Problem Solutions

By

Dean Updike

Chapter |

Pye

Ao

ws

sss. 4.1 Two solid.cylindrical rods 4B and BC are welded together. at Band loaded as.

Problem 1.1

-~ P.~

~

120kN

50 im

e CSOY = 1963-5 inin®

Ana?

ona

shown. Determine the magnitude of the force P for which the tensile stress in rod AB

is-twice-the-magnitude-of-the-conmpressive-stress-in-t0d BE

?P

P

Aas "(963-5

iat

= $09-3x107 oP

Ag.

75 min

B

120 kN

=

Yr (75° = 4417-9 mm*

_

(220) - P

A

AB

See. -

- 240-P

44IT GF

Equating

.

750 man

pe

FOO mi

4

~ 9.0543 — 226-420 °P

Sa,

to

~

2 Og

.

£09-3 xr" Px

Problem

=

2(0-0543 - 226-4x10

1.2

~&

P)

Po = 1/259

kN

<4

1.2 In Prob. 1.1, knowing that P = 160 kN, determine the average normal stress at

the midsection of (a) rod AB, (h) rod BC.

1.4 Two solid cylindrical rods 48 and BC ate welded together at B and loaded as

shown, Determine the magnitude of the force P for which the tensile stress in rod AB

is twice the magnitude of the compressive stress in rod BC.

Roe

{a)

AB.

50 mim

P= soo kN Ctension)

Mo = Fai

6,

AB

Cb) Red

Fr

he

=_ 2.

~ BON. 1968-5 mm

3

160 x16

Tr fee

Nag | (1963-5

ot OLS MPa

LOKN

2

7 mm

A

P= 160 KN

~<a

750 mit —---~- I ere ren

<—.

— 1000 mim

a

»{

3

BC.

(60-(2)\G20)

=~ fo

_ Taee

Kec * td

One = EL

Age

.

-

mWz7s)?

onal

_=80xs07

GAIT

kw

> AGITE

e@.

Bo

EN

Compression,

min

Ope ~18-1 MPa <A

Proprietary Materiat. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the Eoited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student asing this manual is using it without permission,

_Problem.1.3

1.3 Two solid cylindrical rods 4B and BC’ are welded together at B and loaded as

shown. Knowing that the average normal stress must not exceed 175 MPa in rod AB

and TSO MPa in tod BCY determine The Sinallest allowable valties OF J

Red

AB.

P

300 mm

=

40

S

Pe

MG

a,

= TOkKY

-_P.

Ane

._

yo

+30

=e

f4P

_~

_ Tex6

.

=

Foxlo’

N

4YP

At

wa,*

|“WOT

Geox)

S x 10"

5

amd

22.6

A,

%1loO

pe

= 22-6

wy

wy

<i

mn

=x

250 mm

Rod BC,

P=

30 kN

30 UN = 30xJo'N

.

Ce

PL.

PH

7 oe

tA?

= AP

Ta”

(4) (20 x 10)

d= fae.

°

TSO x (0%)

opt

IS--96x10

a,

Problem 1.4

=|596

1.4 Two solid cylindrical rods AB and BC are welded together at B and loaded ag

shown. Knowing that d, = 50 mm and d; = 30 num, find average normal stress at the

midsection of (a) rod AB, (b) rod BC.

(.) Rod ARB.

40 +30 = 70 kN

P=

= 70 x10°N

A = Bare E (60)= 1.9635 xlo%men = LAGS THIS

300 mam

Sas = x " eae.

= 35.710" Pa

ng = 3S.1 MPa

250 mm

(bo.

Rod

P

BC,

= ZO kN

A = Fa;

3OKN

<a

Gye =

FE.

A

30x10" N

F (a)? = 706.86 mm= 706.86x10" m*

3o xo?

706, 861s

= 42.4x10*° Fa

One

-

44.4 MPa

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without peérroission.

<0

So

Problem

4 5

~

oe

oe ESA strain gage jocated at C on the surface of bone AB indicates that the average

normal stress in the boné is 3.80 MPa when the bone is subjected fo two 1200-N

POYEES AS

SHOWA.

ASS

1200 N

eek

a

A

Az

Geom edvy

>

=

2

a

A=

tan

2

an

1200 N

At

each

1.6

boSt

ee

poe

Pi, of the

plate

upwavel

equi

3h

dl

2

4P

TE

CAYC1209)

GET aBox 18s}

222.9 *107°

=

14,93

WwW

A, = 14.9%

lo ym

mm

a

1.6 Two steel plates are to be held together by means of 16-mm-diameter highstrength steel bolts fitting snugly inside cylindrical brass spacers. Knowing that the

average riormal stress must not exceed 200 MPa in the balts and 130 MPa in the

spacers, determine the outer dianteter of the spacers that yields the most economical

and safe design.

focatron

fowce

|.

ai

B

&,

GA

Ayo = (25x

‘Problem

a

knowing that its outer diameter is 25 mm, determine the inner diameter of the bone’s

cross section at C.

the

boft,

At

a

with

Upper

plate

is

publled

the same time

the

force

compressive

dlown

by the

spacey pushes

fe

Phat

marntain

over te

Tn

Ts.

tens;

4; lrtam

Fon

the

heft

For

the

Spacer,

Equating

GS, *

Py

Se

ana

i

As

>

athe

T

= chy? )

P,

or

P

= -

=~

S,

$ 6.

di,

|

(d,°- d,")

Pe,

EG de = P&ldeaf

be

ov

A=

de)

fi4+ 200

dg = 25.2 mm <a

-

Problem

1.7

1,7 Each of the four vertical links has an 8 x 36-mm uniform rectangular cross

ae0.4

~ section and cach of the four pins has a 16-mm diameter. Determine the maximum

value of the average norma

ting (a), points B and, D,.(b)

he links co!

|

points C and E.

Cc

0.25

body,

Sree

a

a$

ABC

bar

Use

oO ¥N

BBEN

O.ORS

i.

A

4

A

ON. —

(),

>be

B

|

c

Fee

W Fan

oO:

i

2M.

(0,00) Fi, — (0.025+ 0.040) (20x10?) = ©

Fey

=

stress

=

(Geo

Area

Feo|

in

N

m tension.

aa

ia

(0,008)(0,036.-

=

And?

BD.

BRO KIO"

in

CE

parole) Din Ks ,

2 325 IO"53

Din k

Lin’

fewsion

Sor

Drak

Any

one

fon

«1a

For twe

Mm.

160 x10”

Tensile

-=IQS

Sink

ong

of

aAKEea

Net

-

js

- (0.025 )(20 x10") = ©

~(0,040)F,

0:

=M,=

BD

Link

N

32.5 xjo

=

Feo

Com

2 \o).66 «10%

=

(0,008

Dio 2

Hales ,

pression

Com Phe 351 On.

0.016

)

B20

“jo *

,

Sep=

2

R&B

x

jo"

mi

’

For

+wo

pera

13

2

—&

(bog = RE = RS 2 wai 70 010

=

,

jOLGM

)€0.036)

A

ut

= S76

2

Le MPa a

So

=~

yw

wn

*lO

Gage -RLTM

.

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited’distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

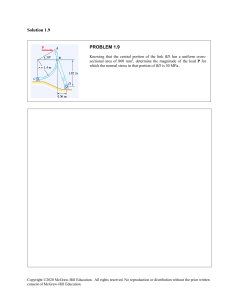

_ Problem 1.8

1.8 Knowing that the central portion of the link BD has a uniform cross-sectional

area of 800 mni’, determine the magiiitude of the load P for which the normal stress’

P

in that portion of BD is 50 MPa.

P

a

o.7m

:

SA

=

Feo

A

.

(300 x 15%)

= (50%10*)

1,

N

lO

40

=

BD

4m

tA2m

\ |

_

Bd=./ (0.56)4 (1-92)"

a

=

DDH.

DDMe

==. Oo:

O

.

0.56

Pal

1.92

2:88

4) +4 92

GLH

Fae (HO™ (uox We ya VC.)

Ee (dow1c)AAY CH)

- P(o.74h4)

P=

Problem

0.5m

for staties,

Free Baoly AC

Use

=

m

2.00

=

1.9

2

0

s

1.9

2

.

323.) xlO'N

Ps 83.)kN

Knowing that link DEE is 25 nm

-=8

wide and 3 mm thick, determine

the normal stress in the central portion of that link when (a) 0 = 0, (b) 6 = 90°.

Use

bev

CEF

as

a

free

body

HIM. = O

Foe (0:2) (240 sin®)-(o- 4) (240 cos @) =O

~O3

Foe = —/bo sin® —3200e08 0 N

~- (0-025) (os 003)

1

>

5

mem

Spe

(a)

me

6=-

“Roe

oO:

Foe = ~320

~320

Soe *> Frye

(b)

-6

= 76 %Xto0

o

n

Pf

@= 40":

- ~f60

Coe — 7s 0e®

me

AT

4.27

N

OM

MPa

at

- {LoN

Fy

=

~2-12 MPG

—<

Problem 1.10

Ds

a

-

960 N

80 Link AC has a uniform rectangular cross section 3 mm thick and 12 mm.wide.. .

Determine the normal stress in the central portion of the link. -

»

Free

75 mm

AEREEARDA

~

BER

once

rere

SRR DRUIDS

SN

Body

Diagraw,

of

Pilate

ace nneestnnneyge -

i175 mm

wh

Note

960 N

that

Forme

the

a

+wo

coupte

oF

(960 N\(015m)

OIM,-0!

oy

Stress

: Povces

mament

|

;

= 144 Nm

44 Kin

Fre 7 6651

Aven

9bOrN

~ (Fye cog 30° (025m) = O

W

Bink!

Gre =

Age

Me.

ta

s (3 mm

=

\(l2 inm)

b6$:

—

>

36

mmZ

= 18-475 MPa

.

>

Sper 18:5 MPa

Ac

Proprictary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved, No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

<a

~-- Problem

oblem 1.14

.

. . 4,74 The rigid bar EFG is supported by. the truss system shown. Know- ing that the meraber CG is a solid circular rod of 18 mm diameter, determine.

th

HO

Yona

“bpp

dots:

HnOPMar suvess nree;

Using

portion

HOE,

ew

“Lm.

=O:

Fae =

Te

OS

Fag

-/5

&

as

a Fee

2

beaw

EFG

becly

¢

Fee

=

Cress

Fae

=

Re + U2) (4

NENENS

A

Fer

SLE

Foe

Problem 1.12

of

member

anh

USE.

254M AKIO

ce

7.42

yg

o

Z

VISEA

2

rane

CG,

in

1 oe

;

CG

= 4 (o-olb y = 25464 x19 Pin

etvess

Novw af

Fes

N\

avea

=

Keo = Fa"

¥ cer

Fi.) = ©

25 kW

sectionat

>

e

=

25 EN

9M, = 0! (2 ok

Fae

a Free. badly

ms |e~ 2 ms

Using

Fae

EVeC®

<a

The rigid bar EFG is supported by the truss system shown. Deter-

mine the cross-sectional area-of member AE for which the normal stress in the

member is 105 MPa.

Using

portion

.

a

2Or2S

WEF

Fag

Stress

EFGECB

=

Fre -

as

_

a

Free

body

=O

LEkN

in are ws Lew

AE

Gace

*

{05M fra

Ene

Cae ~ Age

Mew

FE,

ue

AE

i0 .

sam

=

25x

105 %f0

238/X/0 ~eé m2 e '

Proprietary Material, © 2609 The McGraw-Hilt Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation, A student using this manual is using it without permission.

7 Problem

OC

1.13

_—_—s«&LA.- A couple M of magnitude 1500 N - mis applied to the crank of an engine. For

the position shown, determine (a) the force P required to hold the engine system in

equilibriv

|

|

P

-

Use

piston, rod, and evank

together

200 vim

"

wall

ae

ME

as

peaction

reactions

ome

#)

4

G0 san

| stress.in the connecting rod BC, which has.a45Qreceou{uncsev- enews

mm’ uniform cross section.

L.

Ma

Tree

H

bady,

and

.

Aclol

.

beaning

Ay and Ay.

=

Of

(0.230m)H ~ 1SOO Nem

H= 5.3571 x10% N

Use

piston

= ©

alone

as ree

body.

Note that rod

a

two-force mem ber;

is

hence

the

oF Force

Fee

is known.

Draw

triangle

ane

sodve

ane

far P

divection

the fovee

Fre

by

proportions.

Q =f 2007 4.60" = 208.81 mm

=~

—

xo

200

4002

=

Go

(a)

TE 7

So

Rod

BC

Stress,

is &

Compression

Og.

-

~Fe

AO

member.

~

BEL

Ets

17. 86xlo*

P=

17. 36 kW

N

=a

Fag = 18.643 xO

area

—/8-643x/0*

Taso

xio®

Cb)

P=

_

is

4SOmm=

AL.4 jo

&

450 x JO” mn

Pa

See = - 41.4

MPa

<a

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

_ Problem 4.14

1,14 An aircraft tow bar is positioned by means of-a single hydraulic cylinder

connected by’a 25-mm-diameter steel red to two identical arm-and-wheel units DEF.

Lire tow bar is 200 kpc and its center of gravityis located at G-For

the position shown, determine the normal stress in the rod.

Dimensions in mm

0

450

250

850

500 |

FREE

Goby

825

675

- EXTRE

“tow BAR!

W = (200 kg)(4.81 m/s?) = 1162.00 N

Ay,

Ay

HFomm

—

.

“y

ty]

G

.

fF se.

2 |

om

re

850mm

Govyr

-

F WHEEL

=

BSOR - usS0(I4G2.00 N) =O

N

ZQS4,5

R=

R

BoTH

OS

A

OF

A

FREE

Ww

Atwr

UniTs 2

loo

tan

xg

=

Lye

Ts

A=

$.4270°

+5EmM, 20:

(Ecos KSS0)

~ R(S0Od) = O

S00

Feo =

$50

C05 8.4210" (2654.5

= 2439.5

S0omm

GTS mero

Fep

cp”

Aco

=

N

we

Coome.)

2439.5

N

41 (0.0125 yn)*

#

R226S4.5 kN

ooz

Hw)

- 4,9697 * 10° Pa

oz,= 74.97 MPa 4

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation, A student using this manual is using it without permission.

~~

~

Problem

1

-

45

11S

of.

©.

Coa

| ESkN

T he wooden members 4A and B are to be joined by plywood Splice plates that

will’ be fully glued on the surfaces in contact. As part of the design of the joint, and

knowing that the clearance between the ends of the members is to be_6

determine the smallest allowable length 1 if the average shearing stress in the glue is

—_

not to exceed 700 kPa.

al

There

I

Fach

Gam

ave

of

the

foor

separate

these

15 KN

AVEAS

doade

aveas

tut

mits

ane

trans

ane

giued-

ha OT

the

Thos

F=4P

= 4(15)=

7.5 \N

=

7500N

~ 75 mm

Fo.

Po eee

aa

ret

lf

Lo

Aength

Foy

each

gqbued

Average

The

tn

shearing

3 p

or

one

.

area

Az

Y=

Shearing

4

Ls

>

ond

stress

EF

W

E

i's

>= 78 rm?0.0718m

=

Xs:

Joox)o?

1.16

15 mm

(Joox10 (0.075)

La lgap)+

mz ON4286

Steet

Shearing

.

~

286

m

=

JURA

B= 142.8546+ 14285

242mm

-—ed

1.16 When the force P reached 8 KN, the wooden specimen shown failed in shear

along the surface indicated by the dashed line. Determine the average shearing stress

along that surface at the time of failure.

\.

At

Avea

mt

»

|

90 mat

wrath.

Pa

L =

Problem

be its

E

7TS00

~

Tw

Le

\

Lw

styess’

4,

Tote? Fength

qdued

area

eDlowalhle

.

Sedv

ot

> 22

Fo.

{

Let

—}

being

A= Jommy

sheared

[Simm

1

=

1aSOumm

2

= 1350 *(/O%

m

\

Wood

stress

Force

wr - F

A

Pr

.

8~1l0°>

8x10?

(Rea

xo-6

=~

N

5.93 wl?

xfo” P2=Piz5.93 MPa

met

Proprietary Material. © 2009 ‘The McGraw-Hill Companies, Inc. Alf rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

ETT wo wooden planks, each 12 mm thick and 225 mm wide, are joined by the dry

Knowing that the wood used shears offalong ifs grain when the

ress reaches’

8 MPas determine the magnitude ? of the axial load

co

‘1.17.

Problem

—

16 mm

which will cause the joint to fail.

|-~ 16 mm

:

Siy

aveas

when

the

areas

its

hag

area

must

jot

be

sheared

Pails.

Each

climeasrouns

off

&

[Gum

*

these

12 mm,

being

A= UG KIZ) = 192 met = 192 410°

At

Far

uve

F=Since

the

Force

vA

theve

Problem

F

caveied

= (@x10%)(142 xo)

ave

SIX

foe Yove

1.18

aK

+

each

oF

= 1536

Pe

AvVEaS

Aaneag

N =

GF

1m

1.536

kM

= (Y0.836)

=

F22kN

<a

1.18 A load P is applied to a steel rod supported as shown by an aluminum plate into

which a 12-mim-diameter hole has been drilled. Knowing that the shearing stress

must not exceed 180 MPa in the steel rod and 70 MPa in the aluminum plate,

determine the largest load P that can be applied to the rod.

- 40 mm 7

10m mo

by

__

For the stee? rod ,

8mm

.

o1e)

Yo.

olG

A, = TA h = (N

m= 376.99 *10°% m*

12 aml

-

—

Fe

GA,

P = (180 «10*)(376..97» 10°) = €7.86r10*N

Fox

the

a fuminum

plate,

A,= Wd,t, = (rY0.040X0, 008) = 1.005 a1nIO* m

TG

ie

w

Re

TA

= (7ox10%)(1,0053%10°°)

The

oF

Aimiting

P,

amd

vale

Por

the

Poacl

=

oe

70,372 «10° N

ts

the

smaller

Pr.

P= 67.8610" N

PeC77kN

«a

Problem 4.19

1.19 The axial force in the column supporting the timber beam shown is P = 75 KN. Determine the smallest allowable length 1 of the bearing plate if the bearing stress in

the timber

isnot to exceed’

30 MPa

SOLUTION

O,

~P

.

A

_P.

~~

tov

Solving

3

tw

RP

2

|

|<

Ow

75 ¥{O

_.

Gora? Wryoy

178.6 «107° m

[=

min

wh

1.20 The load P applied to a steel rod is distributed to a timber support by an annular

washer, The diameter of the rod is 22 mun and the ner diameter of the washer is 25

mm, which is slightly larger than the diameter of the hole. Determine the smallest

allowable outer diameter d of the washer, knowing that the axial normal stress in the

siecl rod is 33 MPa and that the average bearing stress between the washer and the

timber must not exceed 5 MPa.

A=

rod!

Stee)

Ps

6A

=

(0.092\"

=

F

BQO .1Fr1IO ow

35x10° Pa

GS =

= (25K10E

3 BB0, |e VF

Y

13,.305*/07N

Wachen?

6,

Required

=

Swipe

bearing

Pa

aves?

13.205 «1p

bh

4

’

de= d;° + te

24 +

es

HNE-S60F

“IO

=

3

3

WwW

oS

oN

2

3

8

a4

ts

fF)

A

yw

= (O.025)°

ul

1.20

Q.

Problem

173.6

1.21

Problem 1.21

A 40-KN axial load is applied to a short woaden post that is supported by a

concrete footing resting on undisturbed soil. Determine (@) the maximum bearing —

stress on the concrete footing, (4) the size of the footing for which the average

P= 40kN

bearing stress in the soil is 145 kPa.

120 mm

(a)

Bearing

on

concrete

Yo kN =

ty

P=

stress

a

A = (JOOMI2@)=

"

6 = p

Footing.

4oOx%/o* N

IQx1O we = (2/07 me

Yoxjo*

alo

_

=

3.33x10°

2.323

(b)

Footing

VO

Tae

C

Since

the

~

ey

PR

A

avea

be fA

Problem

P=

1.22

A

is

_

~

Yo

40x

-

Fe

S

«103

-

(4s*

Square,

.

= f0.27586

=

A=

N

/O>

a

fo?

-

Ss

145

kPa=

oO.

27586

mw

Pa

MPa,

45x10°

aah

Pa

Rr

b*

0.525m

b = S25

mm <i

1.22 An axial load P is supported by a short W200 * 59 column of

cross-sectional area A = 7560 mm’ and is distributed fo a concrete foundation

by a square plate as shown. Knowing that the average normal stress in the column must not excecd 200 MPa and that the bearing stress on the concrete

foundation must not exceed 20 MPa, determine the side a of the plate that

will provide the most economical and safe design.

For

the

ov

column

P=

For

the

axa

A = Since

a=

OA

the

/A

ABb

=C200%00°)( 7560%/0" )=/5/2 kN

po. te

5

eo Gi

= S25

prate

_=

GC

GS:

2 007eb/m

=

:

Aza’

is Sqoave

-40,:0756

20M;

o«n.7h

™

a275

mm

Proprietary Material, © 2009 The McGraw-Hill Companies, Inc, All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

A 6-mm-diameter pin is used at connection C of the pedal shown. Knowing that

. P = 500 N, determine (a) the average shearing stress in the pin, (b) the nominal. .

bearing stress in the pedal at C, (c) the nominal bearing stress in each support bracket

— Problem 1.2300

é

a

——- 300 mm

|

Dvaw

P

Svee

body

Diag tom

Since

of

ACD

3- force

the

Frow

the

Cc

tow

dines

ot

oval

porn

action

of

E

the

the

intevseatian

ot hey two

forces.

Ce = {200s 125* = 325 rm,

3 ea met “y?

te

2

Tpin * “Ap:

at

divected

of

at ZF, = 0:

(2)

is a

member,

reustion

is

3 math

ACD.

Bec-P=o

- £o

AS

“Eg?

Mo

‘)

O,-oA,G-

(C)

6 ° = tC

2% AL

=

Problem

1.24

_

<

~ 22.0x10" Pa

=

!

Gin’ 43.9 MPa, a

= 24.

| «10° € Pe

(6x10?

4x lo"*)

{Zoo

.

= (2.6500)= 1300N

(2)C1300)

op ALMISOOL

~ Wlexios)?

100

£dt =

C

2c

Fan

Wa®

~

qj -

C=26P

= 2 T«lo®

Rat = (2)\Cexlo# )CSx10°? }

6

Ss

FA

= 24.) MPa wa

6,2

217M

Pa —ea

6

1.24 Knowing that a force P of magnitude 750 N is applied to the pedal shown,

determine (a) the diameter of the pin at C for which the average shearing stress in the

pin is-40 MPa, (4) the corresponding bearing stress in the pedal at C, (c) the

corresponding bearing stress in the each support bracket at C.

75 mm

300 mt

9mm

Draw

Pr

Free

Aiagvam

|

Siuce

tt 3h =0:

@ Tn=w= AE

322

“ROF

(bo) Gi=

~-

2.

©

=

*#¢

NK

GE€

OC

2dt

mem ber,

of the

of action

#Cc-Pz=o

2 BO

Ba

a

at C

ftowavel

CE =_[3007 + [25°

qeo metry >

ACD.

the

peactrou

is Aivected

5 mm

From

of

Fig

ACDis

3- Force

D

bo Ay

- f2C

om .

Lines

=

E,

the

intevsect fom

of the other two

fovces.

B25 mm

C= 26P -(26)250)=

1750 N

/BOs#se.

[Tass

ipe) 2 S57 IT tan

[ase

=. @snovGuery

I4So0

© (AMS.57> 10

peiat

* 3% 7"l0 é Fa

.

Sx10"* )

= 85.0%10° Fa

maz ds ESI may mm

G,=. 38.7 MPa <a

= 3S5.0MPa <a

problem

1.25

1.25

senomapsunsttntgsenaepseensnsus

18 mm

A

12-mm-diameter steel rod AB is fitted to a round hole near end

C of the wooden member CD. For the loading shown, determine (a) the max-~

siti AVSER RS’ HOTHNTAT SHOE IW tHE WOOA.” (BY thE TSANLE'B

Tor WHICH the’

4.5 KN

”

erage shearing stress is 620 kPa on the surfaces indicated by the dashed lines,

{c} the average bearing stress on the wood.

fy Os LN

C})

A EC

Mayinon

‘

P=

C= A

_

vy. P .

Us

Nore

ad

stress

in

wood.

RK

> FbE

P

O°

a

_

450 kN = 4¥S50¥10"N

Tiga

| 4 50

Pe

o

* 3.97«x10°

‘

Pa

4.50 x(0*

|

3.77 MPa, ai

.

REE * BilanctVeroxios) = 2O2*IO

b=

CSF *

the

Nret = (75-12 UB) = 11S 410? mom= 1.134 17

[-b

(by

CWVEVAGE

P

aE

dt

4 Sox

F

((2x107

to#

exter?x J

‘

KIO”okFP

= ROB

2

3

202mm

a 0.8

MPa

MPa

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved, No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation, A student using this manual is using it without permission.

«ef

Problem

1.26

1.26

-hctuatianimionm amen mmimiaodninrasancneenences

Two identical linkage-and-hydraulic-cylinder systems control the

OSTHOR-OF-the forks-of-a-forklift-irack: Phe load: supported: by ‘the one-system="

shown is 6 KN. Knowing that the thickness of member BD is 16 mm, determine (a) the average shearing stress in the 12-mm-diameter pin at B, (b) the

bearing stress at B in member BD.

t

300 mm

900mm

6kN

B,

f

*

380 nin

N

Use

one

6S

Ga, free

By

12

}.——.-____

Me

E

OR

|

~

o.

/

-lo5)l6)=

=

£

EN

0

BR. = SKN

=O:

By-

6&6

=0

Oo

—_>

=O

E+B,=

==

+t ZR

body.

=o:

:

ob E

<<»

fark

By: -E

—

By = GEN

B= (ar B = [ETT= rain

(a.\

Shearing

stvess

Apis =

=

t

(\o)

a

Dp

B

=

Ag:

Bearing

in

Tike?

oA

tae

B.

-

lide} x10

~6

mM

2.

—_

=

64

mPa

<a

B.

3

RX

o=- Bee.

At

oA

=f (oe/2)*=

tiB-fy

stress

pin

(0-012)( 0-016

40+ b ipa

Proprictary Material. © 2009 The McGraw-Hill Companies, Inc, All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any-means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

»\

‘1.27 For the assembly and loading of Prob. 1.7, determine (a) the average shearing

Problem 1.2

:

i

stress in the pin at B, (6) the average bearing stress at B in member BD, (c) the

verage bearing stress at B.in.member ABC, knowing that this.n

mm uniform rectangular cross section.

1.7 Each of the four vertical links has an 8 x 36-mm uniform rectangular cross

section and each of the four piris has a 16-mm diameter. Determine the maximum

value of the average normal stress in the links connecting (a) points B and D, (b)

points C and £.

Use

bav ABC

as a tree

body .

Jow ho gag >-— 0.040 —

\,

.

A

°|

C

Fen

(0.040)F,

{ Fee

-(0, 025+ 0.040)(20 “/08) = oO

Feo = 32.5% 10° N

(a)

Shear

pin

at B.

where

A= HAte

~

te

(b)

(c)

Y= =

6, = Fe

. LoS

G

>

dt

=

ABC

sheow,

‘

x10

C=

dt = (0.0i6)(0.00&)-

82.5 4109) ~ 176,95 x10"

ot

830.3MPa

<8

|2R «lo

m

6,127.0

MPa<a

B,.

= (0.016)(0,010)= ]€O0x10° m

Feo.

A

Az

double

201.06%/0° m*

80.8

06 x107§} 7

(2)(201.

BD.

A=

.

32.5 10%

in

for

E- (0,016 Y* =

Bearing : Pinke

Bearing

Zh

Feo

32.5 x/0%

160 x1o-*

~

R03 x 10

6

2

6,- 203 MPa ~<a

Proprietary Material. © 2009 The McGraw-Hill Companies, Fac. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

-

Problem1.28

.

1.28 Link AB, of width 6 = 30 mm and thickness ¢ = 6 mm, is used to support the

end of a horizontal beam. Knowing that the average normal stress in the link is -140

__ MPa, and that the av.

hearing stress_in,¢:

f the. two..pins.is .80..MP acc.

pins, (b) the average bearing stress in the link.

oO

Rot

AB

is

in

Az

bt

wheve

A?

(0,050\(0.006)5

P==-GA

=

(2)

Diametey

compvess1on,

al.

=

br 50mm

and

900x210

AT

.

m

Gum

2

-C1y0x«0%)(300%107%)

42 «10>N

=

j

aaa

1525«107°)

~

= 2.589 *}/O

a

.

Ex

42»})07

(25.85 *107 YO, 0296)

=

wy

x

o*

=

25.9

3

Ww

aa

<A

oO

Pa

ATIMIO"

S,7

271

MPa

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc, All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

=<

' Problem

1.29

1.29

The 5.6-KN load P is supported by two wooden members of uni-

__.form cross section that are joined by the simple glued scarf splice shown. De-_

termine the normal and shearing stresses in the glued spli

P

VG.

75 mm

125 mm

or

P-

Ao

6127N

=

Ce

9 = Yo” -60"°

t26)(6075)

~ (€<227

P cos"

G-

A.

«3

1.30

375

Ka? (cos

-3

xlo”

mm

30°)"

6 0049 MPa,

Kx

_ (6.227 x0"

sin 60°

(204-375 159)

aRe

.

|

T + Oe28f MPa<a

1.30 Two wooden members of uniform cross section are joined by the

simple scarf splice shown. Knowing that the maximum allowable tensile stress

in the glued splice is 525 kPa, determine (a) the largest load P that can be

safely supported, (6) the corresponding tensile stress in the splive.

75 mm

@)

P+

SA,

Cos

os

‘DO

1

iO

aes]

a

"

A, = (0-125 )L0+075) 3 9325 X10” ine

iO

‘0

Probiem

Ge

TATSRIC

EsinkO

v=

=

= 30°

3

=

~2

(28x10) (9375 x70 7)

cus*

a

3

ENG LN

wn

ot

tk

P-6162

E sin 28 - £66 62) sin Go"

we

C2) 9375 Ke)

T=0'303

EN

<a

|

MPa «lle

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed

in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation, A student using this manual is using it without permission.

Problon 7 3

oo

1.31 Two wooden members of uniform rectangular cross section are joined by the

simple glued scarf splice shown. Knowing that P= LE KN, determine the normal and

_Shearing stresses in the glued splice.

O67

P

For-

Pr

Yo?

i} kN

=

=

neesnennnutttnty uns an

HE?

jlxto*N

75 mam

A

= (ISO)CIS)

oO

S

=

© ASHI

Peos'@

—

A,

.

“

—

P sin2O

IAS &10° m

#107 }cos* 45°

¥Bqwio

-

(Iheto*

ZA,

Pe

Xsin

Sz

489 kPA <8

40°)

(2X .2sxtio*)

=

Problem 1.32

©

1.25 «(or

=

T=

CS)

me

4.89xIO

Pe

Ye YQd KPA at

1.32 Two wooden members of uniform rectangular cross section are joined by the

simple glued scarf splice shown, Knowing that the maximum allowable tensile stress

in the glued splice is 560 kPa, determine (a) the largest load P that can be safely

applied, (6) the corresponding shearing stress in the splice.

A, = (ISoX75 © IL2S*

IO mm

75 mm

S=

Or

P

—

cos

ER,

= SG0~/0°

Pa

8

_ (S60 x10° Olas

~

cos * 4g?

12.60x10°

PsinB

t

mh

(b)

FP

=

& Aro

“eos? QO

Ny

@

S60kPa

= LL 2SKeIC

N

corO

A.

= S60x%]0"

»Jo”)

~ 12.60

LM) eh

_

(12. 60 “to

\GintS *Yeos 95°)

W.2S «1077

Pa

t= SCO KPa <a

Problem 1.33 0

1.33.

A centric load P is applied to the granite block shown. Knowing

“thatthe resulting maximum value of the shearing stress in the block -is'17-MPay~

determine (a) the magnitude of P, (b) the orientation of the surface on which

the maximum shearing stress occurs, (c) the normal stress exerted on the surface, (d) the maximum value of the normal stress in the block.

O-=

45°

CY

Low

plane

Cag 2 tel

of

jpl=

Coy, 7 VT MPa

mn

Ag zo-IS (015): 010225

TC mese

aA.

Tmeepe, =(2)(0+0228)(ITMO)

“

150 mii

()

Gye = EAs cos* 45 =

~

e

1.34

1,34

eo,

FP

<<

@245°

90°

sin2Oz}]

.

Problem

20%

(b)

—_

KN

= 765

3

MPa

7b6S kre

=

2. — 76S

QR. TG

SK

[0.0125)

_7bL KIO

oe

2G

4

A 960-kN load P is applied to the granite block shown. Determine

the resulting maximum value of (a) the normal stress, (b) the shearing stress. Spec-

|

ify the orientation of the plane on which each of these maximum values occurs.

Pp

Ao

(0-15) (018 )=

G

=

+

cosO

06-0225

~ 7 G0 Kto

=

souee

o

(u.)

mow

tensife

150 mm

To.

P

= BAL

°

6

©

=

stress

ot

(b)

2

a

tos O = -42671KI0

&

cos"

OL:

Mong, Compressive

{50 mm

m

3

stress

-

2 (0022S)

O=

=

@

=

4267

Yo®

MAR

=a

MPa

=a

cy”

Kio’

Ybo "

oF

ot

of

eB

45°

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

~ Problem

1.35 A steel pipe of 400-mm outer diameter is fabricated from 10-mm-thick plate by

1.35

welding along a helix that forms an angle of 20° with a plane perpendicular to the

axis

of the pipe: Knowing that the maximum_allowable

normal and shearitig stresses”

in the directions respectively normal and tangential to the weld are o = 60 MPa and t

= 36 MPa, determine the magnitude ? of the largest axial force that can be applied to

the pipe.

16 mm

dy = 0. 4OD m

Y=

fh -

A. =

eta

t=

0.200

Wrt- ne)

|

=

MPa:

0,200 ™

~0.010

=

O./90

m

10, 200*~ 0.1907)

12.25

6

69

=

=

x/O78

m*

20°

G

=

re

cos*Q

(R29.€osx10"20 U6OX IO") _ g33.x 10% N

MPa

a Ae’ Cc

P

Smaller

“

sia

Bin

QM

x}

a

07?

sia 20

)(3Ex

jo

1272

¥/o”

N

sin YD ?

26.

vafue

Problem

=

rs

is the

ebPowehble

value

ot Pe.

P=

—

—

333 KN

=i

1.36 A steel pipe of 400-mm outer diameter is fabricated from 10-mm-thick plate by

welding along a helix that forms an angle of 20° with a plane perpendicular to the

axis of the pipe. Knowing that a 300-kN axial force P is applied to the pipe,

determine the normal and shearing stresses in directions respectively normal and

1.36

tangential to the weld,

Oar

fo = tal, = D. 200 m

do= 0.400m

0.200-0,010 = 0,196 m

Ye= VWo-t =

A. = W(We"- Wy") = 1 (0. 200% - 0.1907)

SF 12.25

B=

xpo™4

hm”

20°

= B00 xg" cog 20"

-

= Poo tag

>

30

IZ) =

§

on

—

Based

B+21.6x10°R

St

.

°

26

=-

CO =-BIGMPa

om

~300 x}o? sin Yor

(212. 25") oO)

=< 7, %7 xjo°

C=

7.37 MPa, <#

Problem

1.37

- ta

sonnei

,

pe 240 aren

—

1.37 A steel loop ABCD of length 1.2 m and of 10-mm diameter is placed as shown

around a 24-1mm-diameter aluminum rod AC. Cables BE and DF, each of 2-mm fo

aa ara ed IB ply THe Téa O KHOW!

)

atrengtiv of th

uséd for the loop and the cables is 480 MPa, determine the largest load Q that can be

240 mma

applied if an overall factor of safety of 3 is desired.

Using

anal

joint

cons

2+

B

de

Fae

Q=

‘

bods.

sgume

~Q

)

=o

& Fin

A asa Free

joist

Usina

asatvee

ran

body

and considering symmetry,

@Gamem

2-3Fin~ Fae = O

$EQ-FeeO

Based on strength

Qy

Based

=

&A

of cable

=

on streng H

Fe

“

Qe Fgh.

BFE,

& Eat =

of steed

Qu* Fav?

(ygox$F io®)

(0.012)" =

Poop,

54.24%10*

GAs $6, Fa%

= £(480«1l0%) F(0.010)" = 45,24~/0°

= £(aCoxjot)F (0.024)* =

Blow

b Le

Joan

GL =

Quy

a

is the smadbest.-.

=

1524 xl

N

a

Qeigh.

= FGA = FOFa

Road

N

|

Based on strength of tod AC.

Actua? ultimote

EZ,

3

=

.

88.22/02

OQ =

IS.ORxjJo

Qs

N

45.24~l0"

oO

N

N

15,08

kN

Proprietary Material, © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of (he publisher, or used beyond the Hinvited distribution fo teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

<a

1.38 Member ABC, which is supported by a pin and bracket at € and a cable BD,

was designed to support the 16-kN load P as shown. Knowing that the ultimate load

Problem 1.38

_..£0F cable BD is 100 KN, determine

the factor of safety

with respect to. cable failure... fo...

Use

member

Free

body, ancl

that

member

two-foree

0.5 m

DS=EM,

04 m|

ABC

=

as a

note

BD

P

A

:

is a

member

3%

(Pros HO? )C1. 2) + (P sin 40") (0.6) —{ Fa, cos 30° 0.6 )- (Fey sin 30° MOY) = O

l.3O4Yd3 P -— O.71962 Fen = oO

Fen

=

1.31335

Fuse

=

[00x(O*

Te

Mm.

Problem

=

Fuet

_

Fan

1.39

P

= (C.B12aS)(iG%

109) = 2.49014 x10? N

N

100

%

x*fO

S

2.4014*10%

£39

FS

=

3

Se

aS

<2

Knowing that the ultimate load for cable BD is 100 KN and that a factor of

safety of 3.2 with respect to cable failure is required, determine the magnitude of the

largest force P which. can be safely applied as shown to member ABC.

Use member

body, andl note

that

member

DEM,

0.4 n-|

as a

Free

4wo-fovce

OS sa

ABC

=

BD

P

A

is a

member.

Oo:

(Pees HOC.2) + CP sin 40°)(0.6) ~ (Fa, cos 30°100.6)~ CF a, sm 30°04) = 0

|.30493 P - 0.71962 Fy = 0

P=

ADPow adbe

0.55404

vetue

of

Fy,

,

Foo .

Py 7 (0.88 404)(3,105)

Fon 7

Fig

ne

7

SS

le

v

Pe?

a

SS

\.732 kN

Proprietary Material. © 2009 The MeGraw-Hili Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or ased beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

<8

Problem 1.40

1.40

The horizontal link BC is 6 mm thick, has a width w = 30 mm,

:

:

_ and_is.mad

is the factor of safety if the structure shown is designed to support a load

P= 40 kN?

|

|

DEM. = 0

40EN

(0-3 cos 80°) Fag — (0:45 sin 30°40) = 0

r

Fac

Ay?

300 map

KN

3$4°6

(0.006)00+035)

=

i-8

Xion#

m

G. = Fe

- Som

Nec

f

Aec. Gort ob BY 104) (450 x10") _= 2034.

Ss

Problem

1.41

FS.

~

Fee

:

3a»

& x10?

1.41

The horizontal link BC is 6 mm thick and is made of a steel with

a 450-MPa ultimate strength in tension. What should be the width w of the link

if the structure shown is to be designed to support a load P = 32 KN witha

factor of safety equal to 3?

4) 2M:

©

(O+3cos 30°) Fxg ~ (0-45 sin 30" (32)

Fas

>

gc. = Fe

_

Ars

2 Je]

=

KN

Fee

iw

. Sot

ES.

0217 xo)

wow LF+S GowFae _” (3

(pr 0eb) (450 x10)

W 2010807

=

30° 8

m ae

mm

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course prepatation. A student using this manual is using it without permission.

Problem

-

1.42

-

..

1.42 Link AB is.to be made of a steel for which the ultimate normal stress is 450

‘MPa, Determine the cross-sectional area for AB for which the factor of safety will be

that the link will be adequately reinforced around the pins ata and B:

<3:50-Assume

-

i

dam

Yo0

kN4m

t O4m

044

Pe

(1.2)¢8)

tO ZM

y

Fig

~ (9.8

it

-

9g

= OF

Sin 35°)

+(0.4 (20)

Faa 7 21619

=

6

AG

tae

Aue

FE Ss.

:

Fas

ie

.

+ (0.2)(9.6)

IN =

Q

O.2m

Dy

oO

21.619«I1O'

N

~ (ES) Fa . (B.50\( 21.619 x10")

A

- Soe

kN

if

Ae

iF

SAN

AR

Gon

= 168.1 x10 Sm

HOO

“ {o*

Aggy? 168.) mm”

Proprietary Material. © 2009 The MeGraw-1Hll Companies, bre. All rights reserved. No part of this Manual may be displayed, ceprodaced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individeal course preparation. A student using this manual is using if without permission,

eat |

Problem

1.43

1.43 The two wooden members shown, which support a 16-kN load. are joined by

ae

___ plywood

splices fully glued on the surfaces in contact. The ultimate shearing stress in

the ghic is 2-5 MPa and the Clearance

between the members is 6 mm. Determine the

required length Z of cach splice if a factor of safety of 2.75 is to be achieved.

iGkN

125 wim

gre

Fack

atve

of

x

6mm

There

sheav

LOKN

SkN

Requirec

Requivad

Py

>

Ferg th

ot each,

oeTA

OF

i, A LYa

.

Length

af sptices

Problem

GEN

>

qhve

.

1.44

®P,

JGKN

of

spdiec

e

cSeaprauce.

Area

of geue,

vdimete

22

(2.75 )(8+10*) =

(2.51 O° V6, 125)

=

N

“le

10.4107" m

.

= (270.4 x10? )+ 0.006 = OY6R x10

Theve

ave

Fach

qiue

of

4

sheav

doacd.

le

ap

ta

where

L=4t(L-c)

A=

Iw

separate

avea

wk

Mm

of saletye

of

adue.

3

kM

Poad.

3kN

2

=

Jew

= 8xlo'N

yh

A\

oy

7.4

Doe and

= $@.180-0.006) =

(0.087\0.125)

Poe BAz

aveas

must transmit

=

=~

aq

0.037 m

10.375107*

m

(2.5%10°)(l0.375% 10") = 27,1875«10% N

.

Factor

Poacd.

92x10"

5

P=

th

KN

1.43 The two wooden members shown, which support a 16-kN load, are joined by

plywood splices fully glued on the surfaces in contact. The ultimate shearing stress in

the glue is 2.5 MPa and the clearance between the members is 6 mm. Determine the

required length £ of each splice if a factor of safety of 2.75 is to be achieved.

6mm

g

8

8x«i0°N

=

.

2D 40

travemit

1.44 For the joint and loading of Prob. | 43, determine the facter of safety. knowing

that the Jength of each splice is L = 180 mm.

225 mm

en

=

(F.S.)P

=

AVER »

,

must

vt timate

j ro

thw

Le

avea

aveas oF q due.

boas,

Ps

Po

sepawvate

3

ES

=

B.

RUN oete

Eis,

=

3.40

<a

“Po

Problem 1.45

4.45 Three 18-mm-diameter steel bolts are fo be used to attach the steel plate shown

to a wooden beam, Knowing that the plate will support a 110-kN load and that the

of safety...

__Uitimate shearing stress for the steel used is 360 MPa, determine the factor

for this

design.

As

bolt,

each

For

=

7 d*

E (ig)

254-47

©

mnt

= 254.47 10% m

ce

« 10°)

1360 7

x105 .4

Poe AT, = (854

HO-kN

,

|

For

the three

Fucton

oe

boSts >

sabety

ms, =.

P

Problem

1.46

N

x lo

4.609

=

Po

(3 \(41.€09« (0°)

= 274.83 xjo? N

.

74 x {o*

FMI

110 * to?

saa so

at

- 1.46 Three steel bolts are to be used to attach the steel plate shown to a wooden

beam. Knowing that the plate will support a 110 KN load, that the ultimate shearing

stress for the steel used is 360 MPa, and that a factor of safety of 3.35 is desired,

determine the required diameter of the bolts.

For each bolt,

P= HE = 3e.667 kW

Requived

Py =

(FS.)P =(3.35 (86.667)

= 122.83 kw

wept

a A

|. BR

~ Ta

LLO KN

d=

[ARs

TT

—~

. 4

~ Wat

[(4122.93 x40*)

wl3to~x 10%)

=

-3

40.8 XID “im

A =2O.8

mm

Proprietary Material, © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of.this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by MeGraw-Hill for their individual course preparation. A stadent using this manuat is using it without permission.

st

_

Problem

1.47 A load P is supported as shown by a steel pin that has been inserted in a short

wooden member hanging from the ceiling. The ultimate strength of the wood used

1 AT

__.is 60 MPa in tension and 7.5 MPa in shear, while the ultimate strength ofthe steclis |

145 MPa in shear. Knowing that b= 40 mm, c= 55 mm, and d= 12 mm, determine

the load P if an overall factor of safety of 3.2 is desired.

1.48 For the support of Prob. 1.47, knowing that the diameter of the pin is d = 16

mm and that the magnitude of the load is P = 20 KN, determine (a) the factor of

safety for the pin, (6) the required values of 5 and c if the factor ofsafety for the

wooden members is the same as that found in part a for the pin.

P=: 20 kN=

2oxlo’ N

Sk

Pur

As Tat = £(0. 016)= 201.06 x10 m

P, = 2A% = GN Ror. Igxio® (145 * 10%)

a0 0m

53.336%10"

~c

F.S.

(bo) Tension

Gy

in wood

AKy

=

b=d

Py

=

wib-ol )

=

Bo

Py

W Go

+

:

O.

=

N

. Pa _ 58.336xI0°

_

=

”

P

~

2Z20x%10%

§8.336 s/o" N

where

|

Ol6

+

for

Wr ~ 4Omm

Shear

in

wood

Py

Double shear;

Py

|

C=

=

wre

_

2A

each

Po

Jw te

=

53.336*10

area

P.

2.42

A

same

F.S,

*=v

0.040nm

58.236%10°

== yo40.Bx%/0

Byjo*

—

+5 940 \(GO *1O*)

b

te

Ty = Fe

x

v>

shear

Double

v

is

N

At we

Qwe

(2V0.040)(7.

10%)5

4O.B

Lon

ewv ere Peerer

8336x103

=

=

mM

mm

same

<a

FES.

|

97.2 xlo”? m

Cz

.

97,2

mm

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc, All rights reserved, No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual

is using it without permission,

—_

|

1.48 A load P is supported as shown

ROWE by a steel pin that has been inserted, in a short

Problem 1.48

ae

So,

“48

wooden member hanging from the ceiling. The ultimate strength ofthe wood used

60 MPa

iii tension atid

7.5 MPa in shear, while the tiltimate strength of the steel is

145 MPa in shear. Knowing that

= 40 mm, ¢ = 55 mm, and d= 12 mm, determine

-the load P if an overall factor of safety of 3.2 is desired,

“fa

~ Based

aouble

shear

iv pin

Py = 2A = 2Ed*y,

uy

r mm. Ly 7

40

on

~

E (2)(o.012) (14510*) = 32.30 x10° N

Based

Po

=

on

tension

AS,

—

In

Ww dod

wilb-d)6,

= (0.040)(0.040 - 0.012)(60x 10%)

=

-_

Based

Py

t

~

Ose

.

on

double

ZAT,

=

sheav

67.2 xlo? N

in the

2wety

oa

wood.

(2)(0.040)(0.

058 )(7.5

10%)

33.0 x)0° N

smattest

P,

=

32.8

xo"

.

APowalhde

NV

3

Pr

ie

=

-

24-2

“lor

/

*

10.25" )0"

N

10.25 kN

a

Proprictary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the Jimited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without perinission.

|

_ Problem

1.49

|

1.49 Each of the two vertical links CF connecting the two horizontal members AD

..and.£G.bas.a.10.x.40-mm.unifonm

rectangular cross.section. and is. made.of.a steeh

with an ultimate strength in tension of 400 MPa, while each of the pins at C and F

has a 20-mm diameter and is made ofa steel with an ultimate strength in shear of 150

MPa. Determine the overall factor of safety for the links CF and the pins connecting

[ 250 mm

és

them to the horizontal members.

400 mm

250 nim

as free body,

t Fee

EFG

Use memher

| Fee

e._&S

LE

LL.

0.40

025)

24kN

24 kN

4) aa Me

=O

0.40 FE, ~(06S5)(a4vI0*) = ©

F, = 37x10"

Based

on tension

A= (b-d)t

in Pinks

CF

= (0.040 - 0.02)(0.010) = 200 r10% m* (one Bink )

F, #26, A= C2{400x10%)(200 *io®)

Based

on

dovide

N

=

166.0 x]o*

N

shear in pins

a

A = Fd* = 2F(o.020)* = 314.16 x10" m*

*

10°) = 74.248 10° N

0

«10° (314.16

Fy = 2TA = AY(15

fy is smaller vahve, ie

Aetuad

Fy = 94.248 10° N

;

Factor

of

satety

FS,

=

os

=

Tee

3

=

2.42

Cr

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc, All rights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

al

oof oocoscnm ne oon

Problem

ne

1.50

1.50 Solve Prob. 1.49, assuming that the pins at C and

with a 30: mm diameter,

have been replaced by pins

1.49 Each of the two vertical links CF connecting the two horizontal members 42)

and EG has a uniform rectangular cross section 10 mm thick and 40 mm wide, and

250

is made of a stee! with an ultimate strength in tension of 400 MPa. The pins at Cand

F each have a 20 mm diameter and are made of a steel with an ultimate strength in

mm

Me

ae

shear of 150 MPa. Determine the overall factor of safety for the links CF and the pins

460 mm

A

connecting them to the horizontal members.

~Ta50

my

Use

member

EFG

as free body.

Fee

Fee

(e

le

D2M_

pam |

=

Ot mo

24.KN

ba—o:25 mo

8

24 &A

O;

(0-65°\(24x00 )

=

O

Fi. = 39 EN

Fa dure

by

tension

in

Pinks

Net section avea for

CE,

(2

| Jinks

pavatte?

bin ks)

A=(b-d)E =(0-04-0-02\60.01) = 200 x16 "m*

Fy = 2A6, = (2) (4vox1a”)(200x

*)

ig*) = tbo kM

eet Puye

by

douhte

A = ga

Fy

Actual

=

2ZA%T,

vi timate

Factov of safety:

shear

in

pins.e

* % (0122) = 314-16 x10 m?

= (2) (31e- tence *VGS0x108) = 94.26 kM

Doad

is

the

smaller

= FS= =

ce

Vadue

e

Fy

= 94625

EN

F.S.2242

<i

Proprietary Material. © 2009 The McGraw-Hill Companies, Inc. All rights reserved, No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

1.51 Each of the steel links AB and CD is connected to a support and to member

Problem 1.51

a.

tsp

50 mm

ameter

soc]. pins

pins acting

iameter.stcel

acting, in.sin

12 mm

Use

——

<=

|e 450

450 pam

mum

ing.

~

ae)

member

=. 4

2

=

BCE

Of e

O35

as

Free

body,

E ep

~—aoqTs FP

=

Fep h

Pp

P

(

OFM=

&

5

:

he |

Cc

OS

.

Din

ks

have

Theve Fove,

they

by

pin

the

Same

have

the

in singe

area,

same

A=

sheav,

cdiametev

aude

3 Fre

metevial

,

foad.

Bd*=

EX G.028)'= 440-9410 me?

-d)

3x06 *m?

t= (os — owrs)o-o1zz

A=(b

tension in Sink.

by

pin

ubtimete

2

=

~~

= (2toxo®) (490-9xj6°) = 103-09 kN

Fy = tA

F, = GA

Ditimate

2

~

Ss Feo

&

;

Farbure

©

.

P=

Fark ore

i

03% g-04P =O

a

y

Both

the

ed in the pins and that the ultimate normal

stress is 490 MPa for the steel used in the links, determine the allowable load P if an

overall factor of safety of 3.0 is desired. (Note that the links are not reinforced

around the pin holes.)

.

Pp

|

= (490x10°) (3x10 *) = 147 kW

Poad

#iruk

and pin

F, 7/0309

LY

for

is the

smelber.

ADlow abte values of Fin and Fra,

Fy? fe = AGRO = 34.36 kN

Abbowahte

Aoad

For structuve

Pp: 2 34.36)

is

the

smatber

of

Ry

amel = Fy,

Ps/s-7 ky

Proprictary Material. © 2009 The McGraw-Hilt Companies, Inc, Allrights reserved. No part of this Manual may be displayed, reproduced, or

distributed in any form or by any means, without the prior written permission of the publisher, or used beyond the limited distribution to teachers

and educators permitted by McGraw-Hill for their individual course preparation. A student using this manual is using it without permission.

<li

Problem

1.52

:

1,52 An alternative design is being considered to support member BCE of Prob.

a

1.51, in which

stissmonen eas snc

link CD will be replaced by two links, each of 6«50-mm

cross

SOCtOR;. causing.-the-pins-at-C-and-D-to. be-in-double-shear: Assuming -that-all-othere-<fo.0-.-.~

specifications remain unchanged, determine the allowable load P if an overall

50 mm

factor of safety of 3.0 is desired,

12 min

L534 Each of the steel links 4B and CD is connected to a support and to member

BCE by 25-mm-diameter steel pins acting in single shear. Knowing that the

ultimate shearing stress is 210 MPa for the steel used in the pins and that the

a

ultimate normal stress is 490 MPa

for the steel used in the links, determine the

allowable load P if an overall factor of safety of 3.0 is desired. (Note that the links

are not reinforced around the pin holes.)

member

BCE

as

free.

body.

O

Use

Avea

E

492 Me=z

of afl pins

Fab pre

by

avea of

pins

by

He

2 Paks

A and B

in

tenston

in

Bink

(Fie u = (49x12 9B x16 *)

Wihimate

foad Pow Pink

Covrespen ding

Faifure

by

vIt+imate

pins

Mi

a

P=

Fre

Aner= (bd) tag = (oes ores) O.012) = 3x/9 in

CD

ic the

sing fe

shear,

(Fro), = (20x10 )(490-9x10"*) = 103-09

FacPuse

03 Fp - oar

_

F.

A iin* E f* = TE (ovasy = 490-9 x0" be

Net section avea of Prek AGE

Net sectron

Ol

Pe

P =

O

|

wip

Fas

= ei

Cand

same.

Fae). =

EN

AB,

“ay

XT, Apin

Fase =

65 Anuet

ka

and pins AB is the smaller’ (Fixg)y = 103-09 kW

Load ,

Py

=

3(Faady

in double shear.

= 68°73

CRs

EN

2 Apia

(Findy = (2 UZ10x1%) (490-9 x10" 9) = 206-18 KN

Faifuve by tension in Inks CD.

(Fro),

DOtimate

2 (440x10%) (3x10"*) = 147

Poud

Corres ponding

Acti A

Lor Pinks

ultimate

vstimate

Load

Mlowshte Load P:

kf

anef pius

doz:

is the

(Fis) 2 Sb Avet

CD

iis the smabler;

Ps = 2 Feo)y

smatter.

p- ES,tv

y 7/47

kN

> SE-B kA

9 = S88

_ 508

3.0

CR

kA

PaI0b kN aes

Problem

resent

1.53

1.53

In the steel structure shown, a 6-mm-diameter pin is used at C and 10-mm-

diameter pins are used at B and D. The ultimate shearing stress is 150 MPa at all

staan

sooo CONN CCHONS: and the ultimate normal stressis 400 MPa imiink 2D: Knowing thata™

factor of safety of 3,0 is desired, determine the largest load P that can be applied at 4.

Note that link BD is not reinforced around the pin holes.

Use

Lyee

ocd.

ABC.

Front view

“18 mm

ADEM, = 0:

0.230 P - 0.120 Fep = ©

-—ia<—-— 6 mim

BB

P=

&

Fap

(1

Side view

452M,

20:

0.1460

P CFB

Top view

P=

° [

|

a

4

Tension

on

nel section

G

ef

Band

Frou

value

in

Sheav

of

Fen

is

pin

af

of Pink

BD,

ig-1oe)

2927010

= 3.9270 «10° N

N,

1.683 K 10" N|

C

20 apm = ae ay. (2) (SPO EY (exo? = 2.8274 x10" N

Cr

From

|

D.

P= (S)(3:7270xl0"} =

(1)

(2)

6. 46xjo* N

Fey = TAp.> ot Fa? = (SLAVE Vio eto?

Sma dber

O

Fas? CAnt = SE Aw

ij

im pins

=

#C

(Hognlo'(e vio

Shear

CG

—

Fae

G

O.l20

Pe Yasar}

@)

Smaller

vehue

F

P

is

aDlivus «Ade

=

212x107N

ve due »

Pre

1.692x1lo

N

P= 1.683 kN =f

Problem

M

1.54

tie

1.54

mt

Solve Prob. 1.53, assuming that the structure has been redesigned to use 12-

min-diameter pins at # and D and no other change has been made.

ho

diameter pins are used at B and 0. The ultimate shearing stress is 150 MPa at all

connections, and the ultimate normal stress is 400 MPa in link BD. Knowing that a

factor of safety of 3.0 is desired, determine the largest foad P that can be applied at 4.

Note that link BD is not reinforced around the pin holes.

Use free body ABC.

Front view

tDEM,

<— 18 nm

= Or

O.2BOP

P=

| mn

160 mre

ania

Bo

120 min _£

Side view

4 4 oa

- OL120

3 Fap

Me

fe

Ps

‘Top view

Fae

,

‘Tanston

!

on

net

Dp

P

|

doo

x

B

and

to

vabse

From (0)

«¢

Ox1O* 7 Ey

= (52

of Fen

ts

\CH Cats

Sheaw im pin at C,

Drak

BD,

Se

7

f

xJfo®?

N

-3\2

Y= S654 «(oN

2.06 xI0° N

|

C= 2UAm = Zoe Edt= = (2 Be

Smabler

PY

4.80x%lo' N,

P=(S\4.80%[o%) =

From G\,

'2)

D.

* ao a

Fen7 TApi

SmmeWevr

C

\guio® U8-i2ie

3

= 40

eA

=O

«lots FS.

= (129

th pins

3

section

~

Ve

‘Shear

- O.2200

C

f

G

Q)

=o:

9.160 P

AB

Fey = O

VE\Geiwe

= 2.8274 4107 N

P= B\(zez7teict) = 21axlN

valve

of

P

ors

the

aD Poute

be

Vodue

P-

2.6618

P= 206kN

NV

«a

Problem

1.55

1.55 In the structure shown, an 8-mm-diameter pin is used at A, and 12-mm-diameter

_ pins are used at B and D. Knowing that the ultimate shearing | stress is 100 MPa at all

“connections and that the ultimate normal stress is 250 MPa in each of the two links

joining B and D, determine the allowable load P if an overall factor of safety of 3.0 is

.

desired.

Top view

. [- 200 mm ap

80 nam

|

ft

12 mm

Statics 2? Use

Simm

as

ABC

free

body.

7

B

ah

ozs —H

20 mm

Fa

8 mm

=

0.18 —|

Fao

8mm

HFMe,

Based

double

on

P=

12 mm

Front view

-

pis

A

Based

on

Based

on

davble

pins

tu

shean

A= Ed*= Foo} =

Eye = au

eee

Fow

compression

one

A=

Pink

Fao = “es

= Gila

P= ig Feo =

Movable “valve

in

of

O18

P

=o

Fan

3.35} ¥Jo32 N

N

3.72 x10

=

PF,

Fz-

LF,

Paes

A.

A=Bd*= $(0.008)* = 50.266 x10 * m

re ZtvA _ (A100 x10%)($0.266 ¥Jo_ 2

A

ES.

3.0

p=

0.20

OF Map= 0: 0.20 Fep-0.38P

= 2

Side view

shear

20:

a}

Band

D.

113.10 x/Q° m™

“6

es loxlons)

2 zea yig® N

Sinks

BD.

(0.020 )(O, 008)

=

xlo WigoxissS)

_

160 x/0-

mo

ae 7 #)0° N

14.04 »1o* N

P

is

smatlest.

+.

Pr

3.72

P=

*1O" N

3.72 KN

~<a

soe seseespettte te

.

Problem

4.56 In an alternative design for the structure of Prob. 1.55, a pin of 10-mm-diameter

1.56

is to be used at A. Assuming that all other specifications remain unchanged,

oon determine the allow:

ad.P if.an overall factor of safety. of 3.0 is desired

eenccccscrnnudeace ose ous

1.55 In the structure shown, an 8-mm-diameter pin is used at A; and 12-mm-diameter

pins are used at B and D. Knowing that the ultimate shearing stress is 100 MPa at all

connections and that the ultimate normal stress is 250 MPa in each of the two links

joining B and D, determine the allowable joad P if an overall factor of safety of 3.0 is

desired.

Top view

[200 mmorten 180 min

Smt <I

| 12mm

i.

;

at

as

2

ot

.

.

Statics

>

Use

A

Fp

0.18 “y

Feo

P

=

“ Mp=

Based

on

double

rc.

=

= ¥ (0.0.16)*

A=4d*

pin

1”

shear

.

RS.

Pp

Fa

fo

1y

0.20 Fep- 0.38 P= a

*¢ Be

.

Fe.5¥ x10°% m”

= ZteA | (100 xjos)( 7B.S4 xfo”)

A

3.0

P

0.20 Fy-ONRP=0

0:

P=

A. oe

body.

.

HEMg=O%

~

free

c

ee

V

12mm

as

8

H-——-}.20

8 mim

ABC

=

:

5,236

x Jo?

N

P= BPR = §.82 x10" N

Based on double shean in pins at B and D= 113.10 x0" m™

R= Bd* = Boom)

Fan = AGA

_=

Coo xI10S0 )(113.1oxlo”*) = 7.54x/0° N

=e

3.97 x107 N

P= 12 Fin =

on

one

Fov

Feo

compression

=~

in Minks

BD.

A = (0.020 )(0,008)

Pink

1Go x/o* my

285A _ (2)( 250 0‘ igo xI0"*)

FS.

|

3.0

.

‘|

Based

26.7 *10° N

P= ag Fan = 14.04 xJo3 N

AVowabde

value

of P

is

smatlest.

..

P=

3.97 *1O> N

P= 2.97KN

«a

_

Problem

1.57

*1,57 A 40-kg platform is attached to the end B of a 50-kg wooden beam AB, which

_ is supported as shown by a.pin at 4 and by a-slender steel-rod BC with a 12-kN

“ultitnate load: (ay Using the ‘Load and Resistance Factor Design method with

resistance factor ¢ = 0.90 and load factors 7 = 1.25 and

»% = 1.6, determine the

‘largest load that can be safely placed on the platform. (6) What is the corresponding

conventional factor of safety for rod BC?

DEM,

0:

(24)8P-

240-120,

For dead toading,

W,= (40)(9.81) =

W, = ($0)(97.31) = 490.5 N