Chapter

1

Welcome to Bentley

SewerCAD V8i Help

“Getting Started” on page 1-1

“Loading” on page 7-297

Learn about Bentley SewerCAD V8i, how to install and uninstall the

product, and how to contact Bentley Systems.

Learn how to use Bentley SewerCAD V8i data loading features to

extend your model.

“Introducing the Workspace” on page 2-9

“Calculating Your Model” on page 8-369

Learn about the Bentley SewerCAD V8i workspace, including menus,

toolbars and dockable managers.

Learn how to create and manage "what-if" scenarios.

“Quick Start Lessons” on page 3-51

“Using Scenarios and Alternatives” on page 9-397

Perform these tutorials to learn the basics of using Bentley SewerCAD

V8i.

Learn how to define calculation options, calculate your model, and

review your results.

“Starting a Project” on page 4-109

“Presenting Your Results” on page 10-453

Learn how to set up a new project, manage existing project and set

project and other global options.

Learn how to present results in graphs, profile s and reports.

“Using Modelbuilder” on page 5-135

“Working in AutoCAD Mode” on page 12-607

Learn how to use ModelBuilder in ArcGIS mode or the Stand-Alone

Editor.

Learn how to use Bentley SewerCAD V8i in AutoCAD mode.

“Creating Your Model” on page 6-169

“Theory” on page 13-619

Learn how to use Bentley SewerCAD V8i layout and editing tools to

build your model.

Learn about the theory behind Bentley SewerCAD V8i.

DAA038110-1/0001

Bentley SewerCAD V8i User’s Guide

1-1

1-2

Bentley SewerCAD V8i User’s Guide

Chapter 1: Welcome to Bentley SewerCAD V8i

Help1

Chapter 1: Getting Started1

What is Bentley SewerCAD V8i?1-1

Installation, Upgrades, and Updates1-2

Municipal License Administrator Auto-Configuration1-2

Software Updates via the Web and Bentley SELECT1-3

Troubleshooting1-3

UPDATING YOUR SENTINELLM LICENSES IF YOU MOVE YOUR LICENSE SERVER1-4

UPDATING YOUR BENTLEY SELECT SERVER LICENSES IF YOU

MOVE YOUR LICENSE SERVER1-4

Checking Your Current Registration Status1-4

Documentation1-4

Quick Start Lessons1-5

Contacting Us1-6

Sales1-6

Technical Support1-6

SUPPORT HOURS1-7

Addresses1-7

Your Suggestions Count1-8

Chapter 2: Introducing the Workspace9

The Workspace2-9

Stand-Alone Editor2-9

Microstation Mode2-10

AutoCAD Mode2-11

Menus2-11

File Menu2-11

Edit Menu2-15

Analysis Menu2-17

Components Menu2-18

View Menu2-19

Tools Menu2-22

Report Menu2-24

Help Menu2-24

Toolbars2-25

Layout Toolbar2-27

Standard Toolbar2-28

Edit Toolbar2-30

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-i

View Toolbar2-30

Scenarios Toolbar2-32

Analysis Toolbar2-32

Compute Toolbar2-33

Tools Toolbar2-33

Help Toolbar2-34

Zoom Toolbar2-34

Customizing the Toolbars2-36

Adding and Removing Toolbar Buttons2-36

Controlling Toolbars2-36

Dynamic Manager Display2-37

Opening Managers2-38

Customizing Managers2-40

Using Customizations2-42

Customization Manager2-42

CUSTOMIZATION EDITOR DIALOG BOX2-44

Using Named Views2-44

Copying and Pasting Data To and From Tables2-46

Chapter 3: Quick Start Lessons51

Lesson 1 - Creating a Schematic Network3-51

Part 1 - Creating a New Schematic Project File3-52

Part 2 - Entering Data3-56

ENTERING DATA THROUGH THE PROPERTIES EDITOR3-57

ENTERING DATA THROUGH FLEXTABLES3-59

ENTERING INFILTRATION DATA FOR GRAVITY PIPES3-61

STEADY STATE LOADING3-61

EXTREME FLOW FACTORS3-66

Part 3- Calculating the Model3-69

Lesson 2 - Automatic Design3-71

Part 1: Specifying Design Constraints3-71

Part 2: Design3-75

Lesson 3 - Scenario Management3-76

Part 1 - Opening the Project File3-76

Part 2 - Creating Alternatives3-76

Part 3 - Editing Base Scenarios3-81

Part 4 - Creating Child Scenarios3-82

Part 5 - Calculate and Compare3-84

Lesson 4 - Presentation of Results3-86

Part 1 - Reports3-86

Part 2 - FlexTables3-89

Part 3 - Element Annotation3-93

Contents-ii

Bentley SewerCAD V8 XM Edition User’s Guide

Part 4 - Create a Profile3-95

Part 5 - Color Coding3-97

Lesson 5 - Running an Extended Period Simulation3-98

Part 1 - Entering and Applying Loading Patterns3-99

Part 2 - Entering Hydrographs3-101

Part 3 - Running the Extended Period Simulation3-103

Part 4 - Time Based Graphs and Tables3-103

Part 5 - Animations3-105

Chapter 4: Starting a Project109

Welcome Dialog Box4-109

Projects4-110

Setting Project Properties4-110

Setting Options4-111

Options Dialog Box - Global Tab4-111

Options Dialog Box - Project Tab4-114

Options Dialog Box - Drawing Tab4-116

Options Dialog Box - Units Tab4-117

Options Dialog Box - Labeling Tab4-120

Options Dialog Box - ProjectWise Tab4-121

Considerations for ProjectWise Users4-123

General Guidelines for using ProjectWise 4-123

Performing ProjectWise Operations4-124

Importing Data From Other Models4-127

Importing Data from a SewerCAD V8 Database4-128

Importing a Submodel4-128

Importing from LandXML4-129

Importing StormCAD V84-130

Importing from SewerGEMS V84-131

Exporting Data4-132

Exporting a .DXF File4-132

Exporting a Submodel4-132

Exporting to LandXML4-133

4-133

Chapter 5: Using Modelbuilder135

Preparing to Use ModelBuilder5-135

ModelBuilder Connections Manager5-138

ModelBuilder Wizard5-141

Step 1—Specify Data Source5-141

Step 2—Specify Spatial Options5-142

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-iii

Step 3—Specify Field Mappings for each Table/Feature Class5-144

Step 4—Build Operation Confirmation5-146

Reviewing Your Results5-146

Multi-select Data Source Types5-147

ModelBuilder Warnings and Error Messages5-147

Warnings5-147

Error Messages5-148

Specifying Network Connectivity in ModelBuilder5-149

Sample Spreadsheet Data Source5-151

Handling Collection and Curve Data in Modelbuilder5-152

Importing Pump Definitions Using ModelBuilder5-153

Using ModelBuilder to Import Pump Curves5-158

Using ModelBuilder to Import Patterns5-162

Chapter 6: Creating Your Model169

Elements and Element Attributes6-169

Link Elements6-170

ENTERING ADDITIONAL DATA TO LINK ELEMENTS6-170

Adding a Minor Loss Collection to a Pressure Pipe6-171

Diversion Rating Curve Dialog Box6-172

Defining the Geometry of a Link Element6-172

Irregular Channel Editor Dialog Box6-173

Defining the Cross-Sectional Shape of a Link Element6-174

SECTIONS RESULTS DIALOG BOX6-175

Manholes6-175

FLOW (DOWNSTREAM CONDUIT)6-176

FLOW HEADLOSS CURVES DIALOG BOX6-176

DROP MANHOLES6-178

Transitions6-178

Wet Wells6-179

PERCENT FULL6-179

INFLOW (WET) COLLECTION DIALOG BOX6-180

Outfalls6-180

ADDING ELEVATION VS. FLOW DATA TO AN OUTFALL6-181

Pressure Junctions6-182

Pumps6-182

PUMP DEFINITIONS DIALOG BOX6-183

SUBMERSIBLE PUMPS6-189

Variable Speed Pump Batteries6-190

Air Valves6-191

Other Tools6-192

Adding Elements to Your Model6-193

Contents-iv

Bentley SewerCAD V8 XM Edition User’s Guide

Modeling Curved Pipes6-194

Connecting Elements6-194

What Is A Virtual Conduit?6-195

Connecting a Pump to a Wet Well6-195

Manipulating Elements6-195

Splitting Pipes6-198

Disconnecting and Reconnecting Pipes6-199

Editing Element Attributes6-199

Property Editor6-199

RELABELING ELEMENTS6-201

SET FIELD OPTIONS DIALOG BOX6-202

What Length is Used for Conduits and Pressure Pipes When I Don't

Enter a User-defined Length?6-203

Automatic Design6-204

Default Design Constraints6-205

Minor Loss Coefficients6-208

Using the Totalizing Flow Meters6-210

Totalizing Flow Meters Manager Dialog6-210

Totalizing Flow Meter Editor Dialog6-211

System Head Curves6-213

System Head Curves Manager Dialog6-213

Element Property Inferencing6-215

Element Property Inferencing Dialog6-217

NEW ELEMENT LAYOUT SUMMARY DIALOG6-223

Changing the Drawing View6-223

Panning6-223

Zooming6-224

USING THE ZOOM CENTER COMMAND6-226

Using Selection Sets6-227

Selection Sets Manager6-228

Viewing Elements in a Selection Sets6-230

Creating a Selection Set from a Selection6-231

Creating a Selection Set from a Query6-231

Adding Elements to a Selection Set6-233

Removing Elements from a Selection Set6-234

Performing Group-Level Operations on Selection Sets6-234

Network Navigator6-236

Using Prototypes6-239

Creating Prototypes6-239

Engineering Libraries6-241

Working with Engineering Libraries6-242

SHARING ENGINEERING LIBRARIES ON A NETWORK6-245

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-v

Converting Legacy Engineering Library Files6-245

Conduit Catalog Dialog Box6-247

Adding Hyperlinks to Elements6-251

Hyperlinks Dialog Box6-251

Using Queries6-254

Queries Manager6-255

QUERY PARAMETERS DIALOG BOX6-256

Creating Queries6-257

USING THE LIKE OPERATOR6-261

Controls6-262

Controls Tab6-264

Conditions Tab6-269

Actions Tab6-275

Control Sets Tab6-279

LOGICAL CONTROL SETS DIALOG BOX6-280

User Data Extensions6-280

User Data Extensions Dialog Box6-283

User Data Extensions Import Dialog Box6-287

Sharing User Data Extensions Among Element Types6-287

Shared Field Specification Dialog Box6-288

Enumeration Editor Dialog Box6-289

Batch Pipe Split Dialog Box6-290

External Tools6-291

External Tools Workflow6-292

TRex Wizard6-293

Chapter 7: Loading297

Loading7-297

Methods for Entering Loads7-298

Types of Loads7-299

Adding Fixed Loads7-301

Hydrograph vs. Pattern Loads7-301

Adding User Defined Hydrographs7-302

Pattern Loads7-303

WORKING WITH PATTERNS7-303

Pattern Manager7-305

DEFINING PATTERN SETUPS7-307

Unit Sanitary Loading7-309

TYPES OF UNIT SANITARY (DRY WEATHER) LOADS7-310

ADDING UNIT SANITARY (DRY WEATHER) LOADS7-311

Composite Hydrographs7-318

Composite Hydrograph Window7-318

Contents-vi

Bentley SewerCAD V8 XM Edition User’s Guide

Composite Hydrograph Data Table Window7-318

Inflows7-319

Defining Inflow Collections7-322

Inflow Control Center7-325

APPLY SANITARY INFLOW TYPE TO SELECTION DIALOG7-329

Sanitary Load Control Center7-329

APPLY SANITARY LOAD TO SELECTION DIALOG7-332

Sanitary (Dry Weather) Flow Collections7-332

Using LoadBuilder to Assign Loading Data7-335

Allocation7-336

Billing Meter Aggregation7-338

Distribution7-339

Projection7-341

Using LoadBuilder to Assign Loading Data7-342

LoadBuilder Manager7-342

LoadBuilder Wizard7-343

LoadBuilder Run Summary7-354

Generating Thiessen Polygons7-354

Thiessen Polygon Creator Dialog Box7-357

Creating Boundary Polygon Feature Classes7-359

Pipeline Infiltration7-360

Hydrograph Curve Dialog Box7-360

Extreme Flows7-361

Extreme Flows Dialog7-361

Extreme Flow Setups Dialog7-366

Chapter 8: Calculating Your Model369

Steady State/Extended Period Simulation8-369

Steady State Simulation8-369

Extended Period Simulation8-369

EPS RESULTS BROWSER8-370

Calculation Options Manager8-373

Creating Calculation Options8-374

Calculation Option Attributes8-376

FLOW PROFILE METHOD8-382

Controlling Results Output8-382

REPORTING TIME STEPS DIALOG BOX8-383

Check Data/ Validate8-383

Detailed Calculation Summary Dialog Box8-384

Executive Summary Tab8-384

Calculation Options Tab8-385

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-vii

Pressure Summary Tab8-391

Pipe Report Tab8-392

Node Report Tab8-392

User Notifications8-393

User Notifications Manager8-393

USER NOTIFICATION DETAILS DIALOG BOX8-395

8-395

Chapter 9: Using Scenarios and Alternatives397

Understanding Scenarios and Alternatives9-397

Advantages of Automated Scenario Management9-398

A History of What-If Analyses9-398

BEFORE HAESTAD METHODS - DISTRIBUTED SCENARIOS9-398

WITH HAESTAD METHODS: SELF-CONTAINED SCENARIOS9-400

The Scenario Cycle9-400

Scenario Attributes and Alternatives9-402

A Familiar Parallel9-402

Inheritance9-403

OVERRIDING INHERITANCE9-404

DYNAMIC INHERITANCE9-404

Local and Inherited Values9-405

Minimizing Effort through Attribute Inheritance9-405

Minimizing Effort through Scenario Inheritance9-406

Scenario Example - Simple Water Distribution System9-407

Building the Model (Average Day Conditions)9-408

Analyzing Different Demands (Maximum Day Conditions)9-408

Another Set of Demands (Peak Hour Conditions)9-409

Correcting an Error9-409

Analyzing Improvement Suggestions9-410

Finalizing the Project9-411

Summary9-411

Scenarios9-412

Base and Child Scenarios9-413

Creating Scenarios9-413

Editing Scenarios9-413

Running Multiple Scenarios at Once (Batch Runs)9-414

Scenario Manager9-415

Alternatives9-417

Types of Alternatives9-417

Base and Child Alternatives9-418

Creating Alternatives9-418

Editing Alternatives9-419

Alternative Manager9-419

Alternative Editor Dialog Box9-420

Contents-viii

Bentley SewerCAD V8 XM Edition User’s Guide

Active Topology Alternative9-421

CREATING AN ACTIVE TOPOLOGY CHILD ALTERNATIVE9-422

ACTIVE TOPOLOGY SELECTION DIALOG BOX9-423

Physical Alternatives9-424

PHYSICAL ALTERNATIVE FOR CONDUITS9-424

PHYSICAL ALTERNATIVE FOR MANHOLES9-431

PHYSICAL ALTERNATIVE FOR TRANSITIONS9-432

PHYSICAL ALTERNATIVE FOR WET WELLS9-432

PHYSICAL ALTERNATIVE FOR OUTFALLS9-434

PHYSICAL ALTERNATIVE FOR PRESSURE PIPES9-435

PHYSICAL ALTERNATIVE FOR PRESSURE JUNCTIONS9-437

PHYSICAL ALTERNATIVE FOR PUMPS9-437

PHYSICAL ALTERNATIVE FOR VARIABLE SPEED PUMP BATTERIES9438

PHYSICAL ALTERNATIVE FOR AIR VALVES9-439

Design Alternative9-440

Headloss Alternative9-443

Boundary Condition Alternatives9-444

Initial Settings Alternative9-445

Sanitary Loading Alternative9-447

SANITARY LOADING ALTERNATIVE FOR MANHOLES9-448

SANITARY LOADING ALTERNATIVE FOR WET WELLS9-448

SANITARY LOADING ALTERNATIVE FOR PRESSURE JUNCTIONS9448

Infiltration and Inflow Alternatives9-449

INFILTRATION AND INFLOW ALTERNATIVE FOR CONDUITS9-449

INFILTRATION AND INFLOW ALTERNATIVE FOR MANHOLES9-450

INFILTRATION AND INFLOW ALTERNATIVE FOR WET WELLS9-450

INFILTRATION AND INFLOW ALTERNATIVE FOR PRESSURE JUNCTIONS9-450

System Flows Alternative9-451

Operational Alternative9-452

User Data Extensions Alternative9-452

Calculation Options9-452

Chapter 10: Presenting Your Results453

Using Background Layers10-453

Background Layer Manager10-454

Working with Background Layer Folders10-456

Adding Background Layers10-457

Deleting Background Layers10-457

Editing Background Layers10-458

Renaming Background Layers10-458

Turning Background Layers On and Off10-458

Image Properties Dialog Box10-458

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-ix

Shapefile Properties Dialog Box10-460

DXF Properties Dialog Box10-461

Annotating Your Model10-462

Element Symbology Manager10-463

Using Folders in the Element Symbology Manager10-465

Adding Annotations10-466

Deleting Annotations10-467

Editing Annotations10-467

Renaming Annotations10-467

Annotation Properties Dialog Box10-468

FREE FORM ANNOTATION DIALOG BOX10-469

Zoom Dependent Visibility10-470

Color Coding Your Model10-470

Adding Color-Coding10-471

Deleting Color-Coding10-471

Editing Color-Coding10-472

Renaming Color-Coding10-472

Color-Coding Properties Dialog Box10-472

Using Profiles10-474

Profiles Manager10-475

Viewing Profiles10-476

Creating a New Profile10-477

Editing Profiles10-478

Deleting Profiles10-478

Renaming Profiles10-478

Profile Setup Dialog Box10-479

Profile Viewer Dialog Box10-480

AXIS OPTIONS DIALOG BOX10-483

Engineering Profile Viewer Dialog Box10-483

ENGINEERING PROFILE OPTIONS10-485

GROUND PROFILE OPTIONS10-487

ANNOTATION PROPERTIES DIALOG BOX10-487

LINK ANNOTATION PROPERTIES DIALOG BOX10-487

TEXT PROPERTIES10-488

Viewing and Editing Data in FlexTables10-488

FlexTables Manager10-489

Working with FlexTable Folders10-491

FlexTable Dialog Box10-492

STATISTICS DIALOG BOX10-494

Opening FlexTables10-494

Creating a New FlexTable10-495

Deleting FlexTables10-495

Naming and Renaming FlexTables10-495

Editing FlexTables10-496

Sorting and Filtering FlexTable Data10-498

Contents-x

Bentley SewerCAD V8 XM Edition User’s Guide

CUSTOM SORT DIALOG BOX10-501

Customizing Your FlexTable10-501

FlexTable Setup Dialog Box10-502

Element Relabeling Dialog Box10-504

Copying, Exporting, and Printing FlexTable Data10-505

Using Predefined Tables10-507

Reporting10-507

Using Standard Reports10-507

CREATING A PROJECT INVENTORY REPORT10-507

CREATING A SCENARIO SUMMARY REPORT10-508

CREATING A CONDUIT AND PRESSURE PIPE INVENTORY10-508

Reporting on Element Data10-508

Report Options10-508

Graphing10-509

Graph Manager10-510

Creating a Graph10-511

Printing a Graph10-512

Working with Graph Data: Viewing and Copying10-512

Graph Dialog Box10-512

GRAPH SERIES OPTIONS DIALOG BOX10-517

FILTER DIALOG BOX10-517

OBSERVED DATA DIALOG BOX10-517

Sample Observed Data Source10-519

Chart Options Dialog Box10-520

Chart Options Dialog Box - Chart Tab10-521

SERIES TAB10-522

PANEL TAB10-522

AXES TAB10-525

GENERAL TAB10-532

TITLES TAB10-533

WALLS TAB10-538

PAGING TAB10-539

LEGEND TAB10-540

3D TAB10-546

Chart Options Dialog Box - Series Tab10-547

FORMAT TAB10-547

POINT TAB10-548

GENERAL TAB10-549

DATA SOURCE TAB10-550

MARKS TAB10-551

Chart Options Dialog Box - Tools Tab10-555

Chart Options Dialog Box - Export Tab10-556

Chart Options Dialog Box - Print Tab10-558

Border Editor Dialog Box10-559

Gradient Editor Dialog Box10-560

Color Editor Dialog Box10-561

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-xi

Color Dialog Box10-561

Hatch Brush Editor Dialog Box10-562

HATCH BRUSH EDITOR DIALOG BOX - SOLID TAB10-562

HATCH BRUSH EDITOR DIALOG BOX - HATCH TAB10-563

HATCH BRUSH EDITOR DIALOG BOX - GRADIENT TAB10-563

HATCH BRUSH EDITOR DIALOG BOX - IMAGE TAB10-564

Pointer Dialog Box10-565

Change Series Title Dialog Box10-566

Chart Tools Gallery Dialog Box10-566

CHART TOOLS GALLERY DIALOG BOX - SERIES TAB10-566

CHART TOOLS GALLERY DIALOG BOX - AXIS TAB10-570

CHART TOOLS GALLERY DIALOG BOX - OTHER TAB10-573

TeeChart Gallery Dialog Box10-578

SERIES10-578

FUNCTIONS10-578

Customizing a Graph10-578

Print Preview Window10-587

Contours10-588

Contour Definition10-590

Contour Plot10-591

Contour Browser Dialog Box10-592

Enhanced Pressure Contours10-592

Using Named Views10-592

Using Aerial View10-593

Time Series Field Data10-594

SELECT ASSOCIATED MODELING ATTRIBUTE DIALOG BOX10-596

Chapter 11: Features of the MicroStation Version

597

MicroStation Environment11-598

MicroStation Mode Graphical Layout11-598

MicroStation Project Files11-599

Bentley SewerCAD V8i Element Properties11-599

Element Properties11-600

Levels11-600

ELEMENT LEVELS DIALOG11-601

Text Styles11-601

Working with Elements11-601

Edit Elements11-601

Deleting Elements11-602

Modifying Elements11-602

CHANGE PIPE WIDTHS11-602

Contents-xii

Bentley SewerCAD V8 XM Edition User’s Guide

EDIT ELEMENTS11-602

Working with Elements Using MicroStation Commands11-602

BENTLEY SEWERCAD V8I CUSTOM MICROSTATION ENTITIES11603

MICROSTATION COMMANDS11-603

MOVING ELEMENTS11-603

MOVING ELEMENT LABELS11-604

Snap Menu11-604

Undo/Redo11-604

Special Considerations11-605

Import Bentley SewerCAD V8i11-605

Annotation Display11-605

Use SewerCAD V8i Z Order Command11-605

Chapter 12: Working in AutoCAD Mode607

The AutoCAD Workspace12-608

AutoCAD Integration with SewerCAD V8i12-608

AutoCAD Mode Graphical Layout12-609

Menus12-609

Toolbars12-609

Drawing Setup12-610

Symbol Visibility12-610

Layout Options Dialog12-610

AutoCAD Project Files12-611

AutoCAD Project Files12-611

Drawing Synchronization12-612

Working with Elements Using AutoCAD Commands12-613

SewerCAD V8i Custom AutoCAD Entities12-613

SewerCAD V8i Custom AutoCAD Entities12-614

AutoCAD Commands12-614

Explode Elements12-614

Moving Elements12-615

Moving Element Labels12-615

Snap Menu12-615

Undo/Redo12-615

Special Considerations12-616

Importing SewerCAD V8i Data12-617

Importing SewerCAD V8i Data12-617

Working with Proxies12-617

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-xiii

Chapter 13: Theory619

Loading13-620

Common Load Types13-620

HYDROGRAPHS13-620

PATTERN LOADS13-621

HYDROGRAPHS VS. PATTERN LOADS13-621

Sanitary (Dry Weather) Loading13-621

UNIT SANITARY (DRY WEATHER) LOADS13-622

EXTREME FLOW FACTOR13-622

COMMON VARIABLE PEAKING FACTORS13-623

Wet Weather Loading13-624

INFILTRATION13-624

INFLOW13-625

Known Flow13-625

Gravity Pipe Hydraulics13-626

The Energy Principle13-626

THE ENERGY EQUATION13-627

Hydraulic and Energy Grades13-628

HYDRAULIC GRADE13-629

ENERGY GRADE13-629

Friction Loss Methods13-629

CHEZY’S EQUATION13-629

COLEBROOK-WHITE EQUATION13-630

HAZEN-WILLIAMS EQUATION13-631

DARCY-WEISBACH EQUATION13-631

Swamee and Jain Equation13-633

MANNING’S EQUATION13-633

Flow Regime13-634

PRESSURE FLOW13-635

UNIFORM FLOW AND NORMAL DEPTH13-635

CRITICAL FLOW, CRITICAL DEPTH, AND CRITICAL SLOPE13-635

SUBCRITICAL FLOW13-636

SUPERCRITICAL FLOW13-636

Gradually Varied Flow Analysis13-636

SLOPE CLASSIFICATION13-636

ZONE CLASSIFICATION13-638

PROFILE CLASSIFICATION13-639

Energy Balance13-640

STANDARD STEP METHOD13-641

DIRECT STEP METHOD13-641

Mixed Flow Profiles13-641

SEALING (SURCHARGING) CONDITIONS13-642

RAPIDLY VARIED FLOW13-642

Backwater Analysis13-642

FREE OUTFALL13-643

STRUCTURE FLOODING13-643

Contents-xiv

Bentley SewerCAD V8 XM Edition User’s Guide

Frontwater Analysis13-643

Pipe Average Velocity13-644

UNIFORM FLOW VELOCITY13-644

FULL FLOW VELOCITY13-644

SIMPLE AVERAGE VELOCITY13-644

WEIGHTED AVERAGE VELOCITY13-645

PIPE AVERAGE VELOCITY AND TRAVEL TIME13-645

Capacity Analysis (Approximate Profiles)13-645

FULL CAPACITY PROFILES13-646

EXCESS CAPACITY PROFILES13-646

COMPOSITE EXCESS CAPACITY PROFILES13-648

Junction Headlosses and Minor Losses13-648

Manhole Head Loss Equations (AASHTO/HEC-2 Overview)13-649

Junction Headlosses13-649

STRUCTURE HEADLOSS13-649

SPECIAL ASSUMPTIONS13-652

Pressure Flow, Free Surface Flow, and Transitional Flow13-652

Initial Headloss Coefficient13-652

Correction for Pipe Diameter13-653

Correction for Flow Depth13-653

Correction for Relative Flow13-654

Correction for Plunging Flow13-654

Correction for Benching13-655

Headloss - AASHTO Method13-656

AASHTO Contraction Loss13-657

AASHTO Bend Loss13-657

AASHTO Bend Loss Original Equation13-658

AASHTO Expansion Loss13-659

AASHTO Correction For Non-Piped Flow13-660

AASHTO Correction for Shaping13-660

Minor Losses13-660

FITTING LOSS COEFFICIENTS13-661

Pump Theory13-662

Variable Speed Pumps13-663

Constant Horsepower Pumps13-666

Conservation of Mass and Energy13-667

CONSERVATION OF MASS13-667

CONSERVATION OF ENERGY13-668

The Gradient Algorithm13-668

Derivation of the Gradient Algorithm13-669

The Linear System Equation Solver13-671

Extended Period Simulations13-673

Extended Period Simulations Overview13-673

Routing Overview13-673

Convex Routing13-674

Weighted Translation Routing13-675

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-xv

Hydrologic and Hydraulic Time Steps13-676

Transitioning Between Gravity and Pressure Networks13-676

Identifying Gravity Pipes and Force Mains13-676

Direction of Flow in Gravity and Pressure Systems13-677

Transitioning From Gravity Pipes to Force Mains13-677

Transitioning From Force Mains to Gravity Elements13-678

Subnetworks13-682

Constraint Based Automatic Design13-683

Gravity Pipes and Structures Design13-683

Part Full Design13-683

Allow Multiple Sections13-684

Limit Section Size13-685

Pipe Matching13-685

Offset Matching13-686

Drop Structures13-686

Structure invert Elevations13-686

Design Priorities13-686

Automatic Design with Hydrograph and Pattern Loads13-689

Constraint Based Warning Messages13-690

Open and Closed Channel Weighting Methods13-690

Note to HEC-2, WSP-2, and WSPRO Users13-693

Special Considerations13-693

Energy Discontinuity13-693

Structure Energy Grade13-694

Design Considerations13-694

Reporting Flow Attributes13-694

Manning’s n Coefficients13-695

Headloss Coefficients for Junctions13-698

Roughness Values—Manning’s Equation13-699

Roughness Values—Darcy-Weisbach Equation (Colebrook-White)

13-700

Appendix 14: References703

Chapter 15: About Bentley Systems705

Software15-705

CivilStorm15-706

SewerGEMS15-707

SewerGEMS15-707

WaterGEMS15-708

WaterCAD15-708

StormCAD15-709

Contents-xvi

Bentley SewerCAD V8 XM Edition User’s Guide

PondPack15-709

FlowMaster15-709

CulvertMaster15-710

HAMMER15-710

GISConnect15-710

Bentley Institute Press15-711

Training15-712

Accreditations15-712

Bentley SewerCAD V8 XM Edition User’s Guide

Contents-xvii

Contents-xviii

Bentley SewerCAD V8 XM Edition User’s Guide

Chapter

1

Getting Started

Thank you for purchasing Bentley SewerCAD V8i. At Bentley Systems, we pride

ourselves in providing the very best engineering software available. Our goal is to

make software that is easy to install and use, yet so powerful and intuitive that it anticipates your needs without getting in your way.

When you first use Bentley SewerCAD V8i, use the intuitive interface and interactive

dialog boxes to guide you. If you need more information, use the online help by

pressing the F1 key or selecting Bentley SewerCAD V8i Help from the Help menu.

A help topic describing the area of the program in which you are working appears.

•

•

“Documentation” on page 1-4

•

“Quick Start Lessons” on page 1-5

•

“Contacting Us” on page 1-6

What is Bentley SewerCAD V8i?

SewerCAD V8i is an extremely powerful program for the design and analysis of

gravity flow and pressure flow through pipe networks and pumping stations. The

program can be run in Microstation and AutoCAD mode, giving you all the power of

Microstation and AutoCAD’s capabilities, or in Stand-Alone mode utilizing our own

graphical interface.

SewerCAD V8i allows you to construct a graphical representation of a pipe network

containing information such as pipe data, pump data, loading, and infiltration. You

have a choice of conveyance elements including circular pipes, arches, boxes and

more.

Bentley SewerCAD V8i User’s Guide

1-1

Installation, Upgrades, and Updates

The gravity network is calculated using the built-in numerical model, which utilizes

both the direct step and standard step gradually varied flow methods. Flow calculations are valid for both surcharged and varied flow situations, including hydraulic

jumps, backwater, and drawdown curves. You also have the flexibility to mix gravity

and pressure components freely, building your systems in parallel or in series as they

exist in the field. Pressure elements can be controlled based on system hydraulics,

turning pumps on and off due to changes in flows and pressures.

SewerCAD V8i’s flexible reporting feature allows you to customize and print the

model results in both a report format and as a graphical plot.

Installation, Upgrades, and Updates

For instructions on installing, registering, activating, and updating the software please

refer to the Readme.pdf in the Program Files/Bentley/SewerCAD8 directory.

Municipal License Administrator Auto-Configuration

At the conclusion of the installation process, the Municipal License Administrator will

be executed, to automatically detect and set the default configuration for your product,

if possible. However, if multiple license configurations are detected on the license

server, you will need to select which one to use by default, each time the product

starts. If this is the case, you will see the screen below. Simply press OK to clear the

Warning dialog, then press Refresh Configurations to display the list of available

configurations. Select one and press Make Default, then exit the License Administrator. (You only need to repeat this step if you decide to make a different configuration the default in the future.)

1-2

Bentley SewerCAD V8i User’s Guide

Getting Started

Software Updates via the Web and Bentley SELECT

Note:

Your PC must be connected to the Internet to use the Check for

Updates button.

Bentley SELECT is the comprehensive delivery and support subscription program

that features product updates and upgrades via Web downloads, around-the-clock

technical support, exclusive licensing options, discounts on training and consulting

services, as well as technical information and support channels. It’s easy to stay up-todate with the latest advances in our software. Software updates can be downloaded

from our Web site, and your version of Bentley SewerCAD V8i can then be upgraded

to the current version quickly and easily. Just click the Check for Updates button on

the toolbar to launch your preferred Web browser and open our Web site. The Web site

automatically checks to see if your installed version is the latest available, and if not, it

provides you with the opportunity to download the correct upgrade to bring it up-todate. You can also access our Knowledgebase for answers to your Frequently Asked

Questions (FAQs).

For more information, see “Technical Support” on page 1-6.

Troubleshooting

Because of the multitasking capabilities of Windows, you may have applications

running in the background that make it difficult for software setup and installations to

determine the configuration of your current system. If you have difficulties during the

installation or uninstallation process, please try these steps before contacting our technical support staff:

1. Shut down and restart your computer.

2. Verify that there are no other programs running. You can see applications

currently in use by pressing Ctrl+Shift+Esc in Windows 2000 and Windows XP.

Exit any applications that are running.

3. Disable any antivirus software that you are running.

Caution:

After you install Bentley SewerCAD V8i, make certain that

you restart any antivirus software you have disabled. Failure

to restart your antivirus software leaves you exposed to

potentially destructive computer viruses.

4. Try running the installation or uninstallation again (without running any other

program first).

If these three steps fail to successfully install or uninstall the product, contact our

Technical Support staff. For more information, see “Contacting Us” on page 1-6.

Bentley SewerCAD V8i User’s Guide

1-3

Documentation

Updating Your SentinelLM Licenses if You Move Your License

Server

If you move your SentinelLM license manager to a different server, following these

steps to update the licenses:

1. Install the license file on the new server.

2. Replace the server name in the license.ini file on all client workstations with the

new server name (on the line containing “Server=”). Don’t forget to save the file

on each workstation. The license.ini file is usually located in the Haestad Method

product directory.

Updating Your Bentley SELECT Server Licenses if you Move Your

License Server

If you move your Bentley SELECT Server license manager to a different server,

following these steps to update the licenses:

1. Obtain a new license file (license string) from Bentley Systems, then update the

license.lic file on the new server with the new license string.

2. Replace the server name in the license.lic file on all client workstations with the

new server name. Don’t forget to save the file on each workstation. The license.lic

file is usually located in the Haestad Method product directory.

Checking Your Current Registration Status

After you have registered the software, you can check your current registration status

by opening the About... box from within the software itself.

To view your registration information

1. Select Help > About Bentley SewerCAD V8i Edition.

2. The version and build number for Bentley SewerCAD V8i Edition display in the

lower-left corner of the About Bentley Bentley SewerCAD V8i dialog box.

The current registration status is also displayed, including: user name and

company, serial number, license type and check-in status, feature level, expiration

date, and SELECT Server information.

Documentation

Bentley SewerCAD V8i documentation is available in two parts:

1-4

Bentley SewerCAD V8i User’s Guide

Getting Started

Online help:

The online help is accessible from the Help menu or

by pressing F1. Additionally, when you are using

Bentley SewerCAD V8i, you can call the online help

at any time by clicking a help button in any dialog

box or window.

The context-sensitive online help is designed to make

it easy for you to quickly find specific information

about a feature you are using in Bentley SewerCAD

V8i. The online help makes extensive use of

hyperlinks and provides a table of contents, index,

and keyword search to help you locate the

information you need.

Online PDF Book:

Note:

The content in the online help is also available in .pdf

format and is available at docs.bentley.com. This pdf

contains the same content as the online help, but

includes hypertext and is designed to be printed by

you from a local printing device. As well as being

more easily printable than the online help, the online

book also uses hypertext and is searchable.

On-screen display of graphics in .pdf files is dependent on the

zoom level you use. For more optimal viewing of graphics in

Adobe® Acrobat® Reader, try using 167% and 208% zoom.

Quick Start Lessons

The lessons quickly introduce you to specific features of Bentley SewerCAD V8i. To

access the lessons, select Quick Start Lessons from the Help menu. Run a lesson by

selecting one of the entries in the list.

Bentley SewerCAD V8i User’s Guide

1-5

Contacting Us

Contacting Us

Contact Bentley Systems if you want product information, to upgrade your software,

or need technical support.

Sales

Bentley Systems, Inc.’ professional staff is ready to answer your questions. Please

contact your sales representative for any questions regarding Bentley Systems, Inc.’

latest products and prices.

Toll-free U.S. Phone:

800-727-6555

Worldwide Phone:

+1-203-755-1666

Fax:

+1-203-597-1488

Email:

sales@haestad.com

Technical Support

We hope that everything runs smoothly and you never have a need for our technical

support staff. However, if you do need support, our highly-skilled staff offers their

services seven days a week, and may be contacted by phone, fax, email, and the

Internet. For information on the various levels of support that we offer, contact our

sales team today and request information on our ClientCare program, or visit our Web

site.

When calling for support, in order to assist our technicians in troubleshooting your

problem, please be in front of your computer and have the following information

available:

1-6

•

Your computer’s operating system (Windows 2000 or Windows XP).

•

Name and build number of the Bentley Systems, Inc. software you are calling

about. The build number can be determined by clicking Help > About Bentley

SewerCAD V8i. The build number is the number in brackets located in the lowerleft corner of the dialog box that opens.

•

A note of exactly what you were doing when you encountered the problem.

•

Any error messages or other information displayed on your screen.

Bentley SewerCAD V8i User’s Guide

Getting Started

When emailing or faxing for support, please provide the following details, in addition

to the above, to enable us to provide a more timely and accurate response:

•

Company name, address, and phone number

•

A detailed explanation of your concerns

•

If you are emailing us, the Haestad Bentley SewerCAD V8i.log files located in the

product directory (e.g., C:\Documents and Settings\All Users\Application

Data\Haestad\Bentley SewerCAD V8i\1)

Support Hours

:Technical Support is available 24 hours a day, seven days a week.

You can contact our technical support team at:

Phone:

+1-203-755-1666

Fax:

+1-203-597-1488

Email:

support@haestad.com

Addresses

Use this address information to contact us:

Internet:

http://www.haestad.com

Email:

support@haestad.com

sales@haestad.com

Toll-free U.S. Phone:

800-727-6555

Worldwide Phone:

+1-203-755-1666

Fax:

+1-203-597-1488

Mail:

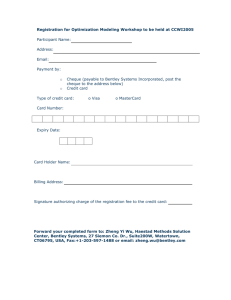

Bentley Systems, Inc., Incorporated

Haestad Methods Solutions Center

Suite 200W

37 Brookside Road

Watertown, CT 06795

Bentley SewerCAD V8i User’s Guide

1-7

Contacting Us

Your Suggestions Count

Bentley Systems, Inc. strives to continually provide you with sophisticated software

and documentation. We are very interested in hearing your suggestions for improving

the Bentley SewerCAD V8i software, online help, and printed manual. Your feedback

guides us in developing products that make your work easier.

Please let us hear from you!

1-8

Bentley SewerCAD V8i User’s Guide

Chapter

2

Introducing the

Workspace

Click one of the following links to learn more about the Bentley SewerCAD V8i

workspace.

•

“The Workspace” on page 2-9

•

“Menus” on page 2-11

•

“Toolbars” on page 2-25

•

“Customizing the Toolbars” on page 2-36

•

“Dynamic Manager Display” on page 2-37

The Workspace

You use Bentley SewerCAD V8i in one of these modes:

•

“Stand-Alone Editor” on page 2-9

•

“Microstation Mode” on page 2-10

•

“AutoCAD Mode” on page 2-11

Stand-Alone Editor

The Stand-Alone Editor is the workspace that contains the various managers, toolbars,

and menus, along with the drawing pane, that make up the Bentley SewerCAD V8i

interface. The Bentley SewerCAD V8i interface uses dockable windows and toolbars,

so the position of the various interface elements can be manually adjusted to suit your

preference.

Bentley SewerCAD V8i User’s Guide

2-9

The Workspace

By default, the Bentley SewerCAD V8i environment looks like this:

Microstation Mode

Microstation mode lets you create and model your network directly within your

primary drafting environment. This gives you access to all of Microstation‘s drafting

and presentation tools, while still enabling you to perform Bentley SewerCAD V8i

modeling tasks like editing, solving, and data management. This relationship between

Bentley SewerCAD V8i and Microstation enables extremely detailed and accurate

mapping of model features, and provides the full array of output and presentation

features available in Microstation. This facility provides the most flexibility and the

highest degree of compatibility with other CAD-based applications and drawing data

maintained at your organization.

Note:

2-10

For more information about runnning Bentley SewerCAD V8i in

Microstation mode, see “MicroStation Environment” on page 12702.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

AutoCAD Mode

AutoCAD mode lets you create and model your network directly within your primary

drafting environment. This gives you access to all of AutoCAD’s drafting and presentation tools, while still enabling you to perform Bentley SewerCAD V8i modeling

tasks like editing, solving, and data management. This relationship between Bentley

SewerCAD V8i and AutoCAD enables extremely detailed and accurate mapping of

model features, and provides the full array of output and presentation features available in AutoCAD. This facility provides the most flexibility and the highest degree of

compatibility with other CAD-based applications and drawing data maintained at your

organization.

Note:

For more information about runnning Bentley SewerCAD V8i in

AutoCAD mode, see “Working in AutoCAD Mode” on page 13-711.

Menus

Menus are located at the top of Bentley SewerCAD V8i stand-alone editor window

and provide access to program commands, which are broken down by type of functionality.

The following menus are available:

•

“File Menu” on page 2-11

•

“Edit Menu” on page 2-15

•

“Analysis Menu” on page 2-17

•

“View Menu” on page 2-19

•

“Tools Menu” on page 2-22

•

“Report Menu” on page 2-24

•

“Help Menu” on page 2-24

File Menu

The File menu contains the following commands:

New

Creates a new project. When you select this

command, a new untitled project is created.

Open

Opens an existing project. When you select this

command, the Open dialog box appears, allowing

you to browse to the project to be opened.

Bentley SewerCAD V8i User’s Guide

2-11

Menus

2-12

Close

Closes the current project without exiting the

program.

Close All

Closes all currently open projects.

Save

Saves the current project.

Save As

Saves the current project under a new project name

and/or to a different directory location.

Save All

Saves all currently open projects.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

ProjectWise

Opens a submenu containing the following

commands:

•

Open—Open an existing SewerCAD V8i

project from ProjectWise. You are prompted to

log into a ProjectWise datasource if you are not

already logged in.

Note:

•

Save As—Saves the current project to a

ProjectWise datasource. You are prompted to

log into a ProjectWise datasource if you are not

already logged in.

•

Change Datasource—Lets you connect to a

different ProjectWise datasource for future

Open and Save As operations.

•

Import—Lets you import the following file types

into the ProjectWise project:

•

SewerCAD V8 Database—Lets you import

a Bentley SewerCAD V8i project database

file.

•

Submodel—Lets you import a SewerCAD

submodel file.

•

LandXML—Lets you import a LandXML

file.

•

StormCAD V8 —Lets you import a

StormCAD V8 file.

•

SewerGEMS V8 —Lets you import a

SewerGEMS V8 file.

Note:

Bentley SewerCAD V8i User’s Guide

Only projects that were

originally saved into

ProjectWise from the SewerCAD

V8i application can be opened

For more information about

using SewerCAD V8i with

ProjectWise, see “Considerations

for ProjectWise Users” on page 4158

2-13

Menus

Import

Opens a submenu containing the following

commands:

•

Export

2-14

Bentley SewerCAD V8i Database—Lets you

import a Bentley SewerCAD V8i project database file.

•

Submodel—Lets you import a SewerCAD

submodel file.

•

LandXML—Lets you import a LandXML

file.

•

StormCAD V8—Lets you import a

StormCAD V8 file.

•

SewerGEMS V8 —Lets you import a

SewerGEMS V8 file.

Opens a submenu containing the following

commands:

•

DXF—Lets you export the current network

layout as a DXF drawing.

•

Submodel—Exports the currently selected

area of the network as a SewerCAD submodel

file.

•

LandXML—Exports the current project as a

LandXML file.

Page Setup

Defines the print settings that will be used when the

current view is printed.

Print Preview

Opens the Print Preview window, displaying the

current view exactly as it will be printed. You can

select whether you want the print preview to be Fit

to Page or Scaled:

•

Fit to Page—The view will be zoomed in or out

so that the current view fits to a single page of

the default page size.

•

Scaled—The view will be scaled so that it

matches the user-defined drawing scale (this is

defined on the Drawing Tab of the Options

dialog: Tools > Options).

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Print

Prints the current view. You can select whether you

want the print preview to be Fit to Page or Scaled:

•

Fit to Page—The view will be zoomed in or out

so that the current view fits to a single page of

the default page size.

•

Scaled—The view will be scaled so that it

matches the user-defined drawing scale (this is

defined on the Drawing Tab of the Options

dialog: Tools > Options).

Project Properties

Opens the Project Properties dialog box, allowing

you to specify project-level settings.

Recent Files

When the Recent Files Visible option is selected in

the Options dialog box, the most recently opened

files will appear in the File menu. See “Options

Dialog Box - Global Tab” on page 4-147 for more

information.

Exit

Closes the program.

Edit Menu

The Edit menu contains the following commands:

Undo

Cancels the last data input action on the currently

active dialog box. Clicking Undo again cancels

the second-to-last data input action, and so on.

Redo

Cancels the last undo command.

Delete

Deletes the currently highlighted element.

Bentley SewerCAD V8i User’s Guide

2-15

Menus

Select By Polygon

2-16

Lets you select elements in your model by

drawing a polygon in the drawing pane. Click in

the drawing pane to draw each side of the

polygon. After the polygon has been drawn, rightclick to select from the following options:

•

As Selected - All elements contained within

the polygon will be selected. Elements that

were selected before the Select By Polygon

opperation will be de-selected.

•

Add to Selection - All elements contained

within the polygon will be selected in addition

to any elements that were selected before the

Select By Polygon operation were performed.

•

Invert Selection - All elements contained

within the polygon that were selected before

the operation will be de-selected; all elements

contained within the polygon that were not

selected before the operation will be selected

•

Remove From Selection - All elements

contained within the polygon that were

selected before the operation will be deselected.

Select All

Selects all of the elements in the network.

Invert Selection

Selects all currently unselected elements and

deselects all currently selected ones.

Select by Element

Opens a submenu listing all available element

types. Select one of the element types from the

submenu to select all elements of that type in the

model.

Select by Attribute

Opens a menu listing all available attribute types.

Select one of the attribute types from the menu

and the Query Builder dialog box opens.

Clear Selection

Deselects the currently selected element(s).

Clear Highlight

Removes Network Navigator highlighting for all

elements.

Find Element

Lets you find a specific element by entering the

element’s label.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Analysis Menu

The Analysis menu contains the following commands:

Scenarios

Opens the Scenario Manager, which lets you

create, view, and manage project scenarios.

Alternatives

Opens the Alternative Manager, which lets you

create, view, and manage alternatives.

Calculation Options

Opens the Calculation Options Manager, which

lets you create, view, and manage calculation

settings for the project.

Totalizing Flow

Meters

Opens the Totalizing Flow Meters manager where

you can create new meters.

System Head Curves

Opens the System Head Curves manager.

EPS Results Browser

Opens the EPS Results Browser dialog box, which

lets you manipulate the currently displayed time

step and to animate the drawing pane.

Calculation Summary

Opens the calculation summary report, which

reports the details of the calculations performed

on your model.

User Notifications

Opens the User Notifications Manager, allowing

you to view warnings and errors uncovered by the

validation process.

Validate

Runs a diagnostic check on the network data to

alert you to possible problems that may be

encountered during calculation. This is the manual

validation command, and it checks for input data

errors. It differs in this respect from the automatic

validation that SewerCAD V8i runs when the

compute command is initiated, which checks for

network connectivity errors as well as many other

things beyond what the manual validation checks.

Pressing CTRL+F7 also selects this command.

Bentley SewerCAD V8i User’s Guide

2-17

Menus

Compute

Calculates the network. Before calculating, an

automatic validation routine is triggered, which

checks the model for network connectivity errors

and performs other validation. For more

information, see “Calculating Your Model” on

page 8-433. Pressing F9 also selects this

command.

Components Menu

The Components menu contains the following commands:

2-18

Default Design

Constraints

Opens the Default Design Constraints dialog,

whiach allows you to specify constraints for pipes,

nodes, and inlets to be used during an automatic

design and while checking constraints for an

analysis calculation.

Controls

Opens the Controls manager where you can set

controls, conditions, actions, and logical control

sets.

Conduit Catalog

Opens the Conduit Catalog dialog box, which lets

you create, edit, and view catalog conduits.

Catalog conduits are an efficient way to reuse

common physical conduit definitions.

Flow Headloss Curves

Opens the Flow-Headloss Curves dialog.

Minor Loss

Coefficients

Opens the Minor Loss Coefficients Manager

dialog.

Unit Sanitary (Dry

Weather) Loads

Opens the Unit Sanitary (Dry Weather) Loads

dialog box, which lets you create, edit, and delete

unit sanitary loads. For more information, see

“Adding Unit Sanitary (Dry Weather) Loads” on

page 7-372.

Patterns

Opens the Pattern Manager where you can create

and edit diurnal loading patterns for use with

extended period simulations. For more

information, see “Defining Patterns” on page 7364.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Pattern Setups

Opens the Pattern Setup Manager where you can

associate diurnal patterns with the appropriate unit

sanitary loads for a given scenario. For more

information, see “Defining Pattern Setups” on

page 7-367.

Extreme Flows

Opens the Extreme Flows dialog.

Extreme Flow Setups

Opens the Extreme Flow Setups dialog.

Pump Definitions

Opens the Pump Definitions dialog box, which

lets you view, edit, and create pump curve

definitions. For more information, see “Pump

Curve Definitions Dialog Box” on page 6-235.

Time Series Field

Data

Opens the Time Series Field Data dialog.

Engineering Libraries

Opens the Engineering Libraries Manager.

View Menu

The View menu contains the following commands:

Element Symbology

Opens the Element Symbology Manager, which

lets you create, view, and manage annotation and

color-coding in your project.

Background Layers

Opens the Background Layers Manager, which

lets you create, view, and manage the background

layers associated with the project.

Network Navigator

Opens the Network Navigator.

Selection Sets

Opens the Selection Sets Manager, which lets you

create, view, and manage selection sets associated

with the project.

Queries

Opens the Query Manager, which lets you create

SQL expressions for use with selection sets and

FlexTables. For more information, see ADD

LINK

Bentley SewerCAD V8i User’s Guide

2-19

Menus

2-20

Prototypes

Opens the Prototypes Manager, which lets you

enter default values for elements in your model.

Prototypes can reduce data entry requirements

dramatically if a group of network elements share

common data. For more information, see ADD

LINK

FlexTables

Opens the FlexTables Manager, which lets you

create, view, and manage the tabular reports for

the project.

Graphs

Opens the Graph Manager, which lets you create,

view, and manage graphs for the project.

Profiles

Opens the Profile Manager, which lets you create,

view, and manage the profiles for the project.

Contours

Opens the Contours manager where you can create

and edit contour definitions.

Named Views

Opens the Named Views manager where you can

create, edit, and use Named Views.

Aerial View

Opens the Aerial View navigation window.

Properties

Turns the Properties Editor display on or off.

Customizations

Opens the Customization Manager dialog.

Auto-Refresh

Turns automatic updates to the main window view

on or off whenever changes are made to the

Bentley SewerCAD V8i datastore. When selected,

a check mark appears next to this menu command,

indicating that automatic updates are turned on.

Refresh Drawing

Updates the main window view according to the

latest information contained in the Bentley

SewerCAD V8i datastore.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Zoom

Opens a submenu containing the following

commands:

•

Zoom Extents—Sets the view so that the

entire network is visible in the drawing pane.

•

Zoom Window—Activates the manual zoom

tool, which lets you specify a portion of the

drawing to enlarge.

•

Zoom In—Enlarges the size of the model in

the drawing pane.

•

Zoom Out—Reduces the size of the model in

the drawing pane.

•

Zoom Realtime—Enables the realtime zoom

tool, which lets you zoom in and out by

moving the mouse while holding down the left

mouse button.

•

Zoom Center—Opens the Zoom Center

dialog box, which lets you enter drawing coordinates that will be centered in the drawing

pane.

•

Zoom to Selection—Zooms to the element(s)

that are currently selected in the drawing

pane.

•

Zoom Previous—Resets the zoom level to

the last setting.

•

Zoom Next—Resets the zoom level to the

setting that was active before a Zoom

Previous command was executed.

Pan

Activates the Pan tool, which lets you move the

model within the drawing pane. When you select

this command, the cursor changes to a hand,

indicating that you can click and hold the left

mouse button and move the mouse to move the

drawing.

Toolbars

Opens a submenu that lists each of the available

toolbars. Select one of the toolbars in the submenu

to turn that toolbar on or off. For more

information, see “Toolbars” on page 2-25.

Reset Workspace

Resets the Bentley SewerCAD V8i workspace so

that the dockable managers appear in their default

factory-set positions.

Bentley SewerCAD V8i User’s Guide

2-21

Menus

Tools Menu

The Tools menu contains the following commands:

2-22

Active Topology

Selection

Opens a Select dialog to select elements in the

drawing to make them Inactive or Active.

ModelBuilder

Opens the ModelBuilder Connections Manager, which

lets you create, edit, and manage ModelBuilder

connections to be used in the model-building/modelsynchronizing process. For more information, see

“ModelBuilder Connections Manager” on page 5-175.

TRex

Opens the TRex node elevation assignment tool.

LoadBuilder

Opens the LoadBuilder manager where you can assign

demands to model nodes using data from outside

sources.

Thiessen Polygon

Opens the Wizard used to create Thiessen polygons

for use with LoadBuilder.

Inflow Control Center

Opens the Inflow Control Center, allowing you to

create, edit, and delete sanitary inflow definitions.

Element Property

Inferencing

Opes the Element Property Inferencing dialog.

Hyperlinks

Lets you associate external files, such as pictures or

movie files, with elements. For more information, see

“Adding Hyperlinks to Elements” on page 6-326.

User Data Extensions

User Data Extensions—Opens the User Data

Extension dialog box, which lets you add and define

custom data fields. For example, you can add new

fields such as the pipe installation date. For more

information, see “User Data Extensions” on page 6337.

Sanitary Load Control

Center

Opens the Sanitary Load Control Center, allowing you

to create, edit, and delete sanitary load definitions.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Database Utilities

Opens a submenu containing the following

commands:

•

Compact Database—When you delete data from

a Bentley SewerCAD V8i project, such as

elements or alternatives, the database store that

Bentley SewerCAD V8i uses can become fragmented, causing unnecessarily large data files,

which impact performance substantially.

Compacting the database eliminates the empty

data records, thereby defragmenting the datastore

and improving the performance of the file.

Note:

Every tenth time a file is saved,

Bentley SewerCAD V8i will

automatically prompt you to

compact the database. If you open

a file without saving it, the count

does not go up. If you open and

save a file multiple times in the

same session, the count only goes

up on the first save. If you open,

save, and close the file, the count

goes up. Click Yes to compact the

database, or no to close the prompt

dialog box without compacting.

Since compacting the database can

take time, especially for larger

models, you may want to postpone

the compact procedure until a later

time. You can modify how Bentley

SewerCAD V8i compacts the

database in the Options dialog box.

•

Synchronize Drawing—Synchronizes the current

model drawing with the project database.

•

Update Database cache—Updates the current

model to reflect any changes made in the database.

•

Update Results from Project Directory—This

command copies the model result files (if any) from the

project directory (the directory where the project .mdb

file is saved) to the custom result file directory. The

custom result directory is specified in

Tools>Options>Project tab. This allows you to make a

copy of the results that may exist in the model's save

directory and replace the current results being worked

on with them.

•

Copy Results to Project Directory—This

command copies the result files that are currently being

used by the model to the project directory (where the

project .mdb is stored).

•

Bentley SewerCAD V8i User’s Guide

Batch Update Conduit Descriptions—Updates

the Conduit Description field to reflect any changes

2-23

made to the underlying attributes.

Menus

Layout

Opens a submenu that lists each of the available

element types. Select one of the element types in the

submenu to place that element in your model.

External Tools

Run an existing external tool or create a new one by

opening up the External Tools manager.

Options

Opens the Options dialog box, which lets you change

global settings such as display pane settings, drawing

scale, units, display precision and format used, and

element labeling.

Report Menu

The Report menu contains the following commands:

Element Tables

Opens a submenu that lets you display FlexTables

for any link or node element. These predefined

FlexTables contain most of the input data and

results for each instance of the selected element in

the model.

Element Details

Allows you to select one or more elements from

the drawing view. A report is generated containing

the details of the selected element(s).

Scenario Summary

Opens the Scenario Summary Report.

Project Inventory

Opens the Project Inventory Report, which

contains the number of each of the various

element types that are in the network.

Conduit and Pressure

Pipe Inventory

Opens the Conduit and Pressure Pipe Inventory

report.

Report Options

Opens the Report Options box where you can set

Headers and Footers for the predefined reports.

Help Menu

The Help menu contains the following commands:

2-24

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Bentley SewerCAD V8i

Help

Opens the online help Table of Contents.

Quick Start Lessons

Opens the online help to the Quick Start Lessons

Overview topic.

Welcome Dialog

Opens the Welcome dialog box.

Check for Updates

Opens your Web browser to the our Web site,

allowing you to check for Bentley SewerCAD V8i

updates.

Bentley Institute

Training

Opens your browser to the Bentley Institute

Training web site.

Bentley Professional

Services

Opens your browser to the Bentley Professional

Services web site.

Online Support

Opens your browser to SELECTservices area of

the Bentley web site.

Discussion Groups

Opens your browser to Bentley’s Haestad

Discussion Groups.

Bentley.com

Opens the home page on the Bentley web site.

About Bentley

SewerCAD V8i

Opens the About Bentley SewerCAD V8i dialog

box, which displays copyright information about

the product, registration information, and the

current version number of this release.

Toolbars

Toolbars provide access to frequently used menu commands and are organized by the

type of functionality offered. Many of the toolbars have additional buttons available

that are not displayed by default. You can display these additional buttons by

following the procedure in “Adding and Removing Toolbar Buttons” on page 2-36.

The following toolbars are available:

•

“Layout Toolbar” on page 2-27

•

“Standard Toolbar” on page 2-28

•

“Edit Toolbar” on page 2-30

•

“View Toolbar” on page 2-30

Bentley SewerCAD V8i User’s Guide

2-25

Toolbars

2-26

•

“Scenarios Toolbar” on page 2-32

•

“Analysis Toolbar” on page 2-32

•

“Compute Toolbar” on page 2-33

•

“Tools Toolbar” on page 2-33

•

“Help Toolbar” on page 2-34

•

“Zoom Toolbar” on page 2-34

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Layout Toolbar

You use the Layout toolbar to lay out your model in the drawing pane. The Layout

toolbar contains the following buttons:

Select

Layout

Manhole

Transition

Wet Well

Bentley SewerCAD V8i User’s Guide

Changes your mouse cursor into a selection

tool. The selection tool behavior varies

depending on the direction in which the mouse

is dragged after defining the first corner of the

selection box, as follows:

If the selection is made from left-to-right, all

elements that fall completely within the

selection box that is defined will be selected.

If the selection is made from right-to-left, all

elements that fall completely within the

selection box and that cross one or more of the

lines of the selection box will be selected.

Changes your mouse cursor into a network

layout tool. Right-click to change the type of

element and the type of link.

•

Pressure Pipe—Lets you place an

element through which water moves under

pressure. Pressure pipes typically

discharge from a pumping station located

upstream in the sewer collection system.

•

Conduit—Lets you place a closed section

element through which water moves. A

conduit has a constant roughness and

cross section shape along its entire length.

Available conduit shapes consist of both

open and closed cross sections.

Changes your mouse cursor into a manhole

element symbol. Clicking the left mouse button

while this tool is active causes a manhole

element to be placed at the location of the

mouse cursor.

Changes your mouse cursor into a transition

element symbol. Clicking the left mouse button

while this tool is active causes a manhole

element to be placed at the location of the

mouse cursor.

Changes your mouse cursor into a wet well

element symbol. Clicking the left mouse button

while this tool is active causes a wet well

element to be placed at the location of the

mouse cursor.

2-27

Toolbars

Outfall

Pressure

Junction

Pump

Variable Speed

Pump Battery

Air Valve

Border

Text

Line

Changes your mouse cursor into an outfall

element symbol. Clicking the left mouse button

while this tool is active causes an outfall

element to be placed at the location of the

mouse cursor.

Changes your mouse cursor into a pressure

junction element symbol. Clicking the left

mouse button while this tool is active causes a

manhole element to be placed at the location of

the mouse cursor.

Changes your mouse cursor into a pump

element symbol. Clicking the left mouse button

while this tool is active causes a pump element

to be placed at the location of the mouse cursor.

Changes your mouse cursor into a variable

speed pump battery element symbol. Clicking

the left mouse button while this tool is active

causes a manhole element to be placed at the

location of the mouse cursor.

Changes your mouse cursor into an air valve

element symbol. Clicking the left mouse button

while this tool is active causes a manhole

element to be placed at the location of the

mouse cursor.

Changes your mouse cursor into a border

symbol. When the border tool is active, you can

draw a simple box in the drawing pane using

the mouse. For example, you might want to

draw a border around the entire model.

Changes your mouse cursor into a text symbol.

When the text tool is active, you can add

simple text to your model. Click anywhere in

the drawing pane to display the Text Editor

dialog box, which lets you enter text to be

displayed in your model.

Changes your mouse cursor into a line symbol.

When this tool is active, you can draw lines and

polygons in your model using the mouse.

Standard Toolbar

The Standard toolbar contains the following buttons:

2-28

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

New

Creates a new Bentley SewerCAD V8i project.

When you select this command, the Select File to

Create dialog box appears, allowing you to

define a name and directory location for the new

project.

Open

Opens an existing Bentley SewerCAD V8i

project. When this command is initialized, the

Select Bentley SewerCAD V8i Project to Open

dialog box appears, allowing you to browse to the

project to be opened.

Save

Saves the current project.

Print Preview

Opens the Print Preview window, displaying the

current view exactly as it will be printed.

Print

Prints the current view of the network as

displayed in the drawing pane.

Bentley SewerCAD V8i User’s Guide

2-29

Toolbars

Edit Toolbar

The Edit toolbar contains the following buttons:

Undo

Cancels your most recent action.

Redo

Lets you redo the last cancelled action.

Find Element

Lets you find a specific element by choosing it

from a menu containing all elements in the

current model.

View Toolbar

The View toolbar contains the following buttons, which give you easy access to many

of the managers in Bentley SewerCAD V8i.:

2-30

Element

Symbology

Opens the Element Symbology manager,

allowing you to create, view, and manage the

element symbol settings for the project.

Background

Layers

Opens the Background Layers manager,

allowing you to create, view, and manage the

background layers associated with the project.

Network

Navigator

Opens the Network Navigator dialog box.

Selection Sets

Opens the Selection Sets Manager, allowing you

to create, view, and modify the selection sets

associated with the project.

Queries

Opens and closes the Query Manager.

FlexTables

Opens the FlexTables manager, allowing you to

create, view, and manage the tabular reports for

the project.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Graphs

Opens the Graph manager, allowing you to

create, view, and manage the graphs for the

project.

Profiles

Opens the Profile manager, allowing you to

create, view, and manage the profiles for the

project.

Contours

Opens the Contours manager, where you can

create and edit contour definitions.

Aerial View

Opens the Aerial View navigation window.

Properties

Opens and closes the Property Editor.

Customization

s

Opens the Customizations Manager.

Bentley SewerCAD V8i User’s Guide

2-31

Toolbars

Scenarios Toolbar

The Scenario toolbar contains the following buttons:

Scenario List

Box

Lets you quickly change the current scenario.

Scenarios

Opens the Scenario manager, which lets you

create, view, and manage project scenarios.

Alternatives

Opens the Alternative manager, which lets you

create, view, and manage project alternatives.

Calculation

Options

Opens the Calculation Options manager, which

lets you create different profiles for different

calculation settings.

Analysis Toolbar

The Analysis toolbar contains the following buttons:

2-32

Totalizing

Flow Meters

Opens the Totalizing Flow Meters manager

where you can create new meters.

System Head

Curves

Opens the System Head Curves manager.

Calculation

Summary

Opens the Calculation Summary to view results.

Bentley SewerCAD V8i User’s Guide

Introducing the Workspace

Compute Toolbar

The Compute toolbar contains the following buttons:

Validate

Runs a diagnostic check on the network data to

alert you to possible problems that may be

encountered during calculation. This is the

manual validation command, and it checks for

input data errors. It differs in this respect from

the automatic validation that SewerCAD V8i

runs when the compute command is initiated,

which checks for network connectivity errors as

well as many other things beyond what the

manual validation checks.

Compute

Calculates the network. Before calculating, an

automatic validation routine is triggered, which

checks the model for network connectivity

errors and performs other validation. For more

information, see “Calculating Your Model” on

page 8-433.

User

Notifications

Opens the User Notifications Manager, allowing

you to view warnings and errors uncovered by

the validation process. This button does not

appear in the toolbar by default, but can be

added. For more information, see “Adding and

Removing Toolbar Buttons” on page 2-36.

Tools Toolbar

The Tools toolbar contains the following buttons:

Active

Topology

Selection

Opens a Select dialog to select elements in the

drawing to make them Inactive or Active.

ModelBuilder

Opens the ModelBuilder Connections Manager,

where you can create, edit, and manage

ModelBuilder connections to be used in the

model-building/model-synchronizing process.

Bentley SewerCAD V8i User’s Guide

2-33

Toolbars

Help Toolbar

The Help toolbar provides quick access to the same commands that are available in

the Help menu. The Help toolbar contains the following buttons.

Check for

Updates

Opens your Web browser to our Web site,

allowing you to check for Bentley SewerCAD

V8i updates.

SewerCAD

Help

Opens the Bentley SewerCAD V8i online help.

Zoom Toolbar

The Zoom toolbar provides access to the zooming and panning tools. It contains the