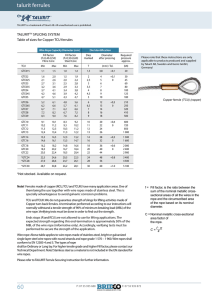

1 Design of Flexible Power Transmission Elements Rope Drives: Wire Ropes Rope Drives The rope drives are widely used where a large amount of power is to be transmitted, from one pulley to another, over a considerable distance. The ropes drives use the following two types of ropes: 1. Fibre ropes, and 2. Wire ropes Fibre of Ropes The ropes for transmitting power are usually made from fibrous materials such as hemp, manila and cotton. Since the hemp and manila fibres are rough, therefore the ropes made from these fibres are not very flexible and possesses poor mechanical properties. The hemp ropes have less strength as compared to manila ropes. The cotton ropes are very soft and smooth. The lubrication of cotton ropes is not necessary. But if it is done, it reduces the external wear between the rope and the grooves of its sheaves. It may be noted that the manila ropes are more durable and stronger than cotton ropes. The cotton ropes are costlier than manila ropes. Notes : 1. The diameter of manila and cotton ropes usually ranges from 38 mm to 50 mm. The size of the rope is usually designated by its circumference or ‘girth’. Manila rope 2. The ultimate tensile breaking load of the fibre ropes varies greatly. For manila ropes, the average value of the ultimate tensile breaking load may be taken as 500d2 kN and for cotton ropes, it may be taken as 350d2 kN, where d is the diameter of rope in mm. Advantages of Fibre Rope Drives 1. They give smooth, steady and quiet service. 2. They are little affected by out door conditions. 3. The shafts may be out of strict alignment. 2 4. The power may be taken off in any direction and in fractional parts of the whole amount. 5. They give high mechanical efficiency. Wire Ropes When a large amount of power is to be transmitted over long distances from one pulley to another (i.e. when the pulleys are up to 150 metres apart), then wire ropes are used. The wire ropes are made from cold drawn wires in order to have increase in strength and durability The various materials used for wire ropes in order of increasing strength are wrought iron, cast steel, extra strong cast steel, plough steel and alloy steel. For certain purposes, the wire ropes may also be made of copper, bronze, aluminum alloys and stainless steels. Uses of wire ropes 1. Elevators 2. hoist 3. cranes 4. drilling conveyors 5. tramways 6. haulage devices 7. suspension cables 8. guy wires Advantages of Wire Ropes 1. These are lighter in weight and high strength to weight ration 2. These can withstand shock loads 3. These are more durable, less danger for damage due to jerks 4. The efficiency is high 5. These offer silent operation 6. These are more reliable in operation 7. They do not fail suddenly 8. The cost is low Materials for wire ropes 1. Plow steel (PS) 2. Mild plow steel (MPS) 3. Improved pillow steel (IPS) 4. Wrought iron 5. Cast steel 6. Alloy steel 7. Stainless steel 8. Copper 9. Bronze Wire ropes Construction Grade and /tensile Strength of Wires 3 Classification of Wire Ropes The individual wires are first twisted into strands, and then the strands are twisted around a hemp or steel center to form a rope. Often the central element is an independent wire rope core (IWRC). 1. Cross or Regular lay – the wires and strands are twisted in opposite directions as shown in Fig. (a). Uses for stationary applications. Such type of ropes are most popular. 2. Parallel or Lang lay – the wires and strands are twisted in the same direction as shown in Fig (b). Uses for moving applications. These ropes have better bearing surface but is harder to splice and twists more easily when loaded. These ropes are more flexible and resists wear more effectively. Since such ropes have the tendency to spin, therefore these are used in lifts and hoists with guide ways and also as haulage ropes. 3. Composite or reverse laid ropes. In these types of ropes, the wires in the two adjacent strands are twisted in the opposite direction, as shown in Fig. (c). Note: The direction of the lay of the ropes may be right handed or left handed, depending upon whether the strands form right hand or left hand helixes, but the right hand lay ropes are most commonly used. Wire Rope Core 1. Fiber core - generally made of cotton twine for cable less than ¼ ‘ thick and hard fiber ropes (manila or sisal) for the larger sizes. Fiber cores extend the life by cushioning the strands and reducing internal abrasion, good for light crushing loads. Hard cores are impregnated with lubricant to deter rust and lubricate. 2. Wire core - offer less stretch, have better resistance to heavy crushing loads and are not effected by heat. Designation of wire ropes First number is the number of strands Second number is the number of wires per strand Nominal Diameter of rope, (Dr) is the diameter of the circle that just encloses the rope. 4 Examples: 6 x 7 IPS, 1” diameter - a rope with 6 strands, 7 wires per strand, having nominal diameter of 1”. Various Rope Sizes and their Application Standard Designation 6 x 7(6 strands each having 7 wires) 6 x 19 fiber core 6 x 37 fiber or wire core 6 x 42 fiber centers and core 6 x 42 fiber centers and core 1 x 19 wire core 19 x 7 wire core 7 x 7 wire core 8 x 19 Description being made of heavy wire, provides maximum resistance to abrasion and wear; used for haulage, tramways, guy wires one of the most popular style, a good for general purpose such as rope, hoists, cranes, drilling, elevators. The standard hoisting cable. Excellent strength, flexibility, and resistance to abrasion and fatigue. it is an extra flexible rope and therefore useful where abrasion is not severe and where relatively sharp bends must be tolerated; Used for high speed elevators, cranes, hoists. More flexible than 6 x 19, good for applications where pulleys are limited sizes. The most flexible of all standard cables, used for moderate loads. The most flexible of all standard cables, used for moderate loads. primarily used for stationary (non-flexible) applications. designated to resist the natural tendency of a cable to rotate when freely suspended under load. The standard flexible aircraft cable. High strength and rugged construction, used for towing and power transmission. Used as an extra flexible hoisting rope Properties of Wire Ropes In these properties, the diameter of the wire rope (d) is in mm. Table 1: Steel wire Ropes for haulage in mines 5 Table 2: Steel wire suspension ropes for lifts, elevators and hoists Table 3: Steel wire ropes used in oil wells and oil well drilling. Table 4: Steel wire ropes for general engineering purposes such as cranes, excavators etc. 6 Diameter of Wire and Area of Wire Rope The following table shows the diameter of wire (dw) and area of wire rope (A) for different types of wire ropes : Table 5: Diameter of wire and area of wire rope. Factor of Safety for Wire Ropes Table 6: Factor of safety for wire ropes. Wire Rope Sheaves and Drums The sheave diameter should be fairly large in order to reduce the bending stresses in the ropes when they bend around the sheaves or pulleys. Table 7: Sheave diameters (D) for wire ropes. 7 Wire Rope Fasteners The efficiencies of various type of fasteners s are given in the following table: Type of Fastening Wire rope socket with zinc Image Efficiency (%) 100 Thimble with four or five tucks 90 Special offset thimble with clips 90 Regular thimble with clips 85 Three bolt wire clamps 75 Stresses in Wire Rope a. Direct tensile stress; St 𝑾 𝝈d = 𝑨𝒅 Wd = W + w Where: Wd = direct load on the wire load W = weight of load lifted w = weight of the rope A = approximate cross sectional area of the rope, a function of rope diameter b. Bending Stress; Sb 𝒅 𝝈b = E 𝑫𝒘 and the equivalent bending load on the rope; Bending load; Wb 𝒅 Wb = 𝝈b A = A ( 𝑫𝒘) E Where: E = modulus of elasticity of wire rope, = 30x106 psi for steel = 77KN/mm2 for wrought iron = 84KN/mm2 for wrought iron 8 dw = wire diameter ; inch, mm D = sheave; inch, mm A = cross sectional area, in2 , mm2 If 𝝈b is the bending stress in each wire, then the load on the whole rope due to bending may be obtained from the following relation, 𝝅 Wb = 𝝈b 𝟒 (𝒅𝒘 )𝟐 𝒏 where: n is the total number of wires in the rope section. ✓ This equation shows the importance of using large diameter sheaves (where it reduces the stress developed in the outer wires). ✓ The recommended D/dw ratio is 400 and up. c. Stresses during starting and stopping. 𝑾+𝒘 Wa = 𝒈 x a (W and w are in Newton) And the corresponding stress; 𝝈a = 𝑾+𝒘 𝑨 𝒂 x𝑨 Where: a= acceleration of the rope and load g = acceleration due to gravity Wa = additional load due to acceleration of the load lifted and rope If the time (t) necessary to attain a speed (v) is known, then the value of ‘a’ is given by 𝒗 a = 𝟔𝟎 𝒕 ➢ When there is no slackness in the rope, then h = 0 and vr = 0, therefore Impact load during starting, Wst Wst = 2 (W + w) And the corresponding stress; 𝝈st = 𝟐(𝑾+𝒘) 𝑨 ➢ Effective load on the rope during normal working (during uniform lifting or lowering of the load) = W +w + Wb ➢ Effective load on the rope during starting = Wst +Wb ➢ Effective load on the rope during acceleration of the load = W +w + Wb + Wa d. Stress due to change in speed. The additional stress due to change in speed is given by 𝒗 −𝒗 a= 𝟐𝒕 𝟏 9 where: (v2-v1) is the change in speed in m/s and t is the time in seconds e. Effective stress. The sum of the direct stress (𝝈d) and the bending stress (𝝈b ) is called the effective stress in the rope during normal working. Effective stress in the rope during normal working = 𝝈d + 𝝈b Effective stress in the rope during starting = 𝝈st + 𝝈b Effective stress in the rope during acceleration of the load = 𝝈d + 𝝈b + 𝝈a Note: While designing a wire rope, the sum of these stresses should be less than the ultimate strength divided by factor of safety. Design Calculation: 1. Weight of rope, w w = 1.58 dr2 h Where: dr = rope diameter ; in h = height; in w = weight of the rope (lb) 1. Acceleration force due to weight of the rope, War 𝑎 War = w (𝑔) Where: War = acceleration force due to weight of the rope; lb w = weight of rope; lb 𝑓𝑡 a = acceleration ; 𝑠𝑒𝑐 2 = 𝑣2 − 𝑣1 𝑡 , when the trope speed changes from v1 to v2 in t seconds 𝑓𝑡 g = acceleration due to gravity ( 32.2 𝑠𝑒𝑐 2) 3. Acceleration force due to the weight connected at the end of the rope, Wla 𝑎 Wla = Wl (𝑔) Where: Wl = useful load ; lb Wla = acceleration force due to the weight connected at the rope ; lb 𝑓𝑡 a = acceleration ; 𝑠𝑒𝑐 2 𝑓𝑡 g = acceleration due to gravity ( 32.2 𝑠𝑒𝑐 2) 4. Total tension of the rope; Ft 𝑎 Ft = ( Wl + w) (1 + 𝑔) + Fb 10 Where: Wl = useful load ; lb Wr = weight of rope; lb 𝑓𝑡 a = acceleration ; 𝑠𝑒𝑐 2 𝑓𝑡 g = acceleration due to gravity ( 32.2 𝑠𝑒𝑐 2) Ft = tension of rope ; lb 5. Ultimate strength for plow steel material Fu = 76,000 dr2 for 6 x 7 and 6 x 19 rope 2 Fu = 76,000 dr for 6 x 7 and 6 x 19 rope Where: dr = rope diameter ; in Fu = ultimate strength ; lb 6. Factor of Safety, N A. Static Approach: N= 𝑭𝒖− 𝑭𝒃 𝑭𝒕 where: Where: Ft = tension of rope ; lb Fu = ultimate strength (ultimate breaking load of rope as given in Table AT -28 Faires) Fb = equivalent bending load due to the curvature of the sheave of drum 𝒅 = 𝝈b A = A ( 𝑫𝒘) E B. Fatigue Approach: dr ds = 𝟐 𝑵 𝑭𝒕 𝑷 ( )(𝑺𝒖 ) 𝑺𝒖 ( 𝑷 N = 𝑺𝒖 )(𝑺𝒖 )𝒅𝒓 𝒅𝒔 𝟐𝑭𝒕 where: dr = rope diameter ds = sheave or drum diameter Su = Ultimate tensile strength of the rope 𝑭 Su = 𝑨 𝒖 𝒎 P = contact pressure between rope and surface drum or sheave 𝑷 = pressure ratio ( Figure 17.30 pg 473 by Faires) 𝑺 𝒖 11