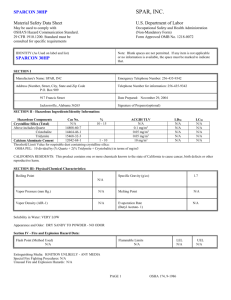

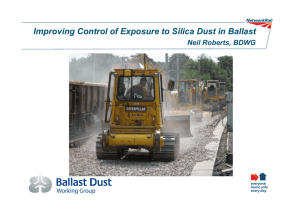

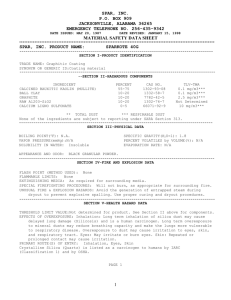

UNIVERSITY OF CAPETOWN FACULTY OF ENGINEERING AND BUILT ENVIRONMENT DEPARTMENT OF CHEMICAL ENGINEERING MSC RESEARCH PROJECT TOPIC: EXPOSURE MONITORING OF MINE DUST AND TOXIC SUBSTANCES TITLE: INVESTIGATING WATER ADDITIVES THAT CAN BE USED TO IMPROVE CAPTURING OF RESPIRABLE DUST AND CRYSTALLINE SILICA IN UNDERGROUND MINES DURING DUST SUPPRESION STUDENT: LOVEJOY NYONI SUPERVISOR: DR C MANGUNDA 1|P a g e TITLE: EXAMINING WATER ADDITIVES THAT CAN BE USED TO IMPROVE CAPTURING OF RESPIRABLE DUST AND CRYSTALLINE SILICA IN UNDRGROUND MINES DURING DUST SUPPRESION 1.1 AIM To examine the use of silica suppressants in enhancing water’s ability to control respirable silica dust. 1.2 SPECIFIC OBJECTIVES 1. To review the characteristics of crystalline silica dust in water 2. To study the properties of different additives that can be used to enhance water-dust contact and select the most effective additive for laboratory testing. 3. To examine the water spray systems for dust control 1.3 BACKGROUND Mining industry is the economic backbone for many countries around the world. (Elizaberth,2011) However, the major drawback posed by the operations presents serious health and environmental problems. Mining operations generate enormous amounts of dust which are environmentally unfriendly resulting in heavy air pollution. (Ghose, 2001) The largest quantities of airborne dust are usually produced in mining facilities by several mechanical operations including blasting, drilling, scrapping, comminution and transportation. (Prostański, 2015). Dust move together with the ventilation air (Bhaskar, 1986) and it settles at the wall and equipment such as excavators (Nawrat et al.2002). The dust from mining operations does not only affect the mining vicinity, but the environment and communities around the mining area. In the process of mining mineral raw materials, workers are exposed to elevated levels of noxious aerosols including respirable dust and crystalline silica. (M Biffi, 2000). Exposure to the dust presented in the ventilation air poses a threat to health eventually leading to debilitating respiratory diseases that can affect the health of workers and it has undesirable influence on working conditions. Numerous research studies have been conducted to combat the health problems presented by mining operations such as rock blasting and polishing, but they continue to escalate. It is important that the mining companies embrace technology in trying to meet health requirements and governmental regulation prescriptions. Major sources of dust are open pit mines, stockpiles, mine dumps, ore processing and metal extraction plants. (Sandton, 2006) This presents a gap in developing technology and framework to curb the global challenges faced by mine workers and mining communities. The actuality of all efforts aiming at combatting of toxic dust particles to health, linked with the silicosis and pneumoconiosis morbidity, requires personal monitoring of the dust exposure (Lebecki and Bywalec, 1998). The outcome of the monitoring gives the basis for undertaking effective preventive measures depending on the type of work performed. The mining laws in South Africa are predominantly regulated by the Mineral and Petroleum Resources Development Act 28 of 2002 (MPRDA). There are several other pieces of legislation which deal with issues such as royalties (the Mineral and Petroleum Resources Royalty Act, 2008), 2|P a g e title registration (the Mining Titles Registration Act, 1967), and health and safety (the Mine Health and Safety Act, 1996). These regulations specify the maximum and minimum concentrations of dust and respirable crystalline silica. In terms of the occupational exposure limits contained in the guidelines for the generation of Mandatory Codes of Practice in terms of Section 9(2) of the Mine Health and Safety Act, 1996 (Act No. 29 of 1996), exposure to silica dust is limited as follows: Crystalline Silica: 0,1 mg/m³(8h), amorphous silica (Inhalable) 6,0 mg/m³(8h) and amorphous Silica (Respirable) 3,0 mg/m³(8h) (Biffi, 2008) There are various means which can be used to determine the amount of respirable dust and crystalline silica inhaled by workers such as mineralogical test methods, including X-Ray Diffraction (XRD). According to NIOSH, CDC, Safety and Health, in order to quantify a miner’s exposure to noxious substances, monitoring is one of the effective methods. Personal monitoring is a widely used approach to evaluate worker exposure, where a sample or multiple samples taken from the breathing area of the worker and at that of time that can be increased to a full shift during that sampling period. A gravimetric-based dust monitor is often used to determine the levels of silica with use of filters and sampling instruments. The whole area can be monitored with multiple samplers used to characterize the level of toxic substances in the air during mining operations. Lastly, monitoring a specific mining activity considered to be as a source of respirable dust enables for a total understanding of the task and the required control technologies. The result of the monitoring gives the basis for undertaking effective preventive measures depending on the type of works performed (Lebecki and Bywalec, 1998). Continuous improvement of dust suppression methods is necessary to achieve the diminishing of silicosis and pneumoconiosis probability in underground mines. 1.4 PROBLEM STATEMENT Despite mining industry playing a major role in the economic stability of many developing countries, the resulting negative impacts of mining operations continue to threaten the health of many citizens. Silica or quartz is the most abundant mineral on the earth and is found in almost all minerals mined. Crystalline silica is a cause of concern amongst other toxic dusts. Coal is a versatile mineral that is often mined, and it comprises of organic and mineral matter. Respirable coal mine dust normally contains a small proportion (usually < 5%) of quartz or silicates, mostly from dirt bands within the coal stratum (Stanton et al, 2006). It was reported that the average measured silica content of South African coal seams was 3.5% (Biffi, 2003). Silicosis is a debilitating and often fatal coal worker's occupational lung disease caused by the prolonged exposure and inhalation of free crystalline silica dust (quartz, tridyrnite, and cristobalite) (Varon et al, 2008). The respirable dust particles and crystalline silica are tiny, less than 10 microns in diameter (for comparison a human hair is 40 – 50 microns in diameter). (Stanton et al, 2006). It has been found that patients with a history of silicosis are at a high risk of developing tuberculosis. Minimising the cases of silicosis will result in a subsequent decrease in the cases for tuberculosis. 3|P a g e 1.5 JUSTIFICATION Social and economic impacts of silicosis attract attention of social leaders, economists, health policy makers and labour organisations. The economy of a state is greatly impacted by the disability and death of productive population. Absenteeism, loss of qualified labour, reduced productivity and burden on workers’ compensation system negatively affects the state economy. Silico-tuberculosis among working and former working miners (Knight et al, 2020) continue to become a health problem. There is an increased incidence of tuberculosis with the increasing severity of silicosis (Palash, 2016) and there has been no decline in silicosis prevalence. Silicosis is an irreversible condition and has no cure, although there are treatment options available to ease the symptoms and related complications. To achieve this objective, research is conducted to identify and develop improved dust control technologies, which can then be implemented by industry to reduce mine workers' respirable dust exposure. 1.6 METHODOLOGY Approved continuous personal devices (CPDM) will be used to obtain required dust measurements. A gravimetric analysis instrument is a continuous personal sampling tool that is worn by a worker and gives a display of a cumulative-mass concentration of quartz in the mine atmosphere. (Walker et al, 2021). Samples are collected onto filters that are taken to a laboratory for quartz analysis using the available spectroscopy. Bulk samples of settled fine dust in the vicinity of each respirable dust sampler are a rough representation of the aggregate dust present in the atmosphere. These bulk samples will be stored in sealed containers for subsequent laboratory processing and analysis (Cauda et al, 2018) Water is used to suppress dust produced by underground mining operations and it is typically applied to the blade through one or two nozzles to suppress dust emissions. The source of water may be a portable pressurized tank or a hose. The recommended flow rate is 0.5 liters of water per minute to suppress dust. Dust is hydrophobic, meaning it fails to mix easily with water. Wet method can not provide a total containment silica dust. To combat this, a silica dust suppressant is required, to break down the barrier between the dust and water. The suppressant commonly used in USA mining companies is the product NeSilex which contains specially formulated surfactants, wetting and agglomerating agents causing dust particulates to saturate and attract to each other. Examples of dust depressants are magnesium chloride and calcium chloride. Both groups of dust suppressants depend heavily on air humidity level. Magnesium chloride attracts and retains moisture at a relative humidity equal to or greater than 32% (at 25°C), whilst calcium chloride needs at least 29% relative humidity (at 25°C). Water sprays Water sprays are often used to control respirable dust in underground mining. Advances in each of this area can contribute to the reduction of silicosis in the South Africa mining workforce, silicosis occurs through exposure to crystalline silica dust, consisting of airborne dust particles less than 10 µm in size. Different water sprays will be evaluated for their airflow induction and airborne respirable dust capture capabilities on crystalline silica. According to NIOSH mining, water sprays with 4|P a g e specific properties are used for airflow induction and airborne dust capture and applying them to appropriate situations can lead to lower exposures to silica dusts and thereby lower the occurrences of silicosis. Optimum parameters for the type of spray, water pressure, type of additive will be determined. (Majee, 2001) REFERENCES 1. Kazimierz Lebecki, Marcin Małachowski, Tomasz Sołtysiak,: Continuous dust monitoring in headings in underground coal mines, Journal of Sustainable Mining, Volume 15, Issue 4, 2016 Pages 125-132, ISSN 2300-3960 2. David W Stanton, Bharath K Belle, Kobus JJ Dekker and Jan JL Du Plessis: South African Mining Industry, Best Practice on the Prevention of Silicosis, March 2006, ISBN 1-919853-21-9 3. South Africa: Consolidated Regulations Occupational Health and Safety Act Act 85 of 1993(updated 7 June 2013) 4. Bradshaw et al., 2010 L. Bradshaw, J. Bowen, D. Fishwick, S. Powell: Health surveillance in silica exposed workers Health and Safety Executive, London (2010), Research Report RR827 5. Nawrat et al., 2002: Proceedings of the Second School of Mine Ventilation, Sekcja Aerologii Górniczej Komitetu Górnictwa PAN, Kraków (2002), pp. 299-310 6. Prostański, 2015: Experimental study of coal dust deposition in mine workings with the use of empirical models, Journal of Sustainable Mining, vol 14 (2) (2015), pp.108-114 7. Kazimierz Lebeki et al: Continuous dust monitoring in headings in underground coal mines, Journal of Sustainable mining, vol 15, issue 4 ,2016, page 125-132 8. Joseph Varon et al: Restrictive Diseases, Mechanical ventilation, Clinical Applications and Pathophysiology, 2008, ISNB 9780721601861, page 3-10 9. Knight, D, Ehrlich, R., Cois, A. et al: Predictors of silicosis and variation in prevalence across mines among employed gold miners employed in South Africa, MBC Public Health 829(2020) ISSN: 1471-2458 10. Cauda E, Chubb L, Reed R, Stepp R. Evaluating the use of a field-based silica monitoring approach with dust from copper mines. Journal of Occupational Environment and Hygiene, 2018;15(10):732-742 11. Walker, R.L.T.; Cauda, E.; Chubb, L.; Krebs, P.; Stach, R.; Mizaikoff, B.; Johnston, C. Complexity of Respirable Dust Found in Mining Operations as Characterized by X-ray Diffraction and FTIR Analysis, Minerals 2021, 11, 383. https:// doi.org/10.3390/min11040383 5|P a g e 12. Steenland, K.: One agent, many diseases, Exposure-response data and comparative risks of different outcomes following silica exposure. American Journal of Industrial Medicine 48(1):16-23, DOI:10.1002/ajim.20181 13. Bang, K.M.; Mazurek, J.M.; Wood, J.M.; White, G.E.; Hendricks, S.A.; Weston, A. Silicosis mortality trends and new exposures to respirable crystalline silica—United States, 2001–2010. MMWR 2015, 64, 117. [PubMed] 14. Center for Disease and Control (CDC). MMWR—Silicosis Screening in Surface Coal Miners—Pennsylvania, 1996–1997; Center for Disease and Control (CDC): Atlanta, GA, USA, 2000. 15. Leung CC, Yu IT, Chen W. Silicosis. Lancet. 2012 May 26;379(9830):2008-18. doi: 10.1016/S0140-6736(12)60235-9. Epub 2012 Apr 24. PMID: 22534002. 16. Cullinan, P.; Muñoz, X.; Suojalehto, H.; Agius, R.; Jindal, S.; Sigsgaard, T.; Blomberg, A.; Charpin, D.; Annesi-Maesano, I.;Gulati, M.; et al. Occupational lung diseases: From old and novel exposures to effective preventive strategies. Lancet Respir. Med 2017, 5, 445–455. 17. Y. Li, Y. Qin, X. Yang, L. Tian: New progress on coal mine dust in recent ten years, Procedia Engineering, 26 (2011), pp. 738-743 18. Palash Das: Epidemiology-Silicosis, Community medicine, CMSDH 700058, 2016 19. Elizaberth Wall, Remi Pelon: Extractive Industries for Development Series #21, Utilizing Mining and Mineral Resources to Foster the Sustainable Development of the Lao PDR, ICMM, Mining: Partnerships for Development, April 2011 20. M K Ghose and S R Majee: Air pollution due to opencast coal mining and its control, Journal of Scientific and Industrial Research vol 60, October 2001, pp 786-797 6|P a g e