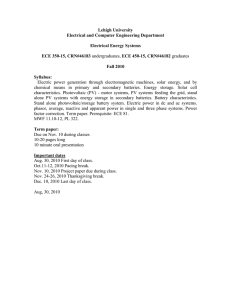

ABSTRACT Solar inverter converts the variable direct current (DC) output of a photovoltaic (PV) solar panel into a utility frequency alternating current (AC) that can be fed into a commercial electrical grid or used by a local, off-grid electrical network. It is a critical component in a photovoltaic system, allowing the use of ordinary AC-powered equipment. In solar inverter, Solar panels produce direct electricity with the help of electrons that are moving from negative to positive direction. Most of the appliances that we use at home work on alternative current. In AC electricity the voltage can be adjusted according to the use of the appliance. As solar panels only produce Direct current the solar inverter is used to convert the DC to AC. In solar inverter all the component is soldered onto the Vero Board, and casing was gotten where the entire circuit was mounted, case allow proper running of inverter by providing proper ventilation and cooling. 1 CHARTER ONE 1.1 Introduction 1.2 Background of the project 1.3 Aim and Objective of the project 1.4 Scope of the project 1.5 Purpose of the project 1.6 Significance of the project 1.7 Problem of the project 1.8 Limitation of the project 1.9 Project Organisation CHAPTER TWO 2.1 Literature Review 2.2 Historical Background Photovoltaic Of Cell 2.3 Theoretical Review of Solar Cell 2.4 Review of Solar Cell Efficiency 2.5 Review of Solar Cell Materials 2.6 Review of Early Inverters CHAPTER THREE 3.1 Basic Designs Of a Solar Inverter 3.2 Block Diagram 3.3 Description of Solar Inverter Units 3.3 Description Of Components Used CHARTER FOUR 4.1 4.2 4.3 4.4 4.5 4.6 4.7 Construction Procedure and Testing Casing and Packaging Assembling of Sections Testing of System Operation Safety of a Solar Inverter Modified Sine Wave Power Solar Inverter Circuit Using Ic 4093 Circuit Operation CHAPTER FIVE 5.1 Conclusion 5.2 Recommendation 5.3 References 2 CHAPTER ONE 1.1 INTRODUCTION A 1KVA Solar inverter is a device that converts the direct Current (DC) Power generated by Solar panels into alternating Current (AC) Power that can be used to run household applications. It's a Key Component , of a Solar power system and helps harness the suns energy For everyday use. The construction of a 1KVA Soar inverter involves Several important components. first, you have the Solar Panels, which Capture Sunlight and Convert it Into DC power . Then, there’s the charge controller which regulates the charging of the battery bank. The battery bank Stores excess energy Produced by the Solar Panels for later use. Next, we have the Inverter Itself .It takes the DC Power from the battery and Converts it into AC Power that con be used to run appliances and devices. finally, there's the monitoring system, which helps Keep track of the Systems Performance and ensures everything is running Smoothly. Overall, the construction and design of a 1KVA solar inverter involve Carefully integrating these components to Create a reliable and efficient system that harnesses Solar energy and power your home or other electrical devices. It's an exciting and eco-friendly way to generate electricity. 1.2 BACKGROUND OF THE PROJECT Solar technology isn’t new. the Construction and design of Solar inverters have evolved over the years as Solar Power technology has advanced. Solar inverters are an essential component of Solar power System, enabling the Conversion of DC power from solar power Into usable AC power . The goal of designing a 1KVA Solar inverter is to Create a System that efficiently converts Solar energy into electricity whole ensuring reliability and Safety. Engineers Consider factors Such as power output, efficiency, voltage regulation, and Protection mechanisms during the design Process . To achieve this, modern Solar inverters often incorporate advanced features like maximum power Point tracking (MPPT), which optimizes the Power output from the Solar Panels, and grid-tie Capabilities, allowing excess energy to be fed back into the electrical grid. 3 Additionally, the construction of a 1KVA Solar inverter involves Selecting high-quality components, Such as durable Semiconductors, Capacitors, and transformers, to ensure longterm Performance and reliability . Overall, the background of the construction and design of a 1KVA Solar inverter is rooted in the continuous advancements in Solar Power technology and the Pursuit of efficient, sustainable, and reliable energy Solutions. It’s exciting to See how Solar inverters have become an integral part of the renewable energy landscape. Solar inverters are also Called as Photovoltaic Solar inverters. These devices Can help you save lot of money. The Solar Panel and the batteries that are Placed on rooftops attract sun rays and then convert the Sunlight into electricity .The batteries too grab the extra electricity so that it can then be used to run appliances at night. 1.3 AIMS AND OBJECTIVE OF THE PROJECT The main Objective of this project is to design and construct a Solar Power generating device that can carry an input DC voltage from the Solar panel and convert it to 220vac output which can be use to power AC appliances which is rated 1KVA. The design aims to maximize power output, ensure voltage regulation, and Incorporate Safety features. Ultimately, the goal is to harness Solar energy effectively and Provide a sustainable and ecofriendly source of electricity. 1.4 SCOPE OF THE PROJECT The main function of Solar inverter is to Convert battery’s Direct Current (DC) into Pure Sine wave Alternative current(AC) to feed home Compliances. Solar power inverter system is consisted of Solar Panel's Charger Controllers, inverters and rechargeable batteries, while. Solar DC Power System is not included inverters. The Inverter is a Power Conversion device, which can be divided into self-excited oscillation inverter and external excited oscillation inverter. 1 .5 PURPOSE OF THE PROJECT The Purpose of Construction and designing a 1KVA Solar inverter is to enable the utilization of Solar energy for powering various electrical devices. it allows the Conversion of the DC 4 power generated by solar Panels into AC power that con be used in homes, offices, or other locations, The design ensures efficient and reliable operation, maximizing the used of Solar energy and reducing dependence on traditional power Sources. it's all about harnessing the Sun's energy and making It accessible for everyday electricity needs. 1.6 SIGNIFICANCE OF THE PROJECT The Construction and design of a 1KVA Solar inverter is Significantly for Several reasons. A Solar inverter is better Optimized For solar power than the regular one. For example, It will Priorities power Supply from the Solar Panels. This means that when the energy from the Sun is adequate like during afternoons, The inverter will draw power entirely from the Solar Panels to power your home or office even if Pubic power Supply is available .This can lead to huge Savings on power bills. Secondly, the design of a 1KVA Solar inverter ensures that the generated Solar Power is Compatible with Standard AC appliances, allowing for seamless integration into existing electrical systems. it enables individuals and businesses to make use of Solar energy without major modification to their infrastructure. Furthermore, the Construction of a 1KVA Solar inverter emphasizes Safety and reliability. Design considerations include protection mechanisms against over voltage, Short Circuits, and other Potential issues. This ensures the longevity and Proper functioning of the inverter, Providing Peace of mind to users. Solar inverters are the best way and they are better than the normal electric ones . Also their maintenance does not cost much money. Overall, the construction and design of a 1KVA Solar inverter is significant as it enables the practical application of Solar energy, contributes to Sustainability efforts, and empowers individuals and Communities to adopt Cleaner and more environmentally friendly power Sources. It’s an exciting Step towards a greener future. Solar Inverter Can work when there is no Sunlight but Provided their battery is Changed fully with the help of Sunlight 5 1.7 PROBLEM OF THE PROJECT Initially to work on the construction of this project you need a lot of money for buying a Solar inverter and time maintenance and replacement may require more effort in the event of a Problem, a technician will need to access the roof to make repairs. Defending on your maintenance Plan and warranty, this may cost you money. 1.8 LIMITATION OF THE PROJECT A 1KVA Solar inverter is the limited Power output it can Provide . A 1KVA inverter may not be Sufficient to Power high - demand appliances or multiple device simultaneously. Additionally, the size and weight of the inverter may be a Constraint, especially for Portable or Space - limited applications. it's Important to Consider the Specific Power requirements and usage Scenarios when Choosing the appropriate size and design of a Solar inverter This device is rated 500w that means any load more than 500w Should for no reason applied to this device. The intensity of the Sun varies throughout The day. This Creates an over- Charging Problem if the Panels are connected to the battery directly, and It Should also be able to tell you when you connect the Panel wrongly (i.e.- positive to negative, etc.) and also provide protection against Short - Circuit. for this reason a Charge Controller must be used to offer protection from high voltage and current from the Panels. 1.9 ORGANIZATION OF THE PROJECT This work is organized in Such a way that every reader of this work will understand how Solar Power inverter is being made. Starting from the Chapter one to Chapter five focused fully on the topic at hand. Chapter one of this work is on the introduction to Solar power inverter. In this Charter, the background, Significance, objective limitation and Problem of Solar power inverter were discussed.Chapter two is on literature review of Solar Power inverter. in this chapter , all the literature Pertaining to this work was reviewed.Chapter three is on design methodology. in the Chapter all the method involved during the design and construction were discussed.Chapter Four is on testing analysis All testing that result accurate functionally was analysed and Chapter five is on Conclusion, recommendation and references. 6 CHAPTER TWO LITERATURE REVIEW 2.1 REVIEW OF THE LITERATURE Numerous studies on the problem of failure of power supply and attendant problem of private means of generating electricity have been carried out in Nigeria. Such have understood the numerous constants that attend the private means of generating electricity whenever there is electrical power supply failure. The problem of electricity power failure is one of the most important current issues in Nigeria. Due to the importance of electricity, writers and researchers have done many works on the topic. But the problems still remain. This chapter therefore reviewed works on problems facing the failure of electrical power supply and authorized body in charge of electricity. The review of the literature for this project is limited in scope. It only deals with those books, articles, journals that are of relevance to the topic of this project. It should be noted that various power works have been dome on the problems of electrical power failure and private means of generating electricity. such researchers have also enumerated the causes and remedies of these problems. It is an undisputable fact the important of electricity in the day to day activities cannot. be over emphasized. its role in the area of manufacturing, commercial, industrial and administrative works cannot be over related. It plays a vital role in the lives of human beings both in developed and developing countries of the world. From the foregoing, the importance of a constant frequency electrical power supply became very obvious in the society. However, consumers are faced with problems of continuous production and administrative processes whenever there is electrical power failure. Numerous project works, which have been, carried out on this problem revealed the consequence of this frequent failure of power supply. Statistics showed that it has led to damage of various machines and has in one way or the other affected negatively, the various activities of companies and organization thereby resulting to low level output. This project work is concern about the private means of generating electricity and backup using available D.C source. It is hoped that this project will provide remedy to the problem inherent in poor supply of electricity from authorized body. 7 However, researchers have revealed that the only way of allowing continuity in administrative works and production processes of various organizations is by the use of a system, which requires no man labour for its operation. A system that will provide electricity immediately when there is power failure and vice-versa. This inverter will therefore reduce the problems caused by power failure. 2. 2 HISTORITICAL BACKGROUND OF PHOTOLOTAIC CELL The history of Photovoltaic (PC)Cells, which are the Key Component of Solar panels , dates back to the 19th century. The discovery of the photovoltaic effect by French Physicist Alexandre - Edmond Becquerel in 1839 Laid the foundation for the development of PV technology. However, it wasn't until the mid-20th century that Significant advancements were made in PV cell design and Construction . In 1954, researchers at Bell Labs, including Daryl Chapin, Calvin fuller, and Gerald Pearson, invented the first Practical silicon solar Cell. This breakthrough led to the commercialization of PV technology and the beginning of the Solar energy industry. Over the years, PV cell technology has evolved, with improvements in efficiency, durability, and cost -effectiveness. Different types of PV Cells hare bean developed, such as Monocrystalline, Polycrystalline, and thin-film cells, each Offering unique advantages and characteristics. The design and Construction of a 1kVA solar inverter involve integrating PV cells into a system that can covert Sunlight into electricity, Store it in batteries, and convert if into usable AC power . The inverter circuitry plays a crucial role in this Process, ensuring efficient and safe conversion of DC to AC power. By harnessing the Power of the Sun, Solar inverters enables the utilization of clean and renewable energy Sources. This contributes to reducing reliance on Fossil fuels and mitigating the impact of climate change. 2.3 THEORETICAL REVIEW Of SOLAR CELL Solar Cells , also known as photovoltaic (PL) Cells, are at the heart of solar energy system. They convert Sunlight directly into electricity using the photovoltaic effect. When sunlight hits the solar cells, it excites the electrons in the semiconductor material, Creating a flow of electricity. 8 In the design and construction of a 1KVA Solar inverter, it's important to Consider the characteristics of Solar Cells ,factors like efficiency, Voltage, and current Output are Crucial in determining the Overall performance Of the Solar energy System. High -quality Solar Cells with good efficiency ratings are Preferred For optimal energy Conversion. The Solar Cells are Connected in Series or Parallel Configurations to achieve the desired Voltage and current levels. This electrical energy generated by the Solar Cells is then fed into the inverter, which Converts the DC power into AC Power Suitable for powering electrical devices. 2.4 REVIEW OF SOLAR CELL EFFICIENCY A 1KVA Solar inverter is designed to Convent the DC (direct current) Power generated by Solar Panels into AC ( alternating current )Power that can be used to Power household appliances. These inverters typically have multiple stages, including a DC - DC Converter to optimize the power . They also have various protection Features to ensure safe and efficient operation. it's fascinating how solar inverters play a crucial role in utilizing Solar energy for our everyday needs. Solar Cells efficiency is a measure of how well a Solar cell Converts sunlight into electricity . The efficiency of Solar cells has been improving over time, with some of the must efficient ones reaching around 20-25%. it Pretty Cool how we Can harness the power of the Sun! The efficiency of Solar Panels has improved dramatically in recent years, from an average of around 15% Conversion of Sunlight to usable energy to around 20%. High -efficiency solar Panels can reach as much as nearly 23%. Solar cells efficiencies vary from 6% For amorphous silicon - based solar cells to 44% with multiple -junction Production Cells and 44.4% with multiple dies assembled into a hybrid Package. Solar Cell energy Conversion efficiencies for Commercially available multi crystalline Si solar Calls are around 14-19%. 2.5 REVIEW OF SOLAR CELL MATERIALS 9 Solar inverters are typically made up of Various component, including Power Semiconductors, capacitors , transformers, and control circuits. These components work together to Convert the DC Power that can be used to Power our homes and devices . As for Solar Cell materials, there are different types commonly used, such as mono crystalline Silicon, Polycrystalline silicon, and thin- film technologies like amorphous silicon Cadmium telluride, and copper indium gallium Selenide (CIGS). Each material has its own advantages and Characteristics, which can impact the efficiency and cost of the solar Cells . It's amazing to see how advancements in Solar Cell materials and inverter technology are making. Solar energy more accessible and efficient for everyone. 2.6 REVIEW OF EARLY INVETERS In the early days, inverters were typically bulky and Less efficient compared to modern designs. They often used older technologies, Such as Square wave or modified Sine wave inverters, which Produced a less Clean and Stable output waveform. Early inverters also had limited Power Capacities and were mainly used for small- scale applications. They were often Standalone units that needed to be manually connected to the Solar Panels and the electrical grid. However, with advancements in technology, modern inverters have become much more compact , efficient, and reliable. They now use more sophisticated designs, such as Pure sine ware inverters, which produce a high -quality AC waveform that is compatible with a wider range of appliances. So, It's fascinating to see how inverters have evolved over time, becoming more efficient and user-friendly, making solar energy a viable and accessible option for many people. CHAPTER THREE 10 METHODOLOGY 3.1 INTRODUCTION In an simple inverter circuit, DC power is connected to a transformer through the centre tap of the primary winding. A relay switch is rapidly switched back and forth to allow current to flow back to the DC source following two alternate paths through one end of the primary winding and then the other. The alternation of the direction of current in the primary winding of the transformer produces alternating current (AC) in the secondary circuit. 3.2 BLOCK DIAGRAM The block diagram of a modified sine wave inverter is as below: 12 3.3 DESCRIPTION OF SOLAR INVERTER UNITS 11 SOLAR CELL A solar cell or photovoltaic cell (PV cell) is an electronic device that converts the energy of light directly into electricity by means of the photovoltaic effect, it is a form of photoelectric cell, a device whose electrical characteristic (such as current voltage, or resistance) vary when exposed to light. Individual solar cell device are often the electrical building blocks of photovoltaic modules, known colloquially as ‘solar panels’. The common single junction silicon solar cell can produce a maximum open circuit voltage of approximately 0.5 to 0.6 volts. SOLAR PANEL A solar panel is a device that converts sunlight into electricity by using photovoltaic (PV cell). PV cell are made of material that produce excited electrons when exposed to light. SOLAR CHARGE CONTROLLER: Solar charge controller limits the rate at which electric current is added to or drawn from solar panel to electric batteries. It prevents overcharging and may protect against overvoltage, which can reduce battery performance or lifespan, and may pose a safety risk. It may also prevent completely draining (“deep discharging”) a battery, or perform controlled discharges, depending on the battery technology, to protect battery life. POWER SWITCH: MOSFET is also known as switch. They are used here as the switching devices. They should stand to withstand the high current of the primary winding (low voltage side) of the transformer. TRANSFORMER: solar inverters have relied on transformer to step up the voltage generated by solar panels to a suitable level for grid connection. However transformers come with certain limitations, including size, weight, cost, and energy losses. 3.4 DESCRIPTION OF COMPONENTS USED Components used in this work are described as below: SOLAR CELL A solar cell (also called a photovoltaic cell) is an electronic device that converts the energy of light directly into electricity by means of the photovoltaic effect, it is a form of photoelectric cell, a device whose electrical characteristic (such as current voltage, or resistance) vary when exposed to light. Individual solar cell device are often the electrical building blocks of 12 photovoltaic modules, known colloquially as ‘solar panels’. The common single junction silicon solar cell can produce a maximum open circuit voltage of approximately 0.5 to 0.6 volts. RECTIFYING DIODE The rectifying diode is used to convert the AC power from the solar panels into DC power. The diode ensures that the current only flows in the correct direction, which is necessary for the converter to function properly. BATTERY An electric battery is a device consisting of one or more electrochemical cell that convert stored chemical energy into electrical energy. Each battery consists of a negative electrode (anode) that holds charged ions, a positive electrode (cathode) that holds discharged ions, an electrolyte that allows ions to move from anode to cathode during discharge (and return during recharge) and terminals that allow current to flow out of the battery to perform work. Batteries are either primary (single-use or "disposable") that are used once and discarded or secondary (rechargeable batteries) that are discharged and recharged multiple times. Batteries are made from many materials including various metals, carbon, polymers and even air. The most common are lead-acid batteries used in vehicles and lithium ion batteries used for portable electronics. Batteries come in many shapes and sizes. LIGHT-EMITTING DIODE (LED) A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (corresponding to the energy of the photons) is determined by the energy required for electrons to cross the band gap of the semiconductor. Appearing as practical electronic components in 1962, the earliest LEDs emitted low – intensity infrared (IR) light. Infrared LEDs are used in remote – control circuit, such as those used with a wide variety of consumer electronics. The first visible – light LEDs were of low intensity and limited to red, but modern versions are available across the visible, ultraviolet, and infrared wavelengths, with very high brightness. When a light-emitting diode is switched on, electrons are able to recombine with holes within the device, releasing energy in the form of photons. This effect is called electroluminescence, 13 and the color of the light (corresponding to the energy of the photon) is determined by the energy band gap of the semiconductor. An LED is often small in area (less than 1 mm 2), and integrated optical components may be used to shape its radiation pattern.[9] LEDs have many advantages over incandescent light sources including lower energy consumption, longer lifetime, improved physical robustness, smaller size, and faster switching. However, LEDs powerful enough for room lighting are relatively expensive, and require more precise current and heat management than compact fluorescent lamp sources of comparable output. CAPACITORS A capacitor essentially consists of two conducting surfaces separate by a layer of a insulating medium called dielectric. The purpose of a capacitor is to store electric energy or electrostatic stress in the dielectric. A parallel palate capacitor as drawn below, are plate is connected to the positive of the power supply and the other is connected to the negative of the power supply. It sis experimentally found that in the presence of an earthed plate B, pate A is capable of withholding more charge than when B is no there. When such capacitor is put across a battery there is a momentary flow of electrons from A to B. As negatively charged electrons are withdrawn from A, A becomes positively charge and as negatively charged electrons are withdrawn from B, becomes negative. Hence a potential difference is established between A and B the transient flow of electrons gives rise to charging current. The charging current is maximum when two plates are uncharged but it decreases and finally leases when potential difference across the plate, slowly equals and is opposite to eh battery emf. Symbolic representation of ceramic capacitor General representation 14 Figure 1 MOSFET (POWER SWITCH) Power MOSFETs are typically the preferred switching semiconductor devices for solar panels because they offer a simple – to – drive option that can be switched efficiently at high frequencies. A rating of 600V and 650V are typically used to ensure enough ‘headroom’ for the safe handling of high voltage transients. Power MOSFETS consist of an inherent body diode. To minimize switching losses and increase system efficiency, fast recovery body – diodes (FRD) are requested depending on the circuit topology. Such |FRDs are basically and simple characterized by reverse recovery times (trr). In addition, choosing devices in which the FRD is integrated into the body of the MOSFET can help to reduce component count, save space, simplify design and streamline inventory Circuit symbols A variety of symbols are used for the MOSFET. The basic design is generally a line for the channel with the source and drain leaving it at right angles and then bending back at right angles into the same direction as the channel. Sometimes three line segments are used for enhancement mode and a solid line for depletion mode. The bulk connection, if shown, is shown connected to the back of the channel with an arrow indicating PMOS or NMOS. Arrows always point from P to N, so an NMOS (N-channel in Pwell or P-substrate) has the arrow pointing in (from the bulk to the channel). If the bulk is connected to the source (as is generally the case with discrete devices) it is sometimes angled to meet up with the source leaving the transistor. If the bulk is not shown (as is often the case in IC design as they are generally common bulk) an inversion symbol is sometimes used to indicate PMOS, alternatively an arrow on the source may be used in the same way as for bipolar transistors (out for nMOS, in for pMOS). Comparison of enhancement-mode and depletion-mode MOSFET symbols, along with JFET symbols (drawn with source and drain ordered such that higher voltages appear higher on the page than lower voltages): 15 For the symbols in which the bulk, or body, terminal is shown, it is here shown internally connected to the source. This is a typical configuration, but by no means the only important configuration. In general, the MOSFET is a four-terminal device, and in integrated circuits many of the MOSFETs share a body connection, not necessarily connected to the source terminals of all the transistors. CENTER TAP TRANFORMER In electronics, a centre tap is a contact made to a point halfway along a winding of a transformer or inductor, or along the element of a resistor or a potentiometer. Taps are sometimes used on inductors for the coupling of signals, and may not necessarily be at the half-way point, but rather, closer to one end. A centre – tap transformer is a special type of transformer that has an additional wire, or ‘tap’, in the middle of the winding. This tap allows the transformer to be used in a variety of applications where a centre – tapped secondary is needed. The center tap can be used to create a grounded neutral, to provide a DC bias, or to create two secondary windings with different voltages. 16 RESISTORS A resistor in its definition is an electrical and electronic component that offers opposition to the flow of electrical current. It also acts as a pre-load on the voltage supplies to a system i.e. causes an initial voltage drop across it this is a pre-load component. TYPES OF RESISTOR variable resistor, rheostat resistor, potentiometer resistor and fixed resistor Table 1.0: A table showing the resistor color code COLOUR FIRST BAND SECOND THIRD BAND TOLERANCE BAND BLACK _ 0 BROWN 1 0 ±1% RED 2 00 ±2% ORANGE 3 000 YELLOW 4 0000 GREEN 5 00000 BLUE 6 000000 VIOLET 7 0000000 17 X10 GREY 8 00000000 WHITE 9 000000000 GOLD _ _ X0.1 ±5% SILIVER _ _ X0.01 ±10% The symbol is as below: Figure 2 HOW TO CHOOSE A RIGHT INVERTER AND BATTERY Inverter is a type of electronic power generator which convert low voltage direct current (DC) from a battery to a high voltage alternating current (AC). Power failures can be really very frustrating at times, especially during the night time. Inverters will help you to cope up with the blackout and do away with your problems. Choosing a right inverter and battery is not very easy. Load Calculation: First of all calculate your Power Consumption. This can be done by adding up the Watts (W) of all loads (CFLs,TV), to be powered by the inverter. For example one 20W CFL + one 60W TV =20+60 =80W. Inverter Capacity: Never select the Volt-Ampere (VA) rating of Inverter. VA=Watts x Power Factor. Power factor value varies from 0.6 to 0.8.Note that a 600VA rated inverter (with power factor 0.8) delivers approximately 480 Watts only! Inverter Type: Square wave, Quasi- Sine wave and Pure Sine wave inverters are now available. In practice, sine wave is the correct waveform on which all electronic equipment, including televisions and computers are designed to run. 18 Battery Selection: Battery is the back bone of any inverter, 24v/200AH battery is used with this solar inverters. Tubular type storage batteries are recommended for inverters because they are capable of long hours of guaranteed backup time. Backup time is simply the number of hours for which an inverter will be able to run the output electric load during power failure. Batteries are available in different voltage and Ampere-Hour (Ah) ratings. Back up time is mainly determined by this Ah rating of the battery. Tubular batteries have higher capacity-tosize ratio. These types can be recharged faster and are energised to deliver increased power and higher efficiency. Backup Time: Formula to Calculate the backup time of Inverter is Ahx24V x PFx0.9/Load VA hours. Where Ah is the ampere-hour capacity of the battery, PF stands for the power factor of the inverter and load is the sum of VA ratings of the electrical loads connected to the inverter 19 CHAPTER FOUR RESULT ANALYSIS 4.1 CONSTRUCTION PROCEDURE AND TESTING In building this project, the following procedures were properly considered: i. Purposing of the entire materials / Components needed ii. Resistance check of the components bought with the help of ohmmeter before making the necessary connection with the components iii. Drafting out a schematic diagram or how to arrange the materials / components. iv. Testing the completed system to see if the design works and v. Finally, implementation of design of the project. Having procured all the materials, I processed into the arrangement of the components into the Vero board but we could not place the MOSFETs on the bread board because the heat it emit when we load it, proper soldering of the components then followed. The components were all soldered into the board after which it was correctly confirmed done. The construction procedures are as below: According to the circuit diagram initially do the assembling of the oscillator part which consist of the small components & IC. It is finely completed by interrelating the part leads itself and fusing the joints. Step 1: Now place the power transistors into the acutely pierced aluminum heat sinks. This is crafted by cutting aluminum sheet into specified sizes and bending their sides, so that it can be hold tightly. Step 2: Make use of mica isolation kit to fix transistors in the aluminum heat sink, evade short circuiting and direct contact of the transistors from ground & each other. Step3: Fasten the heat sink congregation to the bottom of a properly ventilated, strong, thick gauge metal enclosed space. Step 4: Also fasten the power transformer next to the aluminum heat sinks by making use of screw and bolts. 20 Step 4: Now join the suitable points of the assembled circuit board & power transistors on the aluminum heat sinks. Step 5: At last, connect the power transistor’s productions to the subsequent winding of the power transformer. Step 6: End the assembly by fastening and interlocking the outer electrical fittings such as switches, mains cord, fuses, sockets, and the battery inputs. Steo 7: A voluntary solar power supply circuit and a transformer may be added within to charge the battery when necessary. 4.2 CASING AND PACKAGING All the components were soldered onto the Vero Board. Then after that, a case was gotten where the entire circuit was mounted follow by other external components such as indicators, battery contacts and switch. They help to protect the internal component of the inverter from damage, its also help keep the inverter running efficiently by providing proper ventilation and cooling 4.3 ASSEMBLING OF SECTIONS Having provided the casing and having finished the construction of the sections of this system, the assembling into the casing followed. The sections were properly laid out and assembled into the casing where the general coupling and linkages into the peripheral devices took place. Finally; the indicator was brought out to indicate when the system is powered. Switch was brought out for powering the system and battery contact was also brought out where batteries are been connected. And at last the solar panel was hung. 4.4 TESTING OF SYSTEM OPERATION In this stage, the system was due for testing and operation. The system operation was tested where all its required performance was maintained. Batteries were connected and the system was powered through the switch the LED displayed indicating ON. Then after we powered the system, load close to 1000W but not equal to kva was loaded on the system with which was allowed to stay on the system for more than 20mins in other to monitor the amount of heat MOSFETs will emit and to see whether the system will be able to carry such load. 21 If there are no error codes, take a look at the LEDs. They should all be lit up green if the inverter is working properly. A green light on the outside of an older SMA inverter indicates that there is more than 90% output (which is excellent). 4.4 SAFETY OF A SOLAR INVERTER Power inverters should only be used with batteries that are in good condition and fully charged. A weak battery will be drained easily if demand is too high. Working with large batteries can be dangerous, and when not done properly, can result in serious injury. Improper use of a power inverter can even lead to electrocution. For safety reasons, someone attempting to hook a solar inverter directly to a battery should be sure to read and follow any and all safety precautions listed in the inverter's instruction booklet. It is important for people to always use a power inverter that is rated high enough for the device that needs to be run. If a heavy-duty power saw is plugged into a cigarette lighter, for example, the lightweight inverter might overheat and cause a fire in the dashboard. Adapters that allow more outlets than the unit is designed to accommodate should be avoided, and proper ventilation around the inverter is required to prevent overheating. 4.5 MODIFIED SINE WAVE POWER SOLAR INVERTER CIRCUIT USING IC 4093 The post explains a simple modified sine wave inverter circuit using a single IC SG 4093. The circuit is as below: 4.6 CIRCUIT OPERATION From the circuit diagram above, the IC 4093 is rigged in its standard PWM generator/oscillator mode where the frequency of oscillation is determined by C1, R1 R2 and R3. 22 R1 can be adjusted for acquiring accurate frequencies as per the required specs of the application. The range of R1 is from 50Hz to 100Hz, here we are interested in the 50 Hz value which ultimately provides a 50Hz across the two outputs PINS. The above two outputs oscillate alternately in a push pull manner (totem pole), driving the connected MOSFETS into saturation at the fixed frequency - 50 Hz. The MOSFETS in response "push and Pull the battery voltage/current across the two winding of the transformer which in turn generates the required mains AC at the output winding of the transformer. The peak voltage generated at the output would be anywhere around 300 Volts which must adjusted to around 220V RMS using a good quality RMS meter and by adjusting R2. P2 actually adjusts the width of the pulses at the out put pins, which helps to provide the required RMS at the output. This feature facilitates a PWM controlled modified sine waveform at the output. For Charging Batteries up to 250 AH The charger section in the above circuit may be suitably upgraded for enabling the charging of high current batteries in the order of 100 AH to 250 AH. An outboard transistor TIP36 is appropriately integrated across the IC 338 for facilitating the required high current charging. The emitter resistor of TIP36 must be calculated appropriately otherwise the transistor might just blow off, do it by trial-and-error method, start with 1 ohm initially, then gradually go on reducing it until the required amount of current becomes achievable at the output. 23 CHAPTER FIVE CONCLUSION AND RECOOMENDATION 5.1 CONCLUSION The essence of this project is to provide alternative mains for electrical/electronics equipment in case of power failure. There has been an enormous growth in the world of technology today, with many devices which need certain power supply and backup. The inverter, not only serve as a power source but also as a protective device for sophistical equipment in the case of power fluctuation or surge. Inverter offers great benefit for many people either in private sector or public sector. Inverter system is intended to improve the quality of AC power in order to provide uninterrupted operation of AC power equipment. 5.2 RECOMMENDATION i. In view of problems encountered, we hereby make the following recommendations: ii. More enquiring textbooks should be made available in the library in order to alleviate students financial problem. iii. Testing equipment such as meters, oscilloscope should be provided the laboratory for students use. iv. Component should be made available in the practical laboratory for students to undergo some practical. v. Electricity supply and backup like putting on of generator so that students can study at night. vi. Modern day equipment should be provided at the laboratory. 5.3 REFERENCES 1. Theraja B.L. and Theraja, AK. (2001), A Text Book of Electrical Technology, India, S. Chand and Company Ltd. 2. Bolstered, R. and Nashselsky Louis (1996), Electronic Device and Circuit Theory, 6th edition, U.S.A., Prentice Hall Inc. 24 3. Horowitz, P. and Hill, W. (1995), The Art of Electronics, 2nd 4 Edition, Great Britain, University Press, Cambridge. 4. Philips E.C.G. (1998), E.C.G Master Replacement Guide, 18th edition, U.S.A., Philips Consumer Electronics Company. 25