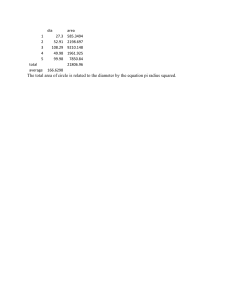

Process Release Frequencies: Risk Assessment Data

advertisement