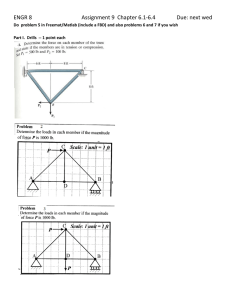

EE035-3-2-SOM Strength of Materials Topic 1: Stress EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress SLIDE 1 TOPIC LEARNING OUTCOMES At the end of this topic, you should be able to: 1. draw proper free body diagram and write equations based on the free body diagram 2. solve problems pertaining to normal stress in various type of scenarios. 3. distinguish shearing between one and multiple cross sections. 4. differentiate bearing stress with normal stress. 5. distinguish cross sections that would be taken account of in the case of pin is introduced in the system. 6. solve problems on factor of safety. 7. able to compute stress in truss structures using both Method of Joints and Method of Sections EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress SLIDE 2 Contents & Structure 1. Types of forces 2. Normal Stress 3. Shearing Stress 4. Bearing Stress 5. Factor of Safety 6. Analysis of Structure EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress SLIDE 3 Recap From Last Lesson • Nil EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress SLIDE 4 PHYSICAL EXAMPLES POINT LOADS DISTRIBUTED LOADS • Hydrostatic Loading • Pressure Vessels P • Aerodynamic Wing Loading P P(x) Loads applied to bodies cause deformation in shape and size of the body which is actually due to the stress that the body experiences. Therefore, it is essential to study on the various kinds of stresses that a body experiences from various kinds of loadings. EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 5 SLIDE 5 TYPES OF FORCES • Normal Forces: – Tensile Force, when a force extends the object, and increases the length in the direction of the forces. Fa Fa – Compressive Force, when a pair of forces applied to an object, it will reduce the length in the direction of the force. Fa Fa EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 6 SLIDE 6 TYPES OF FORCES • Shear Force: – Is when a pair of forces caused on the face of the material and to slide relative to an adjacent face. Fs Fs • Bending Force: – The loads are applied transversely to the longitudinal axis of the member and the member subjected to this bending load will bend along its length. Fb EE035-3-2-SOM STRENGTH OF MATERIALS Fb Chapter 1 - Stress Slide 7 SLIDE 7 TYPES OF FORCES • Torsional Force/ load: – Is one that is subjected to a shaft or a twisting member. Mn Mn EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 8 SLIDE 8 STRESSES Cut section F A→0 A = lim EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 9 SLIDE 9 NORMAL STRESS 4. Stress varies across the cross section. 5. The points very near the application of the loads experience a larger stress value compared to the points faraway from the application of load on the same section. 6. The variation of stress across the cross section is negligible when the section is faraway about equal to the width of the bar, from the application of loads. 7. When a section is assumed to have a uniform distribution of stresses (internal forces are uniformly distributed across the section), resultant, P of the internal forces act at the centroid of the section. This type of loading is called centric loading. EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 10 SLIDE 10 SHEARING STRESS 1. Shear Force is introduced when transverse forces P and P’ are applied to a member. 2. Internal forces are called shearing forces and magnitude, P of the resultant of the shearing forces is called the shear in the section. ave = P A 3. Actual value of τ of shearing stress varies from zero at the surface of the member to a maximum value τmax that may be larger than the average value τave . EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 11 SLIDE 11 SHEARING STRESS Single Shear ave = EE035-3-2-SOM STRENGTH OF MATERIALS Double Shear P F = A A ave = Chapter 1 - Stress P F = A 2A Slide 12 SLIDE 12 BEARING STRESS Diameter of bolt X Thickness of plate EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 13 SLIDE 13 FACTOR OF SAFETY Selection of an appropiate Factor of safety depends on: 1. Manufacturing errors – composition, material strength, dimensions and material properties altered eg. through heating 2. Damage during storage and transportation. 3. Fatigue – over time, ultimate stress decreases as loads are increased and applied to member repeatedly. 4. Possibility of sudden failures through buckling and stability failures. 5. Not designed for certain loadings 6. Deterioration that may occur because of poor maintenance (corrosion, decay) or because of unpreventable natural causes such as storms. EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 14 SLIDE 14 ANALYSIS OF STRUCTURE 5.2 Trusses A truss is a straight link connected together at joints to form a structure. Examples of trusses structure are bridges, roof supports, derricks etc. The loads applied to the structure will be distributed to each truss. In truss analysis, two assumptions are made i) All loadings are applied at the joints. ii) Bolted or welded connections are assumed to be pinned connections. EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 15 SLIDE 15 ANALYSIS OF STRUCTURE 5.2.1 Method of Joints D B A C P Figure 5.1 Simple trusses structure Figure 5.1 shows a structure consists of 4 truss members of ABC, AD, CD and BD. External load P is applied at joint B. This load will be transferred to each member. Procedure of analyzing trusses with method of joints are as follows EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 16 SLIDE 16 ANALYSIS OF STRUCTURE i) Draw the FBD of the whole structure and identify all external and reaction D forces. Determine these forces using the static equilibrium analysis. ii) Explode the FBD to obtain individual RAx A FBD for the joints and trusses. All B RAy C members may be assumed to be in tension at this stage. RC P iii) Now all joints have become particles. Do force analysis at each joint, starting with the joint with least unknown D forces. Since entire structure is in RAD RDC equilibrium, RBD RAD RAx RAC A RAy EE035-3-2-SOM STRENGTH OF MATERIALS joint also in equilibrium. RDC RBD B each RAC P Chapter 1 - Stress C RC Slide 17 SLIDE 17 ANALYSIS OF STRUCTURE 5.2.2 Special Loadings Special loadings condition is when members at a joint carry either zero load or similar load. These conditions are identified by visual inspection and are used to simplify the analysis significantly. The trusses with special loadings are shown as follows. If two members connected at a joint and no FB external or reaction force at the joint, the members are considered zero-load member. FB FA = FB = 0 FA FA If three members connected at a joint, and FB FB FB FB two members are collinear, the third is zeroload member. FA FA FA = 0 If two members connected at a joint, and FA FB collinear, both member shared the same load. FA = FB EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 18 SLIDE 18 ANALYSIS OF STRUCTURE EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 19 SLIDE 19 ANALYSIS OF STRUCTURE Example Note Determine the force in each member of the structure as • shown. First draw the FBD structure to determine th B and C. At A, the con 350N therefore two reaction f 1.8m the connection is roller 30o one normal force. 65o C A • joint. 2m • Solution The reactions at joints A and C are EE035-3-2-SOM STRENGTH OF MATERIALS B Chapter 1 - Stress Once done, draw indi You don’t have to solve obtain all internal forces 350N Once all reaction forces are Slide 20 SLIDE 20 ANALYSIS OF STRUCTURE Example Note Determine the force in each member of the structure as • shown. First draw the FBD for the whole structure to determine the reactions at A and C. At A, the connection is pin, 350N B therefore two reaction forces and at C, 1.8m the connection is roller, therefore only o 30 one normal force. 65o C A • Once done, draw individual FBD at joint. 2m • Solution The reactions at joints A and C are B You don’t have to solve for all joints to obtain all internal forces. Once all reaction forces are identified, draw 350N FBD for each joint, assuming all trusses are 1.8m in tension. 30o RAx B 350N 65o C RAy A RAB RC RBC 2m 350N A → Rx = 0 : RA + 350 N = 0 x 30o 65o RAC 157.5N RA = −350N C 157.5N x Joint A has two unknowns so do joints B and Taking moment about A C, therefore any joint can be chosen to start M A = 0; the analysis. ( ) 350N 1.8m sin 30 − RC ( 2m ) = 0 RC = 157.5N Joint C: Ry = 0 : Ry = 0 : 157.5N + RBC sin 65 = 0 RA + 157.5 N = 0 RBC = −173.782N RA = −157.5 N Therefore link BC is in compression with a y y magnitude of 173.782N EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 21 SLIDE 21 ANALYSIS OF STRUCTURE → Rx = 0 : Note − RAC − RBC cos 65 = 0 • Make sure you stick with the reference − RAC − ( −173.782N ) cos 65 = 0 direction for the positive x and y RAC = 73.4435N respectively. Therefore link AC is in tension with a magnitude of • Since initial assumption is all internal forces are in tension, thus, negative 73.4435N values mean that the internal forces are in compression. Joint A: EE035-3-2-SOM STRENGTH OF MATERIALS Ry = 0 : Therefore RAB sin 30 − 157.5N = 0 Link AB = 315N (Tension) RAB = 315N Link BC = 173.782N (Compression) Link AB is in tension with a magnitude of 315N Link AC = 73.4435N (Tension) Chapter 1 - Stress Slide 22 SLIDE 22 ANALYSIS OF STRUCTURE – METHOD OF JOINTS EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 23 SLIDE 23 ANALYSIS OF STRUCTURE 5.2.3 Method of Sections The method of joints is normally used when the load in all members are required to be determined. If only load in specific members are required, the method of section may be utilized. The procedure is to cut through the members of which the loads are to be determined, and apply static equilibrium equations to the unknown members. EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 24 SLIDE 24 ANALYSIS OF STRUCTURE – METHOD OF SECTIONS EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 25 SLIDE 25 ANALYSIS OF STRUCTURE Example Note Determine the load in the members BE and FE for the • structure shown. there is no zero-load 5kN A From inspection, it B 2m 2m • 8kN C 2m After cutting the FB take either side to D FBD. 2m 2m • Since the system equilibrium, thus, t F 2m assumed to be in equ Substitute into first equat Solution EE035-3-2-SOM STRENGTH OF MATERIALS E The FBD for the whole structure is Chapter 1 - Stress Slide 26 SLIDE 26 ANALYSIS OF STRUCTURE Example Note Determine the load in the members BE and FE for the • structure shown. there is no zero-load link exists. 5kN A From inspection, it can be seen that B 2m C 2m • 8kN 2m After cutting the FBD into 2, we may take either side to become our new D FBD. • 2m 2m Since the system is originally in equilibrium, thus, the cut FBD also E 2m F assumed to be in equilibrium Substitute into first equation, RAy = -4kN Solution The FBD for the whole structure is 5kN RAx A B 2m 2m Since we are interested to determine the 8kN C 2m D load in the links BE and FE, we cut the FBD through these two links. RAy 2m 2m A F B 2m FBC E 2m 2m RE 4kN Applying static equilibrium to obtain all reaction forces Ry = 0 : RA + RE − 5kN − 8kN = 0 y M A = 0 : 5kN ( 4m ) + 8kN ( 6m ) − RE ( 4m ) = 0 F FBE FFE Take moment about point B M B = 0 : − FFE ( 2m ) − 4kN ( 2m ) = 0 FFE = −4kN RE = 17kN EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 27 SLIDE 27 ANALYSIS OF STRUCTURE Note Take moment about point B • Since initial assumption is all members M B = 0 : are in tension, all internal force in − FFE ( 2m ) − 4kN ( 2m ) = 0 negatives are in compression. FFE = −4kN → Rx = 0 : FBC + FFE + FBE sin 45 = 0 Fy = 0 : FBC − 4kN − 5.6569kN sin 45 = 0 4kN + FBE cos 45 = 0 FBC = 8kN FBE = −5.6569kN Therefore Link BE = 5.6569kN (compression) Link FE = 4kN (compression) EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 28 SLIDE 28 ANALYSIS OF STRUCTURE – METHOD OF SECTIONS EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress Slide 29 SLIDE 29 Review Questions • What is another name for normal stress? • What is the difference between shear stress and normal stress? • Which would be the area that would be considered for maximum tensile stress when there is a pin in the link? • What are zero load members? EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress SLIDE 30 Summary / Recap of Main Points • Normal Stress • Shear Stress • Bearing Stress • Factor of Safety • Analysis of Structure EE035-3-2-SOM STRENGTH OF MATERIALS Chapter 1 - Stress SLIDE 31 What To Expect Next Week In Class • Strain EE035-3-2-SOM STRENGTH OF MATERIALS Preparation for Class • Free body diagram • Equilibrium of Rigid Bodies Chapter 1 - Stress SLIDE 32