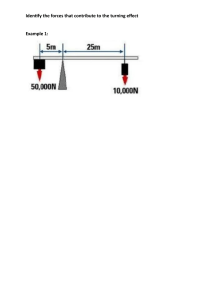

Research and Review Journal of Nondestructive Testing (ReJNDT) - ISSN 2941-4989 - www.ndt.net Using the DIC Technique in Damage Detection for a Cantilevered Composite Beam Anna RZEPKA1, Dominika ZIAJA1 More info about this article: https://www.ndt.net/?id=29389 1 Department of Structural Mechanics, The Faculty of Civil and Environmental Engineering and Architecture, Rzeszow University of Technology, Poznanska 2, 35-084 Rzeszow, Poland, Phone 178651617, e-mail: arzepka@prz.edu.pl (A. Rzepka corresponding author), dziaja@prz.edu.pl (D. Ziaja) Abstract The subject of the article is the use of the Digital Image Correlation (DIC) technique in tests of damage detection in a composite cantilevered beam. Laboratory tests of the beam were conducted using the Q-400 system from Dantec Dynamics GmbH. The research aimed to study the behaviour of the structure under external forces and to analyse the influence of cross-section damage on the displacement field of the beam. The analysed quantities were also the changes in strain fields of the structure. For the laboratory model, the finite element models were prepared, and satisfactory compliance in terms of displacement fields between numerical and laboratory models for undamaged structure was obtained. The research has shown, that it is possible to indicate the approximate location of damage based on the information about changes in the displacement field. Keywords: digital image correlation (DIC), non-destructive testing (NDT), damage detection, cantilever composite beam 1. Introduction Non-contact methods of measuring displacements and strains, including optical-electronic systems, are increasingly being used in the research of building structures. One of the visionbased measurement methods is Digital Image Correlation (DIC), which has been used in the research of a composite cantilever beam presented in this article. The popularity of DIC method continues to grow, and it is currently applied in various scientific fields, including construction. DIC studies are successfully conducted on individual structural elements such as beams or plates, as well as on multielement systems, such as steel frames [1, 2, 3]. The continuously evolving civil engineering field demands increasingly modern and efficient types of non-destructive testing, as well as the search for more efficient and functional materials, examples of which are composites. Composite is a material formed by combining at least two components, called phases, which possess different properties. One type of composite is fibre-reinforced composite, with which the beam analysed in this article was made. Among the diverse group of composites, fibre-reinforced polymers (FRP) are the most efficient. They have low specific weight while exhibiting high-level mechanical and physical properties. Various types of fibre-reinforced composites can be distinguished regarding the fibre material, namely: aramid fibre-reinforced composites (AFRP), carbon fibre-reinforced composites (CFRP), or glass fibre-reinforced composites (GFRP). The usage of selected fibre material results in the specific properties of the whole composite - it gives the possibility to tailor the material for special applications. For example the most important advantages of GFRP composites are high tensile strength with relatively low longitudinal elasticity modulus, high hardness, and excellent corrosion resistance [4, 5]. The combination of DIC and innovative structural materials, such as composites, represents an interesting research area that can contribute to the development of both non-contact measurement methods and the advancement of studies on composite structures, beyond common composite plates. In [5], research on a composite laminate plate (GFRP) was presented. The authors of this article identify and localize damages using different Information about the open peer review -> https://www.ndt.net/search/docs.php3?id=29303 © 2024 The Authors. Published by NDT.net under License CC-BY-4.0 https://creativecommons.org/licenses/by/4.0/ https://doi.org/10.58286/29389 non-destructive testing (NDT). Digital Image Correlation has been utilized there for quick verification in the impact-deformed zones by applying a modified rapid thermal strain field technique. Another example of using DIC for composites is presented in [6]. Researchers identified structural defects in FRP composites. In this context, DIC to monitor the evolution of strain fields was used. It allowed for the detection of damages before permanent signs of destruction became evident. The authors of the paper [7] presented results for a bent sandwich beam. In the study, a comparison of results for several theoretical models and a numerical model was provided. The DIC to monitor the deformation state of the tested samples was used and the displacement field distribution was obtained. The aim of the research described in [7] was to compare experimental results with theoretical models to assess the accuracy of these models in predicting the actual deformation of the beam under different loading conditions. Furthermore, researchers in the study [3] highlight the use of DIC in measuring deformations and strains in various structural elements, including those made of composites. They emphasize that the DIC technique shows promise as an effective method for investigating composite deformations, it provides a full-field measurement tool for strains and displacements. The applications of DIC in non-destructive testing of composite materials, shown in the literature, are limited to simple-shaped structures (plates) or specimens under standard tests. There is a lack of examination of more complicated elements, like those used in civil engineering. Checking the possibility of using DIC in real objects was the main motivation for here-presented research. Therefore, an experiment on a cantilever I-beam made of GFRP was conducted. Its description is presented in the subsequent part of this article. During the analysis of the experiment's results, the focus was placed on aspects such as verifying the anchoring zone, investigating the force-displacement relationship, and, most intriguingly, conducting a trial to detect beam damages based on displacement analysis. 2. DIC in displacement and strain field measurements A pivotal factor in selecting suitable measurement methods lies in their versatility to perform diagnostic procedures in both laboratory settings and during the operation of the structure. The possibility of proficient execution of investigations on existing constructions or their elements, as well as the assessment of material degradation degree, has to be taken into account. Digital image correlation, as a vision-based method, facilitates non-contact measurements encompassing geometry and variations in displacement and strain components of the specimen. The process of conducting structural analyses using this method entails appropriate illumination and monitoring the intensity of the light beam reflected from the surface, both in a zero state (without any load) and in a state after the application of a load, resulting in deformation. The DIC system operates based on algorithms that ascertain the positions of analysed measurement points in successive image sequences. By exploiting the correlation between images, one can obtain an abundance of measurement data concerning displacements and strains. Cameras are utilized during the examination, and their quantity and selection depend on the complexity of the problem [1, 3, 8]. The comprehensive guidelines for the proper execution of measurement using digital image correlation are detailed in the international guide 'A Good Practices Guide for Digital Image Correlation' [8], prepared by the International Digital Image Correlation Society. Despite drawbacks such as the system's sensitivity to lighting conditions, the necessity for precise sample preparation, or time-consuming measurements in specific configurations, DIC offers numerous benefits. These include non-invasive operation, high precision, the ability to study a broad range of materials, real-time monitoring capabilities, and compatibility for integration with other measurement devices [3, 8]. The experiment was conducted on a composite beam with an I-beam cross-section. The profile used in the study was made with a glass fibre-based composite, evident from its light colour. It belongs to the group of fibre composites, as indicated by its shape and texture. A laboratory model was designed and prepared as a cantilever beam. The beam was positioned on a steel frame to stabilize the structure. Additional equipment included a weight, used to measure the applied load, and a winch to introduce tension to a steel cable through which the beam was loaded. The weight was suspended from a metal clamp to ensure the forces were uniformly transmitted to the contact surface. Fixation was achieved using wooden beams, steel C-sections, plates, and connectors. The sample surface preparation adhered to the guidelines outlined in the reference [8]. Figure 1a illustrates the view of the laboratory model of the cantilever composite beam. The tests were carried out on a beam in two states: an undamaged beam and five incremental damages. The research scenario involved inducing damage to one selected cross-section of the beam by gradually weakening it using a device oscillating. Weakening started from the bottom flange (in two steps) then the top flange was cut (also in two steps), and at the end, the notch in the web was made (one-fifth of height from the bottom and the top). Selected damages are shown in Figures 1b and 1c. In all cases, the behaviour of the structure under the influence of increasing external force was checked. a) b) c) . Figure 1 a) Laboratory model of a cantilevered composite beam b) exemplary damage (Damage 4 see Figure 6.) of the cross-section of a beam c) exemplary damage (Damage 5 see Figure 6.) of the cross-section of a beam During the research, two high-resolution cameras of the Q-400 system developed by Dantec Dynamics GmbH were used. This enabled three-dimensional analysis. The measurement setup also included a portable computer with Istra4D software. This software was used for recording images and their evaluation to visualize measurement results. The cameras were attached to a beam on a tripod, allowing for easy adjustment of their positions relative to each other. The tripod was positioned 140 cm in front of the structure, with a spacing of 100 cm between the cameras. The cameras were connected to the laptop and each other using cables for synchronization. The calibration process utilized two boards: Pl-35-WBM_9x9 (calibration for the entire beam view) and Al-08-BMB_9x9 (calibration for the selected part of the beam view). Stable lighting conditions and equipment stability were ensured at the measurement location. The first analysis focused on the unaltered model. Twenty series of tests (S01-S10 and S11-S20) subjected the beam to a defined range of forces (the range of applied force was set at 0 - about 300 N; due to the method of applying the load it was impossible to obtain the exact magnitude of force). Each measurement series consisted of several distinct images (about 10 for each camera: the first one - without loading and each subsequent one after the next increase in load). These investigations aimed to analyse the anchoring zone, determine the extent of the load influence zone and provide an overview of the entire bracket's behaviour under external forces. The accessible format of the presented results, including colour maps from the Istra4D software allowed for initial verification after completing and post-processing of the image series. The exemplary maps of displacement field are shown in Figure 2. Both pictures presented there show the same moment in examination, but they are recorded by two cameras: left (Figure 2a) and right (Figure 2b). Additionally, in Figure 2 a points selected for further analysis were depicted. b) a) Figure 2 Vertical displacement for undamaged beam a) view from the left and b) from the right camera for force 312 N To conduct a thorough verification of the anchoring zone, the decision was made to minimize the observed area to a fragment containing the anchorage. In the analysed region, four main points were strategically chosen (Figure 3a) and their displacements were analysed. During the analysis of the captured images, displacements were analysed in three directions: vertical, horizontal, and in-plane (Figures 3a-3c). Interpreting the outcomes led to the conclusion that the anchoring zone does not exhibit perfect rigidity, as evidenced by the points situated in proximity to this area shifting under the applied load. However, the magnitudes of these displacements were sufficiently small to be deemed non-significant in influencing the overall behaviour of the structure. Figure 3d presents a sample graph illustrating vertical displacement values corresponding to the applied force for one of the points located at the fastening. In each series, the forces increased in steps to the maximal magnitude in the previously specified range. After every load increase, new photos were registered. a) b) c) d) Figure 3 a) X- displacement with selected test points in the anchorage zone b) Y- displacement c) Z- displacement d) Force- displacement diagram for force 325 N (view from the left camera) Further investigations aimed to determine the extent of the influence zone of the applied load. Similar to verifying the anchoring zone, the research area was limited to the location where the weight was attached. However, the obtained strain fields were too small to conclude them. After verifying the support and loading zones, studies on the entire cantilever were conducted. The changing positions of selected points on the beam (see Figure 2) were observed, and the relationship between force and displacement was examined (see Figure 4a). The study aimed to verify whether increasing deflection of the beam would be directly proportional to the increment of the applied load. Displacements in three directions were visible on the displacement maps (exemplary maps are shown in Figure 2 and Figure 5). In the analysis of displacements in three directions for selected measurement points, it is crucial to observe the repeatability of results, independent of the examined area of interest. All measurements conducted within the scope of this task demonstrated a consistent trend, irrespective of the registered area of the beam. Figure 4a illustrates that the displacement values for selected point was highly consistent or sometimes identical across ten conducted (S11-S20) measurement series. The consistent results suggest that the analysed structure operates within the elastic range. The appearance of horizontal displacements indicates that the beam was not perfectly anchored, while the occurrence of out-of-plane displacements along the axis indicates that the bent model twisted during load increments. a) b) 0 0 Figure 4 a) Point 4 (see Figure 2) at an undamaged beam b) Comparison of force-displacement relationships for numerical models and laboratory model a) 0 b) 0 c) 0 Figure 5 Displacement a) horizontal b) vertical c) out-plane (left camera view) For a quick verification of the measurements, a numerical model was created to check if the results from DIC correspond to numerical calculations. The numerical models were created using finite element method (FEM) software- Autodesk Robot Structural Analysis (ARSA). Two models have been prepared: 1) a simple beam model and 2) a shell model. In the first case, a completely clamped and linearly straight beam was built using standard 2-noded elements. Elements connected nodes located at the beginning, consecutive points 1 to 4 (Figure 2), and at the end of the beam. The shell model (second one) has been built to obtain a more accurate reflection of reality in comparison to the beam model. The system had over four thousand nodes and over one thousand one hundred finite elements. In the shell model, two support conditions (fully rigid and hinged) and two loading methods (surface and point) were considered. For both numerical models, the displacement of the system was determined according to the rules of global elastic analysis based on the theory of the first order. Due to the lack of precise parameters, material characteristics were adopted based on the literature [4]: density – 2000 kg/m3, longitudinal elastic modulus - 30,90 GPa, Poisson's ratio - 0,33. As shown in Figure 4b, the results from the considered models are similar. However, comparing the beam and shell models, greater compliance can be observed for the second one - a difference in vertical displacement values is about 3% only, while for the beam model, it reaches 16%. 3. Detecting damage on a beam through displacement field analysis Based on the collected data, the possibility of damage detection in the analysed beam was tested. The research scenario involved weakening the cross-sectional area of the beam in several phases (Figure 6b). After each notching of the flanges and web, a new series of loading was made, and displacements of the beam were recorded. In the next step, the feasibility of identifying the precise location where a disruption in beam continuity occurred was conducted, relying solely on displacement analysis. Initially, it was assumed that when the cross-section became weaker, the displacement values would increase. Comparing Figure 2 and Figure 5b, it is evident that vertical displacements have noticeably increased. The comparison of displacement at selected points (see Figure 2) regarding the damage scenario (Figure 6b) is shown in Figure 6a. The blue horizontal line shows the reference beam axis (without any load). On this line, the location of four selected points is depicted, in which displacement values under a force magnitude equal to 300 N were calculated. The measurement for the points exactly at the beginning, and at the end of the beam was not made. Using information about the displacements in points (1 to 4), the approximate course of the axis's trajectory was determined. The lines, shown in Figure 6b, should not be treated as an exact image of the structure's axis. The influence of successive damages is visible. It is worth noting that the lines approximating the shape of the beam axis for damages 1-4 have a very similar shape to the axis of the undamaged beam. A noticeable difference only appears for damage 5. Between points 2-3, there is a change in the slope of the line compared to the previous cases. Therefore, it can be inferred from the graph alone that weakening of the cross-section occurred at this sector. This deduction finds confirmation in reality, as the damage was intentionally inflicted midway along the entire length of the cantilever. a) b) Point 1 Point 2 Point 3 Point 4 Figure 6 a) Comparison of beam axis slopes regarding different damage scenarios b) Considered damage scenarios 4. Conclusion The digital image correlation system has enormous potential for use and further development, thereby expanding the boundaries of knowledge in the field of static and dynamic testing, among others, in civil engineering. The laboratory research presented in the article shows the potential of the DIC for non-contact displacement and strain measurement methods on structural elements with cross-sections such as I-beams. As shown in this publication, the analysis of displacement field changes enabled the approximate localization of beam damage. Furthermore, it provides insight into the behaviour of profiles made from composites, which could offer a viable alternative to conventional materials such as steel in the future. The analysis in the study primarily focused on changes in displacement fields. Many issues arose during the measurements and result analysis will be addressed in further scientific research. One of the concern areas involves the application of genetic algorithms or artificial neural networks for damage detection of the analysed model. Additionally, the exploration of the behaviour of structures made from various materials (including the increasingly common composites ) under the influence of external forces is planned. Statement The presented work is based on the Master thesis of Anna Rzepka entitled “Experimental verification and validation of the numerical model of the cantilever composite beam”, which was submitted at Rzeszow University of Technology in July 2023. Acknowledgements This publication used measurement data obtained as part of grant Preludium, project no. 2019/35/N/ST8/01086 founded by National Science Centre (NCN), Poland. References 1. 2. 3. 4. 5. 6. 7. 8. M Kempny, 'Digital Image Correlation- method development, scope, principle of functioning and future goals', Journal of Metallic Materials, 74 (3-4), pp. 30-41, 2022. C Rinaldi J Ciambella and V Gatulli, 'Image-based operational modal analysis and damage detection validated in an instrumented small-scale steel frame structure', Mechanical System and Signal Processing, Vol 168, April 2022. M A Mousa M M Yussof T S Hussein L N Assi and S Ghahari 'A Digital Image Correlation Technique for Laboratory Structural and Applications: A Systematic Literature Review', Sensors, 2023 T Siwowski, 'Bridges made of FRP composites. Shaping, design, research.', Polish Scientific Publishers PWN, 2018. K Balasubramaniam D Ziaja M Jurek P Fiborek and P Malinowski, 'Experimental and numerical analysis of multiple low-velocity impact damages in a glass fibre composite strucutre', Materials, 14, 7268, November 2021. D Ziaja M Jurek R Śliwa A Wiater and M Kulpa, 'DIC application for damage detection in FRP composite specimens based on an example of a shearing test ', Archives of Civil and Mechanical Engineering 24, 47, 2024 A Giordano L Mao and F P Chaing, 'Full-field experimental analysis of a sandwich beam under bending and comparison with theories', Archives of Civil and Mechanical Engineering 24, 47, 2024 E M C Jones and M A Iadicola, 'A good practise guide for digital image correlation', International Digital Image Correlation Society, 2018