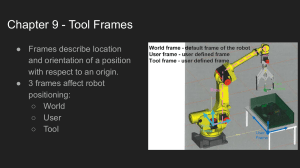

Chapter 9 - Tool Frames ● Frames describe location and orientation of a position with respect to an origin. ● 3 frames affect robot positioning: ○ World ○ User ○ Tool Chapter 9 - Tool Frames ● ● ● ● Default tool frame is the faceplate on J6 Default tool frame’s Z-axis is away from the faceplate and X-axis pointing “upward”. When a point is recorded, it is always referencing the current user and tool frame. The active tool frame can be set by pressing SHIFT+COORD on the TP, or through the frames menu, or from with in a program... UFRAME_NUM=, UTOOL_NUM= . Chapter 9 - Tool Frames ● For gripping tools, use a “pointer” tool to help teach the tool frame. ● 4 common methods of teaching a tool frame: ○ 3-point method (easiest, requires a TCP tool) ○ 6-point method (allows you to change the orientation of the tool frame) ○ Direct Entry (if you know the tool dimensions from the faceplate) ○ Vision TCP ● To set up a tool frame, press MENU and then select Frames, and then options appear at the bottom. Chapter 10 - Offset (User) Frames ● User Frames are based off of the World Frame ● User Frames can be taught at any location and any orientation ● Positions are taught with respect to a User Frame (& Tool Frame!) ● SHIFT+COORD will allow you to change the active frame (or MENU → Frames) Chapter 10 - Offset (User) Frames ● Four common methods for teaching a User Frame ○ 3-Point Method ○ 4-Point Method ○ Direct Entry ○ Automatic Grid Set ● 4 pt or Automatic Grid Set are recommended to teach a user frame used in Vision processes ● With 4-Pt, choose a starting point (Origin), then jog the robot in X-direction, then Y-direction, and finally select the System Origin. Chapter 11 - Calibration Frame ● A user frame must be taught that is used with a vision process. ● It establishes a relationship between the camera’s view and the user frame of the robot. ● Use the same calibration grid to teach the frame as you use to calibrate the camera ● Three large dots will be recognized as the X-axis by the camera. ● Two large dots will be recognized as the Y-axis by the camera. ● The intersection of these lines will be recognized as the system origin. Chapter 11 - Calibration Frame ● Use the FOUR Point method to teach the User frame ● Robots with gripper will need a pointer tool to help make this as accurate as possible. (Z value may need to be adjusted when selecting the System Origin) Chapter 11 - Calibration Frame ● ● ● Many robots come with a feature called the Automatic Grid Set which will teach itself the user frame. This feature is found in the iRVision menu selection under iRVision Utilities. The robot will move around and take pictures to determine the User Frame for the Grid and a Tool Frame for the camera. Chapter 12 - 2D Calibration ● ● ● ● To perform any motion program that uses a Vision Process, the vision system MUST be calibrated. Calibration establishes the camera’s mm/pixel scale and its relationship to the robot. Application Frame: only change this is the robot’s vertical axis is different from camera’s axis. Cal. Grid Frame: ○ Robot Mounted Camera: This is the user frame you taught and will use to do a motion program. ○ Fixed Mounted Camera: This is the Tool Frame of the robot holding the Cal. Grid. Chapter 12 - 2D Calibration ● ● ● Number of planes: ○ 1 Plane = you type in all the distance and focal length info ○ 2 planes = have it determine all the info (this gives best results) - does require to do a SNAP-FIND and set the data for the 2 planes. 2nd plane should be at least 100mm away along the Z-axis. Projection: Choosing Perspective will allow the process to adjust for Z-Height differences in parts. Check Calibration Point data for any erroneous values. Chapter 12 - 2D Calibration Chapter 13 - 2D Single View Vision Process ● This process will produce X, Y, and R offset data that can be used in a motion program. ● The offset data basically just offsets the frame that was used in calibration. ● Two main types of offsets can be accomplished: ○ Fixed Frame Offset: can be used with either fixed cameras or robot mounted cameras. ○ Tool Offset: more useful for fixed mounted cameras. Chapter 13 - 2D Single View Vision Process ● To create a vision process for robot guidance… start the vision setup process and choose the 2-D Single View Vision Process and give it a name. ● Process Tree consist of: ○ Snap Tool (version dependant) ○ GPM Locator Tool ○ Offset Data Calculation Tool (version dependant) Chapter 13 - 2D Single View Vision Process ● After Snap Tool and GPM Locator are setup, then complete the Offset Data Calculation Tool. ● Ref. Data: set this to Static for one part. Set to Model ID if you need to identify different parts with different Z heights. ● Part Z height: taller the object, the more important this is! ● Ref Pos.: This is the kicker!! Set this and then DON’T move the part when you teach points in your program. ○ This location will become the “zero” location of your part in this frame Chapter 13 - 2D Single View Vision Process