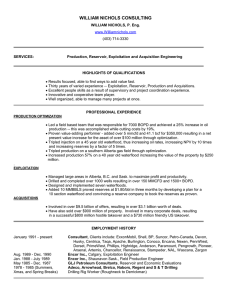

IPTC-18733-MS Success in Arresting Overall Field Decline and Increasing Oil Production in a Mature Field through Effective Production Enhancement Initiatives A. Zamanuri, M. Abdulhadi, H. V. Chin, C. C Lim, and S. Jacobs, Halliburton Bayan Petroleum Sdn. Bhd.; S. M. A. Sayed Zainaiabidin, M. I. M. Khalil, M. I. Abd Wahid, K. A. Dolah, and H. Munandai, Petronas Carigali Sdn Bhd Copyright 2016, International Petroleum Technology Conference This paper was prepared for presentation at the International Petroleum Technology Conference held in Bangkok, Thailand, 14-16 November 2016. This paper was selected for presentation by an IPTC Programme Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the International Petroleum Technology Conference and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the International Petroleum Technology Conference, its officers, or members. Papers presented at IPTC are subject to publication review by Sponsor Society Committees of IPTC. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the International Petroleum Technology Conference is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented. Write Librarian, IPTC, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax +1-972-952-9435. Abstract In a mature oil field that has been producing for over 30 years, declining reservoir pressure and increasing water-cut are the two major factors that are affecting oil production rates. It is a common understanding that without any effort, this decline in oil production will remain until the end of the field's economic life. One of the approach to address this issue is through production enhancement work which has been proven successful in an oilfield offshore of Sarawak not only at arresting the overall field decline, but also increasing the overall oil production. The practice for Production Enhancement (PE) work in this field mainly involves (i) shutting off the existing watered-out intervals, (ii) adding perforations to the existing sand and/or a different reservoir, (iii) zone change and gas lift valve change activities, (iv) re-activation of idle wells, (v) gas lift optimisation and well bean-up, (vi) reservoir management planning and (vii) restoring well integrity. Due to the limited deck space on the platform and the unavailability of living quarters, the application of a work barge was essential for this type of PE work to house the necessary equipment and chemical for the enhancement job as well as acting as an accommodation vessel for the personnel. Concurrent well intervention operations on two different platforms was the selected option for time and cost optimisation and quicker first oil. For the same reasons, 24 hours operation was implemented whenever circumstances permitted. Further cost optimisation was implemented in subsequent campaign by utilizing slickline only as means of well intervention as well as withdrawing the option to have a dedicated work barge on site to support the campaign. After the successful PE Campaign in four (4) consecutive years, this initiative has resulted in over 3500 bopd of incremental oil. The overall technical potential (TP) of the field also increased by more than 100 percent. This has effectively arrested the previously estimated 25 percent field decline before the campaigns and increased in the overall field production. This paper seeks to present the challenges, the plans and operational execution of the well intervention activities. The results of the successful PE campaign, implementation of best practices, lessons learnt and improvement plan will also be shared. 2 IPTC-18733-MS Introduction Field B was discovered in 1976 through the drilling of an exploration well. The field is located in water depth of 90ft approximately 80km North West of Bintulu. Figure 1 shows the three (3) sub-fields of Field B namely B1, B2 and B3. These three (3) sub-fields are further divided into nine (9) fault compartments which are Block 1, 2A, 2B, 3, 4, 5W1, 5W2, 5W3 and NWB. There is a total of eight (8) main reservoirs (S.A / S.B / S.C / S.D / S.E / S.F / S.H) in the Cycle II sand with multiple drive mechanism including water drive, gas cap drive and solution gas drive. Figure 1—Sub-division of Field B Field B first production came on stream in June 1984 from the drilling platform DP-B1.1. Subsequently, three (3) other drilling platforms were installed; DP-B1.2 in 1989 and DP-B3 & DP-B2 in 1992. Four (4) revisit campaigns had been carried out in Field B from 1988 to 2004 which added 11 producing wells making a total of 48 wells in the field. Throughout 30 years of production, the field has seen a peak oil production of up to 30,000 bopd in 1990 and an all-time low of 3000 bopd in 2000. In 2012, total field water cut has increased to a steady 63% while oil production was hovering around 5000 bopd signifying the diminishing economic life of the field. The production enhancement campaign was implemented to curb this steady decline in oil production. In 2013, the strategy for production enhancement was inclined towards well intervention activities with substantial cost which include (i) shutting off the existing watered-out intervals, (ii) adding perforations to the existing sand and/or a different reservoir and (iii) re-activation of idle wells. These approaches were also implemented in 2014 albeit at a smaller scale. In addition, a low cost, with significant oil gain method was enforced in 2014 involving activities such as (i) zone change activities, (ii) well bean-up, gas lift optimization and gas lift valve change activities, and (iii) reservoir management. In addition, a new 3D seismic was acquired in 2013 which could provide a new geological model leading to a new understanding of the whole Field B. IPTC-18733-MS 3 Key Challenges Production enhancement activities in Field B are not without challenges. These challenges vary from subsurface into the wellbore and all the way up to the surface facilities including well intervention execution strategies. These challenges include the following: • • • • • • Heavily faulted reservoir with communication between multiple blocks Mature field with limited opportunity Poorly documented historical data Unmanned satellite platforms with limited deck space, lighting facility and lifting capacity Uncertainty of tubing integrity due to old age of the wells Low reserves with marginal economic One of the main challenges in Field B is the complexity of the reservoir. The field is divided into three (3) sub-fields with nearly 100 faults and numerous reservoir packages. The reservoir drive mechanisms consisted of water drive, gas-cap drive and solution gas drive with multiple instances of communication between the reservoirs. The field has eight (8) main reservoirs with more than 20 sub-reservoirs. Several of these sub-reservoirs are thick sands where communication exist between them through juxtapositions, sharing gas cap or aquifer. Other sub-reservoirs are isolated by thin layers of shale which are apparent in certain wells but absent in others. This complicates the reservoir understanding and therefore requires any opportunity identification to be thoroughly researched and examined. This mature field has been producing for 33 years where numerous attempts have been made to increase field production either through developing new block, infill drilling campaign or production enhancement. As a result, limited opportunity are left within the field and often, opportunities found are unattractive and risky which leads the team to utilize inexpensive and successfully proven technology. In addition to that, poorly documented well and field history from 33 years of production makes understanding and reasoning difficult especially since the field has had several change of operators before. Part of the challenge is to verify historical data using partially available information while another part is to provide reasoning of the decision made in the past. In terms of surface facilities challenges, limited deck space and lifting capacity restricts well intervention options on Field B's satellite platforms especially relating to pumping activities and application of coiled tubing unit. The quick fix to this issue was to employ a dedicated work barge whenever coiled tubing activities are involved. The additional deck space on the barge was used to accommodate the pumping facilities which were connected with a hose to the equipment on the platform for delivery of fluid. In addition, the barge also acted as an accommodation vessel for the personnel. The crane capacity of the work barge is significantly superior compared to the platform's crane allowing weights up to 25 MT to be lifted onto the platform. In 2013 PE Campaign, concurrent operation involving a Coiled Tubing unit on one platform and an E-line unit on another platform was implemented. Since both operation would require high capacity lifting capability, portable crane was procured to assist lifting operation of the E-line unit onto the other platform. In a way, this arrangement has led to some cost saving by not engaging another work barge to facilitate lifting activities while enabling well intervention to proceed on both platforms and hasten oil production. For 2014 PE Campaign involving E-line intervention, a different approach was taken whereby the lightweight E-line unit was utilised (individual equipment weighs less than 4 MT) eliminating the requirement of a barge or portable crane. For further cost saving purposes, whenever PE activities involved slickline operations only, the well intervention personnel will be piggybacked on any available vessel stationed within acceptable distance 4 IPTC-18733-MS from the field. Cost saving was achieved by not having to hire a dedicated work barge at the expense of a slight reduction in operation efficiency. Candidate Selection and Maturation Candidate selection and maturation process follows the workflow as illustrated in Figure 2. Initially, a well by well matrix (Figure 3) was developed which contains all sands penetrated by each well and their respective Open Hole log results. The well by well matrix ensured all possible Behind Casing Opportunity (BCO) are identified and there are no opportunities missed. Figure 2—Production Enhancement workflow used in Field B IPTC-18733-MS 5 Figure 3—Well by well Matrix In parallel with the well by well matrix, reservoir tank models were developed for producing reservoir to validate historical production data. Particular attention were given to wells with fluctuations and irreconcilable production data. Often, substantial re-iteration of the tank models were required to ensure they are in line with production and pressure history. This exercise assisted in acquiring improved understanding of the reservoir which leads to considerably accurate prediction of fluid contact movement and pressure depletion. From the estimation of fluid contact and reservoir pressure, preliminary PE candidates can be identified. If deemed necessary, reservoir contact logging could be run to further support the analysis and confirm the opportunities. Throughout 2012 – 2016, a total of six contact logs were run in Field B to confirm the fluid contacts which lead to identification of several PE candidates. In water drive reservoirs, the strategy of chasing the oil column has generated significant amount of opportunity for the field. Using this method, a well is produced until the perforation is completely wateredout, prompting the oil column to move upwards. New perforations were then added at shallower depth whether in the same well or nearby well to chase the oil. This approach has been proven successful repeteadly where oil was produced from the original gas cap zone of a reservoir. Upon completion of opportunity screening, the candidates were matured through reserves determination and economic screening. Reserves estimation were done through both volumetric calculation as well as Decline Curve Analysis (DCA) which is simple yet reliable. This enable more time to be spent on selecting the optimal execution method and provide the most cost-effective technique to execute the job. Identification and maturation of small scale PE candidates involving Gas Lift Valve Change or Insert String opportunity were done through comprehensive analysis of routine static and flowing pressure surveys in a flowing well or an idle well. In an idle well, Static Gradient Survey (SGS) allows the liquid level to be reasonably estimated within the wellbore. Under this circumstance, placing an orifice valve within the fluid column could remove the possibility of gas lift cycling and potentially revive a well. In the case where there is no available Side Pocket Mandrel (SPM) below the liquid level, deepening of gas lift injection point is implemented through the use of Insert String. In a flowing well, routine Flowing Gradient Survey (FGS) 6 IPTC-18733-MS enables detection of exact point of gas lift injection. From this exercise, passing dummy valves as well as redundant unloading valves can be discovered which would then be replaced for production and gas lift optimisation. Well Intervention and Optimisation Execution Throughout the four Production Enhancement campaigns in Field B, a total of 16 candidates have successfully been executed for enhancement and optimization; WSO & Add Perforation (9), Add Perforation (5), GLVC (2), ZOC (2), Bean-up Optimisation (1) and reservoir management (3). This section will share some of the successful activities which have surpassed the forecasted performance. Well 1S Water Shut Off (WSO) & Add Perforation Well 1S was an idle well after its water production reached 100% in late 2002. WSO was proposed to shut off current perforated zone and a new zone immediately above it was proposed for additional perforation. Since the zone to be shut off was located in the short string, the use of chemical instead of cement was selected to ensure better fluid control in the tubing. In addition to that, residual chemical – if any – left inside the tubing after it has been set, can be effortlessly removed through the use of high speed jetting nozzle. The WSO operation involved pumping approximately 40 bbls of chemical into the well to ensure sufficient penetration into the formation as well as ample isolation of the zone within the wellbore. After 24 hours of setting time, the well was pressure up to 300 psi to determine the integrity of the chemical. Pressure was observed to be holding for 10 minutes which indicated the zone had been successfully isolated. Perforation was added using slickline to the desired zone and the well contributed approximately 2400 bopd with 0% watercut (Figure 4) making this well one of the top producers in the field. Figure 4—Production Performance Before & After WSO in Well 1S Well 2L Water Shut Off (WSO) & Add Perforation Well 2L was an idle well since late 2011 for two reasons: watered-out and fish in tubing. A reservoir contact log run in 2012 confirmed some remaining oil column above the existing perforation interval. The method nominated for this partial zone isolation was through chemical treatment. Chemical was preferred over IPTC-18733-MS 7 cement as this exercise also involved behind casing repair as a result of poor cement bond between the intervals of interest. This task was only able to be achieved by chemical due its higher degree of penetration compared to cement. Prior to commencement of WSO activities, a 23ft slickline fish needed to be removed from the tubing. However, failing to retrieve the fish after several trials prompted the decision to cut the tubing right on top of the fish. Two (2) runs were required to cut the tubing using the Hydraulic Tubing Cutter after which a Blind Box was run together with an Impact Hammer to push the parted tubing all the way into the rat hole, away from the desired perforation interval. WSO execution was not perfect due to high wellhead pressure seen during pumping. As a result, only 17% of the chemicals penetrated into the formation to stop the water. Nevertheless, an acceptable pressure test on the hardened chemical implied zonal isolation, and subsequently perforations were added to the zone of interest which contributed initial instantaneous oil gain of more than 700 bopd at lower watercut of 42% as illustrated in Figure 5 & Figure 6. Figure 5—Production Performance for Well 2L 8 IPTC-18733-MS Figure 6—Water Cut Performance Before & After WSO in Well 2L Well 3S Add-Perforation Well 3S was producing at 150 bopd with 90% WC prior to the add perforation. After the additional perforation, the well produced nearly 500 bopd with 60% WC as can be seen in Figure 7. Figure 7—Production Performance for Well 3S IPTC-18733-MS 9 Well 3S was originally producing from only S.D, a strong water drive reservoir. The well began producing water in 1998 and the water cut since increased until 90% to the point that the well was no longer able to be produced through LP header. Based on the production history, the well was suspected to have been producing the gas cap during early life, which was supported by high GOR at early production and continuous low GOR beginning mid well life. In 2011, Well 3S was tied-in to the Low Production System (LPS) with oil production of 150 bopd with 90% WC. To support the S.D production, it was proposed to perforate S.C which is a solution gas drive reservoir and to commingle the production with S.D. The plan was supported by nodal analysis which showed no cross-flow of the two reservoirs during production and that the well will be able to produce at higher oil rate with reduced water cut. Well 3S E-line perforation was run in parallel with Field B barge operation with the assistance of protable crane to lift the equipment. Since the well was completed with dual strings, the use of a Magnetic Orienting Tool (MOT) was essential to avoid perforating the long string. The perforation operation took five runs to complete and the initial production after the perforation showed Well 3S producing at 150 bopd when tied in to the LP header. The well was then tied-in to the LPS and produced approximately 500 bopd, more than double the target rate of 200 bopd, with reduction of water cut from 90% to 60%. Well 4L Add Perforation & Mechanical WSO Well 4L Add Perforation and WSO activity contributed 395 bopd to Field B’s total production. The well was idle since September 2000 and was reactivated in December 2014. Well 4L was originally completed in S.H.4 which watered-out in May 1996. Previous WSO and additional perforation on S.H.2 in 2009 was not successful with nearly 100% water cut production. Although the Open Hole log showed the presence of oil in the sand, S.H.2 was hydraulically in communication with the rest of the S.H sand and given its strong water drive mechanism, it was believed that the perforation in S.H.2 was below the current Oil Water Contact (OWC). This understanding was confirmed with a reservoir contact log performed at a nearby flowing crestal well in May 2012, which also showed that the oil column had migrated into the original gas cap. This provided an opportunity to perforate the upper part of S.H.2 in Well 4L which was originally a gas column based on the Open Hole log. To monetise the oil reserve, it was decided to perform WSO on the existing perforation and add perforation on the upper part of S.H.2. For WSO, a Through Tubing Bridge Plug (TTBP) was utilised and cement was dumped on top of the plug until 20ft above the existing interval. TTBP was chosen as WSO method due to the significantly lower operation cost compared to other methods since only slickline was required for the intervention. A cost saving of nearly RM 2.7 Million was estimated as a result of applying the TTBP instead of a cement job with the employment of Coiled Tubing. In addition, a good cement bond between the two intervals of interest eliminated the requirement to pump any chemical or cement outside of the wellbore into the formation. The operation was carried out using a smart dump bailer which was controlled by three parameters; time, temperature and motion while adding perforation was done using electronic triggering device, controlled by one additional parameter; pressure. After the operation, the initial production was 395 bopd, double the target rate of 180 bopd which was based on nodal analysis. The well also produced 0% watercut as illustrated in Figure 8 proving complete seal of the old perforation and success of the WSO operation. 10 IPTC-18733-MS Figure 8—Water Cut Performance Before & After WSO in Well 4L Bean-Up Opportunity, Gas Lift Optimization and Gas Lift Valve Change Bean up opportunities and gas lift optimization are two efforts that always come side by side in production optimization. In Field B’s case, most wells were already producing at a high GOR & GLR signifying little opportunity for gas lift optimisation. The opportunities were identified through well modelling and two of the most successful candidates are as below: Well 5L. This well was initially producing to the LPS at a choke size of 40/64" with gas lift injection at 0.3 MMscf/d. Production modelling using existing well test data and the relevant software confirmed potential incremental oil through increase in choke and additional gas lift injection. Both initiatives were implemented simultaneously in late 2014 where bean size was increased to 52/64" and gas lift injection increased to approximately 0.9 MMscf/d. The results were astonishing as oil production boosted from approximately 600 bopd to more than 1200 bopd while watercut was seen to be almost halved from 60% to only 34%. The increment in gas lift injection also resulted in higher Flowing Tubing Head Pressure (FTHP) allowing the well to be flowed to the LP header instead of to the LPS. Indirectly, this allowed another well that was tied to the LPS to flow without competition by the elimination of backpressure. Well 6. This well contributed nearly 200 bopd to Field B total production due to Gas Lift Valve Change (GLVC) activity. Before GLVC, the well was producing intermittently with an average production of 30 bopd. However, the well failed to flow in June 2014. A Static Gradient Survey (SGS) conducted on the well clearly showed that the fluid level was well below the operating mandrel. This was further supported by the fluid level tagged by the drift run. The above two mentioned bits of information confirmed the preliminary theory that the well was recycling its gas lift gas and thus, would require a new gas lift design. From the new gas lift design, the original valve was replaced with a dummy valve and an orifice was installed at a deeper mandrel. As a result, the well was able to produce at 200 bopd, four (4) times higher than the target rate of 50 bopd based on the gas lift design and nodal analysis. Reservoir Management Reservoir tank model was developed for reservoir studies on the subject of Gas Oil Ratio (GOR) on five wells in an effort to find out the effect of producing above the GOR limit (a limit originally placed to preserve IPTC-18733-MS 11 reservoir pressure for maximum reserves production efficiency) on the reservoir. For one of the wells, Well 7, the well was already producing above its GOR limit by approximately 2000 scf/bbl. Forecasted oil and gas production was prepared through reservoir simulation with the aim of estimating the maximum GOR the well will ever reach. Based on the simulation, the GOR will increase to a maximum of roughly 4000 scf/stb – 2500 scf/stb above its original limit – within the next 10 years at a production cut-off of 20 bopd. It was also predicted from the forecast that there will be no detrimental effect on the reservoir should the well produce above its GOR limit. The findings from the simulation ensured the well could continue its production at a relaxed GOR with the rate of approximately 280 bopd. Two other well namely Well 8S & Well 9S achieved a similar objective contributing to a combined oil production rate of approximately 300 bopd. Best practices and Lessons Learnt After completing each PE campaign, an After Action Review (AAR) was held between all parties involved to review the overall performance of the campaign. One of the objective of the workshop was to identify the best practices which contributed to the optimisation of the campaign as well as any lessons learnt that should be implemented for the next PE campaign. 1. The development of Integrated Barge Planning (IBP) is one of the best practices during the campaigns. In this practice, key personnel were identified from various parties (subsurface discipline, well intervention, contractors, marine, operation engineer and the production team) and built into a network of team to support the campaign. The seven (7) days look ahead report was discussed daily and distributed between the network to inform all parties of the current situation and to ensure readiness. A parallel feedback loop between the company site representative and contractors’ office was also established to provide multiple sources of information for quality check and optimisation. The IBP allowed for optimisation by integrating planned activities from other parties and provide support during unplanned situation. 2. Robust onsite operation planning was also a key exercise that contributed to the optimisation of the campaigns. Concurrent operations between barge and barge-less work was planned and executed, providing opportunities to perform significant number of jobs during the whole campaign. Additionally, overlapping crew change throughout the campaigns ensured there was no operation standstill due to insufficient crew. 3. The campaign was also optimised by performing well preparatory work without barge support. The main objective for this well preparatory work was to ensure well readiness as well as to fix any well related issue prior to barge arrival. This would ensure that the barge was fully utilised for coiled tubing intervention instead of spending time on slickline intervention. Throughtout all the PE campaigns, there were a total of 12 well intervention jobs utilising coiled tubing. For optimization, well preparatory works such as Tubing Integrity Test (TIT), Tubing Clearance Check (TCC) and closing of Sliding Side Door (SSD) which can be done using slickline were performed prior to arrival of barge onsite. 4. An important lesson learnt from the PE Campaign include the requirement to design a provisional gas lift valve which should be installed immediately after a job is completed. This is to ensure a well is not idle due to the inability of the well to flow naturally while awaiting for new gas lift design. 12 IPTC-18733-MS Conclusion a. Production Enhancement in mature fields requires thorough and systematic subsurface study combining both software modelling and field data acquisition. b. Well intervention work through concurrent operation and Integrated Barge Planning was essential to reduce the overall operational cost of the Production Enhancement campaign thus making the campaign economically viable. c. Continuous oil boosting initiatives proved to be successful in maximizing oil production and reserves in Field B, contributing to average incremental oil rate of approximately 2,700 bopd throughout the first half of 2016 as illustrated in Figure 9. d. Field B Production Enhancement campaigns successfully arrested the field 25% p.a. production decline from 2013 – 2016. In addition, the field technical potential increased by 162 percent as at May 2016 as shown in Figure 10. Figure 9—Total Field B TP Increase IPTC-18733-MS 13 Figure 10—Existing TP Forecast against Actual TP after PE Initiatives Acknowledgement The authors would like to thank the management of Petroliam National Berhad (PETRONAS) and PETRONAS Carigali Sdn. Bhd. (PCSB) for the permission to publish this technical paper and to all those who have contributed to the success of this project.