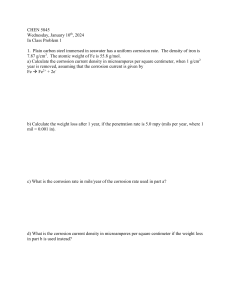

Galvanic corrosion of aluminium aluminium-guide.com/en/galvanic-corrosion-aluminium Naturally resistant to corrosion It is known that the resistance of aluminum and aluminium alloys to normal environmental conditions is very high. The main source of protection against corrosion is a durable, selfhealing oxide film, which is always present on aluminium in the surrounding air atmosphere (Fig. 1). Figure 1 – Surface oxide film is a natural protection of aluminium from corrosion [1] Main types of aluminium corrosion There are many types of corrosion. The most coomom types are [1]: General corrosion Crevice corrosion Exfoliation corrosion Fretting corrosion Exfoliation corrosion Exfoliation corrosion the material Intergranular corrosion and exfoliation The most common design error The most common design errors in aluminum structures are related to galvanic corrosion. Galvanic or electrochemical corrosion occurs when two dissimilar metals form an electrical circuit that is completed by a liquid or film electrolyte or corrosive medium. 1/5 Under these conditions, the potential difference between dissimilar metals creates an electric current passing through the electrolyte, which (current) leads to corrosion primarily of the anode or the less noble metal of this pair (Fig. 2). Figure 2 – Galvanic corrosion of aluminium alloy occurs under conditions of wet or moist contact with another, more “noble” metal, such as copper [1] Galvanic corrosion of aluminum The essence of galvanic corrosion When two different metals are in direct contact with an electrically conductive liquid, experience shows that one of them can corrode, that is, become corroded. This is called galvanic corrosion. The other metal will not corrode; on the contrary, it will be protected from this type of corrosion. This type of corrosion is different from the types of corrosion that would occur if both of these metals were placed separately in the same liquid. Galvanic corrosion can happen to any metal as soon as two different metals are in contact in an electrically conductive liquid. Appearance of galvanic corrosion The appearance of galvanic corrosion is very characteristic. This corrosion does not spread over the entire surface of the product, as is the case with pitting corrosion. Galvanic corrosion is tightly localized in the area of contact between aluminium and another metal. The corrosive effect on aluminium is uniform; it develops deeper in the form of craters, which have a more or less rounded shape [2, 3[. Conditions for galvanic corrosion 2/5 Galvanic corrosion is based on the same principle and in order for it to occur, the following three conditions must be simultaneously met [3]: various types of metals presence of electrolyte electrical contact between two metals. Various types of metals For any metals that belong to various types, galvanic corrosion is possible. The metal with the electronegative potential (or the more electronegative metal if they are both electronegative) acts as the anode. The tendency of various metals to form galvanic couples and the direction of electrochemical action in various corrosive environments (sea water, tropical climates, industrial atmospheres, etc.) are shown in the so-called galvanic series. The further apart the metals in these rows are, the more severe galvanic corrosion can be. In different corrosive environments, these sequences of metals may be different (Figure 3). Presence of electrolyte The contact area must be wetted with an aqueous solution to ensure ionic conductivity. Otherwise there is no possibility of galvanic corrosion. Electrical contact between metals Electrical contact between metals can occur either by direct contact between two metals, or through a fastening connection, such as a bolt or a rivet. Various galvanic corrosion As can be seen from the graphs in Figure 3, aluminium and its alloys become anodes in galvanic cells with most metals, and aluminium corrodes, as they say, sacrificially and protects the other metal of the galvanic pair from corrosion. Only magnesium and zinc, including galvanized steel, are more anodic and therefore, being exposed to corrosion themselves, protect aluminium from it. Aluminum and cadmium generally have almost the same electrode potentials and therefore neither aluminium nor cadmium are subject to galvanic corrosion. Unfortunately, cadmium is recognized as very toxic and is used less and less, and in many countries it is simply banned as an anti-corrosion protection. 3/5 Figure 3 – Galvanic corrosion of aluminium in contact with varios metals in marine, tropical and urban atmospheres [4] How to avoid galvanic corrosion Choose a metal pair with aluminium or its alloy that is as close as possible to it in the galvanic series for the corrosive environment in question (see Figure 3). Use “cathode” fasteners. Avoid combinations with an unfavorable (large) ratio of cathode to anode areas. Provide complete electrical insulation between the two metals being connected. This can be done using insulating spacers, bushings, washers, etc. (Figure 4). If painting is used, the cathode should always be painted. If only the anode is painted, any scratch on it will give an unfavorable ratio of the cathode to anode surfaces. It will lead to corrosion of the scratch. Increase the thickness of the anode or install replaceable massive gaskets made of anode metal into the connection. Avoid threaded connections made of metals that form a galvanic couple. Replace them with soldered or welded joints. If possible, use corrosion inhibitors, for example in systems with circulating fluid, which can act as an electrolyte for galvanic corrosion. In cases where metals must remain in electrical contact through an external electrical circuit, it is necessary to space them as far apart as possible to increase the resistance of the liquid circuit (electrolyte). If necessary and where possible, apply cathodic protection with zinc or magnesium sacrificial anodes. In the most aggressive environments, only zinc, cadmium and magnesium can be in contact with aluminium without causing galvanic corrosion. Note that the use of cadmium coatings is largely limited due to their environmental unsafety. 4/5 Figure 4 – Joints with Different Metals. The Effect of Anode to Cathode Area on Corrosion of Bi-Metal Joints [4] Figure 5 – Prevention of Contact Corrosion by Electrical Insulation. Assemblies “A” and “B” cause galvanic corrosion, the assembly “C” avoids it [4] 5/5