management accounting for business decisions by seal, w. b (z-lib.org) (1)

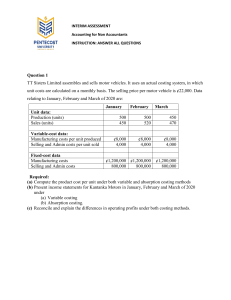

advertisement