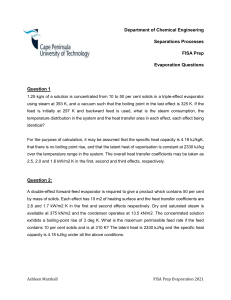

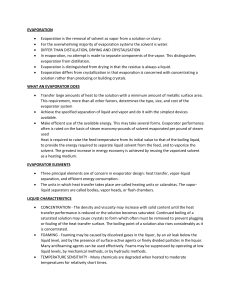

AP Government GATE Online Classes Heat Transfer Day-10 (04.06.2020) Dr. R. Srikanth Professor ANITS-Visakhapatnam Evaporation Evaporation • Evaporation is the conversion of a liquid to a vapor. • Evaporation is the removal of volatile solvent from a solution or relatively dilutes slurry by vaporizing the solvent. Evaporators are used for this process. 4.6.2020 3 Evaporators • Evaporators are used to separate materials based on differences in their boiling temperatures. • Its purpose is to concentrate nonvolatile solutes such as organic compounds, inorganic salts, acids or bases. Typical solutes include phosphoric acid, caustic soda, sodium chloride, sodium sulfate, gelatin, syrups and urea. • Evaporation concentration means removal of water by boiling. Evaporation finds application in a variety of food processing operations. A primary application is concentration of fruit juices (orange juice concentrate), vegetable juices (tomato pastes and purees), and dairy products (condensed milk). Evaporation is also used to concentrate salt and sugars prior to refining. 4.6.2020 4 Requirements for optimal evaporation (l) rapid rate of heat transfer. (2) low-temperature operation through application of a vacuum. (3) efficient vapor-liquid separation. (4) efficient energy use and recovery. Performance of Evaporator • There are three main measures of evaporator performance: – Capacity (kg vaporized / time) – Economy (kg vaporized / kg steam input) – Steam Consumption (kg / hr) • Note that the measures are related, since Consumption = Capacity/Economy Boiling Point Elevation • The vapor pressure of an aqueous solution is less than that of pure water at the same temperature; so the boiling point of the solution will be higher than that of the water. This is called Boiling Point Elevation (BPE) or vapor pressure lowering. • The boiling point of a solution is a colligative property - it depends on the concentration of solute in the solution, but not on what the solute and solvent are. • When working problems involving heat transfer to or from boiling solutions, it is necessary to adjust the temperature difference driving force for the boiling point elevation Boiling Point Elevation • The extent of the boiling-point elevation depends upon the nature of the material being evaporated and upon the concentration changes that are produced. • The extent of the rise can be predicted by Raoult's Law, which leads to: ΔT = kx where ΔT is the boiling point elevation, x is the mole fraction of the solute and k is a constant of proportionality. Duhring's rule • There is no straightforward method of predicting the extent of the boiling-point elevation in the concentrated solutions that are met in some evaporators in practical situations. • Many solutions have their boiling points at some concentrations tabulated in the literature, and these can be extended by the use of a relationship known as Duhring's rule. • Duhring's rule states that the ratio of the temperatures at which two solutions (one of which can be pure water) exert the same vapour pressure is constant. Duhring plot Duhring plot for boiling point of sodium chloride solutions Types of Evaporators 1) Long-Tube Vertical Evaporators 2) Short-Tube (Calandria) Vertical Evaporators 3) Horizontal-Tube Evaporators 4) Forced Circulation Evaporators 5) Agitated, Thin Film Evaporators 6) Plate Evaporator. 7) Centrifugal/Conical Evaporator. 4.6.2020 11 LONG-TUBE VERTICAL (LTV) EVAPORATORS • These types of evaporators are used more than all other types combined for evaporation because of low cost per unit capacity simplicity of construction heat transfer performance • The LTV-type evaporator cannot handle crystallizing solutions but excellent for foaming solution. • There are two main types of LTV evaporators: a)Climbing (Rising) film evaporators b)Falling film evaporators 4.6.2020 12 Long Tube Vertical Rising Film Evaporator • A thin film of liquid food is formed on the inside of the long tubes, with steam providing heat transfer from the outside. The vaporizing bubbles of steam cause film of concentrate to rise upwards inside the tubes. Vapor and concentrate are separated, as they exit the top, in a separate chamber. Climbing (Rising) Film Evaporators • LTV rising-film evaporator is used primarily to concentrate non-salting liquors. • Climbing film evaporators are used mainly in the paper industry, food industry to condense milk. 4.6.2020 16 Long Tube Vertical Falling Film Evaporator • Using gravity to make liquid flow downwards. Steam condensing on the outside of the tubes causes evaporation of a thin film of product flowing down the inside of the tubes. Product and steam exit the bottom of the tubes together, then are separated. Falling Film Evaporators • LTV falling film evaporator can be used to concentrate the non-salting liquids and more viscous liquors. • Principal applications have been for citrus juices. They are also used to concentrate heat-sensitive materials and corrosive solutions. 4.6.2020 19 Short tube Evaporator • A short but wide steam chest in the form of a shell and tube heat exchanger characterize this type of evaporator. Steam is fed to the inside of the internal tubes. Circulation is generated naturally. Density differences due to heating around the steam pipes cause the warmer fluid to rise and the colder fluid to sink. A vacuum source maintains to reduce boiling temperature. SHORT-TUBE (CALANDRIA) VERTICAL EVAPORATORS (STV) • The short tube evaporators were the first developed commercially and still represent probably the largest number of unit in operation. • Used in sugar factory. • Used for noncorrosive materials. 4.6.2020 22 Advantages Inexpensive Efficient heat transfer at high temperature Easy to de-scale Disadvantages × Poor heat transfer at low temperature differences or with viscous liquids × Require a great deal of floor space 4.6.2020 23 HORIZONTAL TUBE EVAPORATORS • Horizontal tube evaporators use a tube and spray method of heat transfer. • The tubes are arranged so as to maximize the heat transfer area between the steam and the liquor. Symbols: C = condensate F = feed N = noncondensibles’ vent P = product or concentrate S = steam V = vapor 4.6.2020 24 • The major use is for making distilled water for boiler feed. Horizontal tube evaporators are used in the pharmaceutical industry, pulp and paper industry. • They are relatively low cost. They have very low headroom. Horizontal tube evaporators are not suitable for salting or scaling liquids, and they have smaller capacity than other evaporators. 4.6.2020 25 Horizontal Tube Evaporator 4.6.2020 26 Forced Circulation Evaporator • Fluid is pumped from the main evaporator chamber through an external steam chest. Vapor-liquid separation occurs in the main chamber, Dilute feed is added to the recirculation loop, and sent through the steam chest • Since external pumping is used to maintain fluid flow, excellent heat transfer can be obtained, But, recirculation of the fluid through the steam chest causes long residence times FORCED CIRCILATION EVAPORATORS • The liquor in a forced-circulation evaporator is pumped through the tubes to minimize tube scaling or salting when precipitates are formed during evaporation. • Submerged-tube type is the most common type forced circulation evaporator. • Forced circulation evaporators are used in the mining industry, and also they are used to evaporate corrosive or highly viscous solutions. • Forced circulation evaporators are efficient the transfers heat from steam to liquid, continuous liquid flow, low amount of salting, scaling and fouling. They are expensive and need power for circulating pump. 4.6.2020 30 Forced Circulation Evaporator 4.6.2020 31 Wipe Film or Agitated Thin Film Evaporator • Very viscous foods are difficult to evaporate efficiently using any of the previously discussed evaporators. Products such as thick fruit or vegetable purees, or even highly concentrated sugar syrups, can be efficiently evaporated when a thin film at the heat transfer surface is continuously agitated or wiped to prevent buildup. AGITATED THIN (WIPED-FILM) FILM EVAPORATORS Agitated film evaporators use mechanical to promote heat transfer. They employ a single large diameter straight or tapered tube as the heating surface, in which a set of the blades is rotated. The cost of these evaporators is very high and the capacity relatively low. These evaporators are used highly viscous liquids or liquids requiring very low residence times. These evaporators exhibit poor heat transfer performance on low viscosity fluids. Their maintenance are difficult because of internal moving parts. Symbols: C = condensate F = feed N = noncondensibles’ vent P = product or concentrate S = steam V = vapor Agitated Thin Film Evaporator 4.6.2020 34 Plate Evaporator • A series of metal plates and frames forms the heat exchange surface both product and steam are directed in alternate gaps. Evaporation can take place within the plate and frame system, or evaporation can be suppressed by maintaining sufficient pressure and allowing evaporation to occur as the heated product flashes into a lower pressure chamber. Evaporator Modeling • In an evaporator, heat is transferred from a heating medium (usually steam) to a solution by conduction through a solid surface (the tube walls). As the solution boils, mass and heat are simultaneously transferred into the vapor phase. Consequently, an evaporator model consists of – an overall material balance – component material balances – energy balances (usually one each on the process side and the heating side) – heat transfer equations Energy and material balances on evaporation units Material balance: F=E+P Solid component balance : F(xf) = P(xp) Heat balance: Mss = Fcpf (Tb-Tf) + E v Influence of feed properties on Evaporation 1. 2. 3. 4. 5. 6. Viscosity, Fouling-scaling tendency, Foaming, Temperature sensitivity, vapor loss, Corrosion characteristics. Heat conservation in evaporator systems Mainly three methods: 1. 2. 3. Feed preheating, Multiple effect operation, Vapor recompression. The key factor in determining the economy of an evaporator is the number of effects. The economy of a single effect evaporator is always less than 1.0. Multiple effect evaporators have higher economy but lower capacity than single effect Single Effect Evaporation • The simplest mode of evaporation is to use a single stage, where steam is fed into the steam chest, concentrate and vapor are removed, and the vapor is condensed into hot water. • However, the vapors produced are still steam, and thus can be used to provide the heat for evaporation in a subsequent stage. Therefore, steam can be used many times to provide evaporation in a series of operations. multiple-effect evaporation • In a two-stage evaporator, the vapors produced by evaporation of water in the first stage are fed into the steam chest of the second stage to provide further evaporation. Since there is no driving force. Thus, operating pressure in the second stage must be reduced to lower the boiling temperature Triple effect evaporation system Forward-feed multiple - effect evaporator Backward-feed multiple - effect evaporator Parallel-feed multiple-effect evaporators Mechanical Vapor Recompression • Mechanical compression can be used to improve the quality of vapors. The vapors from a single stage are compressed to higher pressure in a mechanical compressor and then reused as steam in the steam chest . Reuse of compressed vapors makes up most of the steam addition. Only a small portion of fresh steam is needed to account for inevitable energy losses. Steam economies can be obtained. Thermal Vapor Recompression • The quality of the vapors produced during evaporation can be recompressed. One alternative is to use fresh steam to enhance the value of a portion of the vapors. This combined steam is then fed into the steam chest. High pressure steam is passed through a nozzle (or ejector) before entering the evaporator chamber. As the fresh steam passes through the nozzle. Thermal recompression in evaporation kg steam consumption per kg of water evaporated No. of Without vapor Effects recompression With vapor recompression 1 1.1 0.6 2 0.6 0.4 3 0.4 0.3 Previous GATE Questions SOLVED PROBLEMS Q1: Economy of evaporators used for concentrating sugarcane juice is A. kg of concentrated juice produced/ kg of steam supplied B. kg of steam supplied/kg of sugarcane juice fed C. kg of water vaporized/kg of steam supplied D. kg of sugarcane juice fed/kg of water vaporized Answer: C Q2: Multiple effect evaporator has capacity to process 4000 kg of solid caustic soda per day when it is concentrating from 10% to 25% solids. The water evaporated in kg per day is, A. 800 B. 24,000 C. 60,000 D. 48,000 Q3: It is desired to concentrate a 20% salt solution (20 kg of salt in 100 kg of solution) to a 30% salt solution in an evaporator. Consider a feed of 300 kg/min at 30°C. The boiling point of the solution is 110°C, the latent heat of vaporization is 2100 kJ/kg, and the specific heat of the solution is 4 kJ/kg-K. The rate at which heat has to be supplied (in kJ/min) to the evaporator is (A) 3.06×105 (B) 6.12×105 (C) 7.24×105 (D) 9.08×105 Q4: A dilute aqueous solution is to be concentrated in an evaporator system. High pressure steam is available. Multiple effect evaporator system is employed because A. total heat transfer area of all the effects is less than that in a single effect evaporator system B. total amount of vapour produced per kg of feed steam in a multi-effect system is much higher than in single effect C. boiling point elevation in a single effect system is much higher than that in any effect in a multi-effect system D. heat transfer coefficient in a single effect is much lower than that in any effect in a multi-effect system Answer: B Q5: Steam economy of a multiple effect evaporator system is defined as A. kilogram of steam used per hour B. kilogram of steam consumed in all the effects for each kilogram of steam fed C. kilogram of steam used in all the effects for each kilogram of water vaporized per hour D. kilogram of water vaporized from all the effects for each kilogram of steam fed to the first effect Answer: D Q6: An aqueous sodium chloride solution (10 wt %) is fed into a single effect evaporator at a rate of 10000 kg/hr. It is concentrated to a 20 wt% sodium chloride solution. The rate of consumption of steam in the evaporator is 8000 kg/hr. The evaporator capacity (kg/hr) and economy are (A) 5000, 0.625 (B) 10000, 0.625 (C) 5000, 1.6 (D) 10000, 1.6 Q7: An aqueous solution of a solute is concentrated from 5% to 20% (mass basis) in a single effect short-tube evaporator. The feed enters the evaporator at a rate of 10kg/s and at a temperature of 300 K. steam is available at a saturation pressure of 1.3 bar. The pressure in the vapor space of the evaporator is 0.13 bar and the corresponding saturation temperature is 320K. if the overall heat transfer coefficient is 5000 W/m2K, calculate steam economy and heat transfer surface area required. Enthalpy (kJ/kg) Saturated steam (1.3 bar, 380K) Saturated steam (0.13 bar, 320K) Feed (5%, 300K) Concentrated Liquid (20%, 325K) B.P.E is 5K 2200 80 400 Heat of vaporization (kJ/kg) 2000 Q8: The capacity of multiple effect evaporator when compared with a single effect evaporator both operating with significant boiling point rise at the same terminal temperatures and surface area in each effect equal to surface area of single effect evaporator is, A. Decreases B. Increases C. Remains the same Answer: B Q9: A multiple effect evaporator as compared to a single effect evaporator of the same capacity has A. Lower heat transfer area B. Lower steam economy C. Higher economy D. Higher solute concentration in the product Answer: C Q10: An aqueous suspension at 60C is fed to the first effect of double effect evaporator with a mass flow rate of 1.25 kg/s. The sum of the rates of water evaporated from the first and second effects is 1.0 kg/s. Temperature of exit streams from the first and second effects are 100 C and 60C respectively. Consider the specific heat of aqueous suspension, and the latent heat of phase change for water to 4 kJ/kg K and 2200 kJ/kg, respectively, over this temperature range. The steam economy (in kg per kg) is _______