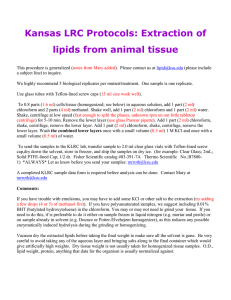

FACULTY OF ENGINEERING Department of Chemical Engineering Bellville Task: Mini project NAME: YAMKELA SURNAME: SOGONI STUDENT NUMBER:220414068 MODULE: DESIGN PROCESSES IV MODULE CODE: PQD470S LECTURE:MR MADZIMBAMUTO DUE DATE: 12 March 2024 Abstract ABC Oil Recycling Company, located in the Parow Industrial Area, aims to address community concerns, and renew its permits by implementing advanced scrubbing technologies to mitigate hydrogen sulphide emissions from its waste processing facility. As the Process Technologist, the feasibility design of this project involves evaluating the effectiveness and cost-efficiency of various scrubbing methods to achieve emission reduction targets. By prioritizing environmental sustainability and community welfare, the proposed solution aligns with the company's objective of fostering a positive public image while ensuring regulatory compliance. i Contents Abstract ................................................................................................................................................... i 1. 2. Introduction ................................................................................................................................... 1 1.1. Problem Statement ............................................................................................................. 1 1.2. Problem Review .................................................................................................................. 1 Possible Solutions ....................................................................................................................... 1 2.1. Focus Solution: Absorption................................................................................................ 1 3. Procedure ..................................................................................................................................... 1 4. Implementations .......................................................................................................................... 1 4.1. Assumptions ........................................................................................................................ 1 References ............................................................................................................................................ 5 Table 1:Concentration values of equilibrium, mini absorbent and operating line. ...................... 4 ii 1. Introduction 1.1. Problem Statement ABC Oil Recycling Company, situated in the Parow Industrial Area, is grappling with community dissatisfaction due to the environmental consequences of its operations, particularly the discharge of chloroform in its gaseous and liquid effluents. 1.2. Problem Review ABC Oil Recycling Company, situated in the Parow Industrial Area, confronts a significant challenge with the emissions from its processes, notably concerning chloroform, a volatile compound present in their flue gas. The community of Parow has expressed grave concerns about the environmental impact of the gaseous and liquid effluent emanating from the factory. The company's board acknowledges the importance of maintaining an environmentally friendly image and is cognizant that existing permits granted by the Cape Town City Council are up for renewal, contingent upon community approval. Chloroform, being volatile, poses a risk not only to air quality but also to water and soil (Agency for Toxic Substances and Disease Registry [ATSDR], 2017). It is released into the air from enterprises using or producing it, and it can also contaminate water and soil when chlorine-containing wastewater is discharged. Despite its natural occurrence as a byproduct of chlorine in water, excessive levels pose significant environmental risks (World Health Organization [WHO], 2004). Given these challenges, the company must devise a feasible solution to improve its waste processing system to mitigate chloroform emissions and address community concerns. The proposed system must not only adhere to regulatory standards but also align with the company's goal of maintaining an environmentally friendly image. The community has made it clear that the renewal of permits hinges on the implementation of an improved waste processing system by the end of 2025, potentially even sooner, as a goodwill gesture from the company's CEO. The feasibility design project aims to identify potential solutions, evaluate their effectiveness in mitigating chloroform emissions, and select the most viable option for implementation. It requires careful consideration of technical, environmental, and regulatory factors to ensure that the chosen solution addresses the root cause of the issue and meets the community's expectations while aligning with the company's objectives 1 2. Possible Solutions According to (EPA,2012; WHO,2004 and ATSDR,2017) the following are the practical solutions to the problem: Absorption: Implement a scrubber system to absorb chloroform from the flue gas using a suitable solvent. Adsorption: Employ activated carbon filters to adsorb chloroform from the flue gas stream. Biological Treatment: Utilize microbial cultures to biodegrade chloroform in the liquid effluent. Chemical Oxidation: Apply advanced oxidation processes to degrade chloroform in both gaseous and liquid effluents. Membrane Filtration: Implement membrane filtration techniques to separate chloroform from liquid effluents. Catalytic Conversion: Use catalysts to convert chloroform into less harmful substances through chemical reactions. Thermal Treatment: Employ high-temperature processes such as incineration to decompose chloroform in the gaseous effluent. 2.1. Focus Solution: Absorption Absorption involves the transfer of a gaseous pollutant into a liquid solvent through contact between the gas and the liquid (C. Xu, Z. Wu, and Y. Liu,2018). In the context of chloroform removal from the flue gas emitted by ABC Oil Recycling Company's operations, a scrubber system can be implemented. In this system, the flue gas containing chloroform comes into contact with a liquid solvent, typically water. Chloroform molecules in the gas phase dissolve into the liquid solvent due to the difference in concentration gradient between the gas and liquid phases (A. Smith and B. Johnson,2019) 1 3. Procedure (A. Smith and B. Johnson,2019) Confirmed that the absorption process can be outlined as follows: 1. Gas-Liquid Contact: The flue gas, containing chloroform, enters the scrubber unit and encounters the liquid solvent. The contact between the gas and liquid facilitates the transfer of chloroform molecules into the solvent. 2. Chloroform Dissolution: Chloroform molecules present in the flue gas dissolve into the liquid solvent. This dissolution occurs until equilibrium is reached, where the concentration of chloroform in the gas and liquid phases stabilizes. 3. Clean Gas Outlet: After absorption, the flue gas, now with reduced chloroform concentration, exits the scrubber unit. This clean gas can be released into the atmosphere or subjected to further treatment if necessary. 4. Solvent Regeneration: Periodically, the chloroform-laden solvent collected in the scrubber unit needs regeneration to maintain absorption efficiency. Regeneration typically involves heating the solvent to drive off the absorbed chloroform, leaving clean solvent for reuse. 1 4. Implementations Pure H2O X1 =0H2O Clean Air Air with CHCl3 (10ppm) Y1 Air+CHCl3 Yn+1 = 100ppm 4.1. Xn+1, H2O with CHCl3 Assumptions Each 90% removal of all contaminants from the waste streams. If solvents are recovered for reuse, the purity must always be > 99.5% pure with water as the major impurity stage operates adiabatically and approximately at 2,0 atm. Total flowrates L and V are Constant (Dilute solutions) Solute does not dissolve in air. 100 ppm of chloroform Data T=25⁰C (Entering liquid) P= 2.0 atm 𝐿 𝐿 = 1.4 ( ) 𝑉 𝑣 𝑚𝑖𝑛𝑖 𝑌𝑛+1 = 100 𝑝𝑝𝑚 𝑌1 = 10 𝑝𝑝𝑚 𝑁𝑜 𝑜𝑓 𝑠𝑡𝑎𝑔𝑒𝑠 =? 𝑌= 𝐻 𝑥 𝑃 𝐻 = 211.19 𝑓𝑟𝑜𝑚 𝑡ℎ𝑒 𝑡𝑎𝑏𝑙𝑒 1 𝑃 = 2 𝑎𝑡𝑚 𝑔𝑖𝑣𝑒𝑛 𝑌= 211.19 𝑥 2.0 𝑌 = 105.595𝑥 X equilibrium at 𝑌𝑛+1 = 100𝑝𝑝𝑚 𝑋𝑒𝑞𝑢𝑖𝑙 = 100 105.595 𝑋𝑒𝑞𝑢𝑖𝑙 = 0.947 𝑝𝑝𝑚 Operating line (𝑋0 , 𝑌1 ) = (0,10 𝑝𝑝𝑚) Minimum operating line 𝑋𝑚𝑖𝑛𝑖 𝑌𝑛+1 = 𝑉 𝑆𝑙𝑜𝑝𝑒 = 100 105.595 = 0.947 (𝑋, 𝑌) = (0.947 , 100) Slope of the minimum operating line 𝐿 ( ) = ( 𝑌𝑛 − 𝑌1 ) ( 𝑋 𝐿 − 𝑋0 ) 𝑚𝑖𝑛𝑖 𝑉 𝑚𝑖𝑛𝑖 𝑉 𝑌𝑁 = 𝑌𝑛+1 + 𝑌1 = 100 + 110 = 110 𝐿 ( ) = ( 110 − 10)( 0.947 − 0) 𝑉 𝑚𝑖𝑛𝑖 = 94.7 2 𝐿 = 1.4 (94.7) 𝑉 𝐿 = 133 𝑉 Solving 𝑋𝑛 with 𝑋𝑜 = 0 𝑋𝑛 = = 𝑌𝑛+1 − 𝑌𝑁 𝐿 𝑉 100 − 10 133 = 0.68 𝑝𝑝𝑚 (0.68 , 100) ∶ (𝑋𝑛 , 𝑌𝑛+1 ) 3 Table 1:Concentration values of equilibrium, mini absorbent, and operating line. x y 0 0.947 x 10 100 y 0 0.677 10 100 x 0 0.947 Y 0 100 X versus Y plot Gas concentration Y (ppm) 120 100 80 60 40 20 0 0 0,2 0,4 0,6 0,8 Concentration of a LIquid X (ppm) Therefore, this graph shows that there are 4,5 number of stages. 4 1 References Agency for Toxic Substances and Disease Registry (ATSDR). (2017). Toxicological Profile for Chloroform. A. Smith and B. Johnson, "Scrubber Systems for Gas Cleaning: Design and Operation," Environmental Engineering Journal, vol. 28, no. 2, pp. 89-102, 2019. C. Xu, Z. Wu, and Y. Liu, "Adsorption and Absorption: Two Promising Methods for Gas Separation," Journal of Chemical Engineering, vol. 42, no. 3, pp. 215-227, 2018. United States Environmental Protection Agency (EPA). (2012). Technologies for the Treatment of Effluents from Chlorine Bleaching in the Pulp and Paper Industry. World Health Organization (WHO). (2004). Chloroform in Drinking-water: Background document for development of WHO Guidelines for Drinking-water Quality. 5