Engineering Economy Group Activity: Drill Bit Production

advertisement

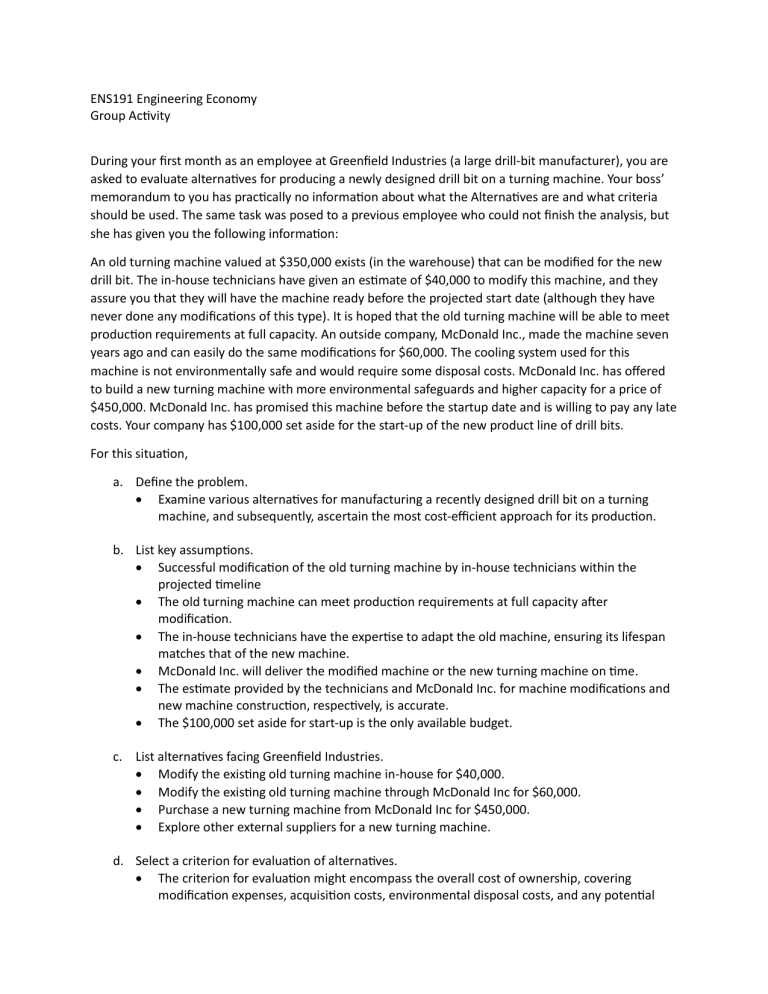

ENS191 Engineering Economy Group Activity During your first month as an employee at Greenfield Industries (a large drill-bit manufacturer), you are asked to evaluate alternatives for producing a newly designed drill bit on a turning machine. Your boss’ memorandum to you has practically no information about what the Alternatives are and what criteria should be used. The same task was posed to a previous employee who could not finish the analysis, but she has given you the following information: An old turning machine valued at $350,000 exists (in the warehouse) that can be modified for the new drill bit. The in-house technicians have given an estimate of $40,000 to modify this machine, and they assure you that they will have the machine ready before the projected start date (although they have never done any modifications of this type). It is hoped that the old turning machine will be able to meet production requirements at full capacity. An outside company, McDonald Inc., made the machine seven years ago and can easily do the same modifications for $60,000. The cooling system used for this machine is not environmentally safe and would require some disposal costs. McDonald Inc. has offered to build a new turning machine with more environmental safeguards and higher capacity for a price of $450,000. McDonald Inc. has promised this machine before the startup date and is willing to pay any late costs. Your company has $100,000 set aside for the start-up of the new product line of drill bits. For this situation, a. Define the problem. Examine various alternatives for manufacturing a recently designed drill bit on a turning machine, and subsequently, ascertain the most cost-efficient approach for its production. b. List key assumptions. Successful modification of the old turning machine by in-house technicians within the projected timeline The old turning machine can meet production requirements at full capacity after modification. The in-house technicians have the expertise to adapt the old machine, ensuring its lifespan matches that of the new machine. McDonald Inc. will deliver the modified machine or the new turning machine on time. The estimate provided by the technicians and McDonald Inc. for machine modifications and new machine construction, respectively, is accurate. The $100,000 set aside for start-up is the only available budget. c. List alternatives facing Greenfield Industries. Modify the existing old turning machine in-house for $40,000. Modify the existing old turning machine through McDonald Inc for $60,000. Purchase a new turning machine from McDonald Inc for $450,000. Explore other external suppliers for a new turning machine. d. Select a criterion for evaluation of alternatives. The criterion for evaluation might encompass the overall cost of ownership, covering modification expenses, acquisition costs, environmental disposal costs, and any potential costs associated with delayed delivery. Additionally, factors such as production capacity, environmental impact, and reliability should be considered. e. Introduce risk into this situation. Potential risks encompass uncertainties associated with the successful in-house modification, potential delays in modification or delivery, and the post-modification capability of the old turning machine to meet production requirements. Moreover, there are risks connected to environmental disposal costs and the reliability of the old machine. f. Discuss how nonmonetary considerations may impact the selection. Other important factors to think about, aside from money, include how safe and environmentally friendly the equipment is, any differences in quality and reliability, how adaptable a new machine is, and the company's commitment to sustainability. Opting for a new turning machine with enhanced environmental features might align with the company's values, even if it involves higher monetary costs. g. Describe how a post audit could be performed. Greenfield Industries has the option to perform a post-audit by assessing the real expenses, production efficiency, and any unexpected challenges encountered during the modification or acquisition procedure. This assessment involves determining the economic justification of maintenance costs on the machines and evaluating whether the machine can generate revenue exceeding the incurred costs.