Types of Couplings: Material & Mechanical Flexing Explained

advertisement

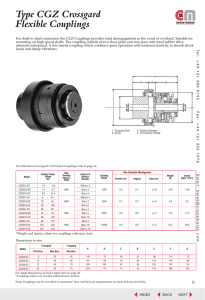

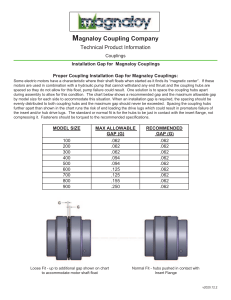

Types of Couplings Coupling fall into two main categories: Material Flexing and Mechanical Flexing. The material flexible types obtain their flexibility from stretching or compressing a resilient material, such as rubber, or from the flexing of thin metallic discs or grid. Material flexing couplings do not require lubrication, with the exception of grid couplings. The mechanical flexing couplings accept misalignment from rocking, rolling or sliding of metal surfaces. All metal mechanical flexing couplings require lubrication. Material Flexing Couplings Material flexing couplings typically do not require lubrication and operate in shear or compression and are able to accept angular, parallel and axial misalignment. Examples of material flexing couplings are jaw, sleeve, tire, disc, grid and diaphragm couplings. - Jaw Couplings The jaw coupling is a material flexing coupling that transmits torque thru compression of an elastomeric spider insert placed between two intermeshing jaws. Flex element is commonly made of NBR, polyurethane, Hytrel or Bronze Accommodates misalignment Transmits torque Used for torsional dampening (vibration) Low torque, general purpose applications - Sleeve Coupling The sleeve coupling transmits low to medium torque between connected equipment in shear through an elastomeric insert with male splines that mate with female hub splines. The insert material is typically EPDM, Neoprene or Hytrel and the insert can be a one or two piece design. Moderate misalignment Torsional dampening (vibration) End float with slight axial clearance Low to medium torque, general purpose applications - Tire Coupling These couplings have a rubber or polyurethane element connected to two hubs. The rubber element transmits torque in shear. Reduces transmission of shock loads or vibration. High misalignment capacity Easy assembly w/o moving hubs or connected equipment Moderate to high speed operation Wide range of torque capacity - Disc Coupling The disc coupling’s principle of operation has the torque transmitted through flexing disc elements. It operates through tension and compression of chorded segments on a common bolt circle bolted alternately between the drive and driven side. These couplings are typically comprised of two hubs, two discs packs, and a center member. A single disc pack can accommodate angular and axial misalignment. Two disc packs are needed to accommodate parallel misalignment. • Allows angular parallel and axial misalignment • • • Is a true limited end float design A zero backlash design High speed rating and balance - Diaphragm Coupling Diaphragm couplings utilize a single or a series of plates or diaphragms for the flexible members. It transmits torque from the outside diameter of a flexible plate to the inside diameter, across the spool or spacer piece, and then from inside to outside diameter. The deflection of the outer diameter relative to the inner diameter is what occurs when the diaphragm is subject to misalignment. For example, axial displacement attempts stretch the diaphragm which results in a combination of elongations and bending of the diaphragm profile. • Allows angular, parallel and high axial misalignments • Used in high torque, high speed applications Mechanical Flexing Couplings The mechanical flexing couplings accept misalignment from rocking, rolling or sliding of metal surfaces. All metal mechanical flexing couplings require lubrication. Examples of mechanical flexing couplings are gear, grid and roller chain couplings. - Gear Couplings Gear couplings transmit the highest amount of torque and the highest amount of torque in the smallest diameter of any flexible coupling. Each coupling consists of two hubs with crowned external gear teeth. The hubs mesh with two internally splined flanged sleeves that are bolted together. Gear couplings accommodate angular and axial misalignment by the rocking and sliding of the crowned gear teeth against the mating sleeve teeth. Parallel misalignment is accommodated by having two adjacent hub/sleeve flex points. Gear couplings require periodic lubrication depending on the application. They are sensitive to lubrication failures but if properly installed and maintained, these couplings have a service life of 3 to 5 years and in some cases they can last for decades. Grid couplings consist of 2 radially slotted hubs that mesh with a serpentine strip of spring steel the grid provides torsional damping and flexibility of an elastomer but the strength of steel. Grid couplings transmit torque and accommodate angular, parallel and axial misalignment from one hub to the other through the rocking and sliding of a tapered grid in the mating hub slots. The grid cross section is generally tapered for better hub contact and easier assembly. As there is movement between contacting hub and grid metal parts, lubrication is required. Roller Chain type couplings consist of two radially sprocketed hubs that engage a strand of double pitch roller chain. Chain couplings are used for low to moderate torque and speed applications. The meshing of the sprocket teeth and chain transmits torque and the associated clearances accommodate angular, parallel and axial misalignment. Chain couplings require periodic lubrication depending on the application. The lubrication is typically brushed onto the chain and a cover is used to help keep the lubrication on the coupling. To learn more about all of the different types of couplings, visitthe Rexnord Coupling Page