. Then the ceramic shell is placed in an oven, and the wax and wood are burned out. The hot ceramic shell is then filled with molten bronze. After the casting has cooled, it is removed from the mold and the sprues and vent lines are cut off. Then the bronze pieces are welded together. Each weld must be ground to make it conform to the contour of the sagebrush branch. The final step is to chemically treat the casting to produce a dark, even color (called a patina). Artworks Cliff Hanger, 2003, Maple burl, cast bronze, polyurethane, 3' × 19" × 10" (91cm × 48cm × 25cm) 42 While many of Ron Gerton’s bronze creations were made to sit on a table or other flat surface, he has made some that hang on a wall. His 2003 Cliff Hanger is one example. Another American Woodturner June 2024 F E AT U R E creation that hangs down, but from a shelf, the 2006 Desert Waterfall, features a multicenter turning (two hollow vessels in one piece of maple burl) suspended by a meandering length of bronze sagebrush. A truly amazing piece that features an impossibly thin section of Australian brown mallee burl, is Ron’s 2020 Lean ’n Mean. The burl’s length stretches 22" (56cm), forming a long wing that is only 3mm thick, and, remarkably, a small hollow vessel resides at one end. This woodturned piece is suspended at one end only by more sagebrush cast in bronze. To form the thin wood wing, Ron used a router mounted on an x-y table that sits on the bed of his lathe. The piece was turned slowly by hand against the spinning router bit. The result is a “turning” that elicits comments like, “How did he do that?” The hollow vessel was turned and hollowed in the usual way on the lathe, and to top it all off, a bronze snake rests near the hollow form’s small opening. Ron also turned an enormous hollow vessel that started with a piece of maple burl weighing 1100 lbs. (500 kg). The result was a vessel titled Big Bertha, which measures 47" (119cm) in diameter and which was hollowed through an opening just 3½" (9cm) wide. The final weight of Big Bertha is 39 lbs. (17.7 kg). In order to do the turning, it was necessary to build a large frame with roller bearings to support the vessel during hollowing. De-segmented vessels Not content to stop when a hollow vessel was completed, Ron got the idea to cut it up and reassemble the pieces into a new form. He calls these works de-segmented vessels. The original turned vessel is rotated through a bandsaw using a jig with an offset center point. Each piece has the same thickness, and Ron glues them together with each section shifted away from the preceding piece by a set and consistent distance. Reassembling all the pieces into one unit results Desert Waterfall, 2006, Maple burl, cast bronze, polyurethane, 3' × 19" × 7" (91cm × 48cm × 18cm) Lean ’n Mean, 2020, Brown mallee burl, cast bronze, slate, polyurethane, 8" × 22" × 8" (20cm × 56cm × 20cm) Big Bertha Big Bertha, 2002, Bigleaf maple burl, 47" (1.2m) diameter Starting at 1100 lbs., Big Bertha required a specially built frame to support it during hollowing. woodturner.org 43 Evolution Revolution, 2003, Maple burl, cast bronze, polyurethane, 31" × 20" × 9" (79cm × 51cm × 23cm) Inside Out, 2002, Madrone burl, polyurethane, 31" × 15" × 24" (79cm × 38cm × 61cm) in a wonderful spiral form, such as Evolution Revolution. When Ron assembled the pieces for Inside Out, he felt that the inside looked as interesting as the outside. So this piece, also made from a single turned hollow form, was reassembled in three parts, which were positioned so that both the inside and outside are displayed. sayings made from laser-cut letters (see this article’s opening image). Another, very large, piece of Ron’s of this nature measures 8' × 4' (2.4m × 1.2m) and resides in the lobby of a local hospital. Other works In the process of turning vessels from maple burl, Ron not surprisingly Wall art Curly Sue, 2019, Maple burl shavings, epoxy, 33" × 23" × 9" (84cm × 58cm × 23cm) generated a huge volume of shavings. He had a mold of a female figure, from the neck to the knees, which he had used for making bronze castings. Ron decided to use that mold to make a female form with the wood shavings. He coated the inside of the form with wax and filled it with shavings saturated with epoxy. The result was Curly Sue. Corrugated teapot, two views Another series of Ron’s artwork entails items that hang on a wall. A former member of Ron’s local woodturning chapter made various items using a laser, including words cut from thin pieces of wood. One day Ron discovered the trash from this club member’s laser operations, which he found to be stunning shapes, symbols, and colors. Ron got the idea that these scraps could be assembled to make art. One of these detailed wall pieces also incorporated broken segments of turned work. In Emerging Vessels, there are also Aces and Spaces, 2014, Cardboard, wood glue, 10" × 12" × 10" (25cm × 30cm × 25cm) 44 American Woodturner June 2024 F E AT U R E Several years ago, many woodturners began making teapots. Not to be left out of this trend, Ron made a turned teapot from cardboard. He glued up a stack of corrugated cardboard, paying particular attention to the orientation of the structure of each layer. The result was quite stunning. From the side, the piece has the familiar shape of a teapot, but the end view reveals the hollow structure of the cardboard. In 2008, Ron’s entry to the AAW’s invitational exhibition, The Sphere, was entitled, This Way, Dear. It featured a sphere being rolled by two dung beetles cast in sterling silver. The sphere was covered with scraps left over from laser cutting (as mentioned earlier), and in a moment of postmodern humor, Ron included on one scrap the words, “Your Ad Here.” More recently, Ron created Hold On, I’m Shifting into 2nd, which reveals an innovative use of a hollow vessel in figured maple. The figure trying to “hold on” is a frog made from sterling silver. Ironically, the vessel, plus head and feet, is a turtle. piece with one of these broken items as the central element. He added bronze to the broken vase to complete it, then made a circular disk of figured maple, cut out a flat section for the vase to sit upon, and added silver castings of insects, frogs, and butterflies. Over the past twenty-five years, many artists have appreciated Ron’s This Way, Dear, 2010, Maple, laser-cut wood scraps, cast bronze, lacquer, 8" × 11" × 10" (20cm × 28cm × 25cm) expertise. Such collaborative interactions continue through events like Frogwood (Oregon) and the Hawai‘i Arts Collaboration. Jerry Johnson is a founding member of the Mid-Columbia Woodturners. His work has been on display at various galleries in the Pacific Northwest. Hold On, I’m Shifting into 2nd, 2018, Curly maple, polyurethane, sterling silver, cast bronze, paint, 4" × 8" × 5" (10cm × 20cm × 13cm) Collaborations Ron Gerton has worked with other wood artists in the U.S. and Europe, many of whom were intrigued by the idea of having their work incorporated with a bronze casting or one of Ron’s turnings. Most notable were the collaborations with Binh Pho, a renowned artist who created thin-walled vessels that he pierced and painted to tell the story of his upbringing and life in Vietnam. Mystic Blooms (2016) couples five of Binh’s artworks with a large bronze casting made by Ron. Binh Pho had some of his turned wood vases converted to glass, which would sometimes break, leaving an incomplete vase. Binh passed away in August 2017, and in an homage to Binh, Ron made a woodturner.org (Above) Untitled, 2018, Curly maple, Binh Pho broken glass vessel, bronze, sterling silver, paint, 13" × 13" × 4" (33cm × 33cm × 10cm) (Left) Binh Pho and Ron Gerton Collaboration, Mystic Blooms, 2016, Birch, airbrushed paint, cast bronze, 47" × 10" × 10" (1.2m × 25cm × 25cm) 45 VISCERAL SIMPLICITY: THE BOLD WORK OF RUBEN VAN DER SCHEER Steve Loar A common acronym of the early years of contemporary woodturning was KISS, which stands for “Keep It Simple, Stupid.” Yes, there were the early patterns in the work of Al Stirt and the carved narrative compositions of Michelle Holzapfel, but by and large turning was about wood turned simply. It is not that anymore. The current field is largely propelled by decorative carving, piercing, pyrography, burning, color, texture, and alternative materials such as resin. In this context, the work of Dutch woodturner Ruben van der Scheer is quite surprising. His pieces are simple in the extreme—quite far from current trends and beyond anything seen in America, looking back or now. It’s as if early 20th-century Modernism never went away in the Netherlands. Ruben claims he follows no formal aesthetic, but his work takes us to the very edges of the KISS mantra. Even though his country’s borders don’t touch any of the five Nordic countries, from afar his work seems to express the flavor of Nordic or Scandinavian design—known for the use of natural materials (especially wood), pale colors, and restrained shapes. A somewhat sparer approach, Minimalism, refers to an unadorned aesthetic with the incorporation of industrial materials such as stainless steel, chrome, and lacquered plastics. Ruben’s Instagram account maintains a steady offering of subtly changing designs and experiments. I am fascinated by his ability to consistently Photo: Marjon Hoogervorst 46 American Woodturner June 2024 F E AT U R E invent forms within an extremely limited format, typically a circle or rectangle executed in dry wood on a faceplate and often with surfaces directly off the tool. Ruben’s work is about an intuitive search for art as “pure form,” but his explanations do sound quite like Minimalism. He refers to Donald Judd, an American artist who also refused to be labeled a Minimalist but was a prolific writer in explaining its sensibilities. Judd wrote, “It isn’t necessary for a work to have a lot of things to look at, to compare, to analyze one by one, to contemplate. The thing as a whole, its quality whole, is what is interesting. The main things are alone and are more intense, clear and powerful.” Ruben adds, “Look at waves in the ocean, on the lake, in a pond. Feel the flow of riding a wind- or surfboard, a skateboard, a bike. See the fields of long grass or grain in motion in the wind and especially how organically beech and plane trees grow. Like the muscles in a body, the body in general.” These connections—between seeing the object as a whole, his experiences and perceptions of nature, and the body’s responses to them—establish the crucial links to understanding Ruben’s work. Serving platters with the offset routed handle that led Ruben to meet his mentor, Maria van Kesteren. Mentor and student Photo: Johannes Schwartz Maria van Kesteren invited Ruben to exhibit with her at the 2018 Speculative Design Archive exhibition at Rotterdam’s Nieuwe Instituut. Freedom to create Ruben’s longest thread of memory from childhood is of inventing, needing to find alternatives, creative problem-solving, and wanting freedom. Despite his memory of schooling being about fitting into a mold, he received a degree in Human Movement Sciences and then a master’s degree in Philosophy. As he worked through his graduate thesis, though, he realized he longed to do something with his hands rather than just his mind. This curiosity about how things work led him to the remarkable decision in 2010 to apply to a respected but traditional cabinetmaking program at the Carpentry and woodturner.org Furniture College in Amsterdam. The students there learn hand tools and methods first, which requires a sharp chisel. As he prepared for his first sharpening exercise, he found himself stiff and awkward from anxiety. Grinding a chisel should be done mindfully, relaxed, swaying slightly with your whole body. His teacher prompted him: “Look, listen, feel.” Ultimately, the result was a gleeful experience. He was seized by the wonders of wood and woodworking, and the idea of making things with his hands became a true passion. This type of interaction, between mind and body, was exactly what he had studied and now also employs in his other profession as a psychomotor therapist. Even in his use of a router, it was his search for freedom that obliged him to use the tool in an unconventional way. For a circular cutting board, Ruben shifted the template slightly, creating a sharp point that swelled to a wide edge, then faded back to a point. Upon seeing this peculiar edge, a woodworking colleague urged him to have a talk with a local woodturner, Maria van Kesteren, who was making a living turning unconventional nonutilitarian forms and was showing her work internationally. When he 47 Dents (Left) Dents, 2020, Ash, Douglas fir, elm, various sizes (Middle) Dent, 2020, Ash, goldleaf, 4¾" × 4¾" × 1½" (12cm × 12cm × 38mm) (Right) Dent, 2021, Ash (sandblasted), paint, 12" × 12" × 2¾" (30cm × 30cm × 7cm) finally visited, Maria was welcoming and quite intrigued by the routed edge Ruben had achieved. How had he created this edge? Surely not on a lathe. This led to ongoing visits, coffee, and conversations—but not about woodturning. He found her home filled with various examples of Minimalist art, many by notable artists. While they did discuss craft and making, they mostly talked about art and being artists. Maria’s work wasn’t really about woodturning, but about the making of form. Editor’s Note: To learn more about Maria van Kesteren, see the accompanying article by Thimo te Duits on page 52. Once he had finished school, Ruben designed and made furniture and cabinetry, but he often lost himself in details and prototypes. “Maria’s greatest wish was to pass on her knowledge of a dying craft, as well as her highly individual approach to the material, to the next generation of woodworkers while she still could,” he explains. To provide inspiration, Maria gifted a large quantity of her uncompleted work to Ruben. Rather than modify the pieces, he used the unaltered turnings to create several upright sculptures. The strength of these works was such that Maria invited him to exhibit with her at the prestigious 2018 Speculative Design Archive exhibition at Rotterdam’s Nieuwe Instituut. The conversations with Maria, her success and, undeniably, her persistence nurtured Ruben as he grew dissatisfied with his chosen pursuits. Maria’s dedication to nonfunctional work and her search for pure form motivated Ruben to stop making useful things and begin his own exploration of non-functional turned forms. This approach offered him the freedom that he longed for. Truth in form Ruben’s designs arise from his search for “truth” in his forms, a certainty of flow in the creation of the form, like “riding the wave.” He wants his personal sense of flow to translate to the viewer’s perception of the whole. He may make an occasional scribble to note a general idea, but there is no sketching, drawing, or calculating that would rationally explain the form. For Ruben, it must be experienced; what is important is the emotional response, not objective reactions. Thus, each piece is a search for pure form that is utterly simple. Ruben is also intrigued by what is absent. The freedom that is inherent in this search for “truth” is what excites him and lures him on. Ruben’s Instagram account reveals an ongoing quest. His style arises from a repetition of these inquiries, but they are ever evolving and are never set repeated designs. A 48 “knowing” can be observed in his Dents series, which can be wall or table pieces. Over time, the Dents have developed from pleasant lumps to graceful hillocks rising gracefully from a static surface. They come smooth or with sandblasted textures, in muted tones, and in sets where one dent relates to another, with the grain adding continuity. Crucial to the viewing experience is learning that there is a corresponding depression in the back, which establishes a mystery, especially for an audience ever-less knowledgeable about what wood is or can do. We know the impression is back there as we respond to the front. With a flat back, there would be no indent and simply a mass on the front, with our body responding to this difference. Ruben’s spin tops are another good example of this search. They began life as tops, left attached to a wasteblock only until the paint was dry. As he made more of them, the inspiration for his Twist of Life tops developed, where a refined base is now part of an interactive art piece. They ask, Did you buy this piece to collect it as a sculpture with an embodied potential for spinning, or did you buy it to physically interact with it, snap it, and release that potential in an actual spin—a spinning that simultaneously makes the top an isolated object that now has a useless wasteblock base? American Woodturner June 2024 F E AT U R E But is pure form ever actually accomplished? When pressed on the concept of intuition and freedom, Ruben offers lekker, a Dutch word meaning “tasty,” or het smaakt goed meaning “it tastes right.” If we each “look, listen, feel,” that knowledge will provide the rigor for excellence— and a good taste. In woodturning, it is what is required before an object is sandblasted, scorched, or textured if it is to be a truly refined form. This is what we desire and respond to in any art form. How does a painting affect you? Is a sculpture interesting in multiple views or just one? Is there an awkward relationship or placement? Or maybe there is a junction where one sweep meets another, rather than one continuous passage. Should it have been a bit taller, or wider, or in another color? Or maybe the proportions are simply lumpish. What does “tastes good” feel like and could it taste better? Another way to think about it is “resonance,” or a quality of reverberation. Does the form have the best “taste,” or is there some subtle element missing that makes it simply another object, rather than something natural and complete? Try it, test it Another aspect of Ruben’s methodology is “try it, test it.” He will take some of his pieces home to view for a while, to judge them, to be critical but emotionally responsive. Drawing, Twist of Life tops Twist of Life (Tops), 2022, Various woods, paint Spinning Tops, 2019, Various woods, paint calculating, or theorizing about whether a piece might look good in black, pink, or red, for example, is inadequate. He must confirm how it actually affects a viewer. Try it, do it. This approach is apparent in Ruben’s post(c)arts. These are turned forms that even with their thickness conform to the Dutch postal code and are mailed worldwide. The recipients accept any scuffs or dents as part of the life of the piece. In making the post(c)arts, Ruben develops his creativity because to be profitable, he must be skillful and efficient in both imagining and responding. His turning skills are honed through the focused repetition of strokes. And what we see in his work is a wide-ranging inquiry into what forms might lie within a solid block. We see examples of shape, color, and texture that may or may not be pure form. Some may not have lekker, not pass this gauntlet, never inspire others. But the post(c)arts are truly visceral, which is Ruben’s main contention. It’s about responding with the right side of the brain. He finds the maximum amount of freedom in work where anything is possible within a few constraints. There are no theories: he must simply “do it, test it.” Post(c)arts (Left and middle) Post(c)arts, front and back. At about ¾" (19mm) thick, these turned “postcards” are fully functional and can be mailed. (Right) One of Ruben’s post(c)arts being mailed via the Dutch postal system. woodturner.org 49 Scale and proportion An oft-cited principle of turning is that all cuts are either a cove, bead, or fillet. In Ruben’s disks, we can see that there is room for a variety of new relationships for these shapes. Coves and beads function somewhat differently when in a circle or on a wall or even on a table surface. In a circle, large or small, they are visceral—you feel it in your gut. Through this interaction with the work, Ruben acknowledges the relationship between object and viewer. Ruben is also committed to the ever-present hole in the middle as an enigmatic void. This is one area where Ruben is traveling alone, apart from Minimalism, Wall Objects, 2022, Ash, ink, paint, oil, largest: 35" (90cm) diameter given that Judd once wrote, “There is no hierarchy nor preexisting ideas, we have the absence of a focal point.” Ruben’s education in psychomotor therapy gives him particularly compelling credentials in discussing this topic, one that some might find a bit “woo-woo.” If his sculptures are placed high on a wall, they are perceived in a wholly objective manner, solely visual. But when Ruben’s larger objects are placed near chest level, they can establish a more direct, even bodily or visceral, response. On the other hand, his smaller pieces may resonate more to the viewer’s hands, eliciting the urge to hold or touch the work. Ruben is a master of scale and proportion, and this supports his observations regarding resonance. Just as other artists use scale to elicit different viewer responses, Ruben accomplishes similar effects with his wall pieces. In art, scale refers to the size of one whole object in relation to another whole object. Proportion, however, refers to the relationship between the different sized parts within one whole composition. Human beings have an innate and finely tuned perception of proportion. The use of color can neutralize some visual cues, specifically proportion, when covering all but the boldest grains, while natural grain gives the knowledgeable viewer a reference to approximate size. Grain, a hand, or a larger grouping can provide a sense of true scale. Ruben’s intention is for the viewer’s eye to travel inward, toward the center, the hole, and not outward. Whether on a small or large disk or on a rectangle, his selective use of proportion is critical. You won’t find photos of Ruben’s pieces where your eyes move outward from the center, simply because those efforts 50 are revised or discarded. Ruben relies on the idea that our objective judgements, or those of drawings and calculations, won’t necessarily correspond to what is viscerally seen and experienced. At work Regarding his modest studio, Ruben reminisces, “What inspired me about [Maria van Kesteren’s] humble studio setting was that in order to make really great art, there is no need for new stuff, big machines, or fancy tools, just technique and a free mind, a vision, and creativity. It helps me to not get caught up in the technical side too much and keep my focus on form, shape, and intuition.” Ruben typically uses elm, ash, or sycamore that has been kiln dried. His favorite is elm for its smooth cutting. He uses single slabs, so the continuity of the grain is part of the form’s truth. He can get kilndried material in 2" and 3" (5-8cm) thicknesses, up to 36" (1m) wide. Quite near him is a wood processor and seller who slices and dries local and sustainable wood for his business in natural-edged slabs—a wonderful family business with lots of Dutch woods to choose from. Ruben will also buy material from a commercial dealer and, occasionally, is gifted wood from a local cemetery that is something of an arboretum. Opportunities Ruben’s year began with the exciting news that he had been granted a scholarship for three days of private professional development at Glenn Lucas’s Woodturning Study Centre in Co. Carlow, Ireland. Additionally, late last year he received an arts grant from the Netherlands government that will allow him to investigate American Woodturner June 2024 F E AT U R E Scale and proportion (Left) Wall objects, disks of varying sizes with a central hole as a focal point, resonate with viewers in a visceral way. (Middle) Wall object showing the importance of proportion when considering relative features within a piece. (Right) Relatively smaller disks, wall pieces with Ruben’s signature central hole as a focal point. some of the collaborative enterprises already taking place in his country. Ruben is interested in establishing a studio where nonartists can work, even though they face various challenges. In the Netherlands, these individuals are referred to as “people with a distance to the job (or labor) market” in that they can’t hold a typical job. In the U.S., these individuals might be regarded as outsiders, untrained idiosyncratic artists who are typically unconnected to the conventional worlds of art or craft—not by choice but by circumstance. Ruben envisions these people contributing in meaningful ways to the making of fine craft, not kitsch or tchotchkes. There is a design-based ceramics company, Cor Unum, that has already implemented this initiative. The company “takes social and cultural responsibility for the legacy of the ceramic crafts. Everyone deserves a place, everyone has got a talent and anyone can contribute to make the world somewhat nicer.” Ruben is interested in obtaining a residency with a like-minded company where he can interact with the designers and staff but, in particular, with the special contributors—including woodturner.org how they might respond to his own work. An exciting possibility is that some of his work could be created in other materials. These are surprising choices, but similar to others Ruben has made. They would certainly expand and diversify his work in unknown ways. So this year looks to be one of growth and diversification as Ruben is challenged by other art and craft professionals and, hopefully, by people “with a distance to the job (or labor) market.” For more, visit rubenvdscheer.nl or follow Ruben on Instagram, @rubenvanderscheer. Steve Loar is a sculptor, teacher, author, mentor, and woodturner living in Grand Rapids, Michigan. He uses wood, especially wooden bowls, to create abstracted compositions that are typically colorful and narrative. Thirty-six years of university teaching give him a depth of expertise in design, creativity, collaboration, and woodworking. Ruben’s studio Ruben van der Sheer’s modest but efficient and organized studio space. 51 Photos by Gallery Marsden Woo, London, except where noted. D MARIA VAN KESTEREN: VARIATIONS ON A THEME Thimo te Duits Maria van Kesteren, 1999, at the Gallery Marsden Woo, London. Photo: Philip Sayer 52 utch woodturner Maria van Kesteren (19332020) had a love-hate relationship with wood. She disliked its characteristic features, such as color variations, grain, and knots. Since 1962, she invariably coated her turnings with a thin layer of acrylic paint to emphasize the objects’ distinct narrative form. She worked on collections, or series, based on a single concept that incorporated variations of shape. She worked as large as her lathe allowed and at modest sizes. Maria was content with both possibilities, as long as the expressiveness was guaranteed. Each object had to be perfect. Material and form In the beginning of her woodturning activities, after lessons from Henk van Tierum and Nel Punt, she worked with tropical hardwoods. But she soon distanced herself from this material because she found it too romantic and started making painted objects from native woods such as elm, maple, stone beech, and lime. For jewelry, she used palm wood and acrylic. Her forms typically are short and wide and stand solidly on a stable base, but very occasionally Maria would incorporate some lift. Besides bowl shapes, she turned lots of boxes. In 1992, Maria introduced taller objects in the shape of a tree trunk, which are made of both wood and crystal. She disliked the transparent nature American Woodturner June 2024 F E AT U R E of glass and therefore applied opaque colors. She also developed ceramic vases. Despite her dislike of wood’s common features, it remained her favorite material to work, which she did with great craftsmanship to achieve forms that were unique to the international field. Maria van Kesteren took great pleasure in mentoring Ruben van der Scheer, teaching him the trade. Sensibilities Maria van Kesteren sought to connect with abstract visual art such as Zero and Minimalist Art. She also had a fondness for strict Modernist design from the 1920s and 1970s. As if to prove the conviction of her own taste, she chose to reside in a 19 th -century house in Hilversum. Her taste was held strictly and was full of respect for the makers of objects she admired. For decades, she advised the iconic craft gallery Kapelhuis in Amersfoort, and she took great pleasure in mentoring Ruben van der Scheer, teaching him the trade. As I have mentioned, Maria worked through various themes since the 1960s: half-spheres, plump forms, upward forms, sucking forms, dyke forms, craters, and tree trunks, to name a few. She leaves behind an impressive and unique oeuvre that found its way worldwide to passionate collectors and Rising Form, 1981-1982, Wood, acrylic paint, 3½" × 11" (9cm × 28cm) woodturner.org A solo exhibition at the Gallery Marsden Woo, London, 1999. museums. A lengthy list of international exhibitions and awards fell to her over four decades. The latest retrospective was at the Kunstmuseum Den Haag (The Hague, Netherlands), which displayed the crowning glory of her artistic life. Wrinkling Form, 1986-1987, Wood, acrylic paint, 2" × 10" (5cm × 25cm) Thimo te Duits is a Dutch art historian, curator, author, and editor. He worked for the National Glasmuseum (1990-1995, Leerdam) and Museum Boymans Van Beuningen (1995-2015, Rotterdam). For the last ten years, Thimo has been focusing his work exclusively on art and design. He is an avid collector of the work of Maria van Kesteren, whom he knew very well. Variation on Circular Form, 1982-1984, Wood, acrylic paint, 2½" × 9½" (6cm × 24cm) Variation on Circular Form, 1982-1984, Wood, acrylic paint, Largest: 3" × 8¼" (8cm × 21cm) 53 GMembers’ Gallery GALLERY Bruce Lee Jones, Maryland I have been involved with art for most of my life. I was a cabinet maker for thirty years, so working with wood is in my blood. I also have worked in acrylic, sterling silver, ceramic, as well as painting with acrylics on canvas. When I started turning in 2017, I wanted to show that I can make higher-end pieces without spending a great deal of money on equipment and tooling. Most of the pieces shown here were turned using modest (not professional level) equipment. It is also important to me to strive to make each project unique. About eighty percent of the carving on my turned pieces is done with hand tools such as knives and gouges. When I need to do power carving, I use a rotary tool with a flexible shaft with bits and burs. My goal is to continue adding my painting, silversmithing, acrylic, pyrography, and carving skills to my turned work. Sinuous, 2021, Teak, cherry, pyrography, lacquer, 8" × 12" (20cm × 30cm) Flower of Life, 2023, Red elm, pommele sapele, tigers eye stones, pyrography, lacquer, 6" × 13" (15cm × 33cm) Can We Stop All the Tears?, 2022, Teak, walnut, acrylic, dye, metallic powder, lacquer, 5" × 15" (13cm × 38cm) Nautilus, 2021, Sapele, curly maple, metallic paint, 9" × 9" (23cm × 23cm) King Nammu’s Decanter, 2023, Padauk, canarywood, African blackwood, sanding sealer, 18" × 12" × 8" (46cm × 30cm × 20cm) After turning the hollow form, the author hand-carved thirty-two flutes into the main body. The spout is made from two pieces that were carved all the way through, so you can pour liquid from this vessel. 54 American Woodturner June 2024 GALLERY William A. Clark, III, Rhode Island and Florida My journey in woodturning began at the age of 8, creating small wooden cabinet drawer knobs. Many years later, upon retirement, I graduated to turning large bed posts on a 12' (3.7m) antique lathe. Eventually, I shifted my focus to crafting bowls and sizable vessels. One such vessel stands out—a six-month labor of thought and design that won a 1stplace prize at the 2024 Florida State Fair. The vessel stands 38" (97cm) tall and features staved pieces with the grain running vertically. Assembly required two people and a twopart epoxy that allowed for extended working time. The choice of materials significantly impacts its aesthetic appeal. Tiger maple, known for its distinctive figuring and iridescence, creates a dynamic visual effect. The interplay of light and dark stripes adds depth and character. In contrast, black walnut—with its rich, chocolate-brown hues—provides a striking complement that enhances the piece’s elegance. Nature’s Artwork on Display, 2024, Tiger maple, black walnut, polyurethane, 38" × 19" (97cm × 48cm) Photo: Randy Saffles Scott Wishart, Pennsylvania After dabbling in woodworking for most of my adult life, I was finally exposed to woodturning about eight years ago. After witnessing someone turning on a lathe and seeing those shaving fly, I was completely hooked. From shaping to sanding and finishing, I was totally mesmerized by the entire process. Shortly after, I bought my first lathe, and the obsession started. Learning woodturning became my focus. I joined my local woodturning club and attended a few local symposia. I was like a sponge absorbing as much information as I could. Spindles, bowls, hollowing, resin hybrids… I found the whole thing fascinating. After several years of woodturning, I now practice “treecycling” as much as possible, primarily using discarded local hardwoods for my projects. My main interest is still learning something new. My goal is not to be better than anyone else, but to be better than I used to be. Woodturning has become a therapeutic process where I create things that make me happy. StarBurst, 2022, Maple (carved and torched), 5" × 7" (13cm × 18cm) My goal is not to be better than anyone else, but to be better than I used to be. Moon Vase, 2023, Red oak, Danish oil, 10" × 5" (25cm × 13cm) woodturner.org Springs, 2023, Boxelder maple, texturing, acrylic paint, 6½" × 7" (17cm × 18cm) X-Wing Sphere, 2023, Mallee burl, urethane resin, walnut, 5" (13cm) diameter 55 G GALLERY Chuck Goldstein, Wisconsin I began my woodturning adventure in 2003 by making a bowl from lumber left over from a grandfather clock that I had made. I discovered segmented bowls about ten years later and have made closed-segment, open-segment, and tangential-segment forms, as well as bowls with rings in them. I like to make forms that have unique shapes and are aesthetically pleasing. With Bubble Bowl, I was challenged to create segments with a diagonal stripe that went perfectly from corner to corner. Each segment had to be carefully cut from long strips. The colored circles are a nice complement to the strong diagonal and horizontal lines and give the piece a light, “bubbly” look, reminiscent of champagne. Bubble Bowl, 2023, Walnut, birdseye maple, wenge, yellowheart, purpleheart, leopardwood, padauk, varnish, 10" × 7" (25cm × 18cm) John Sisak, Michigan I started woodturning about seven years ago and joined the Huron Valley Wood Turners (Dexter, Michigan) to learn from some of their club members. During the pandemic, our chapter offered an online demo by Craig Timmerman on how to turn a torus bud vase. I finally got around to turning several of these forms. Because my woodturning experience has included segmented bowls, I decided to try a segmented torus shape. Infinity Spiral is segmented in two dimensions—eight segments comprising each of the 2"- (5cm-) diameter rings and 24 rings comprising the torus’s 8" (20cm) diameter. Infinity Spiral, 2023, Black walnut, maple, walnut oil, 8" × 8" × 2" (20cm × 20cm × 5cm) Perry Balog, New Jersey Growing up in an environment of craftsmen, inventors, and artists led me at an early age to work with my hands. I started turning wood at the age of 10 and, much later, completed a bachelor’s degree in industrial arts and a master’s degree in fine arts. My passion has been to create custom, one-of-a-kind pieces for clients and to share my knowledge and experience with students at Kean University (Union, New Jersey). As a woodturner and artist, I have always drawn inspiration from the world around me. The evolution of my latest series stemmed from the Covid pandemic. The spread of the deadly omicron, delta, and alpha viruses inspired me to create a unique series of turnings. The augmented edges represent the effect of the viruses’ spread, and as new variants evolved, I added layers. Avoiding gaps between the layers and short grain during shaping was a primary challenge. Alpha #2, 2023 Cherry, curly maple, rosewood, lignum vitae, wipe-on polyurethane, wax, 8½" × 3" (22cm × 8cm) (Left) Alpha #1, 2021, Mahogany, curly maple, ebony, magnets, wipe-on polyurethane, wax, 3½" × 12½" (9cm × 32cm) (Middle) Delta #1, 2021, Spalted maple, black walnut, wipe-on polyurethane, wax, 9" × 6½" (23cm × 17cm) (Right) Omicron #1, 2019, Cherry, wipe-on polyurethane, 3½" × 9" (9cm × 23cm) 56 American Woodturner June 2024 PRO TOOLS FOR TOOL PROS NEW LATHE CHUCK SYSTEM Precision Machined Body Engineered to the highest of standards from 1045 high tensile steel Jaw Slides Deeper body design with wide width for increased hold strength. Industry Leading Warranty We are so con�dent in �uality and performance our 10 Year Warranty is proudly engraved on the chuck! Z3 Precision Gear System Combined with matching key wrench provides strong holding power. Z4 Indexing Ring Rear Cover Sealed to protect the precision gear system from debris. Introducing the new premium line of Lathe Chucks and Jaws Accessories! 4-JAW LATHE CHUCK SYSTEM KIT INCLUDES: 4 Jaw Chuck | T-Handle Chuck Key | 50mm (2”) Standard Jaws Wood Screw | Fasteners & Hex Wrench 50mm (2”) Standard Jaws Wood Screw RH Visit www.rikontools.com for parts & accessories or to find a dealer near you! woodturner.org 57 www.oneway.ca postbox@oneway.ca 1-800-565-7288 Woodturning Lathes GOOD TO BE TURNING TOGETHER 800 Classes | 50 Subjects Weeklong & Weekends Powerful Precise Smooth Unique mechanical features seldom found on competitive lathes: Bed - steel torque tube design Legs - adjustable for height Headstock -welded steel, torque resistant Spindle -chrome alloy, hardened and ground -duplex preloaded ball bearings, both ends -locking groove for reverse turning Patented Banjo clamping 48 position indexing is standard Acme screw tailstock Much much more! Electronic Features: 1-1/2 to 3 hp available Electronic AC drive accepts 220 single or 3 phase Full power reverse turning Drive programmable for ramp up / down Fully moveable pendant Dust proof enclosure ALL ONEWAY PRODUCTS ARE MADE RIGHT HERE IN NORTH AMERICA. The Best Woodworking Chucks In The World. Often Copied, Never Equalled. Stronghold folkschool.org/aaw 58 Oneway Talon Superior Design. Legendary Quality. American Woodturner June 2024 800-228-0000•www.woodworkingshop.com TURN RAW INTO AWE We exist to help you transform raw materials into awesome projects. Attention Wood Turning Club Members Ask your club president about joining the Penn State Industries AAW Club program for access to discounts, door prizes for events and more. To join our club program, have your AAW chapter president call Steve Smith at 1-856-904-6558 Dealer inquirers invited call Todd at 1-877-774-5431 PENN STATE INDUSTRIES 1-800-377-7297 pennstateind.com woodturner.org 59 SouthWest Assoc of Turners - SWAT Aug. 23-25, 2024 Waco, TX t S thWes ou The Largest Regional Woodturning Symposium in America! our 32nd year of turning, Featuring... 2024 Stuart Batty Jason Breach Kirk DeHeer Kurt Hertzog Beth Ireland Sammy Long Laurent Niclot Plus 17 Fantastic Regional Demonstrators with over 63 demonstrations! Plus, welcoming this year... with 5 OTI Demonstrators! So much to see and do at SWAT! Art Gallery, Hands-On TXUQLQJDUHDVKXJHIRU5DfflHDQGWRRPDQ\9endors to list! Not to forget...Lunches too! Thank you to our sponsor... For more information and to Register, visit swaturners.org • Heavy duty construction & flexible configuration. • Quickly & easily attaches Innovative Solutions for Over 90 Years to almost any lathe. • Turn perfect spheres from 1” to 14” in diameter. The PERFECT SPHERE™ Tool • 6mm carbide cutter provided with each system. • Adjustable mounting base that fits on most lathe bed widths. • No drilling or external VIEW mounting required. DEMO www.CarterProducts.com 60 American Woodturner June 2024 www.dayacom.com.tw Find woodworking project kits and supplies to fuel your woodturning passion. Scan to Receive a Free Catalog. HELPING YOU MAKE WOOD WORK ® woodturner.org To Find Your Local Woodcraft Store, Visit woodcraft.com or Call 800-225-1153. 61 tradesman dc The amazing Tradesman 8 just got better Smooth, quiet and Powerful HOLLOWING SYSTEM Wolverine, Tormek Compatible, Micro-Adjust Feed Rest Designed to run Precision plated-Bond grinding wheels www.WoodturningwithTimYoder.com THE original Engineering and Prototyping - 2353 Ridgecrest Place, Ottawa ON K1H 7V4 Manufacturing and Distribution - 8 Proctor Ave, Ogdensburg NY 13669 Call us 1 (800) 417-2171 www.tradesmangrinder.com Canada: Black Forest Wood Co. Calgary, AB | Made in North America USA: Packard Woodworks NC, USA w w w.realmilkpaint.com #SBTT5ISFBEFE3JOHT ! 3 $ % " 5 4 % $ !4 3 7!4 !5 ' 5 3 4 4DBOUPMFBSOBCPVUPVS LJUT BDDFTTPSJFT BOENPSF TUBJOMFTTCPUUMFTUPQQFSTDPN .BEFJO)POFTEBMF 1FOOTZMWBOJB 62 American Woodturner June 2024 IT’S ALL ABOUT FUN! TURNING IS NOT WORK ANYMORE LYLE JAMIESON WOODTURNING LLC LiveInteractiveRemoteDemonstration LIVE WITH LYLE - Ready to go LIVE? IT’S A WHOLE NEW BALLGAME! I am broadcasting Live Interactitive Remote Demonstrations to the comfort and safety of your home. No need for club meetings, open to anyone! See my website for details and topics offered. www.lylejamieson.com 231-947-2348 YouTube-http://www.youtube.com/user/JamiesonLyle Facebook-https://facebook.com/lyle.jamieson1 NEW! FILL N’ FINISH ULTRA THIN PERFECT FOR A SCRATCH-FREE FINISH Creates the best pen finishes by removing sanding scratches. Also great for hardening punky wood and sealing end grain. learn more at www.gluboost.com © 2023 Gear Up Products, LLC. GluBoost®, MasterGlu™, Lac R’ Shot!™, MasterTint™, Fill n' Finish™, MasterShield ™ and EndPoint™ are Trademarks of Gear Up Products, LLC America’s Premier Woodturning School Enjoy hands-on instruction from top professionals in a spacious, comfortable environment. Make new friends and take your skills to the next level! woodturnerscatalog.com • Provo, Utah woodturner.org 63 QUALITY is DESIGNED IN Toolrests for any lathe with Hardened Rod on top We Listen. Our goal is to bring you the finest in woodturning lathes and accessories. We pride ourselves in listening to you, our customers and non-customers, and incorporating the very best of your ideas into our product line. We recognize that when you buy a Robust lathe, you buy the lathe of a lifetime, and we pledge to do our best to make that dream come true. And that pledge applies to everything we make. NEW! Steady rests for any lathe Scrapers, Skews and Gouges Handled and Unhandled Better by design. Enjoyed for a lifetime! 64 608.924.1133. info@turnrobust.com www.turnrobust.com® American Woodturner June 2024 THE BEST FOR YOUR WOODTURNING Brought to the US in partnership with Axminster Evolution SK114 Chuck Package Turn straight out of the box with this super precision chuck package. Made from stainless steel, with a revolutionary direct threaded design, the Axminster Evolution SK114 Chuck is the complete package for your woodturning. Axminster Evolution SK114 Chuck Package T23 - 1 1/4” x 8TPI • Stainless steel body for maximum corrosion resistance • Designed and made in the UK • Enclosed body for protection • Package includes chuck body, C Dovetail Jaws, faceplate ring, screw chuck, interchangeable accessory mounting jaws and chuck key Code: AXM-106875 Axminster Woodturning Eccentric Spiralling Chuck Axminster Woodturning Matched Pair of Ring Centres Axminster Woodturning O’Donnell Dovetail Jaws 3-in-1 Set Create unique, offset pieces with the Axminster Woodturning Eccentric Spiralling Chuck. This matched pair of friction centers allows you to swap your workpiece end for end, reduces risk of timber splitting and is a safe option for those new to turning. A versatile 3-in-1 jaw set which includes the 50mm O’ Donnell Jaws and 25mm, 38mm inserts. The 50mm jaws offers access for closein tool work, while the two additional inserts give a great range of work holding options. • Specialist chuck for spiralling and off-centre designs • Easy to use • Matched pair preserves concentricity • Allows better tool access • Safer option for new turners • UK made from stainless steel • Enables better access to the workpiece • Fits all Axminster 100mm & 114mm chucks Code: AXM-900093 Code: AXM-718166 Code: AXM-718321 Visit: www.thewoodturningstore.com Call: (631) 975-2800 Email: sales@thewoodturningstore.com 81A East Jefryn Blvd Deer Park, NY 11729 woodturner.org FREE Shipping on most orders over $100 Order by 2pm EST for same day shipping 65 Enriching Lives Through Art and Craft 1FSGFDUGPS'VSOJUVSF $VUUJOH#PBSET 4BMBE#PXMT #VUDIFS#MPDLT $PVOUFSUPQT 8PPEFO5PZTBOENPSF Experience the Power of Touch in 2024. Experience Arrowmont. Weekend, one-week and two-week workshops in woodturning, woodworking, and more. REGISTER NOW AT ARROWMONT.ORG OR CALL 865-436-5860 You Can Never Have Too Many Tools find your next tool at TRENTBOSCHTOOLS.COM 66 American Woodturner June 2024 DAVID ELLSWORTH SCHOOL OF WOODTURNING since 1990 Three-day, totally comprehensive workshops on open bowl and hollow form turning. October through July. Five students maximum, all levels of experience welcome. Luncheons served daily. Complete library of tutorial DVDs, hollowing tools, and the Ellsworth “Signature” Gouge and sharpening jig available. 8 ( /0 :*/ 3 3 $" Authorized dealer of Robust lathes. !CSBODIFTUPCPXMT !CSBODIFTUPCPXMT #3"/$)&450#08-4$0. David Ellsworth 208 Ox Creek Rd. Weaverville, NC 28787 E-mail: david.ellsworth3@gmail.com Website: www.ellsworthstudios.com VcYVa^[Zi^bZ\jVgVciZZ idndjgaVi]Z# H]deVilll#XVgiZgVcYhdciddaldg`h#Xdb woodturner.org My Stability Rest brings increased stability & satisfaction to turning with your carbidetip tools! pat ent pen din g Doug Clark Stability Rest dcfinewoodworking@gmail.com dougclarkfinewoodworking.com dougclarkfinewoodworking 67 ³7KH&DUELGH7KDW&876´ XXXFYPUJDXPPECJ[ ZZZKXQWHUWRROV\VWHPVFRP www.woodworkerslibrary.com 100’s of titles for the woodworker Since 1980 | Linden Publishing Save 40% CONTACT ERICA NELSON ERICA.NELSON@EWALD.COM 763-497-1778 YOUR AD HERE Timber Wolf Band Saw Blades *Made from high silicon, TH low carbon steel *Available in any length *50% sharper tooth *Precise hardening *True tracking *Milled teeth *Cooler running blade *Utilizes 20% less 1/8" to 1" wide horsepower Over 30 width and tpi combinations www.pswood.com 1-800-939-4414 3032 Industrial Blvd., Bethel Park, PA 15102 www.mdiwoodcarvers.com EasyInlay.com Precision Inlay Repair System Precut wooden patches with matching router guide Various sizes and wood types. www.woodfinder.com BigIslandEngraving.com 808-982-9987 68 American Woodturner June 2024 Mike Mahoney is doing remote demonstrations. Book an evening for your club today! Also, check out Mike’s new videos. CONTACT MIKE AT: “Thanks for your remote presentation. You nailed it. The technology you’re using is highly educational.” —Barbara Dill ORIGINAL ANCHORSEAL ® Trusted by Woodturners for over 40 years mikemahoneybowls@gmail.com www.bowlmakerinc.com WOOD PROT ECT ION PRODUCTS Order at uccoatings.com © 2023 Anchorseal® is part of the U-C Coatings family of wood protection and restoration products. (716) 833-9366 www.ChefwareKits.com Ϯϲϳ-888-ϲϮϭϲ-Made in USA -sĞƚĞƌĂŶKǁŶĞĚ EZ Threading Combo Jig Steel Index Wheel 5 Rows of Holes 192, 144, 120, 96, 88, 56 Quick & Easy Setup ƵƚƚŚƌĞĂĚƐŝŶƐŽŌǁŽŽĚ Cuts a perfect sphere swinging over the top CNC Made - No Flex Perfect Strait Lines Basket Weave Open Segment Router American Made & Supported Your Canadian Premium Woodworking and Woodturning Tool and Machinery Supplier CENTER for FURNITURE CRAFTSMANSHIP 2024 Summer Workshops (QFRXUDJLQJWKHQH[WJHQHUDWLRQRIZRRGWXUQHUV Turning for Beginners AVAILABLE AT WOODCHUCKERS.COM | Call: 1-800-551-0192 -XQH0DWW0RQDFR Platters and Plates -XO\0DWW0RQDFR THE ESSENTIAL AAW SMOCK! Introduction to Turning -XO\ .HQ:LVH • Breathable • Elastic collar • Full-length zipper • More Turning from A to Z 6HSW%HWK,UHODQG Segmented Turning Order today! • Member price $6 (U.S.), plus shipping woodturner.org 651-484-9094 877-595-9094 (toll free U.S.) woodturner.org $VVRUWHGWXUQLQJVE\0DWW0RQDFR 6HSW&XUW7KHREDOG 2025 Eight-week Turning Intensive -DQXDU\0DUFKZLWK/HDG,QVWUXFWRU%HWK,UHODQG Rockport, Maine 207-594-5611 p www.woodschool.org 69 Established 1992 Turn to Packard Woodworks for all your Turning, carving, and Pyrography Tools and Supplies WWW.PACKARDWOODWORKS.COM turning by molly winton WOODTURNING FUNDAMENTALS AAW’s digital publication featuring the foundations of woodturning Tips and projects for all skill levels Equipment and workshop advice More than 370 articles and videos FREE for AAW members woodturner.org/Fundamentals 70 American Woodturner June 2024 S T U A R T B AT T Y T O O L S . C O M advertisingindex American Association of Woodturners ............ 69/70 651-484-9094 - woodturner.org GluBoost ......................................................................63 201-331-3730 - gluboost.com RIKON Power Tools....................................................57 978-528-5380 - rikontools.com Arrowmont School of Arts and Crafts ...................66 865-436-5860 - arrowmont.org Griffin Exotic Wood llc .............................................68 970-241-2827 - exoticwood.biz Robust Tools ...............................................................64 608-924-1133 - turnrobust.com Artistic Wood and Tool Supply Inc. (Woodchuckers) ........................................................69 800-551-0192 - woodchuckers.com Hunter Tool Systems ................................................68 612-718-7926 - huntertoolsystems.com Ron Brown’s Best, LLC ..............................................63 770-962-3821 - ronbrownsbest.com John C. Campbell Folk School .................................58 828-837-2775 - folkschool.org Southwest Association of Turners - SWAT ............60 817-716-5950 - swaturners.org John Jordan Woodturning .......................................69 615-941-1247 - johnjordanwoodturning.com Stainless Bottle Stoppers .........................................62 570-253-5152 - stainlessbottlestoppers.com Klingspor’s Woodworking Shop.............................59 800-228-0000 - woodworkingshop.com Stuart Batty Tools......................................................71 213-453-2423 - stuartbattytools.com Laguna Tools...............................................................73 800-234-1976 - lagunatools.com Tallahassee Tung Oil .................................................72 850-524-2852 - tallahasseetungoil.com Linden Publishing .....................................................68 800-345-4447 - woodworkerslibrary.com Tradesman Grinder ...................................................62 800-417-2171 - tradesmangrinder.com Lyle Jamieson Woodturning LLC. ...........................63 231-947-2348 - lylejamieson.com Trent Bosch Tools.......................................................66 970-218-6453 - trentboschtools.com MDI Woodcarvers Supply.........................................68 800-866-5728 - mdiwoodcarvers.com U-C Coatings ...............................................................69 716-833-9366 - uccoatings.com Mike Mahoney ............................................................69 530-417-5535 - bowlmakerinc.com Woodcraft Supply, LLC .............................................61 800-225-1153 - woodcraft.com Oneway Manufacturing ...........................................58 800-565-7288 - oneway.ca Woodfinder ................................................................68 877-933-4637 - woodfinder.com Packard Woodworks .................................................70 800-683-8876 - packardwoodworks.com Woodturning with Tim Yoder .................................62 918-508-6425 - wtwtim.com Axminster Tool ...........................................................65 03332 406 406 - axminstertools.com Big Island Engraving ................................................68 808-982-9987 - bigislandengraving.com Branches To Bowls .....................................................67 403-830-3049 - branchestobowls.com Buffalo Woodturning Products..............................68 716-391-2001 - buffalowoodturningproducts.com Carter and Son Tool Works ......................................67 206-878-7672 - carterandsontoolworks.com Carter Products Company .......................................60 616-647-3380 - carterproducts.com Center for Furniture Craftsmanship .....................69 207-594-5611 - woodschool.org Chefwarekits/EZ Jigs ................................................69 267-888-6216 - chefwarekits.com Clapham’s Beeswax Products .................................66 800-667-2939 - claphams.com Clark’s Art Beyond ....................................................67 360-860-2488 - dougclarkwoodworking.com Craft Supplies USA ....................................................63 800-551-8876 - woodturnerscatalog.com Dayacom Industrial Co., Ltd......................................61 886-2-2532-3680 - dayacom.com.tw Easy Inlay.....................................................................68 585-967-3348 - easyinlay.com Ellsworth Studios.......................................................67 215-527-7928 - ellsworthstudios.com woodturner.org Peke Safety .................................................................66 800-277-1637 - pekesafety.com Penn State Industries ...............................................59 800-377-7297 - pennstateind.com PS Wood Machines ....................................................68 800-939-4414 - pswood.com Real Milk Paint Co. ....................................................62 800-339-9748 - realmilkpaint.com To advertise in American Woodturner, contact Erica Nelson, 763-497-1778, erica.nelson@ewald.com. 71 100% PURE TUNG OIL Discover the difference freshness makes 72 Visit us today at American Woodturner June 2024 TallahasseeTungOil.com ELECTRONICALLY VARIABLE SPEED FRONT/REVERSE DRO For More Info *Shown with Optional Accessories lagunatools.com woodturner.org 73 DANIEL MICHALIK NEW YORK Turning Cork In my New York City studio, Daniel Michalik Furniture Design focuses on researching and expanding overlooked materials to create objects that explore the intersections of material, culture, and manufacturing. Recently, we have explored the secrets of cork, an engaging material with vast implications for healthier perspectives on design, agriculture, and production. Cork is a sustainable material, regenerating every nine years for harvest. The Portuguese regions of cork production hold centuries-old farming and manufacturing traditions that can teach us how objects can be made more responsibly. Our objects reflect a love for the origin and context of material. Experiments evolve into products that engage form, color, and function. We have supplied products and solutions for clients worldwide, and our work has been exhibited internationally. For more, visit danielmichalik.com and follow Daniel on Instagram, @danielmichalik. Cork Bowl Trio, 2021, Cork, Each: 3" × 12" (8cm × 30cm) Photo: Andrew Longo Inside This Issue! Learn more about cork as a turning material in Scott Hendricks’ informative article on page 36. And see more examples of Daniel Michalik’s work on page 40.