Applied Transport Phenomena

B40DM Student Guide

Chemical and Process Engineering

February, 2024

Contents

4 Mass Transfer

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Mass transfer in previous courses . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Additions in this topic . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Steady State Diffusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Steady State Diffusion independent of reaction . . . . . . . . . . . . . . .

4.2.2 Steady State Diffusion with Reaction . . . . . . . . . . . . . . . . . . . . .

4.2.3 Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Unsteady-State Diffusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Ficks’s Second Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Transient diffusion in a semi-infinite medium . . . . . . . . . . . . . . . .

4.3.3 Solving finite medium cases using concentration-time charts . . . . . . . .

4.3.4 Using 1-D charts for higher dimensions . . . . . . . . . . . . . . . . . . . .

4.3.5 Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Convective Mass Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Significant Parameters in Convective Mass Transfer . . . . . . . . . . . .

4.4.3 Application of Dimensionless Analysis to Mass Transfer . . . . . . . . . .

4.4.4 Mass, Heat and Momentum Transfer Analogies . . . . . . . . . . . . . . .

4.4.5 Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

1

2

2

2

3

3

7

14

18

18

19

21

23

25

29

29

29

31

33

38

40

43

List of Figures

4.1

4.2

4.3

4.4

4.5

Arnold diffusion cell under steady-state conditions . . . . . . . . . . . . . . . . .

Arnold diffusion cell under pseudo-steady-state conditions . . . . . . . . . . . . .

Thermal oxidation of a silicon wafer. . . . . . . . . . . . . . . . . . . . . . . . . .

SiO2 film thickness as a function of time (Welty et. al) . . . . . . . . . . . . . . .

Homogeneous reaction within the control volume for diffusion vs. heterogeneous

reaction at a catalytic surface. (Welty et. al) . . . . . . . . . . . . . . . . . . . .

4.6 Coal particle combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Absorption of A from a gas phase to a liquid phase. . . . . . . . . . . . . . . . .

4.8 Tutorial question 4.2-4 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Tutorial question 4.2-5 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Tutorial question 4.2-6 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Unsteady-state Diffusion in One-direction. . . . . . . . . . . . . . . . . . . . . . .

4.12 Tutorial question 4.3-2 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Tutorial question 4.3-4 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Tutorial question 4.3-5 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Tutorial question 4.4-3 (Welty et. al) . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 Unsteady State Transport Slab (Welty et. al) . . . . . . . . . . . . . . . . . . . .

4.17 Unsteady State Transport Cylinder (Welty et. al) . . . . . . . . . . . . . . . . . .

4.18 Unsteady State Transport Sphere (Welty et. al) . . . . . . . . . . . . . . . . . . .

3

4

5

7

8

9

12

15

16

16

18

25

26

27

38

40

41

42

List of Tables

4.1

4.2

4.3

4.4

4.5

Error function and complementary error function . . . . . . . . . . . . . . . . . .

Variables in forced convection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variables in natural convection . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical properties for Tutorial Question 4.4.5-Q5 . . . . . . . . . . . . . . . . .

20

31

32

36

39

List of Examples

4.1 Thermal Oxidation of Silicon Wafer . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Unsteady-stat solution using error function . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Unsteady mass transfer using concentration-time charts . . . . . . . . . . . . . . . . .

ii

5

21

22

Applied Transport Phenomena

iii

4.4 Unsteady mass transfer in 2-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Convective intro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 C-C Analogy I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 C-C Analogy II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

29

35

36

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

4 Mass Transfer

Prerequisite knowledge

• Separation Processes A

• Mathematical modeling for Chemical Engineers

• B40DM Topics 1-3

Learning objectives After studying this topic you should be able to:

• Derive the equations and solve problems relating to pseudo-steady state diffusion.

• Derive the equations and solve problems relating to diffusion cases involving reaction.

• Derive Fick’s second law and solve transient diffusion problems using a variety of techniques.

• Use analogies to solve mass transfer problems

1

2

Applied Transport Phenomena

4.1 Introduction

4.1.1 Mass transfer in previous courses

As was demonstrated in Separation Processes A, Mass transfer is the net movement of mass in

a mixture from one point to another due to differences in chemical potential. It is a fundamental process in many chemical engineering unit operations, such as distillation, absorption, and

extraction. Mass transfer can be driven by two main mechanisms: molecular mass transfer and

convective mass transfer. Molecular mass transfer occurs by the diffusion of individual molecules

from a region of high concentration to a region of low concentration. Convective mass transfer is

the macroscopic movement of a fluid carrying the chemical species with it. As such it is expected

that you are familiar with and able to use:

Fick’s law for flux in an isothermal, isobaric binary system:

JA,z = −DAB

dcA

dz

(4.1)

The combined diffusion and convection case, under standard binary mixture assumptions:

NA,z = −c · DAB

dyA

+ yA (NA,z + NB,z )

dz

(4.2)

The special cases of, equimolar counter diffusion;

dyA

dz

(4.3)

dyA

+ yA · NA,z

dz

(4.4)

NA,z = −c · DAB

and, diffusion through stationary phase;

NA,z = −c · DAB

We will discuss the film-theory relying on the knowledge gained from the section “Mass Transfer

in the Vicinity of a Phase Boundary” as well, but the knowledge and equations above are our

starting point.

4.1.2 Additions in this topic

Firstly, we will extend the steady-state conditions to pseudo-steady-state cases.

Next, reactions will be included in the considerations for the diffusion problems. Dealing with

both heterogeneous and homogeneous reactions.

Having started with the pseudo-steady-state the full unsteady-state behavior is covered, where

the tabular solving of integration as well as applying concentration-time charts

Lastly, we will look at convective mass transfer, which is solved using analogies between the

different transfer behaviours.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

3

Applied Transport Phenomena

4.2 Steady State Diffusion

4.2.1 Steady State Diffusion independent of reaction

For unimolecular diffusion in B49CA Example 5.2.4 and seen in Figure 4.1., the following description diffusion was obtained:

NA,z =

P · DAB

(PA2 − PA1 )

R · T · (z2 − z1 ) · PB,lm

(4.5)

Flow of gas B

z = z2

NA,z|z+∆z

∆z

NA,z|z

z = z1

Pure liquid A

Figure 4.1: Arnold diffusion cell under steady-state conditions

However in many mass transfer operations, one of the boundaries may move with time as seen

in Figure 4.2.

If the length of the diffusion path changes a small amount (zt1 –zt0 is small) over a long period

of time, a pseudo steady state diffusion assumption may be used. When this condition exists,

the equation of steady-state diffusion through stagnant gas’ can be used to find the flux.

If the difference in the level of liquid A over the time interval considered is only a small fraction

of the total diffusion path, and (t0 –t1 ) is a relatively long period of time, at any given instant

in that period, the molar flux in the gas phase may be evaluated by Equation 4.13. The z in

this case is the diffusion length.

The molar flux NA,z is related to the amount of A that is evaporated from the liquid by

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

4

Applied Transport Phenomena

Flow of gas B

z=0

NA,z|z+∆z

NA,z|z

∆z

z(t0 ) = zt0

z(t) = zt

Pure liquid A

Figure 4.2: Arnold diffusion cell under pseudo-steady-state conditions

NA,z =

ρA,L dz

MA dt

(4.6)

ρ

is the molar density of liquid A and z is the liquid level in the cell. When a pseudowhere MA,l

A

steady-state assumption is made Equations 4.13 and 4.6 can be combined as:

ρA,L dz

P · DAB

=

(PA2 − PA1 )

MA dt

R · T · z · PB,lm

(4.7)

where z is the diffusion length in the cell (z2 − z1 in 4.13). Equation 4.7 can then be integrated

between τ = t0 = 0 and τ = t as well as z = zt0 and z = zt as follows:

Z t1

dτ =

τ =0

ρA,L

MA · R · T · PB,lm

P · DAB (PA2 − PA1 )

Z zt

z dz

(4.8)

z=zt0

where zt0 and zt represents the total path length at those times (the (z2 − z1 ) in 4.13). Carry

out the two integrations in 4.8 to get:

t=

ρA,L

MA · R · T · PB,lm

z 2 − zt20

( t

)

P · DAB (PA2 − PA1 )

2

(4.9)

which gives the time it takes for a certain depletion to take place.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

5

Applied Transport Phenomena

Example 4.1 Thermal Oxidation of Silicon Wafer:

The formation of a silicon oxide (SiO2 ) thin film on a silicon (Si) wafer surface is an important step in the fabrication of

solid-state microelectronic devices. A thin film of SiO2 serves as a barrier to dopant diffusion

or as a dielectric insulator to isolate various devices being formed on the wafer. In one common process, silicon is oxidized by exposure to oxygen (O2 ) gas at temperatures above 700 °C as:

Si(s) + O2 (g) → SiO2 (s)

Molecular O2 dissolves into the SiO2 solid, diffuses through the SiO2 film, and then reacts with

Si at the Si/SiO2 interface, as shown in Figure 4.3. Assuming that the diffusion of O2 through

the SiO2 film limits the oxidation process, develop a model to predict the thickness of the SiO2

layer (δ) as a function of time at 1000 °C. The density of solid SiO2 (ρ) is 2.27 g/cm3 , and

the molecular weight of SiO2 (MB) is 60 g/mol. The molecular diffusion coefficient of O2 in

SiO2 (DA B) is 2.7 × 10−9 cm2 /s at 1000 °C, and the maximum solubility of O2 in SiO2 (cAs ) is

9.6 × 10−8 mol O2 /cm3 solid at 1000 °C and 1 atm O2 partial pressure

O2 (s)

z=0

cA = cAs

O2

z=δ

cAδ = 0

SiO2 (non-porous)

Si(s) + O2 (g) → SiO2 (s)

Si (crystalline)

z=L

Figure 4.3: Thermal oxidation of a silicon wafer.

Solution:

The steps follow the general steps as covered in B49CA, starting with the assumptions:

1. Diffusion in z-direction

2. Isothermal

3. The reaction only occurs at the interface as seen in Figure 4.3. The unreacted Si at the

interface serves as the sink for molecular mass transfer of O2 through the film. The reaction

is assumed to be instantaneous, which is why the O2 is zero there.

4. The O2 above the wafer can be considered an infinite source of O2 , keeping the gas/solid

interface at a constant O2 saturation concentration, CAs .

5. The rate of SiO2 formation is controlled by the rate of molecular diffusion of O2 through

the solid SiO2 layer to the unreacted Si layer.

6. There are no mass-transfer resistances in the gas film above the wafer surface, as O2 is a

pure component in the gas phase.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

6

Applied Transport Phenomena

7. The film formation of SiO2 -film at the interface is slow, hence no accumulation of SiO2 is

taking place.

8. The film formation will however give a slow increase of SiO2 layer with time, but at such

a slow rate that pseudo-steady-state can be assumed.

9. The overall thickness of the wafer does not change as a result of the formation of the SiO2

layer.

10. The concentration of O2 can be considered is very very dilute in the SiO2 layer.

We note that points 1.-6. means that we can treat it as a non-reactive case and thus as a standard

diffusion through a non-diffusing medium. The diffusion is downwards rather than upwards as

we have had in the previous cases. Points 7.-9. give the pseudo-steady-state assumption. The

steady-state transfer through the SiO2 is given by:

dNA,z

=0

(4.10)

dz

where O2 is species A. Fick’s law for diffusion through non-diffusing is given in 4.4. However,

assumption 10. means that yA ≪ 1 which means we can neglect the second term in 4.4 to get:

NA,z = −c · DAB

dyA

dz

(4.11)

This we recognize as Fick’s equation for equimolar counter-diffusion, and the solution is the

same, integrate between the boundary conditions (z = {0 → δ} and cA = {cAs → 0}):

Z δ

0

NA,z dz = −DAB

Z 0

dcAs

(4.12)

cAs

and thus:

DAB · cAs

(4.13)

δ

which describes the flux of O2 through the SiO2 layer of thickness δ. Just as when the pseudosteady-state was introduced we have to describe the accumulation of the material (in the case

of the Arnold cell it was negative). The molar accumulation of SiO2 (species B) is given by the

ρB

product of the molar density M

, surface area S, and the thickness of the layer δ giving the

B

following molar rate of accumulation:

d ρBM·S·δ

B

(4.14)

dt

This is equal to the molar rate of the SiO2 formation which is the flux times the cross-sectional

area; NA,z · S, to give:

ρB dδ

DAB · cAs

=

(4.15)

MB dt

δ

NA,z =

Separation of variables and integration gives:

Z δ

MB · DAB · cAs

zdz =

ρB

0

to give

©HERIOT-WATT UNIVERSITY

Z t

δ2

MB · DAB · cAs

=

t

2

ρB

B40DM

dτ

(4.16)

0

(4.17)

Spring 2024

7

Applied Transport Phenomena

and finally

s

δ=

2 · MB · DAB · cAs

t

ρB

(4.18)

We note that the thickness of the Silicon dioxide film is predicted to grow with the square root

of the time. For the given values in the question we get:

r

p

2 · 60 · 2.7 × 10− 9 · 9.6 × 10− 8

δ=

t = 1.37 × 10−14 · t

(4.19)

2.27

Figure 4.4 shows the predicted thickness compared to experimental data. Firstly, the model has

a good level of accuracy. Secondly, the process is very slow as can be expected with the small

driving force (concentration difference) and the low diffusion rate.

Figure 4.4: SiO2 film thickness as a function of time (Welty et. al)

4.2.2 Steady State Diffusion with Reaction

Many diffusion operations involve simultaneous diffusion as well as a chemical reaction, either

within or at the boundary of the phase of interest. We distinguish between the two types of

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

8

Applied Transport Phenomena

chemical reactions based on where the the reaction occurs as seen in Figure 4.5. Homogeneous

reaction happens uniformly throughout the entire phase of interest. For example, the yeast

suspension fermenting sugar; the reaction occurs anywhere. The heterogeneous reaction occurs

in a specific region within or at the boundary of the phase, this surface would in many cases

contain a catalyst.

Figure 4.5: Homogeneous reaction within the control volume for diffusion vs. heterogeneous

reaction at a catalytic surface. (Welty et. al)

Heterogeneous combustion

Industrial processes often involve chemical reactions that occur on surfaces. The rates of these

reactions depend on both the diffusion of reactants to the surface and the reaction itself.

If the reaction is much faster than diffusion, the process is diffusion-controlled, and the overall

rate is limited by diffusion.

If the reaction is much slower than diffusion, the process is reaction-controlled, and the overall

rate is limited by the reaction itself.

Understanding the difference is essential for optimizing industrial reactions.

In many power plants, pulverized coal is suspended in a hot combustion chamber, where it reacts

with oxygen in the air to produce carbon monoxide and/or carbon dioxide gas. This process,

which produces energy by burning coal, is an example of a diffusion-controlled heterogeneous

reaction.

In this example, we will examine the combustion of a spherical coal particle of radius R. Very

far from the coal particle, the mole fraction of oxygen is given by yO2 = yO2 (r = ∞) = 0.21.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

9

Applied Transport Phenomena

On the surface of the coal particle, oxygen gas (O2 ) reacts with solid carbon (C) in the coal to

form carbon monoxide gas (CO) and carbon dioxide (CO2 ) gas according to the heterogeneous

reaction equation:

3C(s) + 2.5O2 (g) → 2CO2 (g) + CO(g)

(4.20)

as illustrated in Figure 4.6

NCO2 ,r

R

r

∆r

NO2 ,r

Carbon Sphere

NCO,r

Figure 4.6: Coal particle combustion

Assumptions:

• No reaction occurs along the diffusion path (RO2 (r ̸= R) = 0).

• The reaction is instantaneous on the surface, thus the surface is a sink with (yA (r = R) =

0).

In order for the coal particle to burn, oxygen needs to diffuse from far from the particle to the

surface of the particle.

For every 2.5 molecules O2 that react, two molecules of CO2 and one molecule of CO are created.

These CO molecules diffuse in the opposite direction as the oxygen molecules. Therefore, we

have NCO2 ,r = −1.25NO2 ,r and NCO,r = −1.25NO2 ,r . In addition, we assume that the nitrogen

in the atmosphere is stationary (i.e., NN2 = 0).

We start the problem by performing a balance on oxygen molecules in a control volume specified

by the spherical surfaces at r and r + ∆r. Because the system is at steady state, there is no

accumulation in the shell, we get:

NO2 ,r 4πr2 |r −NO2 ,r 4πr2 |r+∆r = 0

©HERIOT-WATT UNIVERSITY

B40DM

(4.21)

Spring 2024

10

Applied Transport Phenomena

Dividing 4.21 by 4πr2 ∆r and taking the limit δr → 0 we obtain:

∂ r2 NO2 ,r

=0

∂r

(4.22)

This gives us the information that r2 NO2 ,r is constant in the r-direction, which is the spherical

equivalent of 4.10 for the cartesian case. This equation can be integrated to obtain

r2 NO2 ,r = wO2

(4.23)

where wO2 is an integration constant. The physical meaning of wO2 is the total moles of oxygen

that diffuse toward the coal particle per unit-time. We can state the diffusion equation (see 4.2)

for the radial case and multiple components The absolute flux of oxygen can be written as

dyO2

+ yO2 (NO2 ,r + NCO2 ,r + NN2 ,r + NCO,r )

(4.24)

dr

Based on the reactions we can substitute the transfers of the other species into 4.24 to get

dyO2

1

1

NO2 ,r = −c · DO2 −mix

+ yO2 NO2 ,r −

NO2 ,r + 0 −

NO2 ,r

(4.25)

dr

1.25

2.5

NO2 ,r = −c · DO2 −mix

which gives

dyO2

+ yO2 0.2NO2 ,r

dr

c · DO2 −mix dyO2

=−

1 + 0.2yO2 dr

NO2 ,r = −c · DO2 −mix

(4.26)

Multiplying 4.26 by r2 we get

r2 NO2 ,r = −r2

c · DO2 −mix dyO2

1 + 0.2yO2 dr

(4.27)

Separate variables and integrate (using 4.22 to move r2 NO2 ,r outside the integrals).

2

r NO2 ,r

Z ∞

R

c · DO2 −mix

dr

=−

2

r

0.2

Z 0.21

0

0.2

dyO2

1 + 0.2yO2

(4.28)

which gives

c · DO2 −mix

1

=−

ln (1.042)

r NO2 ,r

R

0.2

2

(4.29)

The oxygen transfer (WO2 is the product of the flux and the cross-sectional area 4πr2 :

c · DO2 −mix

WO2 = 4πr2 NO2 ,r = −4πR

ln (1.042)

0.2

(4.30)

Note that WO2 represents the rate at which oxygen is diffusing towards the coal particle. This

is the same rate at which oxygen is being consumed by the combustion reaction. The negative

sign is due to the O2 diffusing in the opposite direction of the increasing radius.

This can also be used to estimate how long it will take for the coal particle to completely react.

4.30 tells us how quickly oxygen reacts to form CO and CO2 . From 4.20 we have 2.5WC = 3WO2 .

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

11

Applied Transport Phenomena

To determine the rate at which the coal particle is shrinking, we perform a mole balance for

carbon. For a particle of radius R, the amount of carbon present is given by 4πR3 cC /3, the

volume of the particle times the molar density of carbon. The rate at which the particle shrinks

is then given by:

∂ 4πR3

cC = WC

∂t

3

∂ 4πR3

c · DO2 −mix

cC = −12πR

ln (1.042)

∂t

3

2.5 · 0.2

∂R

4cC R2

= −24Rc · DO2 −mix ln (1.042)

∂t

∂R

cC R

= −6c · DO2 −mix ln (1.042)

(4.31)

∂t

Separate variables and integrate:

Z Rf

cC

Ri

Rdr = −6c · DO2 −mix ln (1.042)

Z t

dτ

(4.32)

0

to get the time t for the change:

t=

cC Ri2 − Rf2

12c · DO2 −mix ln (1.042)

(4.33)

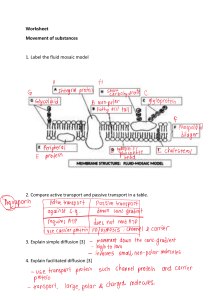

Diffusion with homogeneous reaction

In this example, we consider the absorption of species A from a gas phase into a liquid phase

composed mostly of B (see Fig. 4.7). The mole fraction of A just inside the liquid phase (i.e.,

at z = 0) is equal to yA0 . At a distance δ beneath the surface of the liquid layer, there is an

impenetrable solid wall. In addition to the diffusion of A in the liquid phase, there is also a

first-order reaction that converts species A to species C. The kinetics of this reaction are given

by

σA = −k1 cA

= −k1 cyA

(4.34)

where σA is the rate of generation of A per unit volume, k1 is a kinetic constant, and c is the

overall molar concentration of the liquid.

To begin the problem, we perform a species balance for A on a thin slab in the liquid. Because

we are dealing with a steady-state problem, there is no accumulation in the slab. From the

geometry of the problem, we assume there is only motion in the z-direction. So there is an

influx of A from the left side of the slab and an outflux of A from the right side of the slab.

Unlike the previous examples we considered in this chapter, there is a chemical reaction that

consumes A. Therefore, the balance equation is given by

0 = (NA,z S)|z − (NA,z S)|z+dz − (k1 cyA )Sdz

1 (NA,z S)|z+dz − (NA,z S)|z

0=−

− (k1 cyA )

S

dz

©HERIOT-WATT UNIVERSITY

B40DM

(4.35)

Spring 2024

12

Applied Transport Phenomena

Gas Mixture

(A + inert gas)

z=0

NA,z|z+∆z

∆z

NA,z|z

Pure liquid B

z=δ

Figure 4.7: Absorption of A from a gas phase to a liquid phase.

Taking the limit dz → 0,

1 ∂

(NA,z S) = −(k1 cyA )

S ∂z

∂NA,z

= −k1 cyA

∂z

(4.36)

We assume that B is stationary (i.e., NB = 0). In addition, we assume that species C flows in

the opposite direction of species A (i.e., NC = −NA ). The absolute flux is then given by

NA,z = JA,z + yA (NA,z + NB,z + NC,z )

= JA,z + yA (NA,z + 0 − NA,z )

= JA,z

= −cDAB

∂yA

∂z

(4.37)

Putting this expression into 4.36

−

∂

∂yA

cDAB

= −k1 cyA

∂z

∂z

∂ 2 yA

= ya /l2

∂z 2

(4.38)

where l = (DAB /k1 )1/2 . This is a second-order, linear differential equation with constant coefficients. The general solution to this equation is given by

yA (z) = C1 ez/l + C2 e−z/l

©HERIOT-WATT UNIVERSITY

B40DM

(4.39)

Spring 2024

13

Applied Transport Phenomena

where C1 and C2 are constants, which for the moment are unknown. The flux can be determined

by substituting Eq. 4.39 into Eq. 4.37:

∂yA

∂z

cDAB =−

C1 ez/l − C2 e−z/l

(4.40)

l

We can determine the constants C1 and C2 by using the boundary conditions. At z = 0, we

have yA = yA0 , which leads to

NA,z = −cDAB

yA0 = C1 + C2 .

Since the wall is impermeable to species A, the flux of A at z = δ must be zero:

cDAB NA,z (δ) = −

C1 eδ/l − C2 e−δ/l

l

0 = C1 eδ/l − C2 e−δ/l

(4.41)

(4.42)

The equations can be solved to give the coefficients C1 and C2

e−δ/l

C1 = yA0 δ/l

e + e−δ/l

eδ/l

C2 = yA0 δ/l

e + e−δ/l

Substituting these coefficients into Eq. 4.39, we find

"

!

!#

e−(δ−z)/l

e(δ−z)/l

yA (z) = yA0

+

eδ/l + e−δ/l

eδ/l + e−δ/l

#

"

e−(δ−z)/l + e(δ−z)/l

= yA0

eδ/l + e−δ/l

= yA0

cosh(δ − z)/l

cosh δ/l

(4.43)

(4.44)

(4.45)

To determine the rate at which A is absorbed from the gas phase, we need to determine the flux

of A at the surface of the liquid. The flux is given by

∂yA

∂z "

#

yA0 e−(δ−z)/l − e(δ−z)/l

= −cDAB

l

eδ/l + e−δ/l

"

#

cA0 DAB e(δ−z)/l − e−(δ−z)/l

=

l

eδ/l + e−δ/l

NA,z (z) = −cDAB

=

cA0 DAB sinh((δ − z)/l)

l

cosh(δ/l)

(4.46)

where cA0 is the concentration of A at the left surface of the liquid at z = 0. The flux of A at

the surface is given by

cA0 DAB sinh(δ/l)

l

cosh(δ/l)

cA0 DAB sinh δ/l

=

(DAB /k1 )1/2 cosh δ/l

NA,z (z = 0) =

= cA0 (k1 DAB )1/2 tanh δ/l

(4.47)

This is the rate (per unit area of liquid) at which A is absorbed from the gas phase.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

14

Applied Transport Phenomena

4.2.3 Tutorials

1. An Arnold cell is to be operated as a pseudo-steady-state cell to determine the gas diffusivity of benzene in air at 308 K and 1.0 atm. The 20-cm-long tube, with an inner diameter of

1.0 cm, is initially loaded with liquid benzene to a depth of 1.0 cm from the bottom of the

tube. The tube and the liquid are maintained at a constant temperature of 308 K. At this

temperature, benzene exerts a vapor pressure of 0.195 atm. Air is continually blown over

the top of the tube, removing any of the vaporized benzene vapor; the gas space within

the tube is essentially stagnant. At 308 K, liquid benzene’s density is 0.85 g/cm3 .

a) It was determined that 72.0 h was required to completely evaporate the benzene

initially loaded into the tube. Esti- mate the binary gas-phase diffusion coefficient

for benzene in air using this data.

b) The tabulated data is DAB = 9.62 × 10−6 m2 /s at 298 K. Compare your evaluated

diffusivity with the tabulated value What is a possible reason for any difference in

these values?

DAB = 9.6 × 10−6 m2 /s

DAB = 1.01 × 10−5 m2 /s

2. A tank with its top open to the atmosphere contains liquid methanol (MeOH, molecular

weight 32 g/mol) at the bottom of the tank. The tank is maintained at 30 ◦ C. The

diameter of the cylindrical tank is 1.0 m, the total height of the tank is 3.0 m, and the

liquid level at the bottom of the tank is maintained at 0.5 m. The gas space inside the tank

is stagnant and the MeOH vapors are immediately dispersed once they exit the tank. At

30 ◦ C, the vapor pressure exerted by liquid MeOH is 163 mmHg and at 40◦ C the MeOH

vapor pressure is 265 mmHg. We are concerned that this open tank may be emitting a

considerable amount of MeOH vapor.

a) What is the emission rate of MeOH vapor from the tank in units of kg MeOH/day

when the tank is at a temperature of 30 ◦ C? State all assumptions and boundary

conditions.

b) If the temperature of the tank is raised to 40 ◦ C, what is the new methanol emission

rate?

WA = 1.39kg/day

WA = 2.6kg/day

3. Ethanol is diffusing through a 4-mm stagnant film of water. The ethanol concentrations of

the entrance and the existing planes are maintained at 0.1 and 0.02 mol/m3 , respectively.

If the water film temperature is 283 K, determine the steady-state molar flux of the ethanol

and the concentration profile as a function of the position z within the liquid film. Compare

these results with a 4-mm stagnant film of air at 283 K and 1 atm at the same entrance

and exit ethanol concentrations.

NA,z = 1.57 × 10−8 mol/{m2 s}

NA,z = 2.44 × 10−4 mol/{m2 s}

4. Consider the low-pressure chemical vapor deposition (LPCVD) diffusion reactor as shown

below. It is desired to lay a thin film of the semiconductor gallium, Ga, onto a silicon

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

15

Applied Transport Phenomena

wafer surface. Gallium metal is not volatile, but trimethyl gallium (TMG; Ga(CH3 )3 ,

114.72 g/mol) is volatile. In the presence of an H2 gas, at high temperature, TMG will

decom- pose to solid Ga on a surface by the following reaction:

3

Ga(CH33 )3 (g) + H2 (g) → Ga(s) + 3CH4 (g)

2

At 700 ◦ C, this surface reaction is diffusion-limited. Let gas- phase species A: TMG; B:

Figure 4.8: Tutorial question 4.2-4 (Welty et. al)

H2 and C: CH4 .

a) Develop an integral model to predict the flux of TMG to the wafer surface. Keep

your final model in algebraic form. Provide appropriate assumptions and boundary

conditions. At this point, you may not assume that the process is dilute.

For parts (b) and (c), consider a process where the feed gas consists of 99.98 mol%

H2 and 0.02 mol% TMG. The temperature and total system pressure are 700 ◦ C

and 0.20 atm, respectively. The binary diffusion coefficient of TMG in H2 at 750 ◦ C

and 1.0 atm is known to be 2.0 cm2 /s.

b) What is the simplified form of the model previously developed in part (a)?

c) What is the value of an appropriate diffusion coefficient for this process?

NA,z = cDδAB × 2 × 10−4 mol/{cm2 s}

DAB = 9.276cm2 /s

5. Consider the metallurgical refining process illustrated in the following figure. Iron oxide,

FeO, ore is being reduced to iron, Fe, by hydrogen gas according to the reaction

F eO(s) + H2 (g) → F e(s) + H2 O(g)

The FeO layer is nonporous, but the Fe layer is porous. Pure hydrogen gas flows over

the surface of the slab. As FeO is reduced to Fe, the path length for the diffusion of

H2 gas through the porous slab from the surface to the FeO/Fe boundary increases with

time. In making your model, you may assume that (1) the process operates under constant

conditions of 400 K and 1.0 atm; (2) the reaction is very rapid so that the reduction of

FeO is limited by the diffusion of H2 to the FeO/Fe boundary; (3) the diffusion process

is pseudo-steady state along the path length; and (4) the effective gas-phase diffusion

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

16

Applied Transport Phenomena

Figure 4.9: Tutorial question 4.2-5 (Welty et. al)

coefficient of water in hydrogen is 1.7 cm2 /s within the porous solid under the conditions of the process. The bulk density of the FeO solid is 2.5 g/cm3 , and the molecular

weight of FeO is 71.85 g/g mol.

a) Reduce the general differential equation for mass transfer to describe the diffusion of

H2 .

b) Determine the molar flux of H2 to the FeO/Fe boundary when δ = 1 cm.

c) Determine the minimum time necessary for FeO to be converted to Fe from δ = 1 to

δ = 2.0 cm.

NA,z = 5.18 × 10−5 mol/{cm2 s}

16.79 min

6. As part of the manufacturing process for the fabrication of titanium-oxide-based solar

panels, a layer of nonporous titanium oxide must be reduced to metallic titanium, Ti, by

hydrogen gas as shown in the following figure. The reaction at the Ti/TiO2 boundary is

Figure 4.10: Tutorial question 4.2-6 (Welty et. al)

given by

T iO2 (s) + 2H2 (g) → T i(s) + 2H2 O(g)

Pure H2 gas flows rapidly over the surface of the nanoporous TiO2 slab. As TiO2 (s) is

reduced to Ti (molecular weight Ti = 47.9 g/g mol), the path length for mass transfer

of H2 and H2 O gas through the porous slab from the surface to the Ti/TiO2 boundary

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

17

Applied Transport Phenomena

increases with time. You may assume that (1) the process operates at 1.0 atm and 900 K;

(2) the reaction is very fast so that the concentration of H2 gas at the Ti/TiO2 boundary

is zero and the reduction of TiO2 (s) is limited by the diffusion of TiO2 (g) away from the

Ti(s)/TiO2 boundary; (3) the diffusion process is pseudo-steady state along the diffusion

path; and (4) the effective gas-phase diffusion coefficient of H2 within the porous Ti(s)

containing a mixture of H2 (g) and H2 O(g) is 0.031 cm2 /s at the temperature and pressure

of the process, whereas the effective diffusion coefficient of H2 O(g) within the nanoporous

Ti(s) containing a mixture of H2 (g) and H2 O(g) is 0.01 cm2 /s at the temperature and

pressure of the process. The density of the nanoporous Ti(s) is 2.6 g/cm3 .

a) Determine the flux of H2 to the Ti/TiO2 boundary when d = 0:05 cm, assuming yA0

= 1.0.

b) Determine the number of hours necessary for all the TiO2 to be converted to Ti(s).

c) At z = d = 0.05 cm, determine the concentration profile for H2 (g).

NA,z = 8.39 × 10−6 mol/{cm2 s}

21.55 min

7. Two very large tanks, maintained at 323 K and 1 atm total system pressure, are connected

by a 0.1-m-diameter circular duct which is 5 m in length. Tank 1 contains a uniform gas

of 60 mol% acetone and 40 mol% air, whereas tank 2 contains a uniform gas of 10 mol%

acetone and 90 mol% air. Determine the initial rate of acetone transfer between the two

tanks. The gas diffusivity of acetone in air at 298 K and 1 atm is 0.093 cm2 /s.

WA = 3.11 × 10−7 mol/s

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

18

Applied Transport Phenomena

4.3 Unsteady-State Diffusion

Unsteady state mass transfer processes are those in which the concentration of the species

being transferred changes with time at a given point. These processes must be described by

partial differential equations since there are three independent variables: concentration, time,

and position.

This has an initial coverage in the B49CA Topic on Surface Renewal, though here we will make

it more general and extend to other geometries.

4.3.1 Ficks’s Second Law

Study a small cross-sectional part as in Topic 2 of B48BG:

accumulation

net transport in

net generation

=

+

in system

through system boundaries

in system

(4.48)

[Ack] = [In] − [Out] + [P rod] − [Consumption]

(4.49)

or

Assuming no reaction and stagnant material (solid, stagnant gas, or stagnant liquid) on onedimensional diffusion as seen in Figure 4.11

NA,z|z+∆z

z + ∆z

∆z

z

NA,z|z

Figure 4.11: Unsteady-state Diffusion in One-direction.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

19

Applied Transport Phenomena

we can substitute the transport through the system boundaries as seen in the figure into 4.48

together with the accumulation in the control volume to get:

∂cA

= A · NA,z |z − A · NA,z |z+∆z

∂t

Cancellation of A and division by ∆z gives:

A∆z

NA,z |z − NA,z |z+∆z

∂cA

=

∂t

∆z

(4.50)

(4.51)

As before take the limit ∆z → 0 to obtain:

∂NA,z

∂cA

=−

∂t

∂z

(4.52)

Insert Fick’s law for diffusion only NA,z = −DAB dcdzA to get

∂cA

∂ 2 cA

= −DAB

∂t

∂z 2

(4.53)

This is Fick’s Second law which was introduced in B49CA. The use of Fick’s Second law is

either to model the behavior from an initial state until a steady state is reached or in cases

where a steady concentration is never reached.

Before turning to solving 4.53 let us compare the unsteady state transfer equations for the

different transfers:

• Momentum:

• Heat:

• Mass:

∂ 2 vx

∂vx

=υ 2

∂t

∂y

(4.54)

∂T

∂2T

=α 2

∂t

∂z

(4.55)

∂cA

∂ 2 cA

= −DAB

∂t

∂z 2

(4.56)

They are very similar and hence use similar solution techniques. If we wanted an Analytical

solution either Laplace transform or Separation of variables could be used, but that would

generally require heavy calculations. In practice, we either rely on Formulas and Diagrams

available for common cases (which we will focus on here) or Numerical solutions (as was done

for heat transfer in B48BG Topic 5).

4.3.2 Transient diffusion in a semi-infinite medium

Consider a semi-infinite medium, which extends in the z-direction from z = 0 to z = ∞. How

the x and y coordinates are not of interest because diffusion is assumed to take place only in

the z-direction. Thus, we can use 4.53 for z ≥ 0.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

20

Applied Transport Phenomena

cA = cA0

at t = 0,

for all z

cA = cAs

at z = 0,

for all t

cA = cA0

at z = ∞,

for all t

(4.57)

where cAs < cA0 , creating the concentration that drives the diffusion, and the last condition is

the effect of having an infinite medium in the z-direction.

Solving 4.53 for the conditions 4.57 can be achieved by using the separation of variables or

Laplace transform approaches, both yielding the following solution:

θ=

cA (z, t) − cA0

z

z

= 1 − erf √

= erfc √

cAs − cA0

2 DAB t

2 DAB t

(4.58)

where the error function (erf) and complimentary error function (erfc) are defined as follows:

Z x

2

exp(−η 2 )dη

(4.59)

erfc(x) = 1 − erf(x) = 1 − √

π 0

The error function value is obtained from tables (see Table 4.1) or software, like spreadsheet

programs.

Table 4.1: Error function and complementary error function

x

erf(x) erfc(x)

0.0 0.0000 1.0000

0.4 0.4284 0.5716

0.8 0.7421 0.2579

1.2 0.9103 0.0897

1.6 0.9763 0.0237

2.0 0.9953 0.0047

∞ 1.0000 0.0000

The solution 4.58 applies to semi-infinite mediums as long as there is no bulk flow. Thus applies

directly to solids, but also to liquids and gases as long as the medium is dilute in the diffusing

solute.

√

In 4.58, when z/(2 DAB t) = 2 the complementary error function is only 0.0047. This means

that less than 0.05%, of the change at the surface (z = 0) has been carried through√to the

position z. The penetration depth at any given time is commonly defined as z = 4 DAB t.

4.58 can be applied to medium of finite thickness as long as its thickness is greater than the

penetration depth.

The flux of A across the surface of the medium at z = 0 is:

NA |z=0 = −DAB

dcA

|z=0

dz

(4.60)

The diffusive flux of species A into the semi-infinite medium can be determined by differentiating

equation 4.58 with respect to z. Applying the chain rule of differentiation for the error function

yields:

dcA

(cA − cA0 )

|z=0 = − √ s

(4.61)

dz

πDAB t

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

21

Applied Transport Phenomena

Insert 4.61 into 4.60 to get

r

NA,z |z=0 =

DAB

(cAs − cA0 )

πt

(4.62)

The total amount of A transferred through the surface S is obtained by integrating the flux with

respect to time:

WAt − WA0 = S

Z t

0

NA,z |z=0 dτ = S

Z tr

0

DAB

(cAs − cA0 )dτ = S

πτ

r

4DAB t

(cAs − cA0 ) (4.63)

π

Example 4.2 Unsteady-stat solution using error function:

Determine how long it

c (z,t)−c

will take for the dimensionless concentration change, θ = AcA −cA A0 , to reach 0.01 at a depth

s

0

z = 100 cm in a semi-infinite medium. The medium is initially at a solute concentration cA0 ,

after the surface concentration at z = 0 increases to cAs , for diffusivities representative of a

solute diffusing through a stagnant gas, a stagnant liquid, and a solid.

Solution

For a gas, assume DAB = 0.1cm2 /s. Hence,

0.01 = θ = erfc

z

√

2 DAB t

(4.64)

Using a erfc table for erfc=0.01 gives x=1.8214 and thus:

z

√

= 1.8214

2 DAB t

Solving gives:

t=

100

2 · 1.8214

2

1

= 7540 s = 2.09 h

0.10

(4.65)

(4.66)

Similarly for a liquid, DAB = 1 × 10−5 cm2 /s, and a solid, DAB = 1 × 10−9 cm2 /s the times to

reach θ = 0.01 at 1m can be obtained as 2.39 years and 239 centuries respectively.

4.3.3 Solving finite medium cases using concentration-time charts

The use of concentration-time charts is based on using dimensionless values to describe the

mass transfer process. In the previous example, we used the dimensionless concentration change

c (z,t)−c

θ = AcA −cA A0 , which is dimensionless, but not a favored form. Instead, the unaccomplished

s

0

concentration change :

cA − cA (t, z)

Y = s

(4.67)

cAs − cA0

is preferred. The equation inside the error functions is time-related and 4.65, in the previous

example can be rearranged to get a dimensionless time, the relative time:

XD =

DAB t

x21

(4.68)

where x1 is the characteristic length, which is the distance from the point of symmetry. For a

sphere, it would be the distance from the center point, and for a slab exposed on both sides, it

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

22

Applied Transport Phenomena

would be the distance from the midpoint to the point of interest. If the transfer is just taking

place from one of the faces, the full length of the transfer would be considered characteristic

length. The characteristic length is further used to describe a dimensionless position, relative

position, n:

x

n=

(4.69)

x1

The relative resistance, m, is the ratio of the convective mass-transfer resistance to the internal

molecular mass-transfer resistance:

DAB

m=

(4.70)

k c x1

As long as the molecular diffusion is the limiting factor for the mass transfer, m is generally

approximated as zero. If that is the case 4.57 will hold. If that is not the case, m will be larger

than zero, then the surface concentration of species A differs from its concentration in the bulk

fluid phase.

The concentration-time charts may be applied when the following assumptions hold:

• Fick’s second law of diffusion is assumed; that is, there is no fluid motion, v = 0, no

production, and constant mass diffusivity.

• The body has an initial uniform concentration, cA0

• The boundary is subjected to a new condition that remains constant with time t.

Example 4.3 Unsteady mass transfer using concentration-time charts: A solid slab

of 5.15 wt % agar gel at 278 K is 10.16 mm thick and contains a uniform concentration of urea

of 0.1 kg mol/mm3 . Diffusion is only in the x direction through two parallel flat surfaces 10.16

mm apart. The slab is suddenly immersed in pure turbulent water so that the convection is very

fast and the surface resistance can be assumed to be negligible; i.e. the convective coefficient kc

is very large. The diffusivity of urea in the agar from 4.72 × 10–10 m2 /s.

(a) Calculate the concentration at the midpoint of the slab (5.08 mm from the surface) and 2.54

mm from the surface after 10 h.

(b) If the thickness of the slab is halved, what would be the midpoint concentration after 10 h?

Solution:

(a)

The values for Y are cAs = 0 as it is pure water and cA0 = 0.1 kg mol/m3 .

Y =

0 − cA

= 10 · cA

0 − 0.1

(4.71)

The characteristic length is the distance from the midpoint, x1 = 10.16 mm/2 = 5.08 × 10−3 m.

The relative time:

DAB t

10–10 × 10 · 3600

XD =

=

= 0.658

(4.72)

(5.08 × 10−3 )2

x21

The relative positions are:

• Midpoint: x = 0, hence n = 0.

• 2.54 mm from surface: x = 2.54, hence n = 2.54/5.08 = 0.5.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

23

Applied Transport Phenomena

The relative resistance is assumed zero as the diffusivity is the limiting mass transfer.

Read off the Y in the charts for:

• XD =0.658, n = 0, m = 0.

• XD =0.658, n = 0.5, m = 0.

Midpoint ↔ Y = 0.275

Y = 0.275 = 10 · cA → cA = 0.0275kg mol/m3

(4.73)

x = 2.54 mm ↔ Y = 0.172

Y = 0.172 = 10 · cA → cA = 0.0172kg mol/m3

(4.74)

(b) For half the thickness:

XD =

DAB t

10–10 × 10 · 3600

=

= 2.632

(2.54 × 10−3 )2

x21

(4.75)

n = 0 and m = 0

Y = 0.0020 = 10 · cA → cA = 2 × 10−4 kg mol/m3

(4.76)

4.3.4 Using 1-D charts for higher dimensions

The diagrams are for one-dimensional transport they can be used in higher dimensions too.

The standard possibilities are:

• For transport from a rectangular bar with sealed ends

Ybar = Ya × Yb

(4.77)

where Ya evaluated with the width, x1 = a and Yb evaluated with the depth, x1 = b.

• For transport from a rectangular parallelepiped

Yparallelepiped = Ya × Yb × Yc

(4.78)

where Ya evaluated with the width, x1 = a, Yb evaluated with the depth, x1 = b and Yc

evaluated with the height, x1 = c.

• For transport from a cylinder, including both ends

Ycylinder plus ends = Ycylinder × Ya

(4.79)

where Ycylinder evaluated with the radius, x1 = r and Yb evaluated with the height, x1 = a.

Example 4.4 Unsteady mass transfer in 2-D: Solve the midpoint case problem in example

3 for the case that it’s a semi-infinite parallelepiped with sides being 10.16 mm.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

24

Applied Transport Phenomena

Solution:

For the parallelepiped case, we have Ya = Yb = 10 · cA , XD,a = XD,b = 0.658, na = nb = 0, and

ma = mb = 0, which based on that examples gives us

Ya = Yb = 0.275

(4.80)

Ass all values are the same as in the previous example. As the case is a semi-infinite parallelepiped it can be approximated as the bar:

Y = Ya × Yb = 0.2752 = 0.075625

(4.81)

Y = 0.075625 = 10 · cA → cA = 0.0075625kg mol/m3

(4.82)

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

25

Applied Transport Phenomena

4.3.5 Tutorials

1. A large tank, filled with water with an initially uniform oxygen concentration of 2 kg/mm3 ,

has its surface concentration suddenly raised and maintained at a 9 kg/m3 concentration

level. Sketch a concentration level, cA , as a function of depth z, for a period of

a) 3600 s

b) 36000 s

c) 360000 s

if the water is at a temperature of 283 K.

2. Liquid benzene, C6 H6 , a common industrial solvent with a density of 0.88 g/cm3 , leaked

from a storage tank and seeped into the ground below. As the density of benzene is less

than the density of water, the liquid benzene formed a light nonaqueousphase liquid layer

on top of the water-saturated soil, as shown below. At a depth of 1 m below the watersaturated soil layer is a nonporous, impermeable rock layer. There is no groundwater flow

through the water-saturated soil layer, it is completely stagnant.

Figure 4.12: Tutorial question 4.3-2 (Welty et. al)

We are interested in the transport of benzene into the water-saturated soil layer, so that

we may identify how much soil must be dug up and treated. Although the water-saturated

soil is complex mixture, as a medium for benzene diffusion you may assume that it approximates the properties of a homogeneous substance. At relatively short times or relatively

small penetration depths, a finite-dimensional diffusion medium can be approximated by

a semi-infinite diffusion medium. Calculate the concentration of the dissolved benzene at

a position of 5 cm into the water-saturated soil layer after 72 h of benzene spill. Liquid

benzene is sparingly soluble in water, and its solubility limit is 24 mol/m3 at 293 K. The

effective diffusion coefficient of benzene in the water-saturated soil is 1 × 10−9 m2 /s at

293 K. Initially, there is no benzene dissolved in the water-saturated soil layer. The pure

liquid benzene layer resting on top of the soil is essentially a constant source due to the

low solubility of benzene in water. Finally, you may assume that benzene does not diffuse

into the nonporous rock layer.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

26

Applied Transport Phenomena

CA = 0.744 mol/m3 if using interpolation

CA = 0.672 mol/m3 if using exact error function

3. A large tanker truck overturns and spills a herbicide over a field. If the mass diffusivity

of the fluid in the soil is 1 × 10−3m2 /s and the fluid remains on the soil for 1800 s before

evaporating into the air, determine the depth at which plant and insect life is likely to be

destroyed if a concentration of 0.1% by weight will destroy most of the life.

6.41 m if using interpolation

6.04 if using exact error function

4. In the manufacture of semiconducting thin films, a thin film of solid arsenic is laid down

onto the surface of a silicon wafer by the chemical vapor deposition of arsine, AsH3 , as

2AsH3 (g) → 2As(s) + 3H2 (g)

The arsenic atoms then diffuse into the solid silicon to dope the wafer as shown below:

Figure 4.13: Tutorial question 4.3-4 (Welty et. al)

What is the flux of arsenic atoms into the silicon wafer after 1 h, in units of atoms/(cm2 s)?

What is the arsenic concentration 2 mm into the silicon wafer after 1 h, in units of

atoms/cm3 ?

The initial concentration of residual arsenic in the silicon wafer is 1012 atoms/cm3 . The

process temperature is 1050 ◦ C. The average diffusivity of arsenic in silicon is 5×10−13 cm2 /s

at this temperature, and the maximum solubility of arsenic in silicon is 2×1021 atoms/cm3 .

CA = 2.0 × 1018 atoms/cm3

NA,z = 1.33 × 1013 atoms/{cm2 s}

5. Living cells immobilized within an agarose gel requires glucose to survive. An important

aspect of the biochemical system design is the effective diffusion coefficient of glucose into

the agarose gel itself, which you may consider as a homo- geneous material that is mostly

liquid water. Consider the experiment that is shown below, where a slab of the agarose

gel of 1.0 cm thickness is placed within a well-mixed aqueous

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

27

Applied Transport Phenomena

Figure 4.14: Tutorial question 4.3-5 (Welty et. al)

solution of glucose maintained at a concentration of 50 mmol/L, which is relatively dilute.

The solubility of the glucose in water is equal to the solubility of glucose in the gel.

A syringe mounted at the center of the gel carefully excises a tiny sample of the gel for

glucose analysis. Initially, there is no glucose in the gel. However, after 42 h, the measured

concentration of glucose in the gel at the sampling point is 48.5 mmol/L.

a) What is the general differential equation for mass transfer for this process in terms of

concentration cA ? Propose reasonable boundary/initial conditions for this equation.

List three assumptions made in obtaining this equation.

b) Based on the measurements provided above, what is the effective diffusion coefficient

of glucose into the gel?

DAB = 2.64 × 10−6 cm2 /

6. Determine the time necessary to reduce the center moisture content to 10 wt% if a 5-cmthick slab of clay is placed on a belt passing through a continuous drier, thus restricting

the drying to only one of the flat surfaces. The initial moisture con- tent is 15 wt% and

the surface moisture content under the constant drying conditions is to be maintained at

4 wt%. The effective diffusivity of water through clay is 1.3 × 10−4 cm2 /s.

10.68 h

7. A rectangular oak pole, 10 cm by 10 cm in width and 45 cm in length, having an initial

uniform moisture content of 45 wt%, is placed in a drying kiln where its surface moisture

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

28

Applied Transport Phenomena

is maintained at 15 wt%. The drying rate is controlled by the internal diffusion of the

liquid water to the surface.

a) If the maximum moisture content of the dried pole is set at 25 wt%, how long must

the pole be dried when the ends of the pole are sealed with a vapor barrier?

b) In comparison, how long must the same pole be dried if the side surfaces are sealed

with a vapor barrier and the ends are exposed?

You may assume for the purposes of this problem that wood is an isotropic material. The

diffusivity of moisture through the oak is 1.04 × 10−5 cm2 /s under the specified drying

conditions.

10.85 days

405.6 days

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

29

Applied Transport Phenomena

4.4 Convective Mass Transfer

4.4.1 Introduction

Previously we dealt with molecular diffusion, a concentration-driven transport. When dealing

with liquids and gases it is nearly impossible to isolate molecular diffusion from the influence

of fluid motion, i.e. convection. For a solute dissolving into a moving fluid the convective

mass-transfer coefficient is defined by:

NA = kc (cAs − cA )

(4.83)

Where the flux NA represents the moles of solute A leaving the interface per unit time and

unit interfacial area. The driving force is the difference between the concentration at the phase

boundary, cAs and the concentration at some arbitrarily defined point in the fluid medium, cA .

The convective coefficient kc is a function of the geometry of the system and the velocity and

properties of the fluid similar to the heat transfer coefficient, h.

Example 4.5 Convective intro: Air flows over a solid slab of frozen carbon dioxide (dry

ice) with an exposed cross-sectional surface area of 1 × 10−3 m2 . The carbon dioxide sublimes

into the 2 m/s flowing stream at a total release rate of 2.29 × 10−4 mol/s. The air is at 293 K

and 1.013 × 105 Pa pressure. At that temperature, the diffusivity of carbon dioxide in the air is

1.5 × 10−5 m2 /s and the kinematic viscosity of the air is 1.55 × 10−5 m2 /s. Determine the value

of the mass-transfer coefficient of CO2 subliming into the flowing air under the conditions of the

experiment.

Solution:

From 4.83 we get

NA

WA

=

cAs − cA∞

A(cAs − cA∞ )

(4.84)

4.74 × 103 Pa

PA

=

= 1.946 mol/m3

RT

(8.314Pa · m3 /mol/K × 293K

(4.85)

WA

2.29 × 10−4 mol/s

=

= 0.118 m/s

A(cAs − cA∞ )

1 × 10−3 m2 × 1.946 mol/m3

(4.86)

kc =

At 293 K and 1.013 × 105 Pa

cAs =

Assuming cA∞ ) = 0,

kc =

4.4.2 Significant Parameters in Convective Mass Transfer

Dimensionless parameters are often used to correlate convective transfer data. In momentum

transfer Reynolds number and friction factor play a major role. In the correlation of convective

heat transfer data, Prandtl and Nusselt numbers are important. Some of the same parameters, along with some newly defined dimensionless numbers, will be useful in the correlation

of convective mass transfer data. The molecular diffusivities of the three transport processes

(momentum, heat, and mass) have been defined as:

µ

ρ

(4.87)

B40DM

Spring 2024

ν=

©HERIOT-WATT UNIVERSITY

30

Applied Transport Phenomena

α=

k

ρ × cp

(4.88)

DAB

(4.89)

It can be shown that each of the diffusivities has the dimensions of L2 /t, hence, a ratio of any

of the two of these must be dimensionless. The ratio of the molecular diffusivity of momentum

to the molecular diffusivity of mass is designated the Schmidt number

momentum diffusivity

µ

= Sc =

mass diffusivity

ρ × DAB

(4.90)

The Schmidt number plays a role in convective mass transfer analogous to that of the Prandtl

number in convective heat transfer.

The ratio of the thermal diffusivity to the molecular diffusivity of mass is designated the Lewis

number:

thermal diffusivity

k

= Le =

(4.91)

mass diffusivity

ρ × cp × DAB

The Lewis number is encountered when a process involves the simultaneous convective transfer

of mass and energy. The Schmidt and the Lewis numbers are observed to be combinations of

fluid properties; thus, each number may be treated as a property of the diffusing system.

Let us consider the mass transfer of solute A from a solid to a fluid flowing past the surface

of the solid. For such a case, the mass transfer between the solid surface and the fluid may be

written as in 4.83 with cA = cA∞ as in 4.84. The mass transfer past the surface is given by

NA = −DAB

dcA

|y=0

dy

(4.92)

When the boundary concentration, cAs is constant, equation 4.92 may be written as

NA = −DAB

d(cA − cAs )

|y=0

dy

(4.93)

The convection and diffusion can be equated as

kc (cAs − cA∞ ) = −DAB

d

(cA − cAs ) |y=0

dy

(4.94)

rearrange to get

d/dy(cA − cAs ) |y=0

kc

=−

DAB

(cAs − cA∞ )

(4.95)

Multiplying both sides by the significant length, L, we obtain the following dimensionless expression:

d/dy(cA − cAs ) |y=0

kc × L

=−

(4.96)

DAB

(cAs − cA∞ )/L

The right-hand side of the equation is the ratio of the concentration gradient at the surface to

an overall- or reference-concentration gradient. Accordingly, it may be considered a ratio of the

molecular mass-transport resistance to the convective mass transfer resistance of the fluid. This

ratio is referred to as the Sherwood number, Sh. This is analogous to the Nusselt number in

heat transfer.

These three parameters—Sc, Sh, and Le—will be encountered in the analyses of convective mass

transfer in the following sections.

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

31

Applied Transport Phenomena

4.4.3 Application of Dimensionless Analysis to Mass Transfer

A method to obtain the equations for predicting mass-transfer coefficients is the use of dimensionless analysis. Dimensional analysis predicts the various dimensionless parameters which are

helpful in correlating experimental data. There are two common mass transfer processes, the

transfer of mass into a steam flowing under forced convection and the transfer of mass into a

phase which is moving as the result of natural convection associated with density gradients.

Transfer into a stream flowing under forced convection

Consider the transfer of mass from the walls of a circular conduit to a fluid flowing through the

conduit. The transfer is a result of the concentration driving force, cAs − cA : The important

variables, their symbols, and their dimensional representations are listed here.

Table 4.2: Variables in forced convection

Variable

Symbol Dimensions

Tube Diameter

D

L

Fluid Density

ρ

M/L3

Fluid Viscosity

µ

M/Lt

Fluid Velocity

v

L/t

Fluid Diffusivity

DAB

L2 /t

Mass Transfer Coefficient

kc

L/t

As there are six variables and three dimensions, hence there will be three dimensionless groups,

with DAB , ρ and D as the recurring variables. The three groups are thus:

a

π1 =DAB

ρb Dc kc

(4.97)

d

π2 =DAB

ρe Df v

g

ρh Di µ

π3 =DAB

(4.98)

(4.99)

Expressing the dimensions:

π1 :

1=

L2

t

a M

L3

b

L

(L)

t

c

(4.100)

Dimensions:

L:

t:

M:

0 = 2a − 3b + c + 1

0 = −a − 1

0=b

(4.101)

(4.102)

(4.103)

Solving backwards M , t and L to get b = 0, a = −1 and 0 = −2 − 0 + c + 1 to get c = 1. Thus,

−1 0 1

π1 = DAB

ρ D kc =

kc D

DAB

(4.104)

which is the Sherwood number, 4.96, with L = D. Similarly, we can obtain:

Dv

DAB

(4.105)

B40DM

Spring 2024

π2 =

©HERIOT-WATT UNIVERSITY

32

Applied Transport Phenomena

and

µ

ρDAB

which is the Schmidt number. Taking the quotient between π2 and π3 we get:

π2

Dv

ρDAB

Dvρ

=

=

π3

DAB

µ

µ

π3 =

(4.106)

(4.107)

which we recognize as the Reynolds number. The result of the dimensional analysis of forcedconvection mass transfer in a circular conduit indicates that a correlating relation could be of

the form

Sh = f (Re, Sc)

(4.108)

which is analogous to the heat-transfer correlation

Nu = f (Re, Pr)

(4.109)

Transfer into a phase whose motion is due to Natural Convection

Natural convection currents will develop if there exists any variation in density within a liquid

or gas phase. The density variation may be due to temperature differences or relatively large

concentration differences. In the case of natural convection involving mass transfer from a

vertical plane wall to an adjacent fluid, the variables will differ from those used in the forced

convection analysis. The important variables, their symbols, and dimensional representations

are listed below.

Table 4.3: Variables in natural convection

Variable

Symbol Dimensions

Characteristic Length

L

L

Fluid Density

ρ

M/L3

Fluid Viscosity

µ

M/Lt

Fluid Diffusivity

DAB

L2 /t

Buoyant Force

g∆ρA

M/L2 /t2

Mass Transfer Coefficient

kc

L/t

As there are six variables and three dimensions, hence there will be three dimensionless groups,

with DAB , µ and L as the recurring variables. The three groups are thus:

a

π1 =DAB

Lb µc kc

(4.110)

d

π2 =DAB

Le µf ρ

(4.111)

g

π3 =DAB

Lh µi ∆A

(4.112)

Express the dimensions and solve as in the previous case to obtain.

kc L

= Sh

DAB

ρDAB

1

π2 =

=

µ

Sc

3

L g∆ρA

π3 =

µDAB

π1 =

©HERIOT-WATT UNIVERSITY

B40DM

(4.113)

(4.114)

(4.115)

Spring 2024

33

Applied Transport Phenomena

The product of π2 and π3 we can obtain the equivalent of the Grashof number in natural

convection heat transfer.

π2 π3 =

ρDAB

µ

L3 g∆ρA

µDAB

=

L3 g∆ρA

= GrAB

ρν 2

(4.116)

For both forced and natural convection, relations have been obtained by dimensional analysis

that suggests that a correlation of experimental data may be in terms of three variables instead

of the original six. This reduction in variables has aided investigators who have suggested

correlations of these forms to provide many of the empirical equations.

4.4.4 Mass, Heat and Momentum Transfer Analogies

In the previous analyses of convective mass transfer, we have recognized the similarities in the

differential equations for momentum, energy, and mass transfer and in the boundary conditions

when the transport gradients were expressed in terms of dimensionless variables. These similarities have permitted us to predict solutions for similar transfer processes. In this section,

we shall consider several analogies among transfer phenomena that have been proposed because

of the similarity in their mechanisms. The analogies are useful in understanding the transfer

phenomena and as a satisfactory means for predicting the behavior of systems for which limited

quantitative data are available. The similarity among the transfer phenomena and, accordingly,

the existence of the analogies require that the following five conditions exist within the system:

1. There is no energy or mass produced within the system. This, of course, infers that no

homogeneous reaction occurs.

2. There is no emission or absorption of radiant energy.

3. There is no viscous dissipation.

4. The velocity profile is not affected by the mass transfer; thus, there is only a low rate of

mass transfer.

5. The physical properties are constant. As there may be slight changes in the physical

properties due to variations in temperature or concentration, this condition can be approximated by using average concentration and film temperature properties

Reynolds Analogy

The first reported analogy between the different types of transfers was first reported by Reynolds.

The analogy is limited, it requires that Sc=Pr=1, but highlighted the possibilities. Importantly

it started a search for more general analogies. Reynolds postulated that the following analogies

hold, for laminar flow and Sc=Pr=1:

Cf

kc

h

=

=

v∞

2

ρv∞ cp

©HERIOT-WATT UNIVERSITY

B40DM

(4.117)

Spring 2024

34

Applied Transport Phenomena

Turbulent-Flow Considerations

In a majority of practical applications, the flow in the main stream is turbulent rather than laminar. However, direct analysis of convective transfer coefficients due to the irregular fluctuations

due to random movements. The eddy movements lead to mixing and the so-called eddy-mass

diffusivity. To characterize this type of motion, Prandtl proposed the mixing length hypothesis.

In this hypothesis, any velocity fluctuation vx′ is due to the y-directional motion of an eddy

through a distance equal to the mixing length L.

The Prandtl and von Kármán Analogies

Prandtl modified the Reynolds analogy by writing a regular molecular diffusion equation for the

viscous sublayer and a Reynolds-analogy equation for the turbulent core region. Then, since

these processes are in series, these equations were combined to produce an overall equation.

Cf /2

kc

=

v∞

1 + (vx /v∞ )(Sc − 1)

(4.118)

The Reynolds analogy 4.117 is obtained when Sc=1 and the results also remain poor for fluids

where the Prandtl and Schmidt numbers differ from 1.0.

Von Kármán further modified the Prandtl analogy by considering the buffer region in addition

to the viscous sublayer and the turbulent core. Again, an equation is written for molecular

diffusion in the viscous sublayer using only the molecular diffusivity and a Reynolds-analogy

equation for the turbulent core. Both the molecular and eddy diffusivity are used in an equation

for the buffer layer, where the velocity in this layer is used to obtain an equation for the eddy

diffusivity to give the von Kármán analogy.

Sh =

(Cf /2)ReSc

p

1 + 5 (Cf /2){Sc − 1 + ln[(1 + 5Sc)/6]}

(4.119)

or rearranged as

(Cf /2)

Sh

kc

p

=

=

ReSc

v∞

1 + 5 (Cf /2){Sc − 1 + ln[1 + 5/6(Sc − 1)]}

(4.120)

The results of most analogies can be put in a general form, as illustrated in equations 4.118 and

4.120 in which the denominator of the right-hand side is a complex group of terms that serve as

a correction to the simple Reynolds analogy.

Chilton–Colburn Analogy

Because the Reynold’s analogy was practically useful, many authors tried to extend it to liquids.

Chilton and Colburn, using experimental data, sought modifications to the Reynold’s analogy

that would not have the restrictions that Prandtl and Schmidt numbers must be equal to one.

They defined the j factor for mass transfer as

jD ≡

©HERIOT-WATT UNIVERSITY

kc 2/3

Sc

v∞

B40DM

(4.121)

Spring 2024

35

Applied Transport Phenomena

The factor have an analogy for heat transfer as well. Based on the data collected in both laminar

and turbulent flow regimes, they found.

jD ≡

kc 2/3 Cf

Sc =

v∞

2

(4.122)

The analogy is valid for gases and liquids within the range 0.6 < Sc < 2500. Equation 4.122

can be shown to correlate to experimental for laminar flow over the flat plate as:

1/3

Shx = 0.332 Re1/2

x Sc

(4.123)

Dividing both sides by Rex Sc1/3 gives

Shx

1/3

Rex Sc

=

0.332

1/2

Rex

(4.124)

where the left-hand side can be made to fit the Chilton-Colburn analogy by factoring out Sc2/3

to get

Shx

Shx

=

× Sc2/3

(4.125)

1/3

Rex Sc

Rex Sc

Which brings us back to 4.122 as seen in the following equation

µ

ρDAB

kc 2/3 Cf

kc x

Sc2/3 =

Sc =

DAB

xv∞ ρ

µ

v∞

2

(4.126)

The complete Chilton–Colburn analogy is

jD = jH =

Cf

2

(4.127)

which relates all three types of transport in one expression. Equation 4.127 is exact for flat

plates and is satisfactory for systems of other geometry provided no form drag is present. For

systems where form drag is present, it has been found that neither jH or jD is equal to Cf /2;

however, when form drag is present

jD = jH

(4.128)

which can be expressed as

kc 2/3

h

Sc =

Pr2/3

v∞

ρv∞ cp

(4.129)

which relates convective heat and mass transfer. It permits the evaluation of one unknown

transfer coefficient through information obtained for another transfer phenomenon. It is valid

for gases and liquids within the ranges 0.6 <Sc< 2500 and 0.6 < Pr < 100.

The Chilton–Colburn analogy for heat and mass transfer has been observed to hold for many

different geometries; for example, flow over flat plate, flow in circular pipe and annulus, and flow

around cylinders. In the following three examples, we will apply the Chilton–Colburn analogy

(1) to determine an unknown convective-transfer coefficient, (2) to predict a correlating equation

for mass transfer, and (3) to derive and use the important psychrometry wet-bulb equation.

Example 4.6 C-C Analogy I: Using the statement presented in Example 5 and the masstransfer coefficient determined in that example, determine the value of the heat-transfer coefficient, h, for the stated air stream.

Solution:

In the solution to Example 5, the mass-transfer coefficient was found to be kc = 0.118 m/s and

©HERIOT-WATT UNIVERSITY

B40DM

Spring 2024

36

Applied Transport Phenomena

the mass diffusivity of carbon dioxide in air is 1.5 × 10−5 m2 /s and the kinematic viscosity of the

air is 1.55 × 10−5 m2 /s. From equation 4.128 expressed as

h

kc 2/3

Sc =

Pr2/3

v∞

ρv∞ cp

(4.130)

which can be rearranged as

h = kc ρcp

Sc

Pr

2/3

(4.131)

Obtaining data needed we get:

ρair = 1.206kg/m3

cp,air = 1.0061J/kg/K

Pr = 0.710

Determine the Schmidt:

Sc =

1.55 × 10−5 m2 /s

ν

=

= 1.033

DAB

1.5 × 10−5 m2 /s

Substituting into 4.133 we get

kg

J

m 1.033 2/3

J

h = 1.206 3

1.0061

0.118

= 0.184 2

m

kg K

s

0.710

m Ks

(4.132)

(4.133)

Example 4.7 C-C Analogy II: Dry air at 1.013 × 105 Pa pressure blows across a thermometer whose bulb has been covered with a dampened wick. The classical wet bulb thermometer

indicates that a steady-state temperature is reached by a small amount of liquid water evaporating into a large reservoir of unsaturated vapor– gas mixture. The thermometer reads 290 K. At

this temperature, the following properties were obtained: What is the temperature of the dry air?

Table 4.4: Physical properties

Property

Value

PA , vapor pressure of water

1.94 × 103 P a

ρ, density of air

1.219 kg/m³

λT s , latent heat of vaporization of water 2461 kJ/kg

Pr, Prandtl number

0.71

Sc, Schmidt number

0.61

cp , specific heat of air

1.006 J/kg K

Solution:

In this case, 4.83, refers to the molar flux of evaporation as:

NH2 O = kc (cH2 O,s − cH2 O∞ )

(4.134)

The energy required to evaporate this water is supplied by convective heat transfer;

q

= h(T∞ − Ts ) = λT s MH2 O NH2 O

A

©HERIOT-WATT UNIVERSITY

B40DM

(4.135)

Spring 2024

37

Applied Transport Phenomena

Rearrange to get the air temperature

T∞ =

λT s MH2 O NH2 O

+ Ts

h

(4.136)

Combining with 4.134 to get

T∞ = λT s MH2 O

kc

(cH2 O,s − cH2 O,∞ ) + Ts

h

(4.137)

To get kc /h we use the Chilton-Colburn analogy, 4.133, which can be arranged as

kc

1

=

h

ρcp

Pr

Sc

2/3

(4.138)

which substituted into 4.137 gives

λ T s MH 2 O

T∞ =

ρcp

Pr

Sc

2/3

(cH2 O,s − cH2 O,∞ ) + Ts

(4.139)

Then the concentrations are obtained:

cH2 Oss =

1.94 × 103 P a

PA

mol

=

= 0.804

3

RT

m3

8.314 P a m (290 K)

(4.140)

molK

and

mol

m3

Substituted, together with the given information, gives

kg

18

2461 kJ

kg

kmol

mol

0.71 2/3

0.804

+ 290K = 322.1 K

T∞ = 0.61

m3

1219 kg

1.006 J

cH2 O,∞ = 0

m3

(4.141)

(4.142)

kgK

©HERIOT-WATT UNIVERSITY