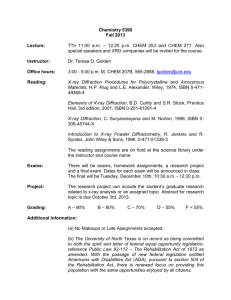

In-situ Synchrotron X-ray Analysis of Metal Additive Manufacturing

advertisement