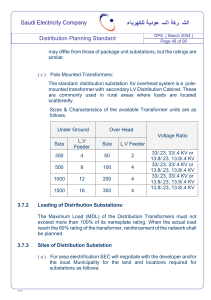

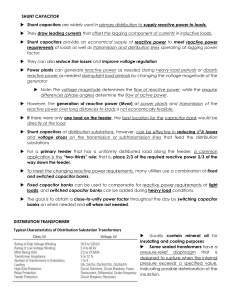

SHUNT CAPACITOR Shunt capacitors are widely used in primary distribution to supply reactive power to loads. They draw leading currents that offset the lagging component of currents in inductive loads. Shunt capacitors provide an economical supply of reactive power to meet reactive power requirements of loads as well as transmission and distribution lines operating at lagging power factor. They can also reduce line losses and improve voltage regulation Power plants can generate reactive power as needed during heavy load periods or absorb reactive power as needed during light load periods by changing the voltage magnitude of the generator Note: The voltage magnitude determines the flow of reactive power, while the angular differences (phase angles) determine the flow of active power. However, the generation of reactive power (Mvar) at power plants and transmission of the reactive power over long distances to loads is not economically feasible. If there were only one load on the feeder, the best location for the capacitor bank would be directly at the load Shunt capacitors at distribution substations, however, can be effective in reducing 𝟏𝟐 𝑹 losses and voltage drops on the transmission or subtransmission lines that feed the distribution substations For a primary feeder that has a uniformly distributed load along the feeder, a common application is the “two-thirds” rule; that is, place 2/3 of the required reactive power 2/3 of the way down the feeder. To meet the changing reactive power requirements, many utilities use a combination of fixed and switched capacitor banks. Fixed capacitor banks can be used to compensate for reactive power requirements at light loads, and switched capacitor banks can be added during heavy load conditions. The goal is to obtain a close-to-unity power factor throughout the day by switching capacitor banks on when needed and off when not needed. DISTRIBUTION TRANSFORMER Typical Characteristics of Distribution Substation Transformers Usually contain mineral oil for insulating and cooling purposes Some sealed transformers have a pressure-relief diaphragm that is designed to rupture when the internal pressure exceeds a specified value, indicating possible deterioration of the insulation. Sealed transformers may also have a sudden pressure relay to either provide an alarm or deenergize the transformer when the internal pressure suddenly increases above a specified threshold. Load Tap Changer (LTC) Allows for variable turn ratios to be selected in distinct steps so that it could regulate voltage levels This is done by connecting to a number of access points known as taps along either the primary or secondary winding. Many distribution substation transformer LTC can automatically regulate voltage level based on loading conditions. Some distribution substations have distribution substation transformers with fixed taps and separate voltage regulators Voltage Regulator-basically an autotransformer with taps that automatically raise or lower voltage, operating in a similar way as LTCs on distribution substation transformers Condensator A tank on the top of the transformer in which expansion and contraction of the oil takes place Also, condensation of moisture and formation of sludge Provided with a sump pump to draw off the moisture and sludge MVA rating Continuous load that the transformers carry without exceeding a specified temperature rise of either 55°C (for older transformers) or 65°C (for newer transformers) above a specified ambient temperature (typically 40°C) Multiple MVA ratings that depends on external radiator used to dissipate heat generated by copper and core losses. OA rating (passive convection with oil circulating pumps and fans off) FA rating (with fans on but oil circulating pumps off) FOA rating (with both fans and oil circulating pumps on). Three-phase 22.9 kVD/ 4.16 kVY distribution substation transformer rated 12 MVA OA/16 MVA FA1/20 MVA FA2. The transformer has fixed taps on the high-voltage side and an LTC on the low-voltage side. A lower FA rating with one of two sets of fans on A higher FA rating with both sets of fans on The nameplate transformer impedance is usually given in percent using the OA rating as the base MVA Read Example 4.1 2 transformer rated 9 MVA OA/ 12 MVA FA1/ 15 MVA FA2 Substation normally operate at or below 15 MVA During emergency (e.g. forced of scheduled outage of one transformer), the other transformer can supply all the feeders For this conservative operating practice, emergency transformer ratings above nameplate are not used. Some utilities operate their distribution substation transformers above nameplate ratings during normal operating conditions, as well as during emergency conditions. ANSI/IEEE C-57.91-1995 entitled, IEEE Guide for Loading Mineral Oil-Immersed Transformer Identifies the risks of transformer loads in excess of nameplate rating and establishes limitations and guidelines Minimize the risks to an acceptable limit Typically, there are two emergency loading criteria for distribution substation transformers: 1. A two-hour emergency rating, which gives time to perform switching operations and reduce loadings. 2. A longer-duration emergency rating (10 to 30 days), which gives time to replace a failed transformer with a spare that is in stock.