Accepted Manuscript

Bending, buckling, and free vibration analysis of MSGT microcomposite Reddy

plate reinforced by FG-SWCNTs with temperature- dependent material properties under hydro-thermo-mechanical loadings using DQM

M. Mohammadimehr, M. Salemi, B. Rousta Navi

PII:

DOI:

Reference:

S0263-8223(15)01058-2

http://dx.doi.org/10.1016/j.compstruct.2015.11.055

COST 7010

To appear in:

Composite Structures

Please cite this article as: Mohammadimehr, M., Salemi, M., Rousta Navi, B., Bending, buckling, and free vibration

analysis of MSGT microcomposite Reddy plate reinforced by FG-SWCNTs with temperature- dependent material

properties under hydro-thermo-mechanical loadings using DQM, Composite Structures (2015), doi: http://

dx.doi.org/10.1016/j.compstruct.2015.11.055

This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers

we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and

review of the resulting proof before it is published in its final form. Please note that during the production process

errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

Bending, buckling, and free vibration analysis of MSGT microcomposite Reddy

plate reinforced by FG-SWCNTs with temperature- dependent material properties

under hydro-thermo-mechanical loadings using DQM

M. Mohammadimehra*, M. Salemia, B. Rousta Navia

a

Department of Solid Mechanics, Faculty of Mechanical Engineering, University of Kashan,

Kashan, Iran

Abstract

In this paper, using third-order shear deformation theory (TSDT) and modified strain gradient theory (MSGT),

bending, buckling and free vibration behaviors of microcomposite plate reinforced by functionally graded singlewalled carbon nanotube (FG-SWCNT) under hydro-thermal environments are investigated. The generalized rule of

mixture is employed to predict mechanical, moisture and thermal properties of micro composite plate. The

governing equations of motion are obtained using energy method and Hamilton's principle, and solved by

differential quadrature method (DQM). There is a good agreement between the obtained results and the other results.

The influences of the material length scale, elastic foundation parameters and temperature and moisture changes for

various boundary conditions on the natural frequency, critical buckling load and deflection of the micro composite

plate reinforced by FG-SWCNT are presented. The obtained results show that critical buckling load and natural

frequency for MSGT are more than that of for classic theory (CT) and modified coupled stress theory (MCST), and

vice versa for the deflection. The material length scale parameters lead to increase the stiffness of system. Also the

effect of moisture on microcomposite plate reinforced by SWCNT is similar to thermal effect; also, with increasing

of moisture change reduces the natural frequency and critical buckling load and increases the deflection of micro

composite plate. Considering the environmental conditions and temperature results are closer to reality.

Keywords: Bending, buckling and free vibration analysis; Micro composite Reddy plate; Hygro-thermal

environments; Generalized rule of mixtures; Temperature- dependent material properties; MSGT.

*

Corresponding author: E-mail: mmohammadimehr@kashanu.ac.ir

Tel:+ 98 31 55912423 Fax: +98 31 55912424

1

1-Introduction

The polymeric composite material is employed in various industrial aspects. They have some

disadvantages which limited them in particular applications. For enhancement their material

properties, various reinforcement can be added to them. This reinforced composite material can

be used in microactuators, microtransducers, microsensor and so on, also because of the high

strength and low weight can be widely used in different industries, including aerospace and

shipping.

Recently many researches have been done in functionally graded carbon nanotube reinforced

composite (FG-CNTRC) materials field that Liew et al. [1] have a review of these papers. Also,

in this section, some of these important works are presented. Abdollahzadeh Shahrbabaki and

Alibeigloo [2] investigated three-dimensional free vibration of carbon nanotube (CNT)

reinforced composite rectangular plates with various boundary conditions by developing a set of

orthogonal admissible functions using Ritz method. They achieved non-dimensional frequencies

vary from minimum values for the plate with CFFF to the maximum values for the plate with

CCCC boundary conditions. Using the first-order shear deformation theory (FSDT) and elementfree improved moving least-squares-Ritz (IMLS-Ritz) method, Zhang et al. [3] carried out free

vibration analysis of functionally graded carbon nanotube (FG-CNT) reinforced composite

triangular plates. Ghorbanpour Arani et al. [4] analyzed the surface stress effect on the biaxial

critical buckling load of nonlocal polymeric nanocomposite rectangular plate reinforced by

CNTs. They showed the biaxial critical buckling load decreases with increasing the CNTs

volume fraction in the inclusion (agglomeration effect).

Yin et al. [5] performed the dynamic analysis of micro non-classical Kirchohof plate based on

modified couple stress theory (MCST). They found that as the thickness to be comparable with

2

material length scale parameter, the MCST natural frequency is dependent on the size effect.

Hasani Baferani et al. [6] studied vibration of rectangular functionally graded Reddy plate based

on elastic foundation. They observed that the frequency more increases as the power law index

of functionally graded material increases. Wang and co-workers [7] presented vibration and

static analysis of rectangular Kirchhoff plate based on the strain gradient theory (SGT). They

found that the stiffness, the critical buckling load and natural frequency affected significantly

using the size-dependent effect. Jomehzadeh et al. [8] analyzed vibration micro plate based on

MCST. They obtained by applying the material length scale parameter increases the stiffness and

natural frequency of the micro plate. Ramezani [9] developed buckling and vibration of micro

plate based on SGT and FSDT. He also showed that the size dependent effect at the micro scale

is significant. Ke et al. [10] examined the vibration analysis of micro plate based on MCST and

FSDT. They concluded that as the thickness is close to the material length scale parameter, the

size effect on the natural frequency of micro plate is important. Thai and Choi [11] extended the

size dependent effect on the bending, buckling and vibration of Kirchhoff and Mindlin

functionally graded plate based on MCST. Their numerical results displayed that considering the

small-scale parameters leads to reduce bending and increases critical buckling load and natural

frequency. Zhang and Liew [12] studied geometrically nonlinear large deformation analysis of

FG-CNTRC quadrilateral plates, and using IMLS approximation for the field variables, they

improved the obtained results. Sahmani and Ansari [13] investigated vibration of functionally

graded micro plate based on SGT. They showed that as the thickness reaches to the material

length scale parameter, the natural frequency is significantly increased. Thai and Kim [14]

studied bending and free vibration analysis of functionally graded Reddy plate. They discovered

that when the thickness is smaller than the small scale parameter, size dependent effect on the

3

natural frequency is important but as the thickness increases, its effect will be negligible. Kim

and Reddy [15] presented exact solution for functionally graded Reddy plate according to

MCST. They illustrated that the plate becomes stiffener considering the small scale effects.

Furthermore the critical buckling load reduced by decreasing of power law index of functionally

graded plate. Zhang and his co-workers [16] used mesh-free kp-Ritz for analysis flexural

strength and free vibration of carbon nanotube reinforced composite cylindrical panels. Thai and

Choi [17] developed two variable plate theories for bending, buckling and vibration of

rectangular plate. Their results have a best agreement with results of FSDT and third order shear

deformation theory (TSDT).

Reddy and Berry [18] used Kirchhoff and FSDT to analyze the bending of circular plate based

on MCST. They presented the analytical solutions of bending, buckling, and free vibration for

the linear case and finite-element models for the nonlinear case to determine the effect of the

geometric nonlinearity, power law index, and microstructure-dependent constitutive relations on

linear and nonlinear response of axisymmetric analysis of circular plates. Mozafari and Ayob

[19] presented the exact solution for buckling of functionally graded plate using FSDT and

TSDT. They concluded that the critical buckling load decreases with increasing of aspect ratio

and power law index. Zhu et al. [20] developed a meshless local Petrov-Galerkin approach for

geometric nonlinear thermoelastic analysis of functionally graded plates in thermal

environments. Jarali et al. [21] studied the effect of electrical, thermal and moisture properties of

carbon nanotubes (CNTs) in composites considering the CNTs accumulation. They noticed that

CNT agglomeration has a strong influence on the effective hygro-thermo-electric properties of

the nanocomposites. Nonlinear bending of spherical shell under hydro-thermo-mechanical loads

is examined by Lal et al. [22]. They used higher-order shear deformation theory and micro-

4

mechanical model in their study and examined the hygrothermal effects are more detrimental as

the working temperature increases and reaches closer to the glass transition temperature. Lei et

al. [23] investigated the buckling analysis of functionally graded carbon nanotube reinforced

composite plate using Ritz method. They employed Mori-Tanaka- model to estimate material

properties of the composite plate. They showed that the effects of carbon nanotube volume

fraction, plate width-to-thickness ratio and temperature change have distinct effects on buckling

strength of CNT. The buckling, bending and free vibration analysis of functionally graded

carbon nanotubes reinforced composite beam using the finite element method (FEM) is carried

out by Mayandi and Jeyaraj [24]. They used the extended rule of mixture to define the

mechanical material properties, and then found the critical buckling temperature is not increasing

significantly with an increase in volume fraction of the CNT. Ghorbanpour Arani et al. [25]

investigated the buckling analysis of single-walled carbon nanotube (SWCNT) reinforced

composite plate using FEM. They reported that non uniform dispersion of CNTs in the polymer

matrix decreases the critical buckling load. Moreover, it increases the difference between the

critical buckling loads obtained by the analytical method and the FEM.

Rafiee et al. [26] studied the dynamic stability of FG-CNT reinforced piezoelectric composite

plate under electro-thermal loadings. They showed that the influence of the temperature rise on

the thin plates is more significant than the thicker one. Zhang et al. [27] carried out FG-CNTRC

moderately thick rectangular plates with edges elastically restrained against transverse

displacements and rotation of the plate cross section. They found when the elastic restraint

parameter Kφ is greater than 105, the natural frequency parameters vary slowly due to the fact

that the stiffness of the spring is great enough to serve as a rigid restraint. Shooshtari and Rafiee

[28] studied vibrations of composite plate reinforced by SWCNTs. It is assumed the properties of

5

SWCNTs to be related to temperature change and theirs obtained from molecular dynamics

simulation. They found that the nonlinear natural frequency to linear natural frequency ratio

increases with increasing of SWCNTs volume fraction. Mohammadimehr et al. [29] considered

the small-scale effect on torsional critical buckling load of double-walled carbon nanotubes

based on Winkler-Pasternak foundation using non-local elasticity theory. Their result disclosed

that the nonlocal critical buckling load increases with increasing of Pasternak shear constant.

Moreover nonlocal critical buckling load is lower than local critical buckling load. Liew et al.

[30] completed post-buckling analysis of cylindrical SWCNTs reinforced nanocomposite panel

subjected to axial compression. They investigated the effects of boundary conditions and

SWCNTs arrangement on the post buckling. Ghorbanpour Arani and his coworkers [31]

accomplished nonlinear vibrations of rectangular polymeric piezoelectric microcomposite plate

reinforced by double zigzag boron nitride nanotubes. They illustrated that with an increase in

elastic coefficients, aspect ratio and volume fraction of boron nitride nanotubes increase the

nonlinear natural frequency while with an increase in the non-local parameter, it reduces.

Bodaghi and Saidi [32] presented Levy solution for the buckling analysis of functional graded

thick rectangular plate. They evaluated effects of boundary conditions, power law index type of

loadings and thickness on the post buckling of the composite plate. Ansari et al. [33] established

vibration analysis of functionally graded Mindlin micro plate with nonlinear geometry. They

solved system of nonlinear equations using the quadratic differential generalized method and

examined the influences of power law index, length to thickness ratio, length scale and different

boundary conditions on natural frequency. Zhang et al. [34] used the IMLS method to present a

set of first known vibration frequencies and mode shapes for FG-CNTRC skew plates is

obtained. Sahmani and Ansari [35] studied free vibration of micro composite plate according to

6

micromechanical Mori-Tanaka approach. They demonstrated that with an increase in the

material length scale parameter, the natural frequency increases considerably. The effects of

material length scale parameter and hydro-thermal loadings on bending of nanoplate surrounded

in elastic medium are investigated by Alzahrani et al. [36]. Mohammadimehr and Salemi [37]

developed SGT for bending and buckling analysis of FG Mindlin nanoplate. They concluded that

considering SGT leads to increase stiffness of nanoplate. Alibeigloo [38] studied the bending

behavior of simply supported functionally graded carbon nanotube reinforced composite plate in

the piezoelectric layer using three dimensional elasticity theory. Bodaghi and Saidi [39] offered

obtained the exact solution for buckling of functionally graded rectangular plate under nonuniformly axial load. Zhang et al. [40] studied the mechanical and thermal buckling analyses of

different types of functionally grade plates by developed the local meshless method based on the

local Petrov–Galerkin weak-form formulation combined with shape functions having the

Kronecker delta function property, constructed by the Kriging interpolation. Jomehzadeh et al.

[41] analyzed the vibration analysis of microplate based on MCST. They concluded that with an

increase in the material length scale parameter increases the stiffness and the natural frequency.

The effect of the SWCNTs volume fraction on electro-magneto-thermal behavior of functionally

graded cylindrical nanocomposite plate is evaluated by Ghorbanpour Arani et al. [42]. Nonlinear

vibrations of rectangle graphene sheets in the thermal environment are established by Shen et al.

[43]. Their results exhibited that with the correct select of the small scale parameters and the

material properties, the nonlocal model presented exact prediction of nonlinear vibration

behavior in thermal environment. Mohammadimehr et al. [44] studied the buckling of doublewalled carbon nanotube surrounded by the elastic foundation under axial compression using

Timoshenko beam theory. Lei et al. [45] considered different distributions of SWCNTs through

7

the thickness of layers to study the free vibration analysis of laminated FG-CNT reinforced

composite rectangular plates using the element-free kp-Ritz method. Using this method, they

[46] studied dynamic stability of carbon nanotube-reinforced functionally graded cylindrical

panels. Rahmati and Mohammadimehr [47] analyzed axial vibration of non-uniform and

heterogeneous boron nitride nanorod embedded in an elastic foundation. They concluded that

with an increase in small-scale parameter and elastic foundation constants reduces the nondimensional frequency ratio.

Zhang et al. [48] presented the nonlinear bending behaviors of FG-CNT reinforced composite

thick plates. Using the element-free IMLS-Ritz method, they observed that the non-dimensional

central deflections of the FG-CNT reinforced composite plates rise as the load increases. Also

they developed this method to large deflection and buckling analysis of FG-CNT reinforced

composite skew plates for numerical solution of three-dimensional wave propagation equations

and for elasto-dynamic problems [49-52]. Mohammadimehr et al. [53] investigated vibration of

viscoelastic piezoelectric polymeric nanocomposit plate reinforced by FG-SWCNTs using

meshless method based on modified strain gradient theory (MSGT) and sinusoidal shear

deformation theory. They concluded that the natural frequency increases with increasing of

elastic foundation parameter, small scale parameters, and magnetic field.

In this article, bending and buckling, and free vibration analysis of micro composite Reddy plate

reinforced by FG-SWCNTs embedded in an elastic foundation and hydro-thermal environments

with temperature- dependent material properties are investigated. The generalized rule of

mixture is used to define hydro-thermo-mechanical material properties. Three material length

scale parameters are considered by MSGT. The governing equations of motion using Hamilton’s

principle are obtained and solved by differential quadrature method (DQM).

8

2- Geometry

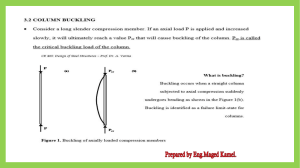

According to Fig. 1, the micro composite rectangular Reddy plate is considered with length a ,

width b and thickness h . This micro composite plate rested on elastic foundation with Winkler

coefficient K w and Pasternak shear coefficient K G . Fig. 2 shows the distribution of FGSWCNTs in micro composite Reddy plate. Uniform distribution (UD), FG-O, FG-V and FG-X

are assumed to reinforce the micro composite plate. Volume fraction for these distributions is

defined as follows [54]:

V CNT

*

V CNT

1 2z V *

CNT

h

2z *

z 2 1 V CNT

h

2z

*

V r 2

V CNT

h

UD

CNTRC

FG V

CNTRC

FG O

CNTRC

FG X

CNTRC

(1)

where:

*

V CNT

w CNT

CNT

w CNT

/ m CNT / m w CNT

(2)

w CNT , m and CNT are SWCNTs mass fraction, matrix density and SWCNTs density,

respectively. Mass and volume of SWCNTs is same for four SWCNT distributions.

9

3- Generalized rule of mixture

The generalized rule of mixture for estimation of hydro-thermo-mechanical properties of micro

composite plate reinforced by FG-SWCNTs are expressed as follows:

Mechanical properties:

E11 1V CNT E11CNT V m E m

2

(3-a)

V CNT V m

CNT

E 22

Em

(3-b)

V CNT V m

G12CNT G m

(3-c)

V CNT CNT V m m

(3-d)

E 22

3

G12

where, i (i 1,2,3) denotes force transformation between SWCNTs and polymeric matrix.

V m is matrix volume fraction.

Thermal properties:

11 V CNT 11CNT V m m

(4-a)

CNT

22 1 12CNT V CNT 22

1 m V m m 1211

(4-b)

and hydro properties:

11 V CNT 11CNT V m m

(5-a)

22 1 12CNT V CNT 12CNT 1 m V m m 12 11

(5-a)

10

4- Governing equations

Displacement fields of the micro composite plate according to Reddy plate theory (third-order

shear deformation theory (TSDT)) can be written as follows [54]:

w

u ( x, y, z , t ) u0 ( x, y, t ) z x ( x, y, t ) c1 z 3 x 0

x

w

v( x, y, z , t ) v0 ( x, y, t ) z y ( x, y, t ) c1 z 3 y 0

y

(6)

w( x, y, z, t ) w0 ( x, y, t )

where, u 0 , v 0 , and w 0 denote middle surface displacements. x and y are the rotation of

middle surface at z 0 . c1

4

and c1 0 are for TSDT and FSDT, respectively.

3h 2

Strain- displacement relations according to TSDT can be expressed as:

x

2 w0

1 w

0 z x c1 z 3 x

x 2 x

x

x 2

x

u0

2

y

y 2 w0

1 w

y

0 z

c1 z 3

y 2 y

y

y 2

y

2

v0

y

2 w0

x y

3 x

xy

z

c1 z y x 2 xy

y

x

x y

x

y

u0

v0

w0 w0

w

xz 1 3c1 z 2 x 0

x

w0

2

, yz 1 3c1 z y

y

Using Hook's law, stress- strain relations can be stated as follows:

11

(7)

0

0 xx 11 (z )T 11 (z )H

xx Q11 Q12 0

0

0 yy 22 (z )T 22 (z )H

yy Q12 Q 22 0

yz

0 Q 44 0

0

yz 0

0

xz

0

0 Q 55 0

xz

xy

0

0

0 Q 66

xy 0

(8)

where, T and H denote temperature and moisture changes and Qij is defined as follows:

Q11 (z )

E 11 (z )

1 12 (z )21 (z )

Q 22 (z )

E 22 (z )

1 12 ( z )21 ( z )

Q12 (z )

21 (z )E 11 (z )

1 12 (z )21 (z )

Q 44 (z ) G 23 (z )

E 22 (z )

2 1 23 (z )

(9)

Q 55 (z ) Q 66 (z ) G12 (z )

The governing equations based on minimum potential energy principle are obtained as follows:

U V

t2

t1

T dt 0

(10)

where U , T and V are strain energy, kinematic energy and work done by external forces,

respectively. The variation of kinetic energy can be written as:

12

T u u v v w w z dAdz

V

T I 0 u0 u0 v0 v0 w0 w0 I1 x u0 u0 x y v0 y v0

A

w0

w

I 2 x x y y c1 I 3 u0 x

u0 x 0

x

x

w0

w0

w0

v0 y

v0 y

c1 I 4 x x

y

y

x

(11)

w

w0

w0

x x 0 y y

y y

x

y

y

w

w0

w0

w0

c12 I 6 x 0 x

y

y

dxdy

x

x

y

y

Work done by external forces can be stated as:

V q (x , y ) k w w 0 k G 2w wdA

(12)

A

where q( x, y) is transverse load per length.

The variation of strain energy based on MSGT can be obtained as follows:

U

A

h /2

x

x y y xy xy xz xz yz yz p x x

h / 2

p y y p z z xxx xxx yyy yyy zzz zzz 6 xyz xyz

3 xxy xxy 3 xxz xxz 3 yyx yyx 3 yyz yyz 3 zzx zzx 3 zzy zzy

m xx xx m yy yy m zz zz 2m xy xy 2m xz xz 2m yz yz dzdA

13

(13)

where ijk(1) , ijs and i are deviatoric stretch gradient tensor, symmetric rotation gradient tensor and

dilatation gradient vector according to TSDT and Eqs. (7)- (9) can be obtained as the following

form:

(1)

xxx

3

3

1 2u 0 2u 0

2v 0

w 0

3 w0

3 w0

2 2 2 2

6c1z

2c1z

3c1z

5 x

y

y x

x

x 3

y 2x

2

w 0 2w 0 w 0 2w 0

w 0 w 0

2

2

6c1z x

2

2

x x

y y x x y

2x 2x

2y

z c1z 3 2

2

x 2 y 2

y

x

(1)

yyy

3

3

1 2v 0 2v 0

2u 0

w 0

3 w0

3 w0

2 2 2 2

6c1z

2c1z

3c1z

5 y

x

y x

y

y 3

x 2y

2

2

w 0 2w 0

w 0 w 0 w 0 w 0

2

2

6c1z y

2

2

x y x y x

y y

2y 2 y

2x

z c1z 3 2

2

y 2 x 2

y

x

2w

1

2w 0 x y x y

z(1)zz 6c1z 2 1 20

5

y 2

x

y x

y

x

(1)

(1)

(1)

(1)

(1)

xyz

yzx

zxy

zyx

yxz

x(1)zy

2

1

2 w 0

c

z

x y

1

x

3

y x y

(1)

(1)

(1)

xxy

xyx

yxx

2

2 w0

c

z

1

y x

8 2u 0

4 2v 0 1 2v 0 2

c1z

15 y x 15 x 2 5 y 2 5

w 0

y

y

2x

2y

2y

4

8

2

x 2

y x y

4 2w 0 w 0 8 w 0 2w 0 1 w 0 2w 0

15 x 2 y 15 x y x 5 y y 2

1 3 3w 0

3w 0 1

c1z

4

z c1z 3

3

2

5

y

y

x

15

(1)

(1)

xxz

xzx

z(1)xx

2

2w 0 2 2 2 y

2 2 1 w 0

4

c1z

4 x

c1z

2

2

15 y

x 5

15 y

x

5

14

(1)

yyx

(1)

yxy

(1)

xyy

4 2u 0 1 2u 0 8 2v 0 2

w 0

c1z x

2

2

15 y

5 x

15 y x 5

x

2 y

2x

2x

4

8

2

y 2

y x x

4 2w 0 w 0 8 w 0 2w 0 1 w 0 2w 0

15 y 2 x 15 y y x 5 x x 2

1 3 3w 0

3w 0 1

c1z

4

z c1z 3

3

2

5

x

x

y

15

(1)

(1)

(1)

yyz

yzy

zyy

2

2w 0 2 2 2 x

2 2 1 w 0

c

z

4

c1z

4 y

1

2

2

15 x

y 5

15 x

y

5

(1)

(1)

zz(1)x zxz

xzz

1 2u 0 1 2u 0 2 2v 0 8

c1z

5 x 2 15 y 2 15 y x 5

w 0

x

x

2x

2y

2x

2

3

2

y x

x 2

y

1 w 0 2w 0 2 w 0 2w 0 1 w 0 2w 0

5 x x 2 15 y y x 15 x y 2

1 3 3w 0

3w 0

c1z

3

5

y 2x

x

1

c1z 3 z

15

(1)

(1)

(1)

zzy

zyz

yzz

w 0

y

y

2 y

2 y

1 3 3w 0

3w 0 1

2x

3

c1z

c

z

z

2

3

1

3

2

5

x 2y 15

y x

y 2

y

x

1 w 0 2w 0 2 w 0 2w 0 1 w 0 2w 0

5 y y 2 15 x y x 15 y x 2

1 2v 0 1 2v 0 2 2u 0 8

c1z

5 y 2 15 x 2 15 y x 5

(14-a)

1

2w 0

xxs 1 3c1z 2

1 3c1z 2 y

2

x y

x

1

2w 0

yys 1 3c1z 2

1 3c1z 2 x

2

x y

y

1

2

y x

y

x

zzs 1 3c1z 2

15

(14-b)

1

4

2w 0 2w 0

1 3c1z 2 x y

2

2

x

y

x

y

xys yxs 1 3c1z 2

s

zx

1 2v

2u 0

20

z 1 c1z 2

4 x

x y

s

zy

1 2v 0 2u 0

z 1 c1z 2

4 x y y 2

s

xz

s

yz

2y

2x

2

x y

x

6c1z

w 0

y

y

2y

2x

2

x y y

6c1z

w 0

x

x

3

2u 0 2v 0

3w 0

3 w 0

x 2

c1z

2 z c1z 3

3

x

y x

y x

x

2x

2y

2

y x

x

2x

2y

2

y x

x

2

2

w 0 w 0 w 0 w 0

2

x x y y x

3

2u 0 2v 0

3w 0

3 w 0

y

c

z

1

3

y x y 2

x 2y

y

2

w 0 w 0

x y x

3

z c1z

(14-c)

w 0 2w 0

2

y y

2w 0 2w 0

1 3c1z 2 x y

2

2

y

y

x

x

z 3c1z 2

Also the following relations for higher-order stresses can be defined as:

M ijh k s ij z h dz i x , y ; j z & h 0,1, 2,3

z

Pi p i z h dz i , j x , y , z & h 0,1, 2

h

z

Y

h

ij

T

h

ijk

(15)

m ijs z h dz i , j x , y , z & h 0,1, 2

z

(1) h

ijk

z dz i , j , k x , y , z & h 0,1, 2

z

where k s is the shear correction factor.

16

Substituting Eqs. (9),(15) and (14) in Eq. (13), the variation of strain energy for MSGT Reddy

microcomposite plate reinforced by SWCNTs subjected to hydro-thermo-mechanical loadings

are given in detail in Appendix A.

Using Eq. (A.1) and separation of variables, the following governing equations of motion for

microcomposite plate reinforced by SWCNTs based on MSGT and TSDT are obtained as

follows:

For u 0 :

0

2 0

2 0

0

0

M xx0 M xy 2 Px0 Py

2 2T xxx

1 2T xxx

2 T yyy

x

y

x 2 x y 5 x 2

5 y 2

5 x y

0

0

8 T xxy 4 T yyx 3 T yyx 3 2T zzx

1 2T zzx

2 T zzy

2

2

2

2

5 x y 5 y

5 x

5 x

5 y

5 x y

2

0

2

0

2

0

2

0

(16)

1 2Y xz0 1 Y yz

2u 0

2x

3w 0

I

(

c

I

I

)

c

I

0

1 3

1

1 3

2 x y 2 y 2

t 2

t 2

x t 2

2

0

For v 0 :

M yy0

y

M xy0

x

2 Py0

y 2

0

2 Px0 2 T yyy 1 T yyy 2 2T xxx

x y 5 y 2

5 x 2

5 x y

2

0

2

0

0

8 T yyx 4 T xxy 3 T xxy 3 T zzy 1 T zzy 2 2T zzx

5 x y 5 x 2

5 y 2

5 y 2

5 x 2

5 x y

2

0

2

0

2

0

2

0

2

0

y

1 Y xy 1 2Y xz0

2v 0

3w 0

I

(

c

I

I

)

c

I

0

1 3

1

1 3

2 x y 2 x 2

t 2

t 2

y t 2

2

0

2

For w 0 :

17

(17)

M

0

xx

2

2

2 M xy3

2w 0

2 M xx3

2 M xx3

0 w0

0 w0

c1

M yy

c1

2M xy

2c1

x 2

x 2

y 2

x 2

x y

x y

0

3Py3

M yz2

3Px3

M xz0

M xz2 M yz

3Px3

3c1

3c1

c1

2 c1

3

y 3

x

x

y

y

y x

x

1

3

3

3Py3

2 Pz2 2 Pz2 6 T xxx

2 3T xxx

3 3T xxx

3

c

c

c

c

1

1

1

1

2

x 2y

y 2 5

x

5

x 3

5 y 2x

x

0

0

2

2

6 T yyy 2 T yyy 1 2T zzz

1 2T zzz

6 2T zzz

6 2T zzz

c1

c1

c

c

1

1

5

y

5

y 3

5 x 2

5 y 2

5 x 2

5 y 2

1

0

2T xyz

3

3

2

2T xyz

1

3 3

2 3

0

6 T xxy 3 T xxy 12 T xxy 4 2T xxz

2

12c1

c1

c1

c1

y x

y x 5

y

5 y 3

5 y x 2 5 x 2

2 3

1

3 3

2 3

2

2

1 T xxy 24 2T xxz

6 T xxz

6 T yyx 3 T yyx 12 T yyx

c1

c1

c1

c1

c1

5 y 2

5

x 2

5 y 2 5

x

5 x 3

5 x y 2

3

3

4 T yyz 1 T yyz 24 T yyz 6 T yyz 3 3T zzx

3 3T zzx

c

c

c

1

1

1

5 y 2

5 x 2

5

y 2

5 x 2 5 x 3

5 x y 2

2

0

2

3

2

2

2

3 3

3 3

1

1

24 T zzx

3 T zzy 3 T zzy

24 T zzy 1 2Y xx0 3 2Y xx2

c1

c

c

c1

1

1

5

x

5 y 3

5 y x 2 5

y

2 y x 2 y x

2 0

2 2

2 0

2 0

2 2

2 2

1 Y yy 3 Y yy 1 Y xy 1 Y xy 3 Y xy 3 Y xy

c1

c1

c1

2 y x 2 y x 2 y 2

2 x 2

2 y 2

2 y 2

Y yz

3u 0

Y xz1

2w 0

3v 0

3c1

q I0

I

c

3 1

2

2

y

x

t 2

t x t y

1

3c1

3

3

c1 I 4 I 6c1 2 x 2 y

t x t y

4

4w 0

2 w0

I

c

6 1 2 2

t 2y 2

t x

(18)

For x :

18

1

1

M xy3

M xx

M xx3 M xy

2 Px1

Px3

c1

c1

M xz0 3c1M xz2

c

1

x

x

y

y

x 2

x 2

2 Py1

c1

x y

2 T

c1

5

x

2

2

0

T xyz

y

3

xxx

2

Py3

x y

1

1

Pz0

P 2 2 2T xxx

1 2T xxx

6

1

3c1 z

c1T xxx

2

2

x

x

5 x

5 y

5

3

0

1 2T xxx

2 T yyy 2 T yyy 2 T zzz

6 T zzz2

c1

c1

c1

5 y 2

5 x y 5 x y 5 x

5 x

6c1

2

2

T xyz

y

1

2

3

0

8 T xxy 8 T xxy 8 T xxz

24 T 2

c1

c1 xxz

5 x y 5 x y 5 x

5

x

2

1

2

3

6 1

4 T yyx 3 T yyx 4 T yyx 3 T yyx 2 T yyz

c1T yyx

c1

c1

5

5 y 2

5 x 2

5

y 2

5

x 2

5 x

2

1

2

1

2

3

2

3

0

1

3

3

6 T yyz 3 2T z1zx 1 2T zzx

3 2T zzx

1 2T zzx

24

1

c1

c

c

c1T zzx

1

1

2

2

2

2

5

x

5 x

5 y

5 x

5 y

5

2

2 1

2 3

0

2

2 T zzy 2 T zzy 1 Y yy 3 Y yy 1 Y zz0 3 Y zz2

c1

c1

c1

5 x y 5 x y 2 y

2

y

2 y

2 y

1 Y xy 3 Y xy 1 2Y xz1 1 2Y xz3 1 Y yz 1 Y yz

c1

c1

c1

2 x

2

x

2 x y 2 x y 2 y 2

2 y 2

0

2

1

3cY

1 yz I 1 c1I 3

2

1

2

3

2u 0

2x

3w 0

2

I

2

c

I

c

I

c

I

c

I

2

1 4

1 6

1 4

1 6

t 2

t 2

x t 2

For y :

19

(19)

1

M yy

c1

y

M yy3

y

1

M xy

c1

x

M xy3

M

x

0

yz

3c1M

2

yz

2 Py1

y 2

c1

Py3

y 2

2 Px1

Px3

P 0

P 2 2 T yyy 1 T yyy 6

1

c1

z 3c1 z

c1T yyy

2

2

x y

x y

y

y

5 y

5 x

5

2

1

2

1

1

3

0

2 T yyy 1 T yyy 2 2T xxx

2 2T xxx

2 T zzz

6 T zzz2

c1

c

c

c1

1

1

5

y 2

5 x 2

5 x y 5 x y 5 y

5 y

2

2

0

T xyz

x

3

6c1

2

2

T xyz

3

8 T yyx 8 T yyx 8 T yyz 24 T yyz

c1

c1

5 x y 5 x y 5 y

5

y

2

x

1

2

3

0

2

0

6 1

4 T xxy 3 T xxy 4 T xxy 3 T xxy 2 T xxz

c1T xxy

c1

c1

5

5 x 2

5 y 2

5

x 2

5

y 2

5 y

2

1

2

1

2

3

2

3

(20)

2

6 T xxz

3 T z zy 1 T zzy 3 T zzy 1 T zzy 24

1

c1

c1

c1

c1T zzy

5

y

5 y 2

5 x 2

5 y 2

5 x 2

5

2

1

2

1

2

3

2

3

1

3

2 2T zzx

2 2T zzx

1 Y xx0 3 Y xx2 1 Y zz0 3 Y zz2

c1

c1

c1

5 x y 5 x y 2 x

2

x

2 x

2 x

0

2

2 1

2 3

1 Y xy 3 Y xy 1 Y yz 1 Y yz 1 2Y xz1 1 2Y xz3

c1

c1

c1

2 y

2

y

2 x y 2 x y 2 y 2

2 x 2

1

1 xz

3cY

2 y

2v 0

3w 0

2

I 1 c1I 3 2 I 2 2c1I 4 c1 I 6

c1 I 4 c1I 6

t

t 2

y t 2

Dimensionless parameters are defined as:

u0

a

z

h

q

q

Em

v0

b

a

1

h

u

D

t

h

i,j

v

Ii

Em

m

Ii

m h i 1

, D i , j , D i, j

w0

x

y

h

a

b

b

l

2

c1 c1h 2

li i

h

h

2

2

12(1 )Na

N

x x

y y

Emh3

w

2

a

h

m

Em

Kw

Kw h

Em

1

D , T D i , j , HD i , j

j 1 i , j

Emh

where:

20

KG

KG

Emh

(21)

D

1, i

,D

1, i

,D

h /2

1, i

Q11 (z ) * z i 1,11 (z ), 11 (z )dz

h / 2

D

2, i , D 4, i , D 4, i

h /2

Q 22 (z ) * z i 1, 22 (z ), 22 (z )dz

h / 2

D 3, i , D 2, i , D

D 3, i , D 3, i

2,i

h /2

,

i

Q12 (z ) * z 1,11 (z ), 11 (z ), 22 (z ), 22 ( z )dz

h / 2

(22)

h /2

D

Q 44 (z ) * z i dz

4, i

h / 2

h /2

D

5, i

i

Q 55 (z ) * z i dz

0...6

h / 2

Using stresses and dimensionless parameters, the dimensionless governing equations of motion

for MSGT Reddy microcomposite plate reinforced by SWCNTs with considering hydro-thermomechanical loadings are expressed in detail in Appendix B.

Clamped and simply supported, free boundary conditions are considered for the micro composite

plate in detail in Appendix C.

5- Solving method

DQM is employed to solve the governing equations. In this method, derivative of any arbitrary

function in arbitrary point as f x, y xi , yi can be rewritten in all interval as follows:

d rf

dx r

d sf

dy s

N

x , y x i , y j

A in r f nj

n 1

M

x , y x i , y j

r s f

x r y s

i 1, 2,..., N

s

A jm

f im

m 1

N

x , y x i , y j

j 1, 2,..., M

r 1, 2,..., N 1

(23)

M

s

A in r A jm

f nm

n 1 m 1

s 1, 2,..., M 1

r

where f ij f x i , y j and A is weighted coefficient matrixes which are defined as ( in x

direction):

21

(1)

A ij

N

(x i x m )

mm 1i , j

, (i , j 1, 2,3,..., N ; i j )

N

(x j x m )

m 1

mj

N

1

, (i j 1, 2,3,..., N )

m 1 (x i x m )

m i

A r A r 1 A 1

(24)

2 r N 1

A well-accepted set of the grid points is given by the Gauss–Lobatto–Chebyshev points for

interval [0, L] that these set of grid points in terms of natural coordinate directions xi and yi are

defined as:

xi

1

(i 1)

]

1 cos[

2

(N 1)

yj

1

( j 1)

]

1 cos[

2

(M 1)

(25)

In two dimensional problems, we have:

uv f ij

v j 1 N i

(26)

Using above expression, the following relations are obtained as follows:

a f b b

T

a u

(27)

where symbol denotes Hadamard products. The following definitions in x and y directions

are used to simplification of relations:

x : A x A 1

B x A 2

C x A 3

D x A 4

y : A y A 1

B y A 2

C y A 3

D y A 4

22

(28)

Using above definitions, the governing equations F and boundary conditions T

rewritten as

differential quadrature form then according to boundary conditions and order of differential

equation for each of displacement variables, displacement vector divided to domain vector U d

and boundary displacement vector U b . In the next step, rows of F which belong to boundary

points are eliminated and matrix, F is obtained. Then column of boundary condition and the

governing equation matrices for boundary points and domain separated and matrix of the

governing equations of boundary points, F b , domain F d and matrices of boundary

conditions for boundary points T

b

and domain T

d

are obtained finally they are related

together with following relation:

F b U b F d U d 0

(29)

T b U b T d U d

(30)

U

b

0

b T d U d

T

1

(31)

Substituting Eq. (31) into Eq. (29), the following equation is derived as follows:

F T

1

b

b

T d F d U d

0

Z U d

0

(32)

For bending analysis, the following equation is used:

K U q

(33)

23

q

where K and

U

are stiffness and external distributed load matrixes.

denotes

displacement vector which are demonstrated as:

U u

v

y

T

x

w

(34)

If Eq. (32) rewritten as Eq. (33), the deflection are determined as follows:

K T

1

b

b

T d K d U d

[q ]d U d K b T

b T d K d

1

1

[q ]d

(35)

Also the critical buckling load is obtained as the following form:

K1 U N K2 U

(36)

where K1 , K 2 , N , and U are stiffness matrices, the critical buckling load and mode

shape. The above equation can be rewritten in the form of boundary points and domain, the

critical buckling load is obtained as:

K T T K U N K T T K U

K T T K N K T T K U

1

1 b

1

b

1 d

d

2 b

d

b

1

1 b

2 d

d

d

1

b

d

1 d

2 b

b

d

2 d

d

0

(37)

For vibration analysis, at first the time expression replaced by following equations:

u0 , , U 0 , ei

v0 , , V0 , ei

w0 , , W0 , ei

x , , x , e

(38)

i

y , , y , ei

24

where , U 0 , , V0 , , W0 , , x , and y , denote dimensionless

frequency and dimensionless vibration domains. The dimensionless natural frequency and

domain are obtained as follows:

K T T K U M T T M U

K T T K M T T M U

1

1 b

1

2

b

1 d

d

2 b

d

1

1 b

b

b

1 d

d

1

2

d

2 d

d

2 b

25

b

d

2 d

d

0

(39)

6- Numerical results and discussion

The numerical results of vibration, buckling and bending of micro composite plate reinforced by

FG-SWCNTs under the distributed load q 0.1MPa and N x f1 Ncr ; N y f 2 Ncr ; N xy 0 are

presented.

The temperature- dependent mechanical properties of PmPV (Poly {(mphenylenevinylene)-co[(2,5-dioctoxy-p-phenylene)vinylene]}) as the matrix are considered as follows [55]:

vm = 0.34

(40)

αm = 45(1 + 0.0005 ΔT) × 10 −6/ K

βm = 2.67(1 + 0.0005 ΔT) × 10 −6/ K

Em = (3.51-0.0047T) GPa

where T = T0+ΔT and T0 = 300 K (room temperature) [55]. It is noted that the temperature of the

top and bottom surfaces is the same. On the other hand, the temperature throughout the thickness

is constant.

The temperature- dependent material properties of armchair SWCNTs (10, 10) as reinforcement

are listed in Table 1 [56].

i coefficients for different SWCNTs volume fractions are shown in Table 2 [57].

The obtained results for Mindlin plate are compared with results of Refs. [23] and [57]. These

results are listed in Tables 3, 4 and 5. A good agreement is observed between DQM results

(present work) and the obtained results by the other researchers.

26

6-1- Bending and buckling of the micro composite Reddy plate reinforced by SWCNTs

The dimensionless deflection ( VCNT 0.11 ) and the dimensionless critical buckling load

( VCNT 0.11 ) of the micro composite plate are calculated for various distribution types of

SWCNT and boundary conditions. Also, the effects of different parameters are examined for

them. Figs. 3(a) and 3 (b), Tables 6 and 7 depict the effects of various boundary conditions on

the dimensionless deflection and the critical buckling load of the micro composite plate

reinforced by SWCNTs for different boundary conditions. In this figure, letter C, S, and F denote

clamped, simply supported, and free boundary conditions in the edge of the micro composite

plate. As it is observed from Fig. 3 (a) that the dimensionless deflection for CCCC and SSSF

have the lowest and highest values. Because of the clamped boundary condition with respect to

simply supported and free boundary conditions leads to increase stiffer of the micro composite

plate. Thus the dimensionless critical buckling load increases and vice versa for dimensionless

deflection of micro composite Reddy plate.

Figs. 4(a) and 4(b) show the effects of material length scale parameters on the dimensionless

deflection and the critical buckling load of the micro composite Reddy plate reinforced by

SWCNTs based on MSGT and MCST and CT. It is observed from this figure that considering

material length scale parameters lead to increase stiffness of the micro composite Reddy plate,

therefore the dimensionless deflection reduces while dimensionless critical buckling load

increases.

Figs. 5(a) and 5(b) illustrate the effects of SWCNT volume fraction on the dimensionless

deflection and the critical buckling load of the micro composite Reddy plate reinforced by

SWCNTs for FSDT and TSDT. It can be seen that the dimensionless deflection for TSDT is

lower than that of for FSDT but the dimensionless critical buckling load for TSDT is higher than

27

that of for FSDT. Also for both plate theories, the dimensionless deflection decreases with

increasing of SWCNT volume fraction and vice versa for dimensionless critical buckling load. It

is noticeable that the increasing volume fraction of SWCNT leads to increase stiffness of micro

composite plate. In Fig. 5a, it can be seen that there are the difference between the FSDT results

and TSDT results. Due to the TSDT, consider higher order terms, thus TSDT results have more

accurate with respect to FSDT, then, in this research the TSDT result is suitable.

Figs. 6(a) and 6(b) display the effects of various distribution types of SWCNT on the

dimensionless deflection and the critical buckling load of the micro composite plate reinforced

by SWCNTs. It is obvious that the micro composite plate is stiffer as reinforced by FG-X

distribution type rather than other distribution types. Thus it means the highest dimensionless

critical buckling load and lowest dimensionless deflection is belong to FG-X distribution type.

Effects of elastic foundation parameters on the dimensionless deflection and the critical buckling

load of the micro composite plate are illustrated in Figs. 7(a) and 7(b), respectively. It reveals

that the elastic foundation parameter enhances the stiffness of the micro composite Reddy plate

hence dimensionless deflection decreases with presence of elastic foundation but the

dimensionless critical buckling load increases in its presence.

Effects of temperature and moisture changes on the dimensionless deflection and the critical

buckling load of the micro composite plate are shown in Figs. 8a, 8b and 8c, respectively. It can

be seen from these figures that the dimensionless deflection increases with an increase in

temperature and moisture changes and this is vice versa for the dimensionless critical buckling

load that means the micro composite plate becomes softer with increasing of moisture and

temperature changes. It is noted that Figs. 8a and 8c have been plotted with considering

temperature-dependent material properties of PmPV (Eq. (40)) and SWCNTs (Table 1).

28

Fig. 9 demonstrates the dimensionless critical buckling load with respect to different axial

loading. It can be observed that applying biaxial compression loading in x and y directions of

leads the micro composite plate buckles earlier. Also the elastic modulus of the micro composite

plate in x direction due to aligning with SWCNT orientation is greater than its elastic modulus in

y direction, applying compression loading in x direction rather than y direction increases the

critical buckling load.

6-2- Vibration of the micro composite plate reinforced by SWCNTs

The dimensionless natural frequency ( VCNT 0.11 ) of the micro composite plate are obtained and

the effects of different parameters such as SWCNT volume fraction, SWCNT distribution types,

boundary conditions and material length small scale parameters are investigated.

Fig. 10 illustrates the dimensionless natural frequencies of micro composite Reddy plate based

on FSDT and TSDT for various volume fraction and aspect ratio a / h . According to this figure,

the dimensionless natural frequency based on TSDT is larger than the dimensionless natural

frequency of FSDT. Also as the SWCNT volume fraction increases, the dimensionless natural

frequency increases.

The dimensionless natural frequency of the micro composite plate against a / h for various

distribution types of SWCNTs is shown in Fig. 11. It is predictable that the micro composite

Reddy plate reinforced by FG-X SWCNTs and FG-O SWCNTs have highest and lowest

dimensionless natural frequency. This is due to that in FG-X reinforcements, SWCNTs are

linearly distributed in all areas of the micro composite plate then the micro composite plate

easily tolerated different loadings.

29

Based on various theories such as MSGT, MCST and CT, dimensionless natural frequencies of

the micro composite plate are depicted for aspect ratio of a / b in Fig. 12. It is found that the

dimensionless natural frequency increases as the material length small scale parameters increases

particularly in higher aspect ratio of a / b .

The dimensionless natural frequency of micro composite plate against elastic foundation

parameters is shown in Fig. 13. As it is expressed, stability of micro composite plate improves

with considering elastic foundation therefore the dimensionless natural frequency increases with

increasing of Winkler coefficient, KW and Pasternak shear coefficient, K G .

The dimensionless natural frequency of micro composite Reddy plate for different moisture and

temperature changes is demonstrated in Fig. 14. It is shown that with an increase in the moisture

and temperature changes, the flexibility of the micro composite plate increases. Consequently the

dimensionless natural frequency decreases with increasing of moisture and temperature changes.

It should be stated that this figure have been plotted based on temperature-dependent material

properties of PmPV (Eq. (40)) and SWCNTs (Table 1).

First six vibration mode shapes of micro composite Reddy plate with clamped boundary

conditions in its four edges are illustrated in Fig. 15. It is shown that the CCCC boundary

conditions are satisfied as well for first six vibration mode shapes.

7- Conclusions

In this paper, bending, buckling, and free vibration analysis of micro composite Mindlin and

Reddy plate reinforced by FG-SWCNTs with temperature- dependent material properties

embedded in an elastic foundation for various boundary conditions such as simply supported,

clamped, and free boundary conditions were investigated. The generalized rule of mixture is

30

employed to predict mechanical, moisture and thermal properties of micro composite Reddy

plate material. The governing equations of motion for micro composite Mindlin and Reddy plate

reinforced by FG-SWCNTs based on Hamilton’s principle are obtained and DQM is used to

solve these equations. The results of research can be listed as follows:

1- The dimensionless natural frequency and critical buckling load of the micro composite

plate decreases with an increase in temperature change while the dimensionless

deflection increases.

2- Humidity effect is similar temperature change. With increasing both them, the natural

frequency and the critical buckling load decrease and vice versa for dimensionless

deflection. It means that the micro composite plate becomes softer with increasing of

moisture and temperature changes.

3- With increasing of Winkler and Pasternak, the dimensionless natural frequency and

critical buckling load of the micro composite Reddy plate increases while the

dimensionless deflection decreases. Also, the influence of Pasternak shear coefficient is

more than Winkler coefficient on the dimensionless natural frequency.

4- The dimensionless critical buckling load and the natural frequency of micro composite

plate for SGT is higher than those for MCST and CT and this behavior is inverse for the

dimensionless deflection. It is due to the material length scale parameter increases the

stiffness of microstructures.

5- Reinforcements enhance the stiffness of micro composite plate; hence the dimensionless

natural frequency and the critical buckling load increase while the dimensionless

deflection decreases. It is noticeable that the increasing volume fraction of SWCNT leads

to increase stiffness of micro composite plate.

31

6- It is obvious that the micro composite plate is stiffer as reinforced by FG-X distribution

type rather than other distribution types. Thus it means the highest dimensionless critical

buckling load and natural frequency and lowest dimensionless deflection is belong to FGX distribution type.

7- The dimensionless natural frequency and the critical buckling load of micro composite

plate Reddy is higher than those for micro composite Mindlin plate.

8- The clamped boundary condition with respect to simply supported and free boundary

conditions leads to increase stiffer of the micro composite plate. Thus the dimensionless

critical buckling load increases and vice versa for dimensionless deflection of micro

composite Reddy plate.

Acknowledgments

The authors would like to thank the referees for their valuable comments. They are also grateful

to the Iranian Nanotechnology Development Committee for their financial support and the

University of Kashan for supporting this work by Grant No. 463855/5.

References

[1] Liew KM, Lei ZX, Zhang LW. Mechanical analysis of functionally graded carbon nanotube

reinforced composites: A review. Compos Struct 2015; 120: 90-97.

[2] Abdollahzadeh Shahrbabaki E, Alibeigloo A. Three-dimensional free vibration of carbon

nanotube-reinforced composite plates with various boundary conditions using Ritz method.

Compos Struct 2014; 111: 362–70.

[3] Zhang LW, Lei ZX, Liew KM. Free vibration analysis of functionally graded carbon

nanotube-reinforced composite triangular plates using the FSDT and element-free IMLS-

32

Ritz method. Compos Struct 2015; 120: 189-99.

[4] Ghorbanpour Arani A, Rousta Navi B, Mohammadimehr M. Surface stress and

agglomeration effects on nonlocal biaxial buckling polymeric nanocomposite plate

reinforced

by

CNT

using

various

approaches.

Adv

Compos

Mater

2015.

DOI:10.1080/09243046.2015.1052189.

[5] Yin L, Qian Q, Wang L, Xia W. Vibration analysis of microscale plates based on modified

couple stress theory. Acta Mech Solida Sin 2010; 23: 386-93.

[6] Hasani Baferani A, Saidi AR, Ehteshami H. Accurate solution for free vibration analysis of

functionally graded thick rectangular plates resting on elastic foundation. Compos Struct

2011; 93: 1842-53.

[7] Wang B, Zhou S, Zhao J, Chen X. A size-dependent Kirchhoff micro-plate model based on

strain gradient elasticity theory. Eur J Mech A-Solid 2011; 30: 517-24.

[8] Jomehzadeh E, Noori HR, Saidi AR. The size-dependent vibration analysis of micro-plates

based on a modified couple stress theory. Physica E 2011; 43: 877-83.

[9] Ramezani S. A shear deformation micro-plate model based on the most general form of

strain gradient elasticity. Int J Mech Sci 2012; 57: 34-42.

[10] Ke LL, Wang YS, Yang J, Kitipornchai S. Free vibration of size-dependent Mindlin

microplates based on the modified couple stress theory. J Sound Vib 2012; 331: 94-106.

[11] Thai HT, Choi DH. Size-dependent functionally graded Kirchhoff and Mindlin plate models

based on a modified couple stress theory. Compos Struct 2013; 95: 142-53.

[12] Zhang LW, Liew KM. Geometrically nonlinear large deformation analysis of functionally

graded carbon nanotube reinforced composite straight-sided quadrilateral plates. Comput.

Methods Appl. Mech. Eng. 2015; 295: 219-239.

[13] Sahmani S, Ansari R. On the free vibration response of functionally graded higher-order

shear deformable microplates based on the strain gradient elasticity theory. Compos Struct

2013; 95: 430-42.

[14] Thai HT, Kim SE. A size-dependent functionally graded Reddy plate model based on a

modified couple stress theory. Compos Part B-Eng 2013; 45: 1636-45.

[15] Kim J, Reddy JN. Analytical solutions for bending, vibration, and buckling of FGM plates

using a couple stress-based third-order theory. Compos Struct 2013; 103: 86-98.

[16] Zhang LW, Lei ZX, Liew KM, Yu JL. Static and dynamic of carbon nanotube reinforced

33

functionally graded cylindrical panels. Compos Struct 2014; 111: 205-12.

[17] Thai H, Choi DH. Analytical solutions of refined plate theory for bending, buckling and

vibration analyses of thick plates. Appl Math Model 2013; 37: 8310-23.

[18] Reddy JN, Berry J. Nonlinear theories of axisymmetric bending of functionally graded

circular plates with modified couple stress. Compos Struct 2012; 94: 3664-8.

[19] Mozafari H, Ayob A. Effect of Thickness Variation on the Mechanical Buckling Load in

Plates Made of Functionally Graded Materials. Procedia Technol 2012; 1: 496-504.

[20] Zhu P, Zhang LW, Liew KM. Geometrically nonlinear thermomechanical analysis of

moderately thick functionally graded plates using a local Petrov-Galerkin approach with

moving Kriging interpolation. Compos Struct 2014; 107: 298-314.

[21] Jarali CS, Patil SF, Pilli SC. Hygro-thermo-electric properties of CNT epoxy

nanocomposites with agglomeration effects. Mech Adv Mater Struct 2014; 22: 428-39.

[22] Lal A, Singh BN, Anand S. Nonlinear bending response of laminated composite spherical

shell panel with system randomness subjected to hygro-thermo-mechanical loading. Int J

Mech Sci 2011; 53: 855-66.

[23] Lei ZX, Liew KM, Yu JL. Buckling analysis of functionally graded carbon nanotubereinforced composite plates using the element-free kp-Ritz method. Compos Struct 2013;

98: 160-68.

[24] Mayandi K, Jeyaraj P. Bending, buckling and free vibration characteristics of FG-CNTreinforced polymer composite beam under non-uniform thermal load. P I Mech Eng L-J Mat

2013; 26: 1-16.

[25] Ghorbanpour Arani A, Maghamikia Sh, Mohammadimehr M, Arefmanesh A. Buckling

analysis of laminated composite rectangular plates reinforced by SWCNTs using analytical

and finite element methods. J Mech Sci Technol 2011; 25 (3): 809-20.

[26] Rafiee M, He XQ, Liew KM. Non-linear dynamic stability of piezoelectric functionally

graded carbon nanotube-reinforced composite plates with initial geometric imperfection. Int

J Non-Linear Mech 2014; 59: 37-51.

[27] Zhang LW, Cui WC, Liew KM. Vibration analysis of functionally graded carbon nanotube

reinforced composite thick plates with elastically restrained edges. Int J Mech Sci 2015; 103:

9-21.

34

[28] Shooshtari A, Rafiee M. Vibration characteristics of nanocomposite plates under thermal

conditions including nonlinear effects. Int J Appl Res Mech Eng 2014; 1: 60-69.

[29] Mohammadimehr M, Saidi AR, Ghorbanpour Arani A, Arefmanesh A, Han Q. Buckling

analysis of double-walled carbon nanotubes embedded in an elastic medium under axial

compression using non-local Timoshenko beam theory. Proc IMech-E Part C: J Mech Eng

Sci 2011; 225: 498-506.

[30] Liew KM, Lei ZX, Yu JL, Zhang LW. Postbuckling of carbon nanotube-reinforced

functionally graded cylindrical panels under axial compression using a meshless approach.

Comput Method Appl Mech Eng 2014; 268: 1-17.

[31] Ghorbanpour Arani A, Vossough H, Kolahchi R, Mosallaie Barzoki AA. Electro-thermo

nonlocal nonlinear vibration in an embedded polymeric piezoelectric micro plate reinforced

by DWBNNTs using DQM. J Mech Sci Technol 2012; 26: 3047-57.

[32] Bodaghi M, Saidi AR. Levy-type solution for buckling analysis of thick functionally graded

rectangular plates based on the higher-order shear deformation plate theory. Appl Math

Model 2010; 34: 3659-73.

[33] Ansari R, Faghih Shojaei M, Mohammadi V, Gholami R, Darabi MA. Nonlinear vibrations

of functionally graded Mindlin microplates based on the modified couple stress theory.

Compos Struct 2014; 114: 124-34.

[34] Zhang LW, Lei ZX, Liew KM. Vibration characteristic of moderately thick functionally

graded carbon nanotube reinforced composite skew plates. Compos Struct 2015; 122: 17283.

[35] Sahmani S, Ansari R. On the free vibration response of functionally graded higher-order

shear deformable microplates based on the strain gradient elasticity theory. Compos Struct

2013; 95: 430-42.

[36] Alzahrani EO, Zenkour AM, Sobhy M. Small scale effect on hygro-thermo-mechanical

bending of nanoplates embedded in an elastic medium. Compos Struct 2013; 105: 163-72.

[37] Mohammadimehr M, Salemi M. Bending and buckling analysis of functionally graded

Mindlin nano-plate model based on strain gradient elasticity theory. Indian J Sci Res 2014;

2: 587-598.

35

[38] Alibeigloo A. Static analysis of functionally graded carbon nanotube-reinforced composite

plate embedded in piezoelectric layers by using theory of elasticity. Compos Struct 2013;

95: 612-22.

[39] Bodaghi M, Saidi AR. Stability analysis of functionally graded rectangular plates under

nonlinearly varying in-plane loading resting on elastic foundation. Arch Appl Mech 2011;

81: 765-80.

[40] Zhang LW, Zhu P, Liew KM. Thermal buckling of functionally graded plates using a local

Kriging meshless method. Compos Struct 2014; 108: 472-92.

[41] Jomehzadeh E, Noori HR, Saidi AR. The size-dependent vibration analysis of micro-plates

based on a modified couple stress theory. Physica E 2011; 43: 877-83.

[42] Ghorbanpour Arani A, Rahnama Mobarakeh M, Shams Sh, Mohammadimehr M. The effect

of CNT volume fraction on the magneto-thermo-electro-mechanical behavior of smart

nanocomposite cylinder. J Mech Sci Technol 2012; 26: 2565-72.

[43] Shen L, Shen H, Zhang C. Nonlocal plate model for nonlinear vibration of single layer

graphene sheets in thermal environments. Comp Mater Sci 2010; 48: 680-85.

[44] Mohammadimehr M, Saidi AR, Ghorbanpour Arani A, Arefmanesh A, Han Q. Torsional

buckling of a DWCNT embedded on Winkler and Pasternak foundations using nonlocal

theory. J Mech Sci Technol 2010; 24: 1289-99.

[45] Lei ZX, Zhang LW, Liew KM. Free vibration analysis of laminated FG-CNT reinforced

composite rectangular plates using the kp-Ritz method. Compos Struct 2015; 127: 245–59.

[46] Lei ZX, Zhang LW, Liew KM, Yu JL. Dynamic stability analysis of carbon nanotubereinforced functionally graded cylindrical panels using the element-free kp-Ritz method.

Compos Struct 2014; 113: 328-338.

[47] Rahmati AH, Mohammadimehr M. Vibration analysis of non-uniform and nonhomogeneous boron nitride nanorods embedded in an elastic medium under combined

loadings using DQM. Physica B 2014; 440: 88-98.

[48] Zhang LW, Song ZG, Liew KM. Nonlinear bending analysis of FG-CNT reinforced

composite thick plates resting on Pasternak foundations using the element-free IMLS-Ritz

method. Compos Struct 2015; 128: 165–75.

[49] Zhang LW, Liew KM. Large deflection analysis of FG-CNT reinforced composite skew

plates resting on Pasternak foundations using an element-free approach. Compos Struct

36

2015; 132: 974-983.

[50] Zhang LW, Lei ZX, Liew KM. Buckling analysis of FG-CNT reinforced composite thick

skew plates using an element-free approach. Compos. Part B. 2015; 75: 36-46.

[51] Zhang LW, Huang D, Liew KM. An element-free IMLS-Ritz method for numerical solution

of three-dimensional wave equations. Comput. Methods Appl. Mech. Eng. 2015; 297: 116139.

[52] Zhang LW, Li DM, Liew KM. An element-free computational framework for elastodynamic

problems based on the IMLS-Ritz method. Eng. Anal. Bound. Elem. 2015; 54: 39-46.

[53] Mohammadimehr M, Rousta Navi B, Ghorbanpour Arani A. Free vibration of viscoelastic

double-bonded polymeric nanocomposite plates reinforced by FG-SWCNTs using MSGT,

sinusoidal shear deformation theory and meshless method. Compos Struct 2015; 131: 65471.

[54] Zhang LW, Song ZG, Liew KM. State-space Levy method for vibration analysis of FG-CNT

composite plates subjected to in-plane loads based on higher-order shear deformation theory.

Compos Struct 2015; 134: 989:1003.

[55] Lei ZX, Liew KM, Yu JL. Free vibration analysis of functionally graded carbon nanotubereinforced composite plates using the element-free kp-Ritz method in thermal environment.

Compos Struct 2013; 106: 128-38.

[56] Lei ZX, Zhang LW, Liew KM. Elastodynamic analysis of carbon nanotube-reinforced

functionally graded plates. Int J Mech Sci 2015; 99: 208-17.

[57] Zhu P, Lei ZX, Liew KM. Static and free vibration analyses of carbon nanotube-reinforced

composite plates using finite element method with first order shear deformation plate theory.

Compos Struct 2012; 94: 1450-60.

[58] Mohammadimehr M, Rousta Navi B, Ghorbanpour Arani A. Modified strain gradient Reddy

rectangular plate model for biaxial buckling and bending analysis of double-coupled

piezoelectric polymeric nanocomposite reinforced by FG-SWNT. Compos. Part B: Eng.

2016; 87: 132-148.

37

Appendix A

The variation of strain energy for MSGT Reddy microcomposite plate reinforced by SWCNTs

subjected to hydro-thermo-mechanical loadings is written as follows [58]:

2

x

u 0 w 0 w 0

1

3

3 w 0

U M xx0

M

c

M

c

M

xx

1

xx

1

xx

A

x x

x

x 2

x

2

y

v 0 w 0 w 0

1

3

3 w 0

M yy0

M

c

M

c

M

1

yy

1

yy

yy

y y

y

y 2

y

2

u 0 v 0 w 0 w 0 w 0 w 0

3 w 0

M

2c1M xy

x

x y

x y

x y

y

M xy1 c1M xy3 y x x y M xz0 3c1M xz2 x wx 0

0

xy

M

0

yz

3c1M

2

yz

2 x 2 y

w 0

1

3

y y Px c1Px x 2 x y

2 u 0 2v 0 2w 0 w 0 2w 0 w 0 2w 0 w 0

P

2

x y

x 2 x

x 2 x

x y y

x

3

2

2w 0 w 0

3w 0

2v 0

3 w 0

0 u 0

c

P

P

1 x

y

3

x y y

x y 2

y 2

x

x y

0

x

2w 0 w 0 2w 0 w 0 2w 0 w 0 2w 0 w 0

y 2 y

y 2 y

x y x

x y x

2 y 2 x

3w 0 3w 0

1

3

c1Py3

P

c

P

y

1 y

3

y 2

y x 2

x y

y

38

(A-1)

2

x y

2w 0

2 w 0

Pz0 3c1Pz2

3c1Pz

2

y

y 2

x

x

2 2 u 0 2w 0 w 0 2w 0 w 0 1 2 u 0

2v 0

0

T xxx

2

2

x 2 x

x 2 x 5 y 2

x y

5 x

2 2x

2w 0 w 0 w 0 2w 0 w 0 2w 0

1

2

T

xxx

2

x y y

x y 2

x

y 2

5 x

2 2 x

2 y

1 2 x

w 0

3

2

6

c

T

1

x

xxx c1

2

5 y 2

x y

x

5 x

2 y

3w 0 c1 2 x

3w 0

2

3

x 3 5 y 2

x y

x y 2

2 2v 0 2w 0 w 0 2w 0 w 0 1 2v 0

2 u 0

0

T yyy

2

2

y 2 y

y 2 y 5 x 2

x y

5 y

2 2 y

2w 0 w 0 w 0 2w 0 w 0 2w 0

1

2

T yyy

2

x y x

y x 2

y

x 2

5

y

2

2

2 2 y

1 y

x

w 0

3

2

6

c

T

1

y

yyy c1

2

5 x 2

x y

y

5

y

3w 0 c1 2x

2 x

3w 0 T zzz0 2w 0 2w 0

2

3

y 3 5 x 2

x y

y x 2 5 x 2

y 2

2

2

6

2w 0 x y

2 w 0

c

T

5 1 zzz x 2

y 2

x

y

y

x y 2w 0

2w 0

2 x

6

c

T

2

1 xyz

y

x

y x

x

y x

y

x

x

2

x

y

0

2T xyz

4 0 2 u 0 2v 0 3 2v 0 3 2w 0 w 0 3 2w 0 w 0

T xxy 2

5

x 2

4 y 2

4 y 2 y

4 y 2 y

x y

2

2w 0 w 0

2w 0 w 0 2w 0 w 0 2w 0 w 0

2

x y x

x y y

x 2 y

x 2 y

4 1

T xxy

5

4 3

T xxy

5

2

2

3 w 0 3

2 x y 3 y

c1 y 2

c1

y

2

y x

x 2

4 y 2

2

3 3w

2 x 2 y 3 2 y

3w 0

0

3

c

c

2

c1

1

1

y x

y 3

x 2y

x 2

4 y 2

4

x 1 y

4 0

2

T xxz 3c1T xxz 2

5

2 y

x

2w 0 1 2w 0

0

2

T

6

c

T

xxz

1 xxz

2

4 y 2

x

39

following

(A-1)

4 0

T yyx

5

2

2v 0 2 u 0 3 2 u 0 3 2w 0 w 0 3 2w 0 w 0

2

y 2

4 x 2

4 x 2 x

4 x 2 x

x y

2w 0 w 0

2w 0 w 0 2w 0 w 0 2w 0 w 0

2

x y y

x y x

y 2 x

y 2 x

4 1

T yyx

5

4 3

T yyx

5

3 w 0 3

2 y 2 x 3 2 x

c1 x 2

c1

x

2

y x

y 2

4 x 2

2

3 3w

2 y 2 x 3 2 x

3w 0

0

3c1 2 c1 2

c1

y x

x 3

y x

y 2

4 x 2

4

y 1 x

4 0

2

T yyz 3c1T yyz 2

5

2 x

y

2w 0 1 2w 0

0

2

T

6

c

T

yyz

1 yyz

2

4 x 2

y

1 0 2 u 0 2 u 0

2v 0

2w 0 w 0

2w 0 w 0

2

3

3

T zzx 3

2

5

y 2

x y

x 2 x

x 2 x

x

2

2w 0 w 0

2w 0 w 0 2w 0 w 0 2w 0 w 0

2

x y y

x y x

y 2 x

y 2 x

3

2 x

2 y 2 x

3w 0

3 w 0

1

3

3c1T zzx

T

c

T

3

2

zzx

1 zzx

3

2

x y 2

y x

y 2

x

x

w 0 1 0 v 0 v 0

u 0

w 0 w 0

1

24c1T zzx

2

3

x

T zzy 3

2

2

x 5

x

x y

y 2 y

y

2

3

2

2

2

2w 0 w 0

2w 0 w 0

2w 0 w 0 2w 0 w 0 2w 0 w 0

2

2

y 2 y

x y x

x y y

x 2 y

x 2 y

3

1 zzy

3c T

2

2 y

3w 0 3w 0

2 x y

1

3

2

T zzy c1T zzy 3

3

2

y x 2

y x

x 2

y

y

2

w 0 1 0

1

2 w 0

2 y

24c1T zzy

Y

3

cY

Y xx0 3cY

xx

1 xx

1 xx

y

y 2

y x

x

1 0

x

2 y

1 zz

2 Y zz 3cY

y

x

2

y

1

2w 0

2 w 0

2 x

Y xy0 3cY

Y xy0 3cY

1 xy

1 xy

2

2

2

x

y

x

y

2 y 2 x

1 0 2v 0 2 u 0

w 0

1

3

1

Y

Y

cY

6cY

xz

xz

1 xz

1

xz

y

2

2

x

2 x

x y

x

y

y

2 y 2 x

1 0 2v 0 2 u 0

w 0

1

3

1

Y

cY

6

cY

Y yz

yz

1 yz

1 yz

x

dA

2 x y

y 2

y 2

x

x y

2

1 0

2 w 0

2 x

Y

3

cY

Y yy0 3cY

yy

1

yy

1 yy

2

y x

y

40

following

(A-1)

Appendix B

Using stresses and dimensionless parameters, the dimensionless governing equations of motion

for MSGT Reddy microcomposite plate reinforced by FG-SWCNTs with considering hydrothermo-mechanical loadings are obtained as following form [58]:

For u 0 :

4

4

2

2 u

2

D

l

D

l

5,0 0

5,0 1

4

13

5

4

D1,0 2u 1 8

1

2

2 u

D

l

D

l

5,0 1

5,0 2

2

4

4

1 2 15

2u

1

1

4

1

4u

2

2

2

2 D 5,0 2 2 2D 5,0 l 0 D 5,0 l 1 D 5,0 l 2 2 2 2D 5,0l 0 2

2

3

4

2 1

1

4

2v

4

1

1 4v 1

1 v

D 5,0l12 D 5,0l 2 2 3

D

D

3,0

5,0

3

15

4

221 3 1

1

5

5

1

4

1

8

w

w

5 2c1D 5,3l 0 2 c1D 5,3l12 5 3 2 4c1D 5,3l 0 2 c1D 5,3l12 2 3

1

5

5

1 2

c D 2c1D 5,3

3

1

12

1 1 3,3

w

2 w

3 c1D1,3 D 5,1c1l1 3 2 12

2

1

5

2 1 D 5,1c1l12

5

5

2

1 12

1

4

x

2

2 w

2

2

c

D

l

c

D

l

D

c

l

c

D

D

1

5,3

0

1

5,3

1

5,1

1

1

1

1,3

1,1

4

2

2

24 1

5

1 5

4

4

1

2D 5,1l 0 2 2c1D 5,3l 0 2 D 5,1l12 c1D 5,3l12 c1D 5,3l 2 2

4

1

3

3

4

2 2

2 x 2

1 2 1

2

D 5,1l 2

4

3

41

(B-1)

1 4

2

2 D 5,1c1l1

5

2

1

8

D 5,1l12 D 5,1l 2 2 4

2

x

3

x 1 15

4

c1D 5,3 D 5,1c1l 2 2 D 5,1

4

2

4

1

2

2 8

2

2

c

D

l

c

D

l

1 5,3 1

1 5,3 2

4

15

2

1

8

3

y

2

2

c1D 3,3 D 5,1 D 5,1c1l1 c1D 5,3 D 5,1c1l 2 D 3,1

12

5

2

4

4

1

2D 5,1l 0 2 2c1D 5,3l 0 2 D 5,1l12 c1D 5,3l12 c1D 5,3l 2 2 4

y

1

15

15

4

3

1 2 1

3

2

D 5,1l 2

4

1

4

1