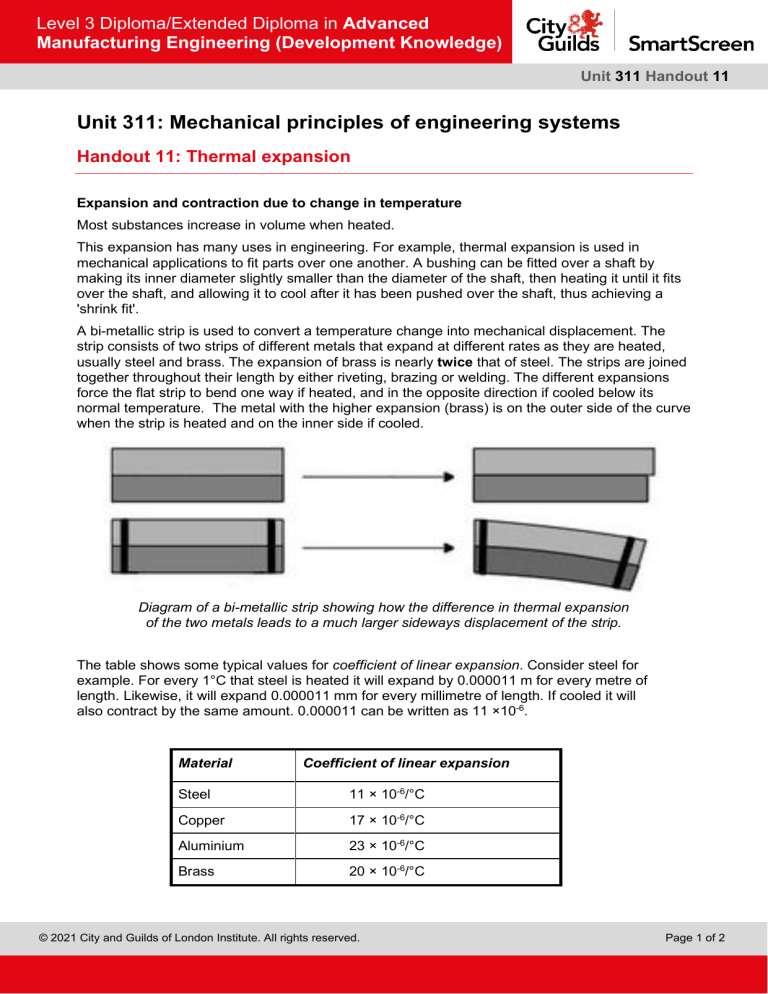

Level 3 Diploma/Extended Diploma in Advanced Manufacturing Engineering (Development Knowledge) Unit 311 Handout 11 Unit 311: Mechanical principles of engineering systems Handout 11: Thermal expansion Expansion and contraction due to change in temperature Most substances increase in volume when heated. This expansion has many uses in engineering. For example, thermal expansion is used in mechanical applications to fit parts over one another. A bushing can be fitted over a shaft by making its inner diameter slightly smaller than the diameter of the shaft, then heating it until it fits over the shaft, and allowing it to cool after it has been pushed over the shaft, thus achieving a 'shrink fit'. A bi-metallic strip is used to convert a temperature change into mechanical displacement. The strip consists of two strips of different metals that expand at different rates as they are heated, usually steel and brass. The expansion of brass is nearly twice that of steel. The strips are joined together throughout their length by either riveting, brazing or welding. The different expansions force the flat strip to bend one way if heated, and in the opposite direction if cooled below its normal temperature. The metal with the higher expansion (brass) is on the outer side of the curve when the strip is heated and on the inner side if cooled. Diagram of a bi-metallic strip showing how the difference in thermal expansion of the two metals leads to a much larger sideways displacement of the strip. The table shows some typical values for coefficient of linear expansion. Consider steel for example. For every 1°C that steel is heated it will expand by 0.000011 m for every metre of length. Likewise, it will expand 0.000011 mm for every millimetre of length. If cooled it will also contract by the same amount. 0.000011 can be written as 11 ×10-6. Material Coefficient of linear expansion Steel 11 × 10-6/°C Copper 17 × 10-6/°C Aluminium 23 × 10-6/°C Brass 20 × 10-6/°C © 2021 City and Guilds of London Institute. All rights reserved. Page 1 of 2 Level 3 Diploma/Extended Diploma in Advanced Manufacturing Engineering (Development Knowledge) Unit 311 Handout 11 The symbol for coefficient of linear expansion is α (alpha). A coefficient is a constant and therefore has no units. The symbol for length is 𝑳𝑳. The symbol for temperature change is ∆𝒕𝒕. The formula for determining the increase (decrease) in length is: Example 1 increase (decrease) in length = α 𝒙𝒙 𝑳𝑳 𝒙𝒙 ∆𝒕𝒕 A steel strip is 1.5348 m long at 12°C and is pre-heated to 100°C prior to welding. How long is the strip of steel at 100°C? Increase in length = α × 𝑳𝑳 × ∆𝒕𝒕 Increase in length = 𝟏𝟏𝟏𝟏 × 𝟏𝟏𝟎𝟎−𝟔𝟔 × 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 × 𝟖𝟖𝟖𝟖 Increase in length = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 × 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 × 𝟖𝟖𝟖𝟖 Increase in length = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 𝐦𝐦 Length of strip at 100°C = original length + increase in length Length of strip at 100°C = 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 𝐦𝐦 + 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 𝐦𝐦 Length of strip at 100°C = 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 𝐦𝐦 An increase in length of 1.5 mm. Example 2 The same steel strip cools from 100°C down to the new ambient temperature of 25°C. How long is the strip of steel at 25°C? Decrease in length = α × 𝑳𝑳 × ∆𝒕𝒕 Decrease in length = 𝟏𝟏𝟏𝟏 × 𝟏𝟏𝟎𝟎−𝟔𝟔 × 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 × – 𝟕𝟕𝟕𝟕 Decrease in length = 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 × 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 × – 𝟕𝟕𝟕𝟕 Decrease in length = – 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 𝐦𝐦 Length of strip at 25°C = original length – decrease in length Length of strip at 25°C = 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 𝐦𝐦 – 𝟎𝟎. 𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎𝟎 𝐦𝐦 Length of strip at 25°C = 𝟏𝟏. 𝟓𝟓𝟓𝟓𝟓𝟓𝟓𝟓 𝐦𝐦 The strip is 0.2 mm longer than it was at 12°C and 1.3 mm shorter than it was at 100°C. © 2021 City and Guilds of London Institute. All rights reserved. Page 2 of 2