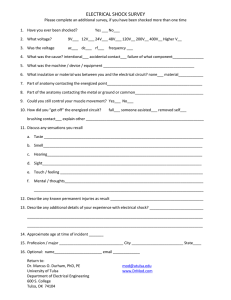

Electrical and LOTO Safety Awareness Introduction 004-2024 • Injuries associated with electrical hazards include: – Heart attack – Thermal burns – Falls resulting in injuries SLIDE-2 Regulations SLIDE-3 004-2024 • Cal-OSHA regulations are listed under Title 8 of the California Code of Regulations (CCR) – General Industry Safety Orders (GISO) – Construction safety orders – Electrical safety orders • Low voltage under 600v • High voltage over 600v Regulations 004-2024 • Only qualified persons shall work on electrical equipment or systems. • Only qualified persons shall be permitted to perform any function in proximity to energized overhead conductors unless means to prevent accidental contact have been provided. SLIDE-4 Electric Shock 004-2024 SLIDE-5 • When two wires have different potential differences (voltages), current will flow if they are connected together – In most household wiring, the black wires are at 110 volts relative to ground – The white wires are at zero volts because they are connected to ground • If you come into contact with an energized (live) wire, and you are also in contact with the grounded wire, current will pass through your body and YOU WILL RECEIVE A SHOCK • Contact with both energized wires of a 240-volt cable will deliver a shock. – This type of shock can occur because one live wire may be at +120 volts while the other is at –120 volts during an alternating current cycle, which is a potential difference of 240 volts. Shock Severity 004-2024 • Severity of the shock depends on: – Path of current through the body – Amount of current flowing through the body (amps) – Duration of the shocking current through the body • LOW VOLTAGE DOES NOT MEAN LOW HAZARD SLIDE-6 Thermal Burns 004-2024 • Thermal burns are the most common shock-related injury – Occurs when you touch electrical wiring or equipment that is improperly used or maintained • Typically occurs on hands • Very serious injury that needs immediate attention SLIDE-7 Falls 004-2024 • Electric shock can also cause indirect injuries – Workers in elevated locations who experience a shock may fall, resulting in serious injury or death SLIDE-8 LOTO 004-2024 • Apply locks to power source after de-energizing – Tag deactivated controls – Tag de-energized equipment and circuits at all points where they can be energized – Tags must identify who placed the tag and when SLIDE-9 Energized 004-2024 • Work shall not be performed on exposed energized equipment until : – Responsible supervision has determined that the work is to be performed while the equipment is energized. – Involved personnel have received instructions on the work techniques and hazards involved in working on energized equipment. SLIDE-10 Energized 004-2024 • Suitable personal protective equipment and safeguards (i.e., approved insulated gloves or insulated tools) are provided and used. – Rubber insulating gloves shall meet the provisions of the American Society for Testing Materials (ASTM) D 120-95 – Insulated tools shall meet the provisions of the ASTM F 1505-94 • Approved insulated gloves shall be worn for voltages in excess of 250 volts. • Suitable eye protection has been provided and is used. SLIDE-11 Energized 004-2024 • After the required work on energized equipment has been completed, an authorized person shall be responsible for: – Removing from the work area any temporary protective equipment, and – Reinstalling all permanent barriers or covers. • All electrical equipment and systems shall be treated as energized until tested or otherwise proven to be de- energized. SLIDE-12 Work Space 004-2024 SLIDE-13 • Suitable access and working space shall be provided and maintained about all electric equipment to permit ready and safe operation and maintenance of such equipment. – The dimension of the working space in the direction of access to energized parts which require examination, adjustment, servicing, or maintenance while energized, shall not be less than: – 36 inches and – The minimum headroom shall be 6 feet 3 inches. Guarding 004-2024 SLIDE-14 • All openings in boxes, enclosures or fittings shall be effectively guarded against accidental contact by approved cabinets or closed to afford protection substantially. This can also be accomplished by: – By location in a room, vault, or similar enclosure that is accessible only to qualified persons. – By suitable permanent, substantial partitions or screens so arranged that only qualified persons will have access to the space within reach of the energized parts. Marking 004-2024 • On all electrical equipment, markings shall be provided giving: – Voltage, – Current, – Wattage, or other ratings. • Each disconnecting means for motors and utilization equipment and for each service, feeder, or branch circuit at the point where it originates shall be legibly marked to indicate its purpose unless located and arranged so the purpose is evident. • The markings shall be of sufficient durability to withstand the environment involved. SLIDE-15 Accidents 004-2024 • Electrical accidents are caused by a combination of three factors: – Unsafe equipment and/or installation – Workplace made unsafe by the environment – Unsafe work practices SLIDE-16 Accidents 004-2024 • Use guards or barriers • Replace covers • Fix damaged wires • Conductors going into boxes must be protected, and unused openings must be closed SLIDE-17 Inadequate Wiring 004-2024 SLIDE-18 • Hazard - wire too small for the current • Example - portable tool with an extension cord that has a wire too small for the tool – The tool will draw more current than the cord can handle, causing overheating and a possible fire without tripping the circuit breaker – The circuit breaker could be the right size for the circuit but not for the smaller-wire extension cord Wire Gauge WIRE Overhead Powerlines SLIDE-19 004-2024 • Overhead power lines are usually not insulated • Examples of equipment that can contact power lines: – – – – – – – Crane Ladder Scaffold Backhoe Scissors lift Raised dump truck bed Aluminum paint roller Overhead Powerlines 004-2024 • If there is a chance of contact recommend placing warning signs – Stay at least 10 feet away • Assume that lines are energized • Use wood or fiberglass ladders, not metal • Power line workers need special training & PPE SLIDE-20 Cords 004-2024 • Cords can be damaged by: – Aging – Door or window edges – Staples or fastenings – Abrasion from adjacent materials – Activity in the area • Improper use can cause shocks, burns or fire – Remove cords by pulling on the plugs, not the cords SLIDE-21 Flexible Cords 004-2024 SLIDE-22 • Flexible cords shall be used only in continuous lengths without splice or tap. – Hard service flexible cords No. 12 or larger shall be permitted to be repaired if spliced so that the splice retains the insulation, outer sheath properties, and usage characteristics of the cord being spliced. • Flexible cords shall be repaired or replaced if the outer sheath is damaged such that any conductor insulation or conductor is exposed. – Repair of the outer sheath shall only be permitted if the conductors are not damaged and the completed repair retains the insulation, outer sheath properties, and usage characteristics of the cord being repaired. • Flexible cords shall be connected to devices and fittings so that strain relief is provided which will prevent pull from being directly transmitted to joints or terminal screws. Cord Inspection 004-2024 • Deformed or missing pins • Damaged outer jacket or insulation • Evidence of internal damage • If damaged, take out of service until repaired SLIDE-23 Grounding 004-2024 • Tools plugged into improperly grounded circuits may become energized – Check wiring with a tester • Make sure that the plug does not have a broken ground • Do not convert a grounded plug to an ungrounded plug SLIDE-24 GFCI 004-2024 • Ground Fault Circuit Interrupter (GFCI or GFI) protects you from shock – Detects difference in current between the black and white wires – If ground fault detected, GFCI shuts off electricity in 1/40th of a second SLIDE-25 Overloaded Circuits 004-2024 • Too many devices plugged into a circuit can: – Heat up wires and possibly start a fire – Damage tools due to overheating – Melt the wire insulation, which may cause arcing and a fire in the area where the overload exists, even inside a wall – Do not daisy chain multi outlet strips SLIDE-26 Protective Devices 004-2024 • A circuit breaker or fuse automatically opens the circuit if excess current from overload or ground-fault is detected – shutting off electricity – They are for protection of property not people – If activated fuses have to be replaced and circuit breakers have to be reset SLIDE-27 Power Tools 004-2024 • Inspect power tools and extension cord before using them • Use a GFCI • Store in dry place when not using • Don’t use in wet/damp conditions • Don’t carry a tool by the cord • Don’t yank the cord to disconnect it • Keep cords away from heat, oil, & sharp edges • Disconnect when not in use and when changing accessories such as blades & bits • Remove damaged tools from use SLIDE-28 Electrical Hazard Clues 004-2024 • Tripped circuit breakers or blown fuses • Warm tools, wires, cords, connections, or junction boxes • GFCI that shuts off a circuit • Worn or frayed insulation around wire or connection SLIDE-29 Work Practices 004-2024 • Use non prime hand to throw switch – Stand to side of panel when throwing switch – Turn head away from panel right before throwing switch • Remove jewelry • Use barriers and guards to prevent passage through areas of exposed energized equipment – Pre-plan work, post hazard warnings and use protective measures – Keep working spaces and walkways clear of cords SLIDE-30 Training 004-2024 • Train employees on the following: – Deenergize electric equipment before inspecting or repairing – Using cords, cables, and electric tools that are in good repair – Lockout / Tagout recognition and procedures – Use of appropriate personal protective equipment SLIDE-31 Training 004-2024 SLIDE-32 • Qualified workers – How to identify exposed energized parts – How to safeguard or work on energized parts • Unqualified workers – How electricity works – Risks of working with energized equipment – Tasks to be performed only by qualified workers SOP 004-2024 SLIDE-33 • When a circuit is abandoned or discontinued, its conductors shall be removed from the raceways, or be maintained as if in use. • In locations where electric equipment would be exposed to physical damage, enclosures or guards shall be so arranged and of such strength as to prevent such damage. • No grounded or grounding conductor shall be attached to any terminal or lead so as to reverse designated polarity. PPE 004-2024 • Where insulating rubber gloves are used for shock protection, leather protectors shall be worn over the rubber gloves. • Heavy-duty leather work shoes provide some arc flash protection to the feet and shall be used in all exposures greater than 4 cal/cm2 . SLIDE-34 PPE 004-2024 SLIDE-35 • Proper PPE can include Flame Resistant clothing, hardhat, hood, face shield, safety glasses, gloves, shoes, etc. depending upon the magnitude of the arc energy. • Employees working in areas where electrical hazards are present shall be provided with, and shall use, PPE that is designed and constructed for the specific part of the body to be protected and for the work to be performed. • PPE are intended to protect a person from arc flash and shock hazards. – While some situations could result in burns to the skin, even with the protection selected, burn injury should be reduced and survivable. – Due to the explosive effect of some arc events, physical trauma injuries could occur. Insulated Tools 004-2024 • Employees shall use insulated tools or handling equipment, or both, when working inside the limited approach boundary of exposed energized electrical conductors where tools or handling equipment might make accidental contact. – Insulated tools shall be protected from damage to the insulating material. • Insulated tools shall be rated for the voltages on which they are used. • Insulated tools shall be designed and constructed for the environment to which they are exposed and the manner in which they are used. SLIDE-36 Job Briefing 004-2024 SLIDE-37 • Before starting each job, the employee in charge shall conduct a job briefing with the employees involved. • The briefing shall cover such subjects as hazards associated with the job, work procedures involved, special precautions, energy source controls, PPE requirements, and the information on the energized electrical work permit, if required. • Additional job briefings shall be held if changes that might affect the safety of employees occur during the course of the work. Testing 004-2024 SLIDE-38 • Only qualified persons shall perform tasks such as testing, troubleshooting, and voltage measuring within the limited approach boundary of energized electrical conductors operating at 50 volts or more or where an electrical hazard exists. – Test instruments and equipment and all associated test leads, cables, power cords, probes, and connectors shall be visually inspected for external defects and damage before each use. – If there is a defect or evidence of damage that might expose an employee to injury, the defective or damaged item shall be removed from service, and no employee shall use it until repairs and tests necessary to render the equipment safe have been made. – When test instruments are used for testing the absence of voltage on conductors or circuit parts operating at 50 volts or more, the operation of the test instrument shall be verified before and after an absence of voltage test is performed. Stored Energy 004-2024 SLIDE-39 • The procedure shall include requirements for releasing stored electric or mechanical energy that might endanger personnel. • All capacitors shall be discharged, and high capacitance elements shall also be short-circuited and grounded before the associated equipment is touched or worked on. • Springs shall be released or physical restraint shall be applied when necessary to immobilize mechanical equipment and pneumatic and hydraulic pressure reservoirs. • Other sources of stored energy shall be blocked or otherwise relieved. Auditing 004-2024 SLIDE-40 • The electrical safety program shall be audited to verify the principles and procedures of the electrical safety program are in compliance with this standard. – The frequency of the audit shall not exceed 3 years. • Field work shall be audited to verify the requirements contained in the procedures of the electrical safety program are being followed. When the auditing determines that the procedures of the electrical safety program are not being followed, the appropriate revisions to the training program or revisions to the procedures shall be made. • The audit shall be documented. 004-2024 Questions? SLIDE-41