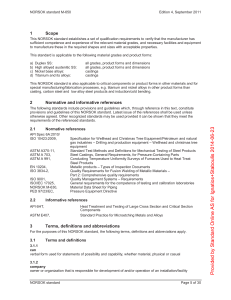

NORSOK STANDARD P-002 Edition 1, August 2014 Process system design This NORSOK standard is developed with broad petroleum industry participation by interested parties in the Norwegian petroleum industry and is owned by the Norwegian petroleum industry represented by the Norwegian Oil and Gas Association and The Federation of Norwegian Industries. Please note that whilst every effort has been made to ensure the accuracy of this NORSOK standard, neither the Norwegian Oil and Gas Association nor The Federation of Norwegian Industries or any of their members will assume liability for any use thereof. Standards Norway is responsible for the administration and publication of this NORSOK standard. Standards Norway Strandveien 18, P.O. Box 242 N-1326 Lysaker NORWAY Copyrights reserved Telephone: + 47 67 83 86 00 Fax: + 47 67 83 86 01 Email: petroleum@standard.no Website: www.standard.no/petroleum NORSOK standard P-002 Edition 1, August 2014 Foreword 6 Introduction 6 1 Scope 7 2 Normative and informative references 2.1 Normative references 2.2 Informative references 7 7 8 3 Terms, definitions and abbreviations 3.1 Terms and definitions 3.2 Abbreviations 8 8 9 PART [I] – GENERAL PROCESS SECTION 10 4 Design pressure and temperature 4.1 General 4.2 Design pressure 4.3 Design temperature 10 10 10 11 5 General system design 5.1 Design for minimum impact of facility movement 5.2 Material selection 5.3 Maintenance and isolation 12 12 12 12 6 Safety requirements 6.1 Objectives 6.2 Safety analysis 6.3 Hazard and operability 6.4 Overpressure protection 6.5 Check valves 6.6 Piping 13 13 13 13 14 15 15 7 Line sizing criteria 7.1 General 7.2 Sizing of liquid lines 7.3 Sizing of gas lines 7.4 Sizing of gas/liquid two phase / multiphase lines 7.5 Sizing of flare and vent lines 15 15 16 18 19 20 8 General process equipment design 8.1 Horizontal separator design 8.2 Vertical separator design 8.3 Scrubber design 8.4 Atmospheric tank design 8.5 Heat exchanger design 8.6 Pig launcher/receiver design 8.7 Filters 21 21 23 23 25 25 29 29 9 Detailed requirements for system and equipment isolation 9.1 General 9.2 Physical separation 9.3 Level of isolation 9.4 Connections to flare, vents and closed drains 9.5 Operational drain, vent and flushing requirements 29 29 29 30 33 35 10 35 35 36 Insulation and heat tracing of piping and equipment 10.1 General 10.2 Heat conservation and frost protection PART [II] – SYSTEM DESIGN SECTION 37 11 37 37 37 37 37 11.1 11.2 11.3 11.4 Topside flow lines and manifolds (system 13) General System design Monitoring Safety NORSOK © 2014 Page 2 of 60 NORSOK standard P-002 12 12.1 12.2 12.3 12.4 12.5 13 Separation and stabilisation (system 20) General Pressure and level control Test separator Layout Injection of chemicals Crude handling (system 21) 13.1 General 13.2 Design requirements 13.3 Safety 14 Edition 1, August 2014 37 37 37 37 38 38 38 38 38 38 14.1 14.2 14.3 14.4 14.5 Gas compression (systems 23, 26 and 27) General System design Compressors Safety Layout 39 39 39 39 40 40 15.1 15.2 15.3 15.4 15.5 15.6 15.7 Gas treatment (system 24) General Glycol contactors Regeneration unit and storage Wet gas inlet coolers Safety Layout Environmental requirements 40 40 40 41 42 42 42 42 16.1 16.2 16.3 16.4 16.5 Gas conditioning (system 25) General Heat exchangers and scrubbers Turbo expander and recompressor unit Design pressure and temperature Layout 42 42 43 43 43 43 17.1 17.2 17.3 17.4 17.5 17.6 17.7 Water injection (system 29) General Filtration Disinfection Deoxygenation Pumps Chemical injection Monitoring 43 43 44 44 44 44 44 44 18.1 18.2 18.3 18.4 18.5 Cooling medium (system 40) General Filtration System operating pressure Expansion tank Layout 44 44 45 45 45 45 19.1 19.2 19.3 19.4 19.5 19.6 Heating medium (system 41) General Pumps Waste heat recovery units Filter Expansion tank Layout 45 45 46 46 46 46 46 20.1 20.2 20.3 20.4 20.5 20.6 Chemical injection (system 42) General Storage tanks Drip trays and drainage Injection points Safety Maintenance 46 46 47 47 47 47 47 15 16 17 18 19 20 NORSOK © 2014 Page 3 of 60 NORSOK standard P-002 21 21.1 21.2 21.3 21.4 21.5 21.6 Flare and vent (system 43) General Knock-out drum Thermal radiation Flare gas recovery systems Layout FPSO Considerations 48 48 48 48 48 49 49 22.1 22.2 22.3 22.4 Oily water treatment (system 44) General Produced water treatment Flash drum Layout 49 49 49 50 50 22 23 Fuel gas (system 45) 23.1 General 23.2 System design 23.3 Fuel gas heating 24 24.1 24.2 24.3 24.4 25 26.1 26.2 26.3 26.4 26.5 Sea water (system 50) General Pumps Filters Prevention of marine growth Layout Fresh water (system 53) 27.1 General 27.2 Fresh water treatment 27.3 Maintenance 28 50 50 50 50 50 50 50 51 51 51 51 51 52 52 52 52 53 53 53 53 53 53 53 28.1 28.2 28.3 28.4 28.5 28.6 28.7 Open drain (system 56) General System capacity Drain tanks Drilling drain Maintenance Layout Safety 54 54 54 54 54 54 54 55 29.1 29.2 29.3 29.4 29.5 29.6 Closed drain (system 57) General Closed drain flash drum Design temperature Reclaimed oil sump Reclaimed oil sump pump Safety 55 55 55 55 55 55 56 30.1 30.2 30.3 30.4 30.5 Diesel oil (system 62) General Storage tanks Hose loading stations Day tanks Maintenance 56 56 56 56 56 56 Compressed air (system 63) 56 29 30 31 Methanol injection (system 46) General System design Storage tank Injection Chlorination (system 47) 25.1 General 25.2 System design 25.3 Electrolysis cells 26 27 Edition 1, August 2014 NORSOK © 2014 Page 4 of 60 NORSOK standard P-002 Edition 1, August 2014 31.1 31.2 31.3 31.4 31.5 31.6 31.7 General Dehydration Filtration Air receiver Sparing Safety Layout 56 57 57 57 57 57 57 32.1 32.2 32.3 32.4 Inert gas (system 64) General System design Sparing Operational requirements 58 58 58 58 58 33.1 33.2 33.3 33.4 33.5 33.6 33.7 Hydraulic power (system 65) General Reservoir Pumps Filters Accumulator capacity Safety Maintenance 58 58 58 59 59 59 59 59 34.1 34.2 34.3 34.4 Sewage (system 66) General System capacity Operating temperature Layout 59 59 60 60 60 32 33 34 NORSOK © 2014 Page 5 of 60 NORSOK standard P-002 Edition 1, August 2014 Foreword The NORSOK standards are developed by the Norwegian petroleum industry to ensure adequate safety, value adding and cost effectiveness for petroleum industry developments and operations. Furthermore, NORSOK standards are, as far as possible, intended to replace oil company specifications and serve as references in the authorities’ regulations. The NORSOK standards are normally based on recognised international standards, adding the provisions deemed necessary to fill the broad needs of the Norwegian petroleum industry. Where relevant, NORSOK standards will be used to provide the Norwegian industry input to the international standardisation process. Subject to development and publication of international standards, the relevant NORSOK standard will be withdrawn. The NORSOK standards are developed according to the consensus principle generally applicable for most standards work and according to established procedures defined in NORSOK A-001. The NORSOK standards are prepared and published with support by the Norwegian Oil and Gas Association, The Federation of Norwegian Industries, Norwegian Shipowners’ Association and The Petroleum Safety Authority Norway. NORSOK standards are administered and published by Standards Norway. Reprint January 2015 In the first print, shadow elements were displayed with some of the figures in Clause 9. They have been removed. Print format was checked and some sections were numbered due to inconsistency in the first print. No words have been changed. Introduction The development of this NORSOK standard is primarily based on proven technology, but it does not preclude the use of new technology. The system design sections are based on the most frequently used systems, but this does not imply that alternatives may not be used (for example dehydration by use of glycol is covered, but not the use of molecular sieves or other means). The following changes have been made to this NORSOK standard: x x x x x x x P-001 and P-100 have been combined into a single document to improve accessibility and remove redundancy. Content has been simplified and some superfluous text has been deleted. The document has been updated to reflect current industry practice and relevant international standards. In clause 21.2, the sizing of knock out drum with respect to liquid accumulation, has been made more consistent with international standards. The use of instrumented protection functions to allow for reduced liquid accumulation capacity requires more stringent documentation. API Std 521, sixth edition issued January 2014 covers acoustic fatigue in piping, sizing of flare knock-out drums, choke valve failure, water hammer and allowance for non-return valves in some depth, so these sections have been removed or edited. ISO 23251 and ISO 28300 have been classed as Informative in this document as they are similar to API Std 521 and API Std 2000, which have been recently updated and better reflect current thinking. For HAZOP studies, the recommendation to use full reporting has been removed. This is seen as being up to the individual company’s standards. The system numbers used in this NORSOK standard are those defined in NORSOK Z-DP-002. NORSOK © 2014 Page 6 of 60 NORSOK standard P-002 1 Edition 1, August 2014 Scope This NORSOK standard provides requirements for the following aspects of topside process piping and equipment design on offshore production facilities: x x x x x design pressure and temperature; safety instrumented secondary pressure protection systems; line sizing; system and equipment isolation; insulation and heat tracing. These criteria are applicable for all processes, process support and utility systems. Additionally this NORSOK standard defines the minimum functional requirements for process systems on an offshore installation. The standard includes a number of recommendations to give additional guidance for the system design. 2 Normative and informative references The following standards include provisions and guidelines which, through reference in this text, constitute provisions and guidelines of this NORSOK standard. Latest issue of the references shall be used unless otherwise agreed. Other recognized standards may be used provided it can be shown that they meet the requirements of the referenced standards. 2.1 Normative references API 2000, API RP 14C API RP 17O API Std 520 API Std 521 API Std 537 BS MA-18 DNV-OS-E201 EN 1473 FOR-1994-02-10-123, IEC 61508, IEC 61882 IEC 61511 (All parts) ISO 4126 ISO 10418 (All parts) ISO 12241 ISO 13628-6 ISO 13702 ISO 13703 ISO 25457 Venting Atmospheric and Low-pressure Storage Tanks Analysis, Design, Installation and Testing of Basic Surface Safety Systems on Offshore Production Platforms Recommended Practice for Subsea High Integrity Pressure Protection Systems Sizing, Selection and Installation of Pressure-relieving Devices in Refineries Pressure-relieving and Depressuring Systems Flare Details for General Refinery and Petrochemical Service, Second Edition Salt water piping systems in ships Oil and Gas Processing Systems Installation and equipment for liquefied natural gas – Design of onshore installations Norwegian Maritime Directorate (NMD): Forskrift for flyttbare innretninger med produksjonstekniske installasjoner og utstyr Functional safety of electrical/electronic/programmable electronic safety related systems Hazard and operability studies (HAZOP studies) – Application guide Functional safety – Safety instrumented systems for the process industry sector Safety devices for protection against excessive pressure Petroleum and natural gas industries – Offshore production installations – Basic surface process safety systems Thermal insulation for building equipment and industrial installations – Calculation rules Petroleum and natural gas industries – Design and operation of subsea production systems – Part 6: Subsea production control systems Petroleum and natural gas industries – Control and migration of fires and explosions on offshore production installations – Requirements and guidelines. Petroleum and natural gas industries – Design and installation of piping systems on offshore production platforms Petroleum, petrochemical and natural gas industries – Flare details for general refinery and petrochemical service. NOTE This standard is similar to API Std 537. NORSOK I-104 NORSOK I-105 NORSOK M-001 NORSOK R-001 NORSOK R-004 NORSOK © 2014 Fiscal measurement system for hydrocarbon gas Fiscal measurement systems for hydrocarbon liquid Materials selection Mechanical equipment Piping and equipment insulation Page 7 of 60