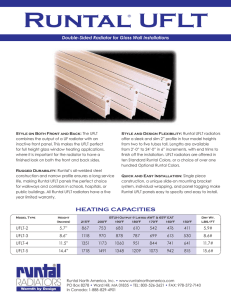

Journal of Building Engineering 23 (2019) 291–300 Contents lists available at ScienceDirect Journal of Building Engineering journal homepage: www.elsevier.com/locate/jobe A combined analytical model for increasing the accuracy of heat emission predictions in rooms heated by radiators T Karl-Villem Võsaa, Andrea Ferrantellia, , Jarek Kurnitskia,b ⁎ a b Tallinn University of Technology, Department of Civil Engineering and Architecture, Ehitajate tee 5, 19086 Tallinn, Estonia Aalto University, Department of Civil Engineering, P.O.Box 12100, 00076 Aalto, Finland ARTICLE INFO ABSTRACT Keywords: Water radiator Heat emission Energy performance Analytical models Computer simulations Operative temperature Radiative temperature The efficiency of heat emitters plays an important role in the improvement of building energy performance, especially in the context of system and product comparison. In particular, it can be directly related to thermal comfort via the operative temperature that is effectively sensed by the users. For the first time in the literature, in this paper we develop a combined analytical model for room and radiator that computes directly the heat output required to maintain a specific operative temperature. The total heat balance of the enclosure is used to accurately quantify and compare the heat emission losses of different radiator types via an analytical calculation of the operative temperature. This determines the efficiency of a selection of panel radiators with different surface temperature, radiation fraction and number of panels, which were tested in a chamber conforming to the EN 442-2 standard. Additionally, we assess the related annual energy consumption in different climates by carrying out annual simulations in old (without heat recovery) and new (with heat recovery) building types located in Tallinn, Estonia and Strasbourg, France. In the new building we find a similar performance for all the radiators. In the old building however, one radiator outperforms the other two with up to 1.38% lower annual energy consumption, due to smaller rear losses and higher thermal comfort provided by the larger front panel surface. 1. Introduction In the context of thermal comfort and emission efficiency in buildings, the physical modelling of heat transfer processes is of primary importance for an accurate assessment of energy saving capabilities [1–3]. Low- and zero-energy buildings increase the energy performance, and accordingly demand an increasing heat emission efficiency. A higher resolution in the related calculations is therefore mandatory when assessing heat emitters in general, and panel radiators in particular. Nevertheless, at the moment the manufacturers do not have any standard methodology for determining the devices' heat emission efficiency. For instance, the authors of [4] found experimentally a fairly different performance compared to the one listed by the manufacturer. Obviously, it is of great importance to know whether the radiator type would lead to a 10% or 1% difference in heating energy demand. A common high resolution method is therefore needed rather urgently. Another issue concerns the operative temperature top , namely the average of mean air- and radiant-temperatures that approaches the ⁎ temperature sensed by the user [1]. Even though it constitutes a fundamental parameter of international thermal comfort standards such as [2], in the EN 15316-2:2017 top is not adopted for computing heating system losses from the air temperature (basically due to loss of resolution for radiation effects) [5]. On the other hand, it is now well understood that, depending on the radiant temperatures in the enclosure, using the top instead of the air temperature induces sizeable differences in the heat emission losses of the radiators [6–9]. The operative temperature is also central to high resolution problems in the optimization of heating emissions towards energy saving and thermal comfort [10,11]: where should we locate the radiator, how are the size and internal design important? Answers to these questions require a resolution level that has not been achieved so far; recent experimental studies (see e.g. [4]) were not conclusive, as they found contrasting results such as differing measured heat emissions in different tests. However it is certain that the radiator design has a critical impact on its emission losses, as illustrated in Fig. 1. Attempts to model the heat exchange induced by the heaters' output in internal spaces have been carried out for a long time [12–16]. Corresponding author. E-mail address: andrea.ferrantelli@taltech.ee (A. Ferrantelli). https://doi.org/10.1016/j.jobe.2019.02.009 Received 23 November 2018; Received in revised form 7 February 2019; Accepted 10 February 2019 Available online 13 February 2019 2352-7102/ © 2019 Elsevier Ltd. All rights reserved. Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. Nomenclature T t top tMRT tin tout tln ta te tse tsi tr qri qre qci qce qcr qw qbw Absolute temperature [K] Temperature [°C] Operative temperature [°C] Mean radiant temperature [°C] Supply water temperature [°C] Radiator outlet temperature [°C] Logarithmic mean temperature difference [°C] Indoor air temperature [°C] External temperature [°C] Temperature of external surfaces [°C] Temperature of internal surfaces [°C] Radiator surface temperature [°C] Net radiative heat exchanged between radiator and internal surfaces [W] Net radiative heat exchanged between internal and F r si Ar Asi Ase d cp Regarding these earlier works, Inard et al. presented in [17] a zonalmethod representation of thermal exchanges in enclosed spaces. They found in particular that on the view point of energy consumption and thermal comfort, distributed heat sources (a hot-water heated floor and an electrical heated ceiling) presented a slight advantage over localized sources (a hot-water radiator and an electrical convector). This constitutes a remarkable precursor of actual numerical studies, e.g. with standard IDA ICE models [18]. Focusing on radiators, Harris investigated in [19] the effect of a reflecting metal foil inserted behind the central heating radiators. Experiments performed in an environmental chamber showed a 30% decrease of the heat loss through the area of wall immediately behind the radiator. The above methodology is therefore extremely useful for investigating the complex processes involved in the physics of space external surfaces [W] Convective heat exchanged at internal surfaces [W] Convective heat exchanged at external surfaces [W] Convective heat transferred from the radiator [W] Heat loss through the external wall [W] Radiator back wall losses [W] Total radiator heat output [W] Total exchange factor from radiator to internal surfaces [-] Radiator panel area [m2] Internal surfaces area [m2] External surface area [m2] Emissivity [-] Thickness [m] Density [kg/m3] Thermal conductivity [W/mK] Specific heat at constant pressure [J/kg K] heating. Specifically, there is a compelling need to quantify efficiently the performance differences from different types of radiators [4,20–22]. Several attempts to do so have been made in the recent past: an analytical model for comparing the efficiency of different radiators was first introduced in [4] and further developed in [23]. Both studies considered a 11-type, a 22-type parallel connected and a 22-type serial connected panel radiators with similar standard heat outputs, with laboratory measurements performed in a test chamber corresponding to the standard EN 442-2:2003 [24]. The energy saving capability of the radiators was measured in [4] at the same operative temperature. In [23], new laboratory measurements with updated devices were combined with new calibrations, where the heat outputs were instead adjusted to the difference between top and the average T of the cooled surfaces. This methodological refinement allowed to identify the most performing radiator in the 11-type, due to its larger panel surface area. Unfortunately, all these encouraging results do not comprise the direct calculation of a specific operative temperature as induced by the radiator surface temperature and heat output. Since these are easily controlled parameters of each device, they constitute a reliable means for comparing different emitters. As a novel result in the literature, we accomplish this task in the present paper, by extending the methodology developed in [23] from the EN 442-2 test chamber to a real room, both windowed and windowless. We formulate an analytical steady-state heat transfer model that calculates the heat balance for both room and radiator in the enclosure, assuming adiabatic internal walls and heat flux only through the external wall. The operative temperature is determined from formulas listed in ISO 7726:1998 [2], while for computing the convective heat transfer coefficients we use two different methods. The first one comes directly from the measurement-based Cconv obtained in [23], while the second method uses the Detailed Natural Convection Algorithm (DNCA) of the simulation software IDA ICE, which is based on phenomenological formulas [18]. Since both calculation methods use the same DNCA model, this comparison is made as a cross check of the calculation. Heat transfer in the same room with identical size and steady-state conditions is also studied numerically with IDA ICE. We find that using the Cconv values results in a general 5–6% overestimation of the radiators heat output when compared to using the DNCA and IDA ICE values, which instead give similar results overall.1 As explained in Section 2.2, this is due to average cooling water temperatures being used in the analytical model, instead of measured surface temperatures. Numerical computations with the IDA ICE software are then used in an analogous transient computation that spans a full solar year. We Fig. 1. Radiator surface temperatures and relation to losses. 1 292 These are remarkably close in the case of windowless room. Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. consider both an old (without heat recovery) and a new (with heat recovery) building, with boundary conditions from climate data for Tallinn (North-Eastern Europe) and Strasbourg (Central Europe). We find that the 22-type serial-connected panel radiator has up to 0.14% and 1.38% lower energy consumption in the defined new and old building types, respectively. The higher front panel surface temperature resulted in the best thermal comfort out of the considered cases, while the lower rear panel temperature corresponds to a lower additional rear heat loss. Due to heat recovery, annual energy consumption differences in the new building were only up to 0.14%. This corresponded to a setpoint difference of only 0.01 °C or less, too small for standardisation or practical calculation purposes. The present article is organized as follows: in Section 2.1 we briefly summarize the experimental setup and results from [23] that are used in this study. In Section 2.2 we illustrate our steady-state analytical model and compare the different results with our choices for the convection coefficients and the IDA ICE computation. In Section 2.3 we describe the annual numerical simulation, and our conclusions are finally drawn in Section 4. Air temperature sensor at controller Anemometer h=1.50m Black globe thermometer h=1.50m Air temperature sensors h=0.05m, 0.60m, 0.75m, 1.50m, 2.95m Temperature and mass flow sensors Fig. 3. Sketch of the EN442 test chamber [23]. 2. Method 2.1. Experimental setup and measurements In this paper we are interested in comparing three different types of radiators: • 11-type panel - single radiative panel configuration with convective fin behind the panel. • 22-type panel, parallel-connected - double radiative panel config• uration with two convective fins in-between. Water flows in parallel through both panels. 22-type panel, serial-connected - double radiative panel configuration with two convective fins in-between. Water flows through the front (room-side) panel first. These are illustrated in Fig. 2. The measurement data here discussed were obtained in a test chamber shown in Figs. 3 and 4, which conforms to EN 442-2 requirements [24]. The walls, floor and ceiling of the test chamber are made from sandwich panels, whose internal surface temperatures can be controlled. The panels consist of four components: a combination of smooth and undulation steel sheets form channels for cooling water, with the smooth sheet facing the interior of the test room. The undulating steel sheet is covered with an 80 mm layer of insulating foam, and the insulation layer with an external sheet whose thickness is 0.6 mm. The minimum overall thermal resistance of each wall, floor and ceiling is 2.5 m2 K/W. The temperatures of internal surfaces are controlled by regulating the water flow inside the flow channels, in order to achieve the desired heat outputs of the radiators. The test room is independent of the environment, since the only opening is an entrance door, also insulated as described above. Radiators are placed symmetrically on the wall opposite the entrance door, with supply and return lines at the same end. The chamber air temperature was controlled by a thermostatic radiator valve equipped with a PI-type controller, set to maintain 20 °C air temperature at the point of occupancy (assumed to be at the centre of the room at h=0.75 m). Two sets of tests were conducted for each of the radiators with projected heat outputs of 380 W and 580 W. The cooling water flow rate for the cooled walls was adjusted for the first Fig. 4. Sensor setup in the EN442 test chamber [23]. tested radiator in each set, until the desired heat output was reached. The flow rate in the circulation pump was then fixed and used as a reference flow rate for the other radiators in the same test set. Temperature sensors were installed for all the cooled surfaces, radiator front panel surface and on the insulation surface behind the radiator, as in Fig. 4. The air temperature was measured in the room centre at different heights. Additionally, we measured the heat flux behind the radiator to compare the heat losses with different rear panel temperatures. Eventual errors from the calibration of different measuring devices were reduced by swapping the same temperature sensors, radiator valve and controllers over in-between tests, in order to reproduce uniform conditions for each and every test. Furthermore, averages of measurements were aggregated from the datasets only after the sensor readings stabilized from the initial excitations. Eventually, the measured differences among the three radiator types were found to be greater than those due to any design differences or measurement errors. Fig. 2. Water flow directions in the tested radiators. 293 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. For further details we remand to [23], where experimental modalities and the full results are thoroughly described and analysed. 2.2. Steady-state analytical model As we are interested in comparing radiators at the same operative temperature rather than that of air, in this paper we make a significant extension of an analytical model which was proposed in [4,23] for the test room. Now the heat balance in the room includes also the heat output of the radiator: the model is able to compute the radiator surface and return temperatures as well as the heat output. In contrast, in [23] these values were taken from the measurements and used as input data for the model. The study at hand therefore constitutes a clear advance in the formulation, also because it extends the comparison of radiators to real rooms under steady-state conditions. Moreover, we use this analytical model to validate the IDA ICE simulation discussed in Section 2.3. The operative temperature is defined as the uniform temperature of an enclosure in which an occupant would exchange the same amount of heat by radiation plus convection as in the existing non-uniform environment [2]. In most practical cases where the relative velocity is small (< 0.2 m/s) or where the difference between mean radiant and air temperature is small (< 4 °C), the operative temperature can be calculated with sufficient approximation as the mean value of air and mean radiant temperature (MRT) [2], top = ta + tMRT . 2 Fig. 5. Sketch of the heat balance for the analytical model. F si se = qri = Fsi se = as 1/ Fr si + (1/ r 1) Tse4 ), (10) ts ), (11) ts ) 0.32. hc = 1.810(ta ts )1/3 1.382 |cos ( )| hc = 9.482(ta ts )1/3 otherwise 7.283 + |cos ( )| = if 90°, (12) n tln tln, n n , (13) where the logarithmic difference of temperatures is calculated as tln = tin tout . t ta ln in tout ta (14) Supply water at temperature tin = 75 °C was used for all the analytical solutions. On the other hand, the radiator heat output can be formulated with Fig. 6, (5) = qri + qcr + qbw . Alternatively, when differing internal wall temperatures are considered, the view factors in Table 1 can be used. The radiation heat rate from internal to external surface is calculated similarly, qre = Asi F si se (Tsi4 The general Newton's cooling law with air temperature ta is written where = 0° for floors and = 180° for ceilings. The radiator heat output is calculated according to the characteristic equation established in [24] as (3) 5 Asin = 3·12 + 2·16 = 68 m2. (9) Here we use the room average Cconv value, obtained experimentally in [23]. Alternatively, convective heat transfer coefficients were also calculated according to the IDA ICE Detailed Natural Convection Algorithm (DNCA), holding as [18] (4) n=1 Ase A Fse si = se . Asi Asi hc = Cconv (ta and the internal surfaces can be considered as a single surface with their areas summed up, Asi = si = se = 0.90 . Since the external wall where the convective heat transfer coefficients were calculated from [26] as with surface emissivity values r = 0.95 and si = 0.90 representing typical values for a white aluminium panel and a room with a white finish, where Ar and Asi are, respectively, the radiator panel and internal surfaces areas. As the defined front panel surface only sees internal surfaces whose temperatures are assumed to be equal, the view factor becomes Fr si = 1 , (7) (8) qc = hc As (ta (2) 1 1) + (Ar / Asi )(1/ si , thus from the reciprocity theorem we obtain The total exchange factor F r si is obtained from [25], F r si = 1) Fse si = 1 , (1) Tsi4 ). 1 1) + (Asi / Ase )(1/ se and surface emissivity values only sees internal walls, In our laboratory measurements, the air temperature was maintained at 20 °C. A windowless and windowed room with identical dimensions to the EN442-2 test chamber are considered, and internal surfaces are assumed to be adiabatic. In other words, all heat emitted to the room is lost through the exterior wall (as illustrated in Fig. 5). For the purposes of radiation calculation, the radiator is modelled as an infinitely thin surface laying on the external wall. Radiation from the top, bottom and sides of radiator is not considered. The net radiative heat exchanged between radiator at Tr and internal surfaces at Tsi can be calculated from the common long-wave radiation equation, Ar F r si (Tr4 1/ Fsi se + (1/ si (15) Having calculated qri from Eq. (2) and assuming qbw = const (measured during the laboratory test), convection from the radiator can be calculated by rearranging Eq. (15), qcr = (6) qri qbw , (16) while convection values calculated from Eqs. (10) and (16) have to be equal for heat balance at the air node, with the total exchange factor 294 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. Table 1 View factors from radiator to room surfaces, valid for a 4 m×4 m×3 m room with radiator placed at h = 0.15 m above the floor on the centreline of the room. Surface Table 2 CEN TC130 WG13 standard room and boundary condition definitions. The room dimensions are x = 4.0 m, y = 4.0 m and z = 3.0 m. Radiator size Opposite wall Floor Ceiling Sidewalls 1.40 m × 0.60 m 2.30 m × 0.60 m 0.1704 0.4111 0.1420 0.1382 0.1672 0.4058 0.1386 0.1442 (17) where -values are taken from [23]. The steady-state heat loss through the external wall is calculated by simple one-dimensional conduction as A qw = se tse Rw te , 3 m2 1.08 W/mK 30% 1.20 W/mK 0.64 3 m2 2.34 W/mK 30% 2.00 W/mK 0.76 qre = qri + qci , 1.0 h 1 18 °C 0.8, texh 0 °C 25 °C 20 °C South 3.8 W/m2 1.0 h 1 outdoor temperature – 25 °C 20 °C South 3.8 W/m2 (22) (23) are simultaneously satisfied. The analytical model itself, along with the mean radiant temperature calculation, is implemented in numerous Excel worksheets according to the described formulae. The iterative process within the model is handled with the OpenSolver VBA add-on. The convection component was addressed with three different approaches: using in the analytical model the Cconv -value derived from the test chamber measurements [23], the DNCA module for convection [18], and numerically, with IDA ICE simulations. (19) 2 Windowed area Window Window frame fraction Frame Window g-value ACH = qcr + qri + qbw = qce + qre + qbw , (18) tln , Old building calculated according to Eq. (1) as the average of air and mean radiant temperature, since the air velocities in the test chamber were low. Having established all the governing equations and dependencies, the analytical model can now be iteratively solved by changing air temperature ta , interior surface temperature of internal walls tsi and radiator outlet temperature tout . This should be done until the target operative temperature top = 20 °C and the heat balance equations for nodes e and c in Fig. 6, written as The radiator front panel surface temperature is estimated as tr = ta + New building Supply air temperature Heat recovery efficiency Cooling setpoint (air) Heating setpoint (operative) Window orientation Internal gains Fig. 6. Analytical model heat balance nodes. a - radiator, b - indoor air, c adiabatic internal surface, d - internal surface of external wall, e - external surface of external wall. qcr = qci + qce . Boundary condition 2 where Rw = 0.700 m K/W and Rw = 2.114 m K/W correspond to the thermal resistances of the walls in windowless and windowed rooms, respectively, with the same external temperature te = 20 °C . The windowless room roughly represents the laboratory test chamber with only one external wall, while the windowed room represents the new building type described in Tables 2 and 3. To compensate for the larger panel surface area of the 11-type radiator,2 R-values of Rw = 0.666 m2 K/W and Rw = 2.011 m2 K/W were used instead, to keep the ratio Ase / Rw constant for all radiators. Since the proposed model considers the window and wall together as one single external wall element, the R-value for the windowed case was calculated as the weighted average R-value of the external wall R w = 2.50 m2 K/W and window Rwin = 1.116 m2 K/W. From global heat balance in the room (Fig. 6), heat loss through the external wall can be formulated as 2.3. Annual simulation The operative temperature was calculated with the angle factors and equations from [2]. Angle factors between a small plane element and the cooled surfaces were used to calculate the plane radiant temperature, as described in Annex C of the standard. The mean radiant temperature was calculated from the plane radiant temperatures in six directions and the projected area factors for a person in the same six directions, given in Annex B [2]. The operative temperature was Numerical simulations of heat transfer processes in the new and old building rooms described above, corresponding to a European reference room defined in CEN TC130 WG13 and shown in Figs. 7 and 8, were performed for Tallinn (Estonian TRY climate file, [27]) and Strasbourg (ASHRAE IWEC climate file, [26]) with the IDA ICE 4.7 simulation software [18]. The numerical computation setup and material properties used are reported in Tables 2 and 3. The layout and components of the IDA ICE room model are shown in Fig. 9. The room model is capable of calculating detailed radiation heat transfer between all surfaces, external and internal building envelope elements, the radiator and various connections between the nodes. For the new building type, design conditions with temperatures 55/ 45/20 °C were used for determining the heat load in the two locations.3 This produced design heat loads of 274 W and 241 W. Consequently, smaller radiators had to be used in the new building simulations (see Table 4). For the old building, radiator sizes tested in the laboratory were suitable at 75/65/20 °C design conditions. Radiator supply water temperature curves used in the simulation were constructed based on the design conditions (assuming also constant flow) and are shown in Fig. 10. Additionally, an ideal convector (all heat is released into the air) was also simulated for comparison. 2 Such a large size is not realistic for ordinary installations, but is required for matching the heat output of the 22-type radiator. 3 Namely, (supply/return/room) T at fixed external air temperatures of −21 °C and −15 °C in Tallinn and Strasbourg, respectively. qw = (20) qbw . Accordingly, the internal surface temperature of the external wall can be calculated by rearranging Eq. (19) as tse = te + qw Rw Ase . (21) 295 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. Table 3 CEN TC130 WG13 standard room and boundary conditions definitions - layer thermal properties for new and old building. Building element External wall, new Gypsum Light insulation/wood frame Internal wall, new Gypsum Light insulation/wood frame Internal ceiling/floor, new Parquetry Screed Heavy insulation Insulation/wooden joists Gypsum External wall, old Brick Internal wall, old Brick Internal ceiling/floor, old Parquetry Concrete d [mm] k [W/mK] [kg/m3] cp [J/kgK] 26 195 0.22 0.052 970 90 1090 2000 26 95 0.22 0.037 970 20 1090 750 10 25 25 100 26 0.14 0.80 0.035 0.044 0.22 500 1800 30 56 970 2300 800 1200 1700 1090 400 0.43 1200 700 150 0.60 1500 900 10 180 0.14 1.20 500 2000 2300 880 Fig. 9. Simulated room layout in IDA ICE. Table 4 Radiator catalogue parameters for annual simulation model, new building type. tln = 29.720 K according to EN 442-2. Location Type n [W] n Size [m2] STRA 11 22-par. 22-ser. 11 22-par. 22-ser. 251 244 248 279 293 298 1.2981 1.3094 1.2776 1.2981 1.3094 1.2776 0.90 × 0.30 0.50 × 0.30 0.50 × 0.30 1.00 × 0.30 0.60 × 0.30 0.60 × 0.30 TAL 0.82 0.81 0.95 0.82 0.81 0.95 Fig. 7. Simulated new building. Fig. 10. Supply water temperature curves. Table 5 Radiator catalogue parameters for the steady-state model. cording to EN 442–2 [24]. Type Rated output 11 22-par. 22-ser. 2341 2393 2332 n [W] tln = 49.833 K ac- Radiator exponent n Size [m2] 1.3115 1.3358 1.2930 2.30 × 0.60 1.40 × 0.60 1.40 × 0.60 0.82 0.81 0.95 Fig. 8. Simulated old building. 3. convective to zone via backside of unit or via extra fins, possibly enhanced by fans. The radiators were modelled using the standard water radiator model provided in the software [18]. On the waterside, the heat transfer calculation uses the logarithmic mean temperature difference between water and air. On the airside, heat transfer between the unit and its environment is split into three components: In our model, the effective heat transfer is described by a power law expression in the temperature difference water to air, Eq. (13); the corresponding coefficients are often supplied by manufacturers (Table 5). It can be noted that, since both the overall power and the transfers 1. and 2. above are specified in the model by separate equations, transfer 3. will have to take up the slack to reach the given power. The surface temperature of the unit is used in the calculation of transfers 1. and 2. above, and obtained from information on the relation 1. convective and radiative via front of unit, 2. exchange with envelope behind unit, 296 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. between surface and total thermal resistance of the water-air interface, Eq. (18). The heat balance of waterside is Table 6 Steady-state model results, windowless (EN 442-2), top = 20 °C . (24) Radiator Model ta ° C W tr ° C where m is the water mass flow and Tin and Tout are entering and leaving water temperatures, respectively. The total heat balance of the unit is written as 11-type Cconv DNCA IDA ICE Cconv DNCA IDA ICE Cconv DNCA IDA ICE 20.45 21.07 21.04 20.59 21.28 21.26 20.56 21.23 21.20 561.7 532.3 534.9 565.6 536.4 538.5 565.2 536.2 537.4 33.88 33.96 33.97 34.13 34.29 34.31 36.38 36.42 36.41 P = mcp (Tin Tout ), Qfront + Qconv + Q wall , 22-par. (25) with Qfront the heat transferred on the front side of the radiator (longwave radiation and convection) modelled in the zone model, Qconv an extra convective heat load, e.g. from back side and possible fins, and Qwall the heat transferred between the back side of the unit and facing zone surface. Q wall is modelled as long-wave radiation between the wall and the unit. Alternatively, a constant heat transfer coefficient can be provided. The model assumes equal surface temperatures for both front and rear surfaces of the radiator. For the 22-type serial panel radiator, these temperatures are different, with the front panel having a higher surface temperature than the rear panel, shown in Fig. 1. Consequently, the model was modified to enable differing temperatures for the front and rear panel surfaces. This will lower the heat loss from the rear of the radiator. The rear panel surface temperature t r was derived as a function of the front panel surface temperature tr and heat output , t r = tr (A 2 + B ), 22-ser. Table 7 Steady-state model results, windowed (new building), top = 20 ° C. Radiator Model ta ° C W tr ° C 11-type Cconv DNCA IDA ICE Cconv DNCA IDA ICE Cconv DNCA IDA ICE 20.20 20.49 20.34 20.27 20.59 20.58 20.26 20.58 20.56 201.1 197.1 190.1 201.6 197.6 189.4 201.5 197.5 188.5 26.33 26.53 26.35 26.52 26.76 26.55 27.38 27.59 27.32 22-par. 22-ser. (26) where the coefficients A = 0.00001937 and B = 0.02307 were calculated from previous laboratory measurements performed in the EN 4422 test chamber, reported in [4] (see e.g. Fig. Fig. 10 there). insufficient when considering buildings with heat recovery through the ventilation system (“new building type” in this paper). The sum of radiator Erad and air heating coil Erad energy consumptions should be used instead, 3. Results (27) Etot = Erad + Ecoil . 3.1. Steady-state analytical model This is evident as higher extracted air temperatures correspond to more heat recovery and lower energy consumption of the heating coil, and vice versa. The differences in energy consumption can be split into two primary components - additional energy losses from behind the radiator Erear and differences due to different thermal comfort provided by the radiator front surface Efront , In our analytical calculation For the windowless room, we found that the Cconv values returned 25–30 W higher heat outputs than the DNCA module and IDA ICE, Table 6. This is expected, since when calculating the Cconv values, average cooling water temperatures were used in place of measured surface temperatures, which led to artificially higher heat transfer coefficients. Such approach was acceptable for corrections inside the test chamber, however using these values in real rooms with similar dimensions may not produce accurate results. The analytical model using DNCA equations and the IDA ICE simulation show instead differences of only 1–3 W. Moreover, among the radiator types, the 11-type reached the same operative temperature emitting 3–4 W less than all the other models. For the windowed room, the results between different models were on a similar 5–6% scale, as illustrated in Table 7. The model using Cconv still had the highest heat outputs by 11–13 W. The DNCA model shows 7–9 W higher heat outputs than the IDA ICE model. This can be explained by our simplified approach used in the analytical model - we considered the wall and window as a single surface with a weighted average R-value. In the IDA ICE model, a window was instead implemented, with convection and radiation calculated separately from the wall. To summarize, the differences between different models are within reason and give us confidence that annual simulation results from IDA ICE will be accurate enough to quantify the differences between radiator types. (28) E = Efront + Erear . Erear was calculated by logging the heat fluxes from the external wall and behind radiator. Erear = Arad (qrear qwall ) t , (29) where t corresponds to the simulation time-step and the summation is done over the heating period (i.e. when the radiator is in use). Efront can then be calculated from Eq. (28). The set-point differences sp were calculated using additional simulations results, where the set-point was varied. For ± 0.25 °C, this difference in energy consumption is proportional to that from the reference set-point of 20 °C, returning the plot in Fig. 15. Simulation results of the 22-type serial panel radiator with additional rear losses deducted ( Erear = 0 ) were used as the relative benchmark in all the following results (Tables 8 and 9), as an ideal reference case is not welldefined for systems controlled by operative temperature. As the ideal convector has no physical location inside the room model and releases heat directly into the air node inside the room, it will also not exhibit any additional rear losses. Annual energy consumption is up to 0.37% higher for the new building type and 1.57% higher for the old building type compared to the relative benchmark. The difference is greater in the old building due to lack of heat recovery. This is evident from the Efront -values - for the new building, the front-side losses are only 0.02–0.10% (compared to 0.73–1.08% in the old building). 3.2. Annual simulation Duration graphs for the panel surface temperatures are shown in Figs. 11, 12, 13 and 14. Comparing annual energy consumption of the radiators is 297 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. Fig. 11. Duration graphs for Strasbourg, old building. Fig. 14. Duration graphs for Tallinn, new building. Fig. 12. Duration graphs for Strasbourg, new building. higher due to the higher supply water T, causing a higher net radiative heat exchange behind the rear wall and rear radiator panel. The size of the radiator naturally corresponds to a proportionally higher additional rear loss. Qualitatively, we observe that the 22-type serial connected radiator performs the best in all four cases. The higher front panel surface temperature resulted in the best thermal comfort out of the considered cases ( Efront =0 as it was used as the reference benchmark), while lower rear panel temperature corresponds to a lower additional rear heat loss (Fig. 1). For the new building, the differences between the tested real radiators (11-type and both 22-types) were up to 0.14% and 0.06% in Strasbourg and Tallinn. This corresponds to a set-point difference of 0.01 °C only. For standardisation and practical purposes, this difference is largely negligible. For the old building, the differences were 1.38% and 1.11% for Strasbourg and Tallinn, corresponding to set-point differences of 0.11 °C and 0.14 °C. Interestingly, an ideal convector outperforms the real radiators in the new building. This is likely due to heat recovery and absence of additional rear losses. Relative differences between the annual energy consumption were higher in Strasbourg. The heating period is shorter and the average temperature differential between the indoor and outdoor air temperatures is smaller, as illustrated in Figs. 15 and 16. Separate steady-state simulations with the same model showed a similar trend - a lower temperature differential leads to a higher relative emission difference. This can be explained with the differences in the supply temperatures - radiator surface temperatures are a few degrees higher in Strasbourg at equal outdoor air temperatures. 4. Conclusions In this paper we have considered annual emission efficiencies at equal operative temperature set-point of serial and parallel connected panel radiators. We formulated for the first time a combined analytical model that solves the heat balance for both room and radiator in a real enclosure, either with or without a window; we thus established a direct connection between heat output and a specific operative temperature, then calculated the corresponding radiator surface and return temperatures. As a consistent extension of an existing, experimentally grounded analytical model for steady-state conditions in a test chamber, this provided a validation for numerical computations in the same room. Differences between the simulated and analytically calculated results were sufficiently small to give us confidence that annual simulations would be able to quantify the differences, if any, between the different radiator types. Interestingly, in the steady-state calculations with windowless model corresponding to the EN442 test chamber, the 11-type radiator performed the best; however, this was not valid any more for the model with a window. Fig. 13. Duration graphs for Tallinn, old building. Although the operative temperatures are maintained at the same level, indoor air temperatures are different due to the differences in tMRT . Extra energy used to heat the air up is lost in the old building. In the new structure, however, this energy can be recouped to a large extent via heat recovery (limited only by its efficiency and by the temperature of the air that can leave the enclosure). Additionally, the radiators in the new building are smaller, and the surface temperatures are lower due to a lower supply temperature. This results in a smaller effect on tMRT and, therefore, on operative temperature and thermal comfort. The differences in performance are thus considerably smaller for the new building. Additional rear losses were higher in the old building type, up to 0.62% for the 11-type radiator. This was to be expected, as the lower level of thermal insulation results in a more intense heat transfer from behind the radiator. Additionally, the rear panel surface temperature is 298 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. Table 8 Annual simulation results for new building in Tallinn and Strasbourg. Loc. Type Strasbourg 11 22-Par 22-Ser 100% convector 22-Ser, Erear = 0 11 22-Par 22-Ser 100% convector 22-Ser, Erear = 0 Tallinn Size Etot 900 × 300 500 × 300 500 × 300 – 500 × 300 1000 × 300 600 × 300 600 × 300 – 600 × 300 102.86 102.68 102.65 102.57 102.48 356.40 355.90 355.80 355.60 355.53 Etot mm ×mm kW h 0.38 0.20 0.17 0.09 0.00 0.87 0.37 0.27 0.07 0.00 Erear Efront Etot Erear Efront 0.31 0.18 0.17 0.00 0.00 0.49 0.29 0.27 0.00 0.00 0.07 0.02 0.00 0.09 0.00 0.37 0.08 0.00 0.07 0.00 0.37% 0.19% 0.16% 0.09% 0.00% 0.24% 0.10% 0.08% 0.02% 0.00% 0.30% 0.17% 0.16% 0.00% 0.00% 0.14% 0.08% 0.08% 0.00% 0.00% 0.07% 0.02% 0.00% 0.09% 0.00% 0.10% 0.02% 0.00% 0.02% 0.00% Erear Efront Etot Erear Efront 8.14 5.00 2.53 0.00 0.00 11.77 7.17 4.42 0.00 0.00 12.39 11.53 0.00 14.13 0.00 19.05 17.35 0.00 21.52 0.00 1.57% 1.26% 0.19% 1.08% 0.00% 1.29% 1.02% 0.18% 0.90% 0.00% 0.62% 0.38% 0.19% 0.00% 0.00% 0.49% 0.30% 0.18% 0.00% 0.00% 0.95% 0.88% 0.00% 1.08% 0.00% 0.80% 0.73% 0.00% 0.90% 0.00% - sp °C 0.02 0.01 0.01 0.00 0.00 0.02 0.01 0.01 0.00 0.00 Table 9 Annual simulation results for old building in Tallinn and Strasbourg. Loc. Type Strasbourg 11 22-Par 22-Ser 100% convector 22-Ser, Erear = 0 11 22-Par 22-Ser 100% convector 22-Ser, Erear = 0 Tallinn Size Erad Etot 2300 × 600 1400 × 600 1400 × 600 – 1400 × 600 2300 × 600 1400 × 600 1400 × 600 – 1400 × 600 1329.30 1325.30 1311.30 1322.90 1308.77 2423.70 2417.40 2397.30 2414.40 2392.88 20.53 16.53 2.53 14.13 0.00 30.82 24.52 4.42 21.52 0.00 mm ×mm kW h - sp °C 0.13 0.10 0.02 0.09 0.00 0.16 0.13 0.02 0.11 0.00 Fig. 16. Operative temperature duration graphs for 22-type serial radiator during annual simulation. Breaks in the graphs mark the length of the heating period, and operative temperatures over 20.0 °C correspond to the non-heating period. Fig. 15. Percentage of additional annual heating energy needed when increasing the set-point by 0.1 K. Annual simulations run with IDA ICE then showed that 22-type serial-connected panel radiators performed best both in new and old buildings. A higher front panel surface temperature results in the best thermal comfort out of the considered cases, while lower rear panel temperature corresponds to a lower additional rear heat loss. Since a large proportion of heat from exhaust air was recouped by means of heat recovery, the annual energy consumption differences in the new building were only up to 0.14%. This corresponded to a setpoint difference of barely 0.01 °C, too small for standardisation or practical calculation purposes. For the old building, the differences were higher, up to 1.38%, leading to a set-point difference of up to 0.14 °C. Additional rear losses had a larger impact on the old building, as expected. All things considered, it seems that the formalism developed in this paper, which extends to ordinary rooms the analytical model introduced in [4] and further developed in [23] for a specific test chamber, constitutes a reliable analytical counterpart of numerical calculations. We should stress that our analytical room heat balance model implementation was directly compared to a corresponding room model in IDA ICE, which is well known to be experimentally validated [18,28]. Rather than seeking a direct experimental validation of a customary heat balance formulation, we validated the generic radiator model in IDA ICE with experimental data of heat emitters against our analytical room and radiator model. This validation exercise revealed that with experimentally measured values, IDA ICE was capable to simulate the performance differences of the radiators studied. This made it possible for the first time to run annual simulations of the heat emission efficiency for the different radiators, which was experimentally measured. One should also notice how, when comparing the annual consumption for different radiator types, no device could be set as our 299 Journal of Building Engineering 23 (2019) 291–300 K.-V. Võsa, et al. baseline, i.e. as an ideal reference case. For systems where the air temperature is controlled, this could be modelled as a purely convective radiator. However, the operative temperature also considers surface temperatures, which in turn are determined by radiation. This poses two questions - where is the heat emitter located and how much of its heat is emitted via radiation. To our knowledge, no common agreement about such ideal emitter exists yet, either it be a radiator, underfloor heating, ceiling heater etc. [29]. The definition of such a benchmark would be thus interesting not only for improving our analytical model, but also in more general investigations for systems with operative temperature control. Some efforts in this sense have been started recently, see e.g. [30]. Lastly, we should remark that in this study we addressed applications only to radiators. The model we developed can however be applied also to other heat emitters, for comparable heat emission efficiency analyses. In other words, as discussed in the introduction, the present formulation constitutes an extension of previous literature results as well. [8] B. Lin, Z. Wang, H. Sun, Y. Zhu, Q. Ouyang, Evaluation and comparison of thermal comfort of convective and radiant heating terminals in office buildings, Build. Environ. 106 (Supplement C) (2016) 91–102, https://doi.org/10.1016/j.buildenv. 2016.06.015. [9] Y. Jian, Z. Yu, Z. Liu, Y. Li, R. Li, Simulation study of impacts of radiator selection on indoor thermal environment and energy consumption, Proc. Eng. 146 (Supplement C) (2016) 466–472, https://doi.org/10.1016/j.proeng.2016.06.430 (the 8th international cold climate HVAC Conference). [10] S. Barbosa, K. Ip, Predicted thermal acceptance in naturally ventilated office buildings with double skin façades under brazilian climates, J. Build. Eng. 7 (2016) 92–102. [11] M. Ibrahim, L. Bianco, O. Ibrahim, E. Wurtz, Low-emissivity coating coupled with aerogel-based plaster for walls' internal surface application in buildings: energy saving potential based on thermal comfort assessment, J. Build. Eng. 18 (2018) 454–466. [12] R.P. Heap, Reduction of losses from emitters sited against external walls-a new approach, Heat. Vent. Eng. (1977) 5–7. [13] J. Hannay, L. Laret, J. Lebrun, D. Marret, P. Nusgens, Thermal comfort and energy consumption in winter conditions: A new experimental approach, ASHRAE Trans. 84 (1978) 150–175 (Part 1). [14] W. Stephan, System simulation : radiator, International Energy Agency, Annex 10. University of Stuttgart, 1985. [15] M.A. Morant, M. Strengnart, Simulation of hydronic heating system: radiator modelling, Proceedings of CLIMA 2000. Sarajevo (1985) pp. 725–729. [16] T. Kalema, T. Haapala, Effect of interior heat transfer coefficients on thermal dynamics and energy consumption, Energy Build. 22 (2) (1995) 101–113, https://doi. org/10.1016/0378-7788(94)00907-2. [17] C. Inard, A. Meslem, P. Depecker, Energy consumption and thermal comfort in dwelling-cells: a zonal-model approach, Build. Environ. 33 (5) (1998) 279–291. [18] EQUA, IDA ICE - Indoor Climate and Energy, EQUA, Stockholm, Sweden, 2013 (Tech. rep.). [19] D. Harris, Use of metallic foils as radiation barriers to reduce heat losses from buildings, Appl. Energy 52 (4) (1995) 331–339. [20] J.A. Myhren, S. Holmberg, Design considerations with ventilation-radiators: comparisons to traditional two-panel radiators, Energy Build. 41 (1) (2009) 92–100, https://doi.org/10.1016/j.enbuild.2008.07.014. [21] S. Beck, S. Grinsted, S. Blakey, K. Worden, A novel design for panel radiators, Appl. Therm. Eng. 24 (8) (2004) 1291–1300, https://doi.org/10.1016/j.applthermaleng. 2003.11.026 (the 8th UK National Conference on Heat Transfer). [22] M. Maivel, J. Kurnitski, Radiator and floor heating operative temperature and temperature variation corrections for EN 15316-2 heat emission standard, Energy Build. 99 (Supplement C) (2015) 204–213, https://doi.org/10.1016/j.enbuild. 2015.04.021. [23] K.-V. Võsa, A. Ferrantelli, T.M. Kull, J. Kurnitski, Experimental analysis of emission efficiency of parallel and serial connected radiators in EN442 test chamber, Appl. Therm. Eng. 132 (2018) 531–544, https://doi.org/10.1016/j.applthermaleng.2017. 12.109. [24] EN 442-2:1996/A2:2003, Radiators and Convectors – Part 2: Test Methods and Rating, CEN, 2003 (Standard). [25] M.F. Modest, Radiative Heat Transfer, 3rd edition, Elsevier, 2013. [26] ASHRAE, Handbook: Fundamentals, ASHRAE Handbook Fundamentals SystemsInternational Metric System, Ashrae, 2013. [27] T. Kalamees, J. Kurnitski, Estonian test reference year for energy calculations, Proc. Est. Acad. Sci. Eng. 12 (2006) 40–58. [28] J. Vesterberg, Improved Building Energy Simulations and Verifications by Regression (Ph.D. Thesis), Umeå Universitet, 2016. [29] EN 442-1:2014, Radiators and Convectors. Technical Specifications and Requirements, CEN, 2014 (Standard). [30] A. Ferrantelli, K.-V. Võsa, J. Kurnitski, Optimization of radiators, underfloor and ceiling heater towards the definition of a reference ideal heater for energy efficient buildings, Appl. Sci. 8 (12). ⟨https://doi.org/10.3390/app8122477⟩. Acknowledgements The authors are grateful for support by the European Regional Development Fund via the Estonian Centre of Excellence in Zero Energy and Resource Efficient Smart Buildings and Districts ZEBE, grant 20142020.4.01.15-0016. Funding by the Estonian Research Council through grant IUT1-15 is also acknowledged. We also wish to warmly thank the Rettig ICC Research Centre for the measurements performed in the EN442 test chamber. References [1] ISO 7730:2005, Ergonomics of the Thermal Environment: Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria, International Organization for Standardization, 2005 (Standard). [2] ISO 7726:1998, Ergonomics of the Thermal Environment - Instruments for Measuring Physical Quantities, International Organization for Standardization, 1998 (Standard). [3] VDI-Fachbereich Technische Gebäudeausrüstung, VDI 6030, Designing Free Heating Surfaces - Fundamentals - Designing of Heating Appliances, VDIGesellschaft Bauen und Gebäudetechnik, 2002 (Standard). [4] M. Maivel, M. Konzelmann, J. Kurnitski, Energy performance of radiators with parallel and serial connected panels, Energy Build. 86 (Supplement C) (2015) 745–753, https://doi.org/10.1016/j.enbuild.2014.10.007. [5] EN 15316-1:2017, Energy performance of buildings. Method for calculation of system energy requirements and system efficiencies. General and Energy performance expression, Module M3-1, M3-4, M3-9, M8-1, M8-., Standard, CEN, 2017. [6] G. Sevilgen, M. Kilic, Numerical analysis of air flow, heat transfer, moisture transport and thermal comfort in a room heated by two-panel radiators, Energy Build. 43 (1) (2011) 137–146, https://doi.org/10.1016/j.enbuild.2010.08.034. [7] A. Jahanbin, E. Zanchini, Effects of position and temperature-gradient direction on the performance of a thin plane radiator, Appl. Therm. Eng. 105 (Supplement C) (2016) 467–473, https://doi.org/10.1016/j.applthermaleng.2016.03.018. 300