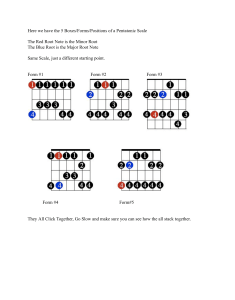

i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Available online at www.sciencedirect.com ScienceDirect journal homepage: www.elsevier.com/locate/he Optimal operating conditions of PEM fuel cells in commercial aircraft €der a,*, F. Becker a, J. Kallo b, C. Gentner a M. Schro a German Aerospace Center (DLR), Institute of Engineering Thermodynamics, Hein-Saß-Weg 22, 21129, Hamburg, Germany b German Aerospace Center (DLR), Institute of Engineering Thermodynamics, Pfaffenwaldring 38-40, 70569, Stuttgart, Germany highlights Novel graphical abstract computationally efficient model for PEM fuel cell water management. System-level performance is linked to water management effects at cell-level. Stack operating conditions (pressure, stoichiometric ratio, humidity) are optimized. Optimal operating conditions depend on flight phase and system sizing. The trade-off between system efficiency and system mass is explored. article info abstract Article history: This work investigates the integration of polymer electrolyte membrane fuel cells (PEMFC) Received 19 April 2021 into recently proposed hydrogen aircraft concepts. Based on a numerical optimization of the Received in revised form stack's operating conditions, the interrelated aspects of efficiency and system mass are 8 July 2021 explored. A novel 1D two-phase PEMFC stack model is developed that captures water Accepted 14 July 2021 management effects in detail and yet features sufficiently low computational cost to be used Available online 19 August 2021 for system-level optimization. The stack model is validated for a wide range of temperatures, current densities and oxygen concentrations. In combination with auxiliary compo- Keywords: nent models, it can relate the effects of the investigated parameters on cell-level water Fuel cells management to system-level effects. This allows for an improved understanding of the Commercial aircraft underlying design tradeoffs, particularly regarding pressurized operation and stack over- Water management sizing. The results show that the conditions that maximize the overall system efficiency for Optimization a given flight phase deviate significantly from those that merely maximize stack efficiency. Auxiliary power © 2021 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved. System efficiency * Corresponding author. € der). E-mail address: matthias.schroeder@dlr.de (M. Schro https://doi.org/10.1016/j.ijhydene.2021.07.099 0360-3199/© 2021 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Nomenclature Symbol A ccm cdi cf cp ; Ci;j D Erev F h i J k krel Mi Ma mi mi;sp m_ i;j ndrag nk ni;j n_i;j N p P Q1 , Q2 R Rsp RHi q Q_ s b DS active cell area ðm2 Þ factor in conformal mapping approach ð Þ coefficients in pressure drop correlation, i ¼ 1…2, Eq. (49) ( ) scaling factor for average saturation, Eq. (69), ð Þ cv specific heat capacities ðJ kg1 K1 Þ molar concentration of species i in control volume j ðmol m3 Þ diffusion coefficient ðm2 s1 Þ reversible cell voltage ðVÞ Faraday's constant ðAs mol1 Þ enthalpy ðJ kg1 Þ current density ðA m2 , A cm2 Þ dimensionless function in Leverett approach ð Þ GDL intrinsic permeability ðm2 Þ relative permeability ð Þ molar mass of species i ðkg mol1 Þ Mach number ð Þ mass of component i (kg) specific component mass, units depend on context as defined in Table 7 mass flow of species i into/out of control volume j ðmol s1 Þ coefficient for electro-osmotic drag ð Þ exponent for relative permeability ð Þ amount of species i in control volume j ðmolÞ molar flow of species i into/out of control volume j ðmol s1 Þ number of components ð Þ pressure or partial pressure ðPa; barÞ electric effective power ðW; kWÞ objective functions for optimizations ideal gas constant ðJ mol1 K1 Þ specific gas constant ðJ kg1 K1 Þ relative humidity in control volume ið Þ switch parameter in flooding sub-model, Eq. (68), ðÞ heat flow ðWÞ liquid water saturation in GDL ð Þ molar standard-state entropy of reaction ðJ mol1 K1 Þ Introduction In order to reduce the impact of aircraft emissions on human health and the climate, the aerospace sector is investigating low-emission power sources that can assist or replace conventional kerosene-based options [1,2]. Low temperature polymer electrolyte membrane fuel cells (PEMFC) are considered as one of several promising technologies [3] that could be used to achieve long-term emission reduction targets [4]. t T U vD vm V V_ x, y, z Xi;j 33219 time ðsÞ temperature ðK; CÞ voltage ðVÞ Darcy velocity ðm s1 Þ molar volume ðm3 mol1 Þ volume ðm3 Þ volume flow ðm3 s1 Þ spatial variables ðmÞ mole fraction of species iin control volume jð Þ Greek letters cathode transfer coefficient ð Þ ac thickness of layer k ðmÞ dk ε GDL porosity ð Þ hc , hm , hU voltage losses ðVÞ h efficiency ð ; %Þ Q contact angle ð Þ k ionic conductivity ðU1 cm1 Þ lmem ; lCCL water content of ionomer ð Þ lO2 ; lH2 stoichiometric ratios for O2 and H2 ð Þ m dynamic viscosity ðPa sÞ r density ðkg m3 Þ s surface tension ðN m1 Þ Subscripts A anode C cathode cap capillary comp compressor-related quantity eff effective fl fluid g gaseous in inlet, inward l liquid out outlet, outward p pore ref reference quantity, reference conditions rel relative cell cell-related quantity stack stack-related quantity sys system-level quantity tot total, combined quantities, all species in mixture Recently, a large aircraft manufacturer announced three new aircraft concepts where hydrogen is burnt in gas turbines for propulsion while fuel cells provide electric energy for auxiliary loads and/or hybrid electric propulsion [1]. Based on this background, this work investigates the use of PEMFCs to provide electric auxiliary power onboard future commercial aircraft. The use of PEMFCs for propulsion of small passenger aircraft [5,6] and small electric loads in commercial aircraft [7] has been successfully demonstrated. However, several 33220 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 technological challenges must be overcome when using PEMFCs to meet the electric auxiliary load demand of commercial aircraft (several hundred kW). Specifically, one must achieve a high system efficiency and a low system mass (stacks and balance-of-plant components). These two interrelated aspects are affecting the aircraft's overall design in various direct and indirect ways, as summarized in Table 1. Achieving good performance for both these aspects is critical for a PEMFC-system to be feasible and competitive to conventional technology options. As a part of the overall assessment of the feasibility of such a PEMFC-based concept, this work analyzes which systemlevel efficiencies can be achieved, discusses the underlying tradeoff between mass and efficiency, and shows how the efficiency can be maximized by choosing the optimal stack operating conditions for each flight phase. The operating conditions of PEMFCs include the current density, stack temperature, stack pressure, oxygen stoichiometric ratio and the amount of humidification. At cell-level and for ground-based applications, their effects are well known [8e10]. However, for aircraft applications the widely varying environmental conditions throughout a flight mission result in significant differences. Previous work on PEMFCs as auxiliary power sources in commercial aircraft had a strong focus on overall system design aspects. Guida et al. [11] developed a methodology for Table 1 e Summary of the major direct and indirect effects of the PEMFC-system's efficiency and mass on the overall aircraft design. The PEMFC-system is defined here as the stacks and their balance-of-plant components (compressors, cooling system, etc.), a detailed definition of the system components and the system-level efficiency is provided in section System description. PEMFC-system parameter Effect Overall aircraft design parameter System efficiency Affects required cooling system mass and size per required net electric power output System efficiency Direct effect on required fuel mass System efficiency Affects required hydrogen tank size and mass (based on required fuel mass) Affects the required reactant air flow per given power output Direct contribution to aircraft mass Indirect contribution to aircraft mass (increased mass leads to higher required propulsive power) aircraft mass volumetric constraints aerodynamic drag from cooling air inlets fuel consumption for design mission aircraft mass aircraft mass volumetric constraints System efficiency System mass System mass aerodynamic drag from reactant air inlets aircraft mass fuel consumption for design mission optimizing the specific energy of such systems. The feasibility of several system integration concepts was assessed by Pratt et al. [12]. Several aviation-related studies focused on systemlevel effects of stack operating conditions in more detail. Campanari et al. [13] investigated different configurations for supplying compressed air to the stacks and determined favorable operating pressures. Lüdders et al. [14] discussed the multi-functional integration of PEMFCs and optimized several system-level design parameters simultaneously. Possible benefits of operating the stacks at lower current densities were discussed by Kadyk et al. [15]. Another set of studies focused on practical aspects for the integration of PEMFCs into € ter et al. [16] investigated the effect of low future aircraft. Schro ambient pressures and pressure drops. The impact of operating parameters and system architecture on the stack's water management was analyzed by Werner et al. [17]. These studies [11e17] all have in common that the overall system analysis is conducted based on relatively simple and computationally efficient PEMFC models or interpolated experimental data. Owing to their wider perspective on the overall system, these studies either do not explicitly consider the effects of the stack's operating conditions on its water management [11e16] or do so only for a limited range of operating conditions [17]. A similar pattern can be observed in studies on the operating conditions of PEMFCs in groundbased applications: studies that focus only on a stack or single cell [8,10,18] capture water management and particularly flooding effects quantitatively and at high detail, while system-level studies typically consider flooding only qualitatively1 [19e21], empirically [22] or not at all [23]. The water management of PEMFCs aims at achieving optimal humidity conditions within the cells so that neither membrane dehydration nor flooding with excess liquid water occurs [9,24]. Both phenomena have been shown to be relevant for typical operating conditions [25,26]. They significantly affect the feasible operating range and achievable efficiency and are therefore highly relevant to the overall system design. Consequently, an improved understanding of the effects of cell-level water management on system-level performance and the system-level optimal operating conditions of PEMFCs is needed.C. The approach that is presented here addresses this challenge with the following improvements: 1. System-level effects of all main stack operating conditions are considered simultaneously instead of one at a time: Pressure, oxygen stoichiometric ratio and humidity are optimized for different current densities and a prescribed stack temperature. 2. The optimization is conducted with a phenomenological stack model that is comprehensively validated for water management effects (including flooding), while still maintaining the overall-system perspective In order to conduct this optimization, one requires a PEMFC model that can capture the combined effects of these operating conditions on the cell's water management and yet 1 Their model equations include liquid water effects but the model is not validated for flooding conditions. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 33221 Table 2 e Comparison of exemplary PEMFC modeling approaches. The computational cost is approximated relative to the other items in the table based on the models’ governing equations. PDE: partial differential equation, ODE: ordinary differential equation, DAE: differential algebraic equation. Ref. Futter et al. [8] Vetter et al. [27] Goshtasbi et al. [18] This work Abdin et al. [9] Liu et al. [28] Type transient, 2D, nonisothermal Steady-state, 1D, non-isothermal transient, pseudo2D, non-isothermal steady-state, 1D, isothermal steady-state, 1D, isothermal steady-state, 1D, isothermal Flooding Membrane dehydration Governing equations ✓ ✓ PDEs moderate to high ✓ ✓ PDEs moderate ✓ ✓ PDEs, DAEs moderate to low (faster than real-time) ✓ ✓ ODEs low e ✓ ODEs very low e ✓ ODEs very low features sufficiently low computational cost to be useable for system-level optimization. Several exemplary PEMFC modeling approaches are compared in Table 2. Examples for high fidelity, phenomenological (physics based) models are described in Refs. [8,18,27]. They capture the effect of varying operating conditions with high accuracy and would, in principle, be well suited to answer the investigated research question. However, even real-time capable approaches among them are too computationally expensive for system-level optimization. Less computationally demanding phenomenological models [9,28] are often based on a detailed description of the processes in the cells, but typically do not consider liquid water transport in the diffusion media and thus do not capture flooding effects. A semi-empirical PEMFC model that considers flooding phenomena and yet achieves low computational cost was developed by McKay et al. [24]. However, this approach has the drawback that it relies on large amounts of experimental data. Due to the large number of relevant operating parameters, it can be prohibitively time consuming to test all their combined effects. Phenomenological models are therefore better suited to answer the investigated research question because they inherently require less experimental data on a particular stack to be parameterized. Based on these considerations and to the authors’ knowledge, there is at present no phenomenological PEMFC model that allows for quantitatively assessing water management at sufficiently low computational cost to conduct the aforementioned optimization of stack operating conditions. Here, we develop a 1D two-phase PEMFC model that captures both flooding and membrane dehydration effects in a wide range of operating conditions, and yet can be used to simulate several hundred steady-state operating points per second and per processor core.2 The model is validated with experimental data for the effects of current density, stack temperature and oxygen content of the supplied air that were measured with a commercial stack. 2 For comparison, the open source reference 1D model by Vetter et al. [27] simulates about 5 operating points per second on the same computer (Intel i9 processor, 32 GB RAM, Matlab version R2019a). Computa-tional cost By combining the stack model with auxiliary component models, we relate the effect of the investigated parameters on cell-level water management to system-level effects. This enables more realistic simulation results for the optimal operating conditions and achievable system efficiencies of PEMFCs in aircraft applications. The outputs of the developed methodology can be easily integrated into high-level system-sizing frameworks such as those proposed in Refs. [11,12,14]. System description In conventional commercial aircraft, electric power is typically provided via two main pathways: - Generators driven by main engine shaft, typical output: 4 250 kVA for large single-aisle aircraft [29]. - Auxiliary power unit (APU), typical output: 2 225 kVA for large single-aisle aircraft [29]. The APU is operated on ground or in case of an emergency, the main engines supply electric power during nominal flight. A small ram air turbine is typically included as another inflight emergency power source. Additionally, a ground power connection is used when the aircraft is parked. A detailed description of electric loads onboard more-electric aircraft was given by Campanari et al. [13]. Because the largest consumer (electric environmental control system) is used continuously throughout the flight, it can be assumed that the electric auxiliary load demand remains fairly constant throughout the different flight phases. This work investigates an exemplary scenario where the engine-driven generators and APU are replaced by PEMFCs (several generators might still be included for redundancy). To arrive at generalized results, the investigations are conducted based on size-independent quantities and without making assumptions for a particular aircraft size and electric load demand. The underlying assumption is that the achievable component efficiencies and optimal operating points do not significantly depend on the exact number of stacks and cells per stack in systems of this scale. 33222 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 System architecture The investigated system architecture is depicted in Fig. 1. To enable operation at high altitudes, the stacks are supplied with compressed air. Under cruise conditions, an air inlet allows for converting some of the ambient air's kinetic energy to an increased pressure at the compressor inlet. These components are comparable to those used in electric environmental control systems of today's aircraft [29]. The compressed air is cooled and humidified before it is supplied to the stacks. At low ambient pressures one could recover part of the compressor's power consumption by expanding the stacks' pressurized cathode exhaust in a turbine. This would require additional components for the dehumidification of the exhaust in order to prevent frost formation in the turbine [13]. Pressure drops along the flow path reduce the amount of recoverable power. Because it is unclear at present whether the achievable efficiency improvement of such an approach can justify the additional mass and complexity, this study focusses on an architecture without energy recovery. The stacks are cooled with a conventional liquid coolant that transfers their waste heat to the ambient air. When the aircraft speed is not sufficient to force air through the channel, a fan is used. In the underlying aircraft concept, the hydrogen will likely be stored in liquid form [1]. Here, it is considered to be present at the required pressure and stack temperature at the system boundary. The underlying assumption is that the pre-conditioning of the hydrogen can be achieved with passive components (heat exchangers, pressure reduction components) and hence does not significantly affect the system's efficiency. The stacks are operated with an anode recirculation loop as described in section Mass balances. Fig. 1 shows an exemplary system configuration. The required number of stacks Nstacks and cells per stack Ncell for a given effective power output under design conditions will be a simulation result. The model assumes that all stacks are operated under the same conditions. The number of compressors Ncomp is a free design parameter; the model assumes that all compressors are each operated under identical conditions if there is more than one. The stacks and the air supply system are simulated in detail because these components affect the system's efficiency most significantly. The cooling system simply acts as a heat sink in this investigation. A generalization of the analysis to consider the cooling system in detail is left for future work, since the design of cooling systems for commercial aircraft is a complex design problem on its own [30]. Efficiency definition The system's net direct-current (DC) power output is Psys;eff ¼ Pstack;tot PBoP (1) where Pstack;tot ¼ Nstacks Pstack is the combined stack power. The compressor's power consumption is considered with PBoP ¼ Fig. 1 e Investigated system architecture, exemplary configuration with Nstacks ¼ 2 and Ncomp ¼ 1. Bypass tubing as well as flow and pressure regulation components for control purposes are not depicted; the stacks' anode recirculation loop is shown in detail in Fig. 2. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 33223 Fig. 2 e Schematic fuel cell stack and modeling domain (not to scale, coolant circuit not depicted). ACL: anode catalyst layer, CCL: cathode catalyst layer, MPL: micro-porous layer (a) top view of stack (b) section of a single cell. Ncomp Pcomp . The power consumption of the other balance-ofplant components (for example fuel and coolant pumps) are neglected because they are small compared to Pstack;tot . Moreover, we focus on operating states where Pfan;RA ¼ 0. Situations where the cooling air fan is necessary (e.g. when waiting on the runway) are not as relevant to the overall design, because the system is sized for cruise conditions where the compressor's power loss is more significant and the fan is not needed. The system's overall efficiency is hsys;HHV ¼ Psys;eff m_ H2 ;sys DhHHV;H2 (2) where DhHHV;H2 is the higher heating value (HHV) of hydrogen and m_ H2 ;sys ¼ m_ H2 ;A;in Ncell Nstacks is the supplied hydrogen flow. Mathematical model development PEMFC stack model The model is implemented in Matlab code and simulates a stack's steady-state behavior by solving the governing equations for one hypothetical average cell. The modeling domain is depicted in Fig. 2 and will be discussed further below. A straight channel, counter-flow configuration is shown exemplarily; the model makes no assumptions regarding these two aspects. The model's main assumptions are. - 1D discretization - isothermal - catalyst layers are considered infinitely thin, except when calculating their ohmic resistance - the micro-porous layers (MPL) are considered infinitely thin - the vapor and liquid phase are assumed to be in equilibrium at all times when solving the governing differential equations for their steady-state solution - ideal gases, ideal gas mixtures, incompressible liquid phase High-fidelity models often resolve the temperature differences that occur between different locations in the stack [8,18,27]. In alignment with previous computationally efficient models [9,28] these temperature differences of several Kelvin are neglected here and an average temperature Tstack ¼ Tcell is used. The average cell voltage in the stack is calculated based on [31]. 33224 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Table 3 e Stack model parameters that are fitted in a nonlinear optimization problem. Sym-bol i0,ref ilim,ref ac cT cH nk cD1 dGDL;eff Description Reference exchange current density (A m-2) Reference limit current density (A m-2) Cathode transfer coefficient () Factor for spatial variation of temperature in channel () Factor for spatial variation of relative humidity in channel ð Þ Exponent for relative permeability ð Þ Combined GDL-specific parameters ðm1 Þ Effective GDL thickness ðmÞ Lower bound l Upper bound u (6) Eq. 10 450 assumed (8) 104 106 assumed (5), (7) (47) 0.2 0.55 0.5 0:95 based on [31] based on [56] (48) 0:5 1:5 assumed (60) 2 5 based on [50] (62) 1,1010 1,106 assumed (65) 1:1,104 2:5,103 dGDL based on [42,53], ccm based on [55] Ucell ¼ Uocv hc hU hm (3) where the open circuit voltage (OCV), cathode side activation losses hc , ohmic losses hU and cathode side mass transport losses hm depend on a number of effects as described below. The anode activation overpotential is neglected [32,33]. The stack's power is Pstack ¼ i A Ucell Ncell (4) Cell voltage (5) The exchange current density i0 is calculated from a fitted value i0;ref for the reference conditions listed in Table 4. CO ;C i0 ¼ i0;ref , 2 CO2 ;ref (6) Cathode side mass transport losses are modelled with [31]. 1 RTcell ilim ln hm ¼ 1 þ ac 4F ilim i (7) where ilim fðCO2 ;C ,DO2 ;eff Þ. By using Eq. (7), the model assumes a linear distribution of oxygen across the GDL and calculates the corresponding additional activation losses and changes in open circuit voltage via the limit current density approach that is described in Ref. [31]. In alignment with Refs. [9,31], the model assumes that a water vapor concentration gradient across the GDL has no direct effect on the cell voltage. The limit current density ilim depends on the operating conditions and is determined based on Eq. (8) with a fitted reference value and the diffusion coefficients described in section Mass transport in cathode GDL. CO ;C DO ;eff ilim ¼ ilim;ref , 2 , 2 CO2 ;ref DO2 ;ref ! dmem dCCL i þ hU ¼ kmem fCCL 1:5 kCCL (9) for an assumed ionomer fraction fCCL ¼ 0:15 in the CCL [36]. 1 1 k ¼ ð0:005139l 0:00326Þ,exp 1268 303 Tcell The model determines activation losses hc based on [31]. with i0 f CO2 ;C The cathode transfer coefficient ac is fitted to experimental data as well. The major part of the cell's ohmic losses arises from proton transport in the membrane and CCL [32,34]. These contributions are considered with [32,35]. The conductivity of Nafion in ðU,cmÞ1 is calculated from Ref. [37]. where i is the current density and A the active cell area. RTcell i ln hc ¼ ; i0 ac 2F Ref. For bounds (8) (10) which is used for both kmem ðlmem;eff Þ and kCCL ðlCCL;eff Þ. Here, l is the water content of the respective component as defined in section Membrane humidity. Since the model is not discretized along the channel length, lumped average conductivities are determined based on effective values lmem;eff and lCCL;eff (see section Fluid temperature and humidity). The OCV is calculated with the Nernst equation and a fitted value DUcr ¼ const for the voltage drop due to hydrogen crossover [38]. Uocv ¼ Erev þ 0:5 RTcell pH2 pO2 ln DUcr 2F p0 p0 (11) The partial pressures pH2 ¼ pA XH2 ;A and pO2 ¼ pC XO2 ;C;mid;gp are determined in the mass balance sub-model. The reversible cell voltage Erev is [31]. Erev ¼ Erev;0 þ b DS ðTcell T0 Þ 2F (12) with parameters from Table 4. The voltage efficiency hstack;V and overall stack efficiency based on DhHHV;H2 are hstack;V ¼ Ucell Erev (13) i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 determined from Eq. (17), which holds true for steady state operation. Table 4 e Stack model parameters that are not fitted. Symbol Description CSO3 ;mem sulfonic charge concentration in ionomer Erev;0 standard-state reversible cell voltage [31] EW ionomer equivalent weight [42] F Faraday's constant fCCL ionomer fraction in CCL [36] higher heating value of DhHHV;H2 hydrogen ndrag coefficient for EOD [42,57] qsw switch condition in flooding sub-model R ideal gas constant sres residual liquid water saturation [50] b DS molar standard-state entropy of reaction ε GDL bulk porosity [36,48] hydrogen stoichiometric lH 2 ratio ionomer density [33] rdry;Naf Standard and reference conditions pressure at standard p0 conditions T0 temperature at standard conditions RHref relative humidity at reference conditions reference oxygen mole XO2 ;ref fraction CO2 ;ref reference oxygen concentration DO2 ;ref reference diffusion coefficient hstack;HHV ¼ Value Unit rdry;Naf =EW mol m3 1:23 V 0¼ (17) The average mole fraction of water XH2 O;C in Vref;C is kg mol 96485 0:15 1:418,108 As mol1 J kg1 1 1:8 8:314 0:08 XH2 O;C ¼ nH2 O;C ntot;C (18) and includes both liquid and gaseous water. The volume Vref;C and the amount of substance in it are split into a gaseous part and a liquid part denoted with the indices “g” and “l”. Vref;C ¼ Vref;C;g þ Vref;C;l (19) J mol1 K1 nH2 O;C ¼ nH2 O;C;l þ nH2 O;C;g (20) 163 J mol1 K1 ntot;C ¼ ntot;C;l þ ntot;C;g (21) 0:6 1:05 is 1980 kg m3 1,105 Pa 298:15 K where Tfl;C is the cathode fluid temperature (see section Fluid temperature and humidity). The relation of Vref;C;g and Vref;C is 0 Vref;C;g ¼ Vref;C 0:209 where rH2 O;l is the density of liquid water evaluated at Tcell [39]. p0 XO2 ;ref RT0 mol m3 Eqs. (20)e(23) form a system of algebraic equations with two independent variables nH2 O;C;l and Vref;C;g . The analytical solu- Eq. (52) m2 s1 tion for Vref;C;g is If the gas phase is saturated, the amount of water in Vref;C;g nH2 O;C;g ¼ (14) Mass balances The mass balance for a single average cell in the stack is formulated with the reference fluid volumes Vref;C and Vref;A as depicted in Fig. 2. Vref;C includes only the fluid volume in cathode channels and GDL pores, while Vref;A includes the fluid volume in the entire anode recirculation loop. Each volume is split equally among the cells. The amount of water nH2 O;C in Vref;C is given by dnH2 O;C iAlO2 XH2 O;C;in ¼ þ n_H2 O;CCL XH2 O;C n_tot;C;out dt 4F XO2 ;C;in (15) where the first term is the water supplied with the incoming air flow. Here, lO2 is the ratio of supplied and consumed molar flows of oxygen. The molar flow of water from the CCL is iA 2F iAlO2 iA n_tot;C;out þ n_H2 O;CCL 4F 4FXO2 ;C;in 1 1:1 Pstack n_H2 ;in;A MH2 Ncell DhHHV;H2 n_H2 O;CCL ¼ n_H2 O;mem;C þ 33225 (16) where n_H2 O;mem;C is the molar flow to or from the membrane and the second term is the produced water. The total molar flow of fluid n_tot;C;out that exits the reference volume is psat Tfl;C ,Vref;C;g R,Tfl;C MH2 O ,nH2 O;C;l rH2 O;l 8 > > > if RHC ¼ 1 : > > > > Vref;C ,rH2 O;l rH O;l 1 psat Tfl;C > < nH2 O;C 2 R,Tfl;C MH2 O MH2 O Vref;C;g ¼ > > > if RH < 1 : > C > > > > : Vref;C (22) (23) (24) The case distinction for the trivial single-phase case is made based on the relative humidity RHC that is defined below. The analytical solution for nH2 O;C;l is 8 if RHC ¼ 1 : > > > > r > > < Vref;C Vref;C;g H2 O;l MH2 O nH2 O;C;l ¼ > > > if RH < 1 : C > > > : 0 (25) The total amount of substance can then be calculated to ntot;C;l ¼ Vref;C;l ,rH2 O;l MH2 O (26) pC ,Vref;C;g R,Tfl;C (27) ntot;C;g ¼ where pC is the known pressure of the cathode side fluid. The lumped relative humidity of the cathode fluid is 33226 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 nH O;C;g p C RHC ¼ 2 ntot;C;g psat Tfl;C (28) With the assumption of a uniform current density across the cell area, the oxygen mole fraction decreases linearly along the channel length. The average value XO2,C,mid,gp is XO ;C; in þ XO2 ;C;out;gp XO2 ;C;mid;gp ¼ 2 2 (29) where XO2 ;C;out;gp is the mole fraction in the gas phase at the outlet. The mole fraction for the two-phase mixture (considering both liquid and gaseous water) is determined from iA lO2 1 1 , XO2 ;C;out ¼ 4F n_tot;C;out (30) (31) The average value CO2 ;C used in Eqs. (6) and (8) is related to XO2 ;C;mid;gp via CO2 ;C ¼ XO2 ;C;mid;gp pC RTcell (32) The anode side mass balance is set up in a similar manner. As shown in Fig. 2, the investigated stack features an anode recirculation loop. The H2 purge valve is opened at a given frequency of about 1 s1 while the inlet valve is controlled to supply just enough hydrogen to maintain a constant anode side pressure. The model considers these discrete purge events as a quasi-steady-state continuous supply and removal of fluid from Vref;A with a small excess hydrogen stoichiometric ratio lH2 ¼ 1:05. Because the investigated system does not use an external humidification of the supplied hydrogen, only conditions without liquid water on the anode side are considered here. Extending the model to consider open-anode configurations, external hydrogen humidification and liquid water on the anode side is straightforward because the equations for the cathode side water balance can be re-used for the anode side with minor adjustments. The amount of water nH2 O;A in Vref;A is given by dnH2 O;A ¼ n_H2 O;mem;A XH2 O;A ,n_tot;A;out dt (33) iAðlH2 1Þ þ n_H2 O;mem;A 2F n_H2 O;mem;C ¼ n_H2 O;mem;A (34) (35) The term n_H2 ;A;in ¼ iAlH2 2F nH2 O;A ntot;A (38) where pA and Tfl;A are the pressure and temperature of the anode side fluid (see sections Fluid temperature and humidity and Fluid pressure). By calculating the relative humidity RHA ¼ XH2 O;A ,pA psat Tfl;A (39) the model's code checks that RHA < 1 holds true in the investigated operating conditions. The model considers diffusion and electro-osmotic drag (EOD) as transport mechanisms for water in the membrane. For entirely liquid-equilibrated membranes the contribution of diffusion would need to be replaced by a pressure-driven flow [40]. As shown in section Stack model validation, both vapor-equilibrated and partially liquid-equilibrated conditions (sact > 0) occur in the simulations. Weber and Newman [41] developed a model that considers both mechanisms simultaneously for partially liquid-equilibrated membranes. However, due to its complexity that approach is not well suited for computationally efficient models. A less complex approach for combining both transport modes would be to simply add their contributions, but has an unclear physical basis [40]. The pressure-driven transport mode under partially liquid-equilibrated conditions is therefore neglected here, which is a reasonable simplification for systemlevel investigations. The model therefore likely underestimates the anode-side membrane humidity under flooding conditions. The molar flow of water through the membrane is calculated from n_H2 O;mem;C ¼ ndrag ,iA þ n_H2 O;diff;C F Diffusion in the membrane is governed by (41) The water concentration CH2 O;mem is related to the water content lmem ¼ CH2 O;mem =CSO3 ;mem of Nafion with its sulfonic charge concentration [31]. A correlation DH2 O;mem ðl; TÞ from Liso et al. [43] is used for the diffusion coefficient of water in Nafion. The membrane water contents at the interfaces to the adjacent gas phases are approximated with [44]. l ¼ llt ðRHÞ þ (37) (40) where the first term describes the EOD and the second term diffusion. The drag coefficient is assumed as ndrag ¼ 1 [42]. (36) is the supplied flow of hydrogen. The molar fraction XH2 O;A of water in Vref;A is XH2 O;A ¼ Vref;A ,pA RTfl;A vCH2 O;mem v2 CH2 O;mem ¼ DH2 O;mem , vt vx2 with n_tot;A;out ¼ ntot;A ¼ Membrane humidity The corresponding mole fraction in the gas phase is ntot;C XO2 ;C;out;gp ¼ XO2 ;C;out ntot;C;g Moreover, it holds XH2 ;A ¼ 1 XH2 O;A . Due to the recirculation, XH2 ;A is assumed to be constant in Vref;A . If there is no liquid water in Vref;A , the total amount of substance ntot;A is lht ðRHÞ llt ðRHÞ ðTcell 303Þ 50 (42) where llt ðRHÞ and lht ðRHÞ are sorption equilibrium relations of Nafion at different temperatures from Refs. [37,45] with aw ∶ ¼ RH. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 llt ¼ 0:043 þ 17:810aw 39:850a2w þ 36:000a3w at 303 K (43) lht ¼ 0:300 þ 10:800aw 16:000a2w þ 14:100a3w at 353 K (44) Because only vapor-equilibrated transport modes are considered here, the maximal water content is kept at lsat ðTÞ ¼ lmem ðRH ¼ 1; TÞ based on Eq. (42). The water contents at the membrane/gas phase interfaces are used as boundary conditions. ,lðRHA ; TÞ CH2 O;mem ðx ¼ 0Þ ¼ C CH2 O;mem ðx ¼ dmem Þ ¼ CSO3 ;mem ,lðRHC ; TÞ SO 3 ;mem (45) Interfacial resistances to water transport at the membrane's surfaces are neglected. The computing time is significantly reduced by approximating DH2 O;mem ðxÞ with an average value DH2 O;mem across the 1D domain. In this case, the steadystate solution to Eq. (41) is a linear increase of lmem ðxÞ. The resulting molar flow is given by Fick's law. CSO3 ;mem ½lðRHA ; TÞ lðRHC ; TÞ n_H2 O;diff;C ¼ A,DH2 O;mem dmem (46) Eqs. (15)e(46) form a system of two first-order ODEs that is solved for its steady-state solution using Matlab's solver ode15s(). 33227 effective properties of the anode side fluid are therefore assumed as Tfl;A ¼ Tcell and RHA;eff ¼ RHA . Fluid pressure The cathode side pressure drop DpC ¼ pC;in pC;out is modelled with a polynomial 2 DpC ¼ cd1 V_ C;tot þ cd2 V_ C;in;tot (49) where V_ C;in;tot is the volume flow entering the cathode side of the cells. V_ C;in;tot is calculated from the known supply air composition based on section Mass balances. The polynomial's coefficients are fitted based on the measured pressure drop for different mass flows from the experiments described in section Underlying experimental data. The average pressure pC along the channel length is approximated with pC ¼ pC;in DpC 2 (50) where pC;in is the known pressure at the cathode inlet. In the investigated stack, the anode side pressure pA is controlled to be 0:06,105 Pa above pC;in . The pressure drop on the anode side is neglected due to the small hydrogen flow. Mass transport in cathode GDL Fluid temperature and humidity When the cathode fluid is supplied at a temperature below Tcell , it is heated up and humidified as it flows through the channels. Therefore, its relative humidity changes considerably along the channel length (y-axis in Fig. 2 (a)), which cannot be captured directly by the 1D model. Below, two fitted parameters cT and cH are introduced, which allow for a simplified linearized consideration of these effects. The value RHC in Eq. (28) can be considered an average value across the channel length and is determined based on an effective cathode fluid gas phase temperature Tfl;C . This temperature is calculated with a fitted coefficient cT that relates it to the fluid temperatures at cathode inlet and outlet (assuming Tfl;C;out ¼ Tcell ). Tfl;C ¼ Tfl;C;in þ cT Tfl;C;out Tfl;C;in (47) Moreover, the cell's average ohmic resistance cannot be directly calculated from the channel-length averaged relative humidity as the ionomer's ohmic resistance depends nonlinearly on RH. This effect is considered with another fitted factor cH . It is used to calculate an effective humidity RHC;eff , based on which the effective water contents lmem;eff and lCCL;eff are determined. RHC;eff ¼ cH ,RHC (48) When operating the stack with anode recirculation and lH2 ¼ 1:05, the amount of supplied hydrogen is small compared to the amount of hydrogen that is already present within the recirculation loop (in steady-state operation). The Per Eq. (8), ilim is affected by oxygen diffusion in the cathode GDL. The effective diffusion coefficient is calculated from Ref. [46]. DO2 ;eff ¼ DO2 ;N2 ,ε3:6 ð1 sav Þ3 (51) where ε is the GDL's porosity and DO2 ;N2 ðTfl;C ; pC Þ the bulk binary diffusion coefficient from Ref. [47]. The effect of water vapor on oxygen diffusion is neglected [42]. Since the modeling approach only requires the ratio DO2 ;eff =DO2 ;ref , this is a reasonable simplification. The reference diffusion coefficient DO2 ;ref is calculated from DO2 ;ref ¼ ε3:6 DO2 ;N2 T0 ; p0 (52) Oxygen diffusion is affected by the GDL's liquid water saturation sact , which is defined as sact ¼ VGDL;p;l VGDL;p (53) with the pore volume filled with liquid water VGDL;p;l and the total pore volume VGDL;p . The model calculates sact ðxÞ in the GDL for a 1D domain under a channel area (see Fig. 2(b)). Since 2D effects are not resolved by the model, an average saturation sav is used in Eq. (51) as discussed below. Generally, cathode flooding can occur at the CCL surface, MPL, GDL and channels [25,48]. However, the saturation in the MPL is typically lower than that of the GDL [48]. In alignment with Ref. [42], the MPL is not explicitly considered here and its effect on oxygen transport is included in the fitted effective GDL properties. Moreover, it can be assumed that flooding of 33228 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 the channels would only occur after the GDL is already severely flooded [25]. Because the system would not be designed to operate in states where the channels are flooded, the model only considers flooding of the GDL. The model furthermore neglects interfacial resistances to mass transport. Transport of liquid water in the GDL is modelled with a gradient of capillary pressure as the driving force. In hydrophobic media, capillary pressure is commonly defined as [46]. pcap ¼ p1 pg (54) where pl and pg denote the liquid and gas phase pressure. The model uses a 1D form of Darcy's law for the liquid phase [49]. It holds k,krel Vp1 vD ¼ m (55) where m(T) is the water viscosity, k the absolute permeability, krel(s) the relative permeability and vD the Darcy velocity. When assuming a uniform gas phase pressure across the GDL, Vpl ¼ Vpcap. Moreover, pcap is commonly considered to be a function of liquid water saturation [48,49] so that Eq. (55) can be rewritten as vD ¼ k,krel vpcap ds dx m vs (56) where s is the effective saturation. Generally, there exists a residual saturation sres due to water being trapped in isolated pores of the GDL [50]. The actual saturation sact used for calculating DO2,eff is calculated with [50]. sact ¼ sres þ s , ð1 sres Þ (57) The model assumes sres ¼ 0.08 [50]. In conditions with RHC<1, sres is set to zero. The relation pcap(s) is modelled with a Leverett approach [51]. pcap ε 12 ¼ JðsÞ s cosðQÞ k (58) where s(T) is the water surface tension [52], Q the GDL's contact angle and J(s) an empirical function. The model is parameterized with a Leverett-type function J(s) that is fitted to the secondary injection curve measured Gostick et al. [53] for an exemplary SGL10BA GDL under compressed conditions (the exact GDL type of the modelled stack is not known to the authors). Assuming that the fitted dimensionless function J(s) can also describe the behavior of other GDLs, it is used with another set of parameters (ε, k, Q) when inserting its analytical derivative into Eq. (59). ε 1 dJðsÞ vpcap 2 ¼ s cosðQÞ k ds vs (59) The GDL's relative permeability is modelled with [8,42,48]. krel ¼ snk (60) where nk depends on the GDL type [49,50] and is fitted with stack-level experimental data. When RHC ¼ 1, capillary flow becomes the only transport mode [49,54]. Accordingly, the Darcy velocity vD is calculated from 8 > if RHC ¼ 1 : > > > > > > > MH2 O ,n_H2 O;CCL < rH2 O ,A vD ¼ > > > > if RHC < 1 : > > > > :0 (61) Eq. (56) is combined with Eqs. (59)e(61) to the nonlinear ODE ds 1 ¼ CD1 CD2 n dx s k , ½JðsÞ 0 (62) where constant properties are grouped into unknown GDLspecific properties cD1 and known properties cD2. pffiffiffiffiffi 1 CD1 ¼ cos Q, kε CD2 ¼ mvD s (63) (64) The combined parameter cD1 is fitted to stack-level experimental data while cD2 is calculated based on water properties sðTÞ and mðTÞ from Ref. [39]. A low saturation s0 ¼ 102 at the GDL-channel interface [42,48] is assumed when solving the initial value problem for sðxÞ with Matlab's solver ode45(). There are two spatial effects to be accounted for. The model considers them in a simplified manner in order to avoid the computational cost of 2D or 3D discretization. 2D effects due to channel ribs (x;z-plane in Fig. 2) are taken into account based on conformal mapping [55]. That approach relates 2D effects of a partially conducting boundary (channel and ribs) to an increased effective layer thickness in the 1D formulation for a fully conducting boundary. For a known cell geometry, the ratio ccm ¼ dGDL;eff =dGDL of effective and actual GDL thickness can be calculated [55]. Eq. (62) can then be solved between locations x1 ¼ dmem and x2 ¼ dmem þ ccm dGDL (65) However, because the exact GDL thickness under compressed conditions is not known to the authors, the term dGDL;eff is directly fitted to stack-level experimental data. The average of sact ðxÞ across the “effective” 1D domain is S*av ¼ 1 dGDL;eff xð2 sact ðxÞdx (66) x1 However, this value does not include variations of saturation along the channel length (y-direction in Fig. 2). Flooding can be expected to occur in cell regions where the gas phase is saturated. Typically, this region gradually expands from the cell's outlet towards the inlet if the humidity in the cell is increased [25]. The following simplified relation based on an empirical model parameter q is used to mimic such a gradual i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 increase of saturation once the fluid in the lumped control volume reaches RHC ¼ 1. 8 > > <0 sav ¼ cf ,s*av > > : s* av q¼ for q 1 for 1 < q < qsw for q qsw nH2 O;C p C ntot;C psat Tfl;C (67) (68) In contrast to RHC, which only considers water vapor in the gas phase and is limited to one (see Eq. (28)), the definition of q allows for values q>1. If q exceeds a limit value, s*av is used without modification. The limit is set to qsw ¼ 1.8 by comparing the model's results to the measurements described in section Underlying experimental data. If q < 1, there is no liquid phase. In between the two cases, the saturation is scaled with a factor cf2[0,1] which is chosen as cf ¼ 1 qsw q qsw 1 (69) and increases linearly as q approaches qsw. Stack model parameter identification Several stack model parameters are fitted to experimental data while others are chosen based on literature values. The parameter DUcr (Eq. (11)) and the coefficients of the pressure drop correlation (Eq. (49)) are determined directly from the experiments described in section Underlying experimental data. The 8 remaining fitted parameters are summarized in Table 3. They are determined by minimizing the simulation error in a nonlinear optimization problem . . . . Q min . 1 C Such that l i < Ci < u i for i ¼ 1…8 C . Q1 ð c Þ ¼ 2 N X . . . wj Um;j Us;j (70) (71) j¼1 where the objective function Q1 includes the complete model and solver code. The search space is constrained by the bounds given in Table 3. Vector c contains the fitted parameters from Table 3, Um and Us of size N-by-1 are the measured and simulated cell voltages (N ¼ 30). Weights w are used to slightly increase the contribution of operating points with higher current densities. To find the global minimum within the search space, Q1 is minimized with Matlab's genetic algorithm ga() with a population size of 6400 and 2000 generations. The simulation results with the fitted parameters are compared to the measurements in section Stack model validation. The stack's geometric parameters A, dCCL , dmem , Vref;C and Vref;A are chosen/assumed based on information from the stack manufacturer. Fluid properties psat ðTÞ, mðTÞ and rH2 O;l ðTÞ are interpolated between data points with 1 C increments from Ref. [39]. The remaining model parameters are summarized in Table 4. 33229 Underlying experimental data A custom-built fuel cell test bench is used to measure the effect of stack temperature, current density and oxygen mole fraction at the cathode inlet under steady-state, galvanostatic operation. The experiments are conducted on two different 40 cell Hydrogenics HD4 stacks with a rated power output of 4 kW. This stack type is not particularly well suited for aircraft applications because it has a lower specific power ðkW kg1 Þ than more recent stack designs [58,59]. Because it uses industry-standard membrane and electrode materials it is nonetheless a reasonably representative testbed for investigating the effect of the stack operating conditions on size-independent quantities (power per cell area, voltage losses, etc.). The stack is supplied with varying mixtures of N2 and O2 at the cathode and pure H2 at the anode. Per the stack's specifications, it is operated without external humidification. The stack's current and voltage as well as a number of temperatures, pressures and mass flows are measured at 0:1 s time steps. Since no temperature sensors are placed inside the stack, the coolant outlet temperature is assumed to represent the stack's temperature with sufficient accuracy and is used as Tstack in the following. The experiments are carried out with a stepwise adjustment of one operating parameter at a time. After each step change the stack is operated for several minutes until it reaches steady-state conditions. The data points that are presented in section Stack model validation are average values of the respective signals over 30 s once a steady-state is reached (hysteresis effects were not studied). A detailed description of the stack test bench is provided by our colleagues Montaner Rı́os et al. [60]. Auxiliary component models In order to determine the stack's optimal operating conditions, the effects of several auxiliary components on the overall system efficiency need to be simulated. However, the model only needs to consider the auxiliary components' rated operating points and does not need to provide detailed information on their internal processes. The air inlet and compressor are therefore modelled based on thermodynamic considerations and typical component efficiencies. For the heat exchanger and humidifier, it is sufficient to include their pressure drop in the model and assume that they fulfill their task as required at the system's design conditions. Under the condition T4 zTstack no significant heat transfer occurs in the humidifier as both the wet and dry fluid have nearly the same temperature. The auxiliary component models are described in Appendix A. Results and discussion Stack model validation As a first step, the stack model is validated for varying stack temperatures, oxygen contents and current densities. Table 5 33230 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Table 5 e Operating conditions in the experiments used in this work. Parameter Data in Fig. 3 2 i Tstack 0:77 A cm varied pC;out XO2 ;C;in lO 2 1:01 to 1:03 bar varied 2:5 RHC;in 0 Data in Fig. 4 varied 50…60 C (set by stack controller based on i) 1:02 to 1:08 bar 0:209 2:2 above 0:7 A cm2 (increased by stack controller at lower i) 0 summarizes the measured operating conditions that are used to parameterize and validate the model. The experiments focus on moderate current densities because these are most relevant to aircraft applications [14,15] (see section The massefficiency trade-off). Effect of stack temperature and oxygen content Fig. 3(a)e(c) show the measured and simulated effect of varying operating temperatures and oxygen concentrations. Increased oxygen contents can be relevant for emergency operation [61] and furthermore provide a good basis for validating oxygen concentration dependent effects. Considering the system-level modeling approach, a good agreement of simulation and measurements is achieved. It should be noted that the simulation results are directly compared to the dataset that the model's parameters were fitted with. However, since a very wide range of operating conditions can be captured, it is unlikely that the model only matches the experimental data well because some of the data points were used to parameterize it. As shown in Fig. 3 (a) and (d), both flooding (sav > 0Þ and membrane dehydration (RHC < 1, RHA < 1) occur within the investigated temperature range for operation with the oxygen content of ambient air. The observed trends in cell voltage and the optimal operating temperature of about 60 C under these conditions are predicted well by the model. With higher XO2 ;C;in no abrupt drop of cell voltage is observed at higher temperatures. This can be explained with the lower total gas flow n_tot;C;in that is required for achieving the desired oxygen stoichiometric ratio, which results in less severe membrane dehydration. The GDL saturation remains similar at increased XO2 ;C;in but results in less severe mass transport losses due to the oxygen concentration effect in Eq. (8). Fig. 3 e Influence of stack temperature and oxygen mole fraction on the average cell voltage in the stack at i ¼ 0:77 A cm2 , experimental conditions given in Table 5. Measurements first published by Becker et al. [62]. (a) to (c): Measured and simulated cell voltage, (d) to (f): simulated relative humidity and saturation of GDL pores with liquid water, (g) to (i): simulated voltage losses. Note: legends for entire row. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 33231 The results in Fig. 5 show that for a given pC;in and Tstack there is a distinct range of combinations of RHC;in and lO2 that result in high stack efficiencies. At low temperature and pressure, the favorable operating range is limited by membrane dehydration at low RHC;in and high lO2 and by cathode flooding at large RHC;in . At increased operating pressures the stack efficiency becomes less sensitive to changes of external humidification and stoichiometry. The highest stack-level efficiency is achieved for high temperatures, high pressures and large lO2 , because these conditions lead to high oxygen concentrations within the cells in combination with a good membrane conductivity (see section Cell voltage). Optimal operating conditions at system level Fig. 4 e Current-voltage characteristic at the stack's rated operating conditions, experimental conditions in Table 5. (a) Measured and simulated cell voltage (b) simulated saturation and relative humidity (c) simulated voltage losses. Effect of current density The measured and simulated current-voltage characteristic at the stack's rated operating temperature are shown in Fig. 4 (a). The curve has the typical shape for PEMFCs, in which activation losses dominate at low current densities and mass transport losses become more relevant at higher current densities. The model can accurately simulate the stack's behavior for a wide range of current densities. At i < 0:4 A cm2 the model becomes less accurate. This is expected with the linearization described in section Fluid temperature and humidity. Influence of operating conditions at stack level Next, the model is used to simulate the effects of the previously introduced parameters RHC;in , lO2 , Tstack and pC;in on the achievable stack efficiency. It should be noted that the model is not directly validated for the effects of lO2 , RHC;in and pC;in : However, it can be assumed to capture the effects of these parameters with sufficient accuracy as it links them to the validated effects of oxygen concentration and humidity conditions in the cells. To show how the system's auxiliary components affect the optimal operating conditions, the effect of lO2 and pC;in on both stack-level and system-level efficiency is explored for typical cruise phase environmental conditions (Mach 0:74 at 11278 m, see Table 8) and a moderate current density of 0:7 A cm2 . As shown in Fig. 6, it is found that the compressor's power consumption reduces the system efficiency significantly at high altitudes. The combination of lO2 and pC;in that result in the highest system-level efficiency deviates considerably from that one that merely results in the highest stack efficiency. As shown in section Influence of operating conditions at stack level, this affects the optimal values for the other stack operating parameters as well. Consequently, all main stack operating parameters should be optimized simultaneously while considering both stacklevel and system-level effects. This nonlinear optimization is conducted by including the overall system model in an objective function 2 Q2 RHC;in ; lO2 ; pC;in ¼ hsys;HHV (72) and optimizing the stack's operating parameters RHC,in2[0, 1], lO22[1.8, 3] and pC,in2[1.1 bar,2.5 bar] to maximize hsys,HHV(RHC,in,lO2,pC,in). Because heat exchangers can be sized smaller with higher temperature gradients to the ambient, Tstack is kept constant at 85 C. Including Tstack in the optimization problem would be straightforward. To prevent convergence to a local optimum and avoid the stochastic nature of evolutionary algorithms, Q2 is first evaluated at 103 equally spaced grid points in the threedimensional search space. The ten most promising grid points are then used as initial guesses for Matlab's gradientbased interior-point algorithm. If the gradient-based optimization converges to multiple minima, the one with the lowest penalty value Q2 is used. The optimization is conducted with the constraint of a given current density ides that the stacks are operated at when meeting the system's design load. Within the feasible range, ides is a free design parameter. With this approach (referred to hereafter as “sizing mode”), the total number of cells Ncell,tot ¼ NcellNstacks that is needed to achieve a given power output Psys,eff is a result of the optimization and depends on the cell voltage at the optimal conditions Ucell,opt ¼ f(ides,RHC,in,lO2,pC,in). It holds 33232 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Fig. 5 e Stack efficiency (HHV-based, see Eq. (14)) at different combinations of oxygen stoichiometric ratio lO2 and relative humidity at cathode inlet (based on Tfl;C;in ¼ Tstack , i ¼ 0:7 A cm2 , contours interpolated from four sets of 100-by-100 single operating points). (a) Low temperature, low pressure (b) low temperature, high pressure (c) high temperature, low pressure (d) high temperature, high pressure. Psys;eff Ncell;tot ¼ Acell;sizing ,Ucell;opt ,ides (73) where the denominator describes the power per cell for a given active cell area. Because the stack model result is used in quantities (Ucell,opt, ides) which are independent of the stack's active cell area, Acell, sizing is a free design parameter and does not necessarily need to match the active cell area that is used by the stack model. The number of cells per stack can be set below a reasonable maximum (e.g. 455 [58]) by choosing Nstacks appropriately. The required air mass flow and compressor power consumption are obtained based on Ncell,tot and the normalized per-cell results from the stack model. The model is also suited to instead conduct the optimization with the constraint of a given Ncell,tot (non-sizing mode). In this case, the model solves for the required current density by iteratively minimizing Q2 for different ides until the required power output is achieved (using iterative guesses for ides from Matlab's algorithm fminsearch). An exemplary result in terms of absolute numbers for a typical in-flight power output of 605 kW [13] is shown in Table 6. The optimization algorithm can effectively find the combination of pC,in, RHC,in and lO2 that results in the highest system-level efficiency (visualized in Fig. 6 (b) for a constant RHC,in). For an exemplary cell area of Acell,sizing ¼ 250 cm2 and ides ¼ 0.7 A cm-2, 18 stacks with 419 cells each are required to achieve the effective power output of 605 kW. One could either i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 33233 Table 6 e Detailed results for one exemplary operating point (fluid states 1 to 6 are defined in Fig. 1, optimized operating parameters pC,in, lO2 and RHC,in are obtained with the “sizing mode” that is described in section Optimal operating conditions at system level, environmental conditions for cruise phase of commercial aircraft as listed in Table 8). Symbol Description System-level results hsys,HHV hstack,HHV hstack,V Nstacks Ncomp Pstack,tot Pcomp,tot Psys,eff Stack-level results Tstack pC,in RHC,in lO2 lH2 Acell,sizing ides Ucell Ncell Fluid states p1 p2 p3 p4 p5 p6 T1 T2 T3 T4 T5 T6 RH1 Value Type System efficiency based on HHV, Eq. (2) Stack efficiency based on HHV, Eq. (14) Stack voltage efficiency, Eq. (13) Number of stacks Number of compressors Combined power output of stacks Combined power consumption of compressors Effective (net) power output 29.50 % 41.21 % 54.35 % 18 2 845.11 kW 240.11 kW 605.00 kW Result Result Result Parameter Parameter Result Result Input Stack temperature Optimized stack pressure Optimized humidity at cathode inlet Optimized O2 stoichiometric ratio H2 stoichiometric ratio (with anode recirculation) Active cell area used for sizing Current density at design conditions Average cell voltage in stacks Number of cells per stack (rounded to integer) 85 C 1.60 bar 0.49 1.8 1.05 250 cm2 0.7 A cm-2 0.64 V 419 Parameter optimized optimized optimized Parameter Parameter Parameter Result Result Ambient pressure Pressure at filter inlet Pressure at compressor inlet Pressure at heat exchanger inlet Pressure at humidifier inlet Pressure at stack inlet (¼pC,in) Ambient temperature Temperature at filter inlet Temperature at compressor inlet Temperature at heat exchanger inlet Temperature at humidifier inlet (¼Tstack) Temperature at stack inlet (¼Tstack) Ambient relative humidity 0.20 bar 0.27 bar 0.26 bar 1.75 bar 1.65 bar 1.60 bar 42 C 17 C 17 C 225 C 85 C 85 C 0.5 Input Result Result Result Result optimized Input Result Result Result Parameter Parameter Input Table 7 e Assumed mass-related parameters in the system analysis. Parameter Value Description Background/Reference mcell,sp 3.5 kg m-2 in Fig. 8, varied in Fig. 9 Mass per cell normalized with active cell area mcomp,sp 5.333,10-4 kg W-1 Compressor mass per rated power consumption mhum,sp 82.353 kg/(kg/s) humidifier mass per rated dry air mass flow mcell,sp is defined here as an average cell mass per active cell area and includes the averaged mass contribution of the endplates and structural stack components: mcell,sp ¼ mstack/(NcellAcell). According to public manufacturer data, today's stacks achieve approximately 2.5 to 4 kg m-2 [58] [63] (The pressure ratio of this compressor is somewhat below the required one. The normalized value is nevertheless reasonably accurate for the purpose of this study.) [64] (typical membrane humidifier for fuel cell systems) decrease the required number of stacks by operating them at higher current density, or further increase their efficiency by choosing an even lower ides. This tradeoff is discussed in the following section. The mass-efficiency trade-off To reduce the required tank size for a given load demand, it can be beneficial to operate the stacks at lower current 33234 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Table 8 e Investigated flight phases and environmental conditions, exemplary flight profile based on Ref. [30]. The ambient relative humidity is kept constant at RH1 ¼ 0:5. Flight phase Geopotential altitude (m) Ambient Pressure (bar) Ambient Temperature ( C) Aircraft velocity (Mach number) Takeoff Climb Cruise Descent Approach 0 2438 11278 6096 457 1.014 0.752 0:200 0:469 0:958 40 22 42 4 36 0.250 0:440 0:740 0:550 0:390 densities than those that lead to the maximum power output [14,15]. This increases the required stack mass but can result in a net improvement of the total system mass due to a lower required tank mass at higher efficiencies [15]. Besides the lower tank mass, there are additional benefits when oversizing the stacks. At low ides, the supplied air is used more efficiently by the stack (higher electric energy output per mol of supplied air). This reduces the required air flow and consequently also the compressor's power consumption and balance-of-plant component mass for a given Psys,eff (with lO2 ¼ const). To visualize this trade-off between improved efficiency and increased mass, the optimizations for the 605 kW scenario from Table 6 are repeated for different ides. The change in stack mass is calculated with mstacks ¼ f(ides) ¼ NstacksNcellAmcell,sp where the required Nstacks and Ncell are simulation results and mcell,sp is the cell mass per active cell area. The change in compressor and humidifier mass is approximated with mcomp ¼ mcomp;sp Pcomp Ncomp (74) mhum ¼ mhum;sp m_ c;tot (75) where mcomp,sp is the compressor's assumed mass per rated power, mhum,sp the humidifier mass per rated mass flow and m_ C;tot ¼ f ðides Þ ¼ m_ c;in Ncell Nstacks the required air flow. Table 7 summarizes the assumed parameters. The mass of the remaining balance-of-plant components (air inlet, tubing, wiring, etc.) is assumed to remain constant for different ides. An increased efficiency also reduces the waste heat per power Fig. 6 e Effect of varying lO2 and pC,in on stack-level and system-level efficiency (i ¼ 0.7 A cm-2, Tstack ¼ 85 C, RHC,in ¼ 0.8, environmental conditions for cruise phase as listed in Table 8, contours interpolated from 100-by-100 grid of single operating points). (a) Stack efficiency (b) system efficiency. Fig. 7 e Change in (a) efficiency and (b) component mass for different design point current densities ides and a constant required power output of 605 kW (environmental conditions from Table 6, mcell,sp ¼ 3.5 kg m-2, optimization was repeated for 50 linearly spaced values of ides in the depicted range). i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 33235 Fig. 8 e Optimized stack operating conditions for different design point current densities ides, datapoints correspond to those in Fig. 7. (a) Cathode inlet pressure, (b) relative humidity at cathode inlet, defined with T5 ¼ 85 C, (c) oxygen stoichiometric ratio. output. This reduction in cooling system mass is not further investigated here (see system boundary in section System architecture), but would further benefit lower ides. The efficiency improvement for different ides is depicted in Fig. 7 and is found to be nearly linear in the investigated range. The required stack mass increases significantly at lower current densities, while the balance-of-plant component mass is improved slightly due to the more efficient use of the supplied air. It can be concluded that a net-improvement in system mass by oversizing the stacks needs to be compensated for by reductions of the hydrogen tank mass and does not occur from benefits to balance-of-plant components alone. The corresponding optimal stack operating conditions are depicted in Fig. 8 and were found to vary only slightly for different ides. The optimization results for pC,in and RHC,in oscillate somewhat (less than ±2%) around an averaged solution. This behavior arises from the chosen optimization approach but has no significant effect on the overall results. As described in section Optimal operating conditions at system level, the operating conditions are optimized by conducting multiple runs of a local optimization algorithm with several different initial guesses. Therefore, the obtained solution can be expected to be close to but not exactly at the global minimum. As shown in the corresponding data in Fig. 7 (a), the oscillations in the optimized parameters have no significant effect on the optimization results and the resulting optimized efficiency curve remains fairly smooth. Because the results scale linearly with the system's effective power output (see Eq. (73)), they can be normalized to arrive at a size-independent relation of these quantities (see Fig. 9). For mcell,sp ¼ 3.5 kg m-2, one can “trade” an efficiency increase from 23.60% to 30.84% by increasing the mass of the stacks and the air supply system by 0.2 kg per kW effective power output when designing the system. With different assumptions for mcell,sp similar trends can be observed. The location of the optimal point on this curve depends on the aircraft type and flight mission (duration, altitude, speed) and can therefore not be determined at this subsystem-level. The developed model can support the overall aircraft design process by providing the proposed relation between added mass and efficiency. Optimal conditions in different flight-phases Different environmental conditions were found to significantly affect the achievable efficiency. This aspect is explored in Fig. 10 for several representative flight phases (see Table 8). In this section, no particular load demand per flight phase is assumed. Instead, the optimization is conducted for a range of typical design-point current densities [14,15] to show more generally which efficiency and optimal stack operating conditions can be expected when designing the system to operate under the respective conditions. The results in Fig. 10 (a) suggest that the achievable efficiency hsys;HHV varies widely for different load requirements and flight phases. When the system is for example designed and oversized to operate at a low current density of 0:4 A cm2 during take-off, the resulting efficiency would be 43:12 % according to the model. On the other hand, when designing and sizing the stacks so that they run at a higher current density of 1 A cm2 during take-off, the efficiency would only be 33:30 %. The model furthermore suggests that the system efficiency for a given current density is generally lower during the cruise Fig. 9 e Relation of system efficiency and added component mass per effective power output (cruise conditions, Dm ¼ DmstacksþDmcompþDmhum, delta defined with respect to operating the system at the current density that leads to the lowest overall system mass). 33236 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 Fig. 10 e Optimization results for the investigated system architecture. (a) System efficiency at optimized conditions (b) stack efficiency at optimized conditions (c) optimized pressure (absolute) (d) optimized stoichiometric ratio (e) optimized humidity at cathode inlet. phase. In this exemplary case, the higher altitudes cause the efficiency to drop as low as 24:81 % when operating the stacks at 1 A cm2 during the cruise phase. This effect is mainly caused by the higher compressor power consumption at lower ambient pressures, and is somewhat reduced by the higher Mach number. As shown in Fig. 10 (b), the stack-level efficiency remains nearly constant throughout the different flight phases with the optimized conditions. The optimal efficiency occurs with moderate operating pressures between 1:59 and 1:90 bar (absolute), which is below typical maximum rated pressures for ground-based applications [58]. Because the optimal stoichiometric ratio was found to be at the chosen minimum limit of 1:8 for the investigated conditions, it can be concluded that stack efficiency improvements of higher lO2 do not outweigh the additional compressor power. One can use the fuel-to-electricity efficiencies of kerosene-based solutions in today's aircraft to put these results into context. Typical APUs achieve efficiencies of < 10 % [65], engine-driven generators up to 32 % [12] (fuel-toelectricity, based on HHV of kerosene). At lower altitudes, the PEMFC system exceeds these efficiencies by far. At higher altitudes, it can match or slightly exceed them when oversizing the stacks and operating them at lower current densities. It should be noted that recent stack designs [58,59] achieve improved efficiencies compared to the investigated Hydrogenics HD4 stack. The reported numbers should therefore not be understood as the full potential of this technology but rather as a baseline for future improvements. The phenomenological approach makes it possible to analyze such improvements in PEMFC technology without major modifications to the model once further information becomes available. To assess the system's feasibility regarding its effect on overall aircraft mass, one needs to include the mass of the cooling system and additional components (wiring, air inlets, etc.) in the analysis. Moreover, several positive and negative aircraft-specific effects need to be considered, including i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 33237 Table 9 e Comparison of typical specific powers of the discussed technology options. PEMFC system mass numbers are based on existing volume-optimized PEMFC systems for ground-based applications. These numbers will likely improve for future weight-optimized aircraft systems. Component Specific power Existing kerosene-based aircraft systems Generators driven by the main engine shaft Conventional APU, including its generators 1:0 kW kg1 1:6 kW kg1 [67] [68], based on APU of the Boeing 787, which is most suitable for a comparison with PEMFCs because it supplies, unlike most APUs, only electrical power to the aircraft (no pneumatic or hydraulic power) 3:0 kW kg1 0:6 kW kg1 [58,59] [69] < 0:6 kW kg1 The mass of the cooling system and power converter will further reduce the system-level specific power, the exact value for aircraft-rated systems with several hundred kW power output is unknown at present Existing PEMFC systems Stacks Stacks and balance-of-plant components, without cooling system and power converter System (stacks, balance-of-plant components, cooling system and power converter) improvements in main engine efficiency if less generators need to be powered by the engine shaft [66], an increased aerodynamic drag due to additional air inlets [12] and possible synergies from a multi-functional integration [7,14]. Because there are no aircraft-rated systems at this scale so far and data from small experimental aircraft is likely not representative for large commercial aircraft, no reliable approximation of the system's overall mass can be made at this point. However, based on the exemplary numbers in Table 9 it seems likely that the stacks and balance-of-plant components will be heavier than the kerosene-based options. For novel aircraft concepts that have a significant electric load demand and use hydrogen as the main energy carrier [1], the higher efficiency of PEMFCs at maximum and part load could nonetheless make them a favorable option despite the increased mass of the energy conversion system itself. Conclusion This work investigated the use of PEMFCs as an electric auxiliary power source for future hydrogen-based aircraft concepts with a focus on the interrelated aspects of efficiency, mass and optimal operating conditions. A steady-state, onedimensional, two-phase PEMFC model was developed and validated with data from a commercial stack. It was shown to capture key aspects of PEMFC water management while achieving sufficiently low computational cost for system-level optimization. The stack model was combined with several auxiliary component models to assess the effect of the stack's operating parameters on both stack-level and system-level. The simulations show that the operating conditions that result in the highest overall system efficiency deviate considerably from those that merely result in the highest stack efficiency. With this aspect in mind, the stack's operating conditions were numerically optimized to maximize the system efficiency. The maximal achievable efficiency depends strongly on the flight phase and system sizing aspects and is generally achieved with moderate pressurization (1:59 to 1:90 bar absolute), low oxygen stoichiometric ratios (1:8) and moderate cathode humidification. Background/Reference In terms of efficiency, PEM fuel cell systems are found to be a promising option to supply auxiliary electric power in future hydrogen aircraft concepts. At high altitudes (about 11 km), sufficiently high system-level efficiencies can be achieved by oversizing the stacks. The developed model can be used to assess this trade-off between improved efficiency, added stack mass and reduced balance-of-plant component mass in detail. For future work, it can be interesting to consider the cooling system and additional balance-of-plant components in higher detail in order to ultimately determine the PEMFCsystem's total mass and volume. This would allow for a direct comparison with other technology options such as batteries and generators driven by hydrogen-burning engines. Ultimately, operational and safety-related aspects such as cost and durability as well as the net environmental impact will need to be considered as well before arriving at a reliable conclusion which technology option is suited best. These aspects are currently under investigation as part of a large multidisciplinary research project at the German Aerospace Center [70]. Declaration of competing interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgements This work was supported by the Federal Ministry of Transport € ger Jülich and Digital Infrastructure of Germany via Projekttra and NOW GmbH (research project number 03B10701) and by the Federal Ministry for Economic Affairs and Energy of Ger€ ger (research project number many via DLR Projekttra 20M1909B, LuFoVI-1). The authors thank their colleagues Igor Sokolov, Simon Coners, Stefan Bleeck and Gema Montaner Rı́os for their support with setting up the fuel cell test bench used in the experiments. 33238 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 The pressure drop in the air filter is considered with p3 ¼ p2 Dpfilt . With the parameters listed in Table A1 the corresponding power consumption is given by Appendix A. Auxiliary component models The air inlet and compressor are modelled based on thermodynamic considerations and typical component efficiencies as described below. The models assume ideal gases, ideal gas mixtures and temperature-independent heat capacities. They make use of the specific gas constant Rsp;air and specific heat capacities cp;air and cv;air of the ambient air (Nomenclature of fluid states 1 to 8 according to Fig. 1, assuming that state 6 ¼ 00 00 00 60 ¼ 6 , 7 ¼ 70 ¼ 7 and 8 ¼ 80 ¼ 8 ). m_ C;tot ¼ m_ C;in Ncell Nstacks Pcomp ¼ Dh23 m_ C;tot hcomp;m hcomp;el hcomp;pc DpHX Dphm;d pffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 2 gair Rsp;air T1 ,Ma 2cp;air T2 ¼ T1 þ p2;stat ¼ p1 g gair1 T2 air T1 Dphm;w Dpstack;C (A.1) for subsonic flow. The maximum achievable static pressure at the diffuser outlet is (A.2) with gair ¼ cp;air =cv;air . The pressure recovery of a non- (A.8) Table A.1 e Parameters of the auxiliary component models Parameter Description Value Air inlet model The model calculates the pressure increase in an adiabatic diffuser with a given pressure recovery. The fluid velocity at the diffuser inlet is assumed to equal the aircraft's true airspeed (given as Mach number Ma). When neglecting the remaining fluid velocity at the diffuser outlet, it holds [71]. (A.7) Dpfilt hcomp;s hcomp;m hcomp;el hcomp;pc Pressure drop in air to air heat exchanger at its rated mass flow [74] Pressure drop in dry side of membrane humidifier at its rated mass flow [64] Pressure drop in wet side of membrane humidifier at its rated mass flow [64] Pressure drop in stack: correlation evaluated at respective volume flow per cell, see section Fluid pressure Pressure drop in air filter at its rated mass flow [75] Isentropic compressor efficiency [13] Mechanical compressor efficiency [76] Electric motor efficiency [77] Power converter efficiency 1:0,104 Pa 5:0,103 Pa 1:1,104 Pa DpC ¼ f ðV_ C;tot Þ 5:0,102 Pa 0:76 0:97 0:94 0:95 isentropic diffuser is defined as [72]. hpr ¼ p2 p1 p2;stat p1 (A.3) The model assumes hpr ¼ 0:75 [72] for a straight lip inlet when calculating p2 from Eqs. (A.1) to (A.3). Pressure drops in air supply components The pressure p4 that is required to achieve a given pressure p60 ¼ p600 ¼ pC;in at the stack's cathode inlet is. p4 ¼ pC;in þ DpHX þ Dphm;d (A.4); The minimum feasible pressure pC;in is limited by pC;in p1 þ Dpstack;C þ Dphm;w (A.5) The component's pressure drops at their rated mass flows are summarized in Table A1. To estimate the stack's cathode side pressure drop, the overall system model uses normalized data from the investigated 4 kW short stack (see section Fluid pressure). Compressor model With the usual simplifications of neglecting the heat transfer between fluid and compressor as well as the fluid velocity difference between inlet and outlet, the enthalpy change in a single stage compressor is given by Refs. [71,73]. Dh34 ¼ 1 hcomp;s cp;air T3 Rcsp;air p4 p;air 1 p3 (A.6) references [1] Airbus S.A.S. Press release from Sept. 21, 2020. Available: https://www.airbus.com/newsroom/stories/these-newAirbus-concept-aircraft-have-one-thing-in-common.html. [Accessed 3 March 2021]. [2] MTU aero engines AG. Integrating hydrogen propulsion into aircraft. Available: https://aeroreport.de/en/innovation/ integrating-hydrogen-propulsion-into-aircraft. [Accessed 3 March 2021]. [3] ElringKlinger AG. Press release October 14, 2020. Available: https://www.elringklinger.de/sites/default/files/releases/ press-releases/2020/201014_elringklinger_-_press_release. pdf. [Accessed 5 March 2021]. [4] European Commission. Flightpath 2050. Europe’s Vision for Aviation 2011. https://doi.org/10.2777/50266. [5] Romeo G, Borello F, Correa G, Cestino E. ENFICA-FC: design of transport aircraft powered by fuel cell & flight test of zero emission 2-seater aircraft powered by fuel cells fueled by hydrogen. Int J Hydrogen Energy 2013;38(1):469e79. [6] Nishizawa A, Kallo J, Garrot O, Weiss-Ungethüm J. Fuel cell and Li-ion battery direct hybridization system for aircraft applications. J Power Sources 2013;222:294e300. [7] Renouard-Vallet G, Saballus M, Schmithals G, Schirmer J, Kallo J, Friedrich KA. Improving the environmental impact of civil aircraft by fuel cell technology: concepts and technological progress. Energy Environ Sci 2010;3(10):1458e68. [8] Futter GA, Gazdzicki P, Friedrich KA, Latz A, Jahnke T. Physical modeling of polymer-electrolyte membrane fuel i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] cells: understanding water management and impedance spectra. J Power Sources 2018;391:148e61. Abdin Z, Webb CJ, Gray EM. PEM fuel cell model and simulation in MatlabeSimulink based on physical parameters. Energy 2016;116:1131e44. Salva JA, Iranzo A, Rosa F, Tapia E, Lopez E, Isorna F. Optimization of a PEM fuel cell operating conditions: obtaining the maximum performance polarization curve. Int J Hydrogen Energy 2016;41(43):19713e23. Guida D, Minutillo M. Design methodology for a PEM fuel cell power system in a more electrical aircraft. Appl Energy 2017;192:446e56. Pratt JW, Klebanoff LE, Munoz-Ramos K, Akhil AA, Curgus DB, Schenkman BL. Proton exchange membrane fuel cells for electrical power generation on-board commercial airplanes. Appl Energy 2013;101:776e96. Campanari S, Manzolini G, Beretti A, Wollrab U. Performance assessment of turbocharged pem fuel cell systems for civil aircraft onboard power production. J Eng Gas Turbines Power 2008;130(2). Lüdders HP, Strummel H, Thielecke F. Model-based development of multifunctional fuel cell systems for MoreElectric-Aircraft. CEAS Aeronautical Journal 2013;4(2):151e74. Kadyk T, Winnefeld C, Hanke-Rauschenbach R, Krewer U. Analysis and design of fuel cell systems for aviation. Energies 2018;11(2):375. € ter J, Graf T, Frank D, Bauer C, Kallo J, Willich C. Schro Influence of pressure losses on compressor performance in a pressurized fuel cell air supply system for airplane applications. Int J Hydrogen Energy 2021;46(40):21151e9. Werner C, Busemeyer L, Kallo J. The impact of operating parameters and system architecture on the water management of a multifunctional PEMFC system. Int J Hydrogen Energy 2015;40(35):11595e603. Goshtasbi A, et al. A mathematical model toward real-time monitoring of automotive PEM fuel cells. J Electrochem Soc 2020;167(2). Kim DK, et al. Efficiency improvement of a PEMFC system by applying a turbocharger. Int J Hydrogen Energy 2014;39(35):20139e50. Kim DK, et al. Parametric study on interaction of blower and back pressure control valve for a 80-kW class PEM fuel cell vehicle. Int J Hydrogen Energy 2016;41(39):17595e615. Chen H, Liu B, Liu R, Weng Q, Zhang T, Pei P. Optimal interval of air stoichiometry under different operating parameters and electrical load conditions of proton exchange membrane fuel cell. Energy Convers Manag 2020;205:112398. Qin Y, Du Q, Fan M, Chang Y, Yin Y. Study on the operating pressure effect on the performance of a proton exchange membrane fuel cell power system. Energy Convers Manag 2017;142:357e65. Hoeflinger J, Hofmann P. Air mass flow and pressure optimisation of a PEM fuel cell range extender system. Int J Hydrogen Energy 2020;45(53):29246e58. McKay DA, Ott WT, Stefanopoulou AG. Modeling, parameter identification, and validation of reactant and water dynamics for a fuel cell stack. 2005. https://doi.org/10.1115/ IMECE2005-81484. Available:. Hussaini IS, Wang C-Y. Visualization and quantification of cathode channel flooding in PEM fuel cells. J Power Sources 2009;187(2):444e51. rida W, Harrington DA. Le Canut J-M, Latham R, Me Impedance study of membrane dehydration and compression in proton exchange membrane fuel cells. J Power Sources 2009;192(2):457e66. Vetter R, Schumacher JO. Free open reference implementation of a two-phase PEM fuel cell model. Comput Phys Commun 2019;234:223e34. 33239 [28] Liu H, Li P, Wang K. Optimization of PEM fuel cell flow channel dimensionsdmathematic modeling analysis and experimental verification. Int J Hydrogen Energy 2013;38(23):9835e46. [29] Sinnett M. Boeing: 787 No-bleed systems: saving fuel and enhancing operational efficiencies. Available: https://www. boeing.com/commercial/aeromagazine/articles/qtr_4_07/ AERO_Q407_article2.pdf. [Accessed 3 March 2021]. [30] Rheaume JM, Macdonald M, Lents CE. Commercial hybrid electric aircraft thermal management system design, simulation, and operation improvements. In: 2019 AIAA/IEEE electric aircraft technologies symposium (EATS); 2019. p. 1e23. [31] O'Hayre R, Cha S-W, Colella W, Prinz FB. Fuel cell fundamentals. 3rd ed. Hoboken: John Wiley & Sons, Inc.; 2016. [32] Mao L, Wang C-Y. Analysis of cold start in polymer electrolyte fuel cells. J Electrochem Soc 2007;154(2):B139. [33] Gerteisen D, Heilmann T, Ziegler C. Modeling the phenomena of dehydration and flooding of a polymer electrolyte membrane fuel cell. J Power Sources 2009;187(1):165e81. [34] Li G, Pickup PG. Ionic conductivity of PEMFC electrodes. J Electrochem Soc 2003;150(11):C745. [35] Ohma A, et al. Analysis of proton exchange membrane fuel cell catalyst layers for reduction of platinum loading at Nissan. Electrochim Acta 2011;56(28):10832e41. [36] Jiang F, Fang W, Wang C-Y. Non-isothermal cold start of polymer electrolyte fuel cells. Electrochim Acta 2007;53(2):610e21. [37] Springer TE, Zawodzinski TA, Gottesfeld S. Polymer electrolyte fuel cell model. J Electrochem Soc 1991;138(8):2334. [38] Vilekar SA, Datta R. The effect of hydrogen crossover on open-circuit voltage in polymer electrolyte membrane fuel cells. J Power Sources 2010;195(8):2241e7. [39] E. W. Lemmon, M. O. McLinden, and D. G. Friend, "Thermophysical properties of fluid systems," in NIST chemistry WebBook, NIST standard reference database number 69, P. J. Linstrom and W. G. Mallard, Eds. Gaithersburg MD: National Institute of Standards and Technology. [40] Weber AZ, Newman J. Modeling transport in polymerelectrolyte fuel cells. Chem Rev 2004;104(10):4679e726. [41] Weber AZ, Newman J. Transport in polymer-electrolyte membranes : II. Mathematical model. J Electrochem Soc 2004;151(2):A311. [42] Goshtasbi A, Pence BL, Ersal T. Computationally efficient Pseudo-2D non-isothermal modeling of polymer electrolyte membrane fuel cells with two-phase phenomena. J Electrochem Soc 2016;163(13):F1412e32. [43] Liso V, Simon Araya S, Olesen AC, Nielsen MP, Kær SK. Modeling and experimental validation of water mass balance in a PEM fuel cell stack. Int J Hydrogen Energy 2016;41(4):3079e92. [44] Ge S, Li X, Yi B, Hsing IM. Absorption, desorption, and transport of water in polymer electrolyte membranes for fuel cells. J Electrochem Soc 2005;152(6):A1149. [45] Hinatsu JT, Mizuhata M, Takenaka H. Water uptake of perfluorosulfonic acid membranes from liquid water and water vapor. J Electrochem Soc 1994;141(6):1493e8. [46] Weber AZ, et al. A critical review of modeling transport phenomena in polymer-electrolyte fuel cells. J Electrochem Soc 2014;161(12):F1254e99. [47] Fuller EN, Schettler PD, Giddings JC. New method for prediction of binary gas-phase diffusion coefficients. Ind Eng Chem 1966;58(5):18e27. [48] Qin CZ, Hassanizadeh SM. A new approach to modelling water flooding in a polymer electrolyte fuel cell. Int J Hydrogen Energy 2015;40(8):3348e58. 33240 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 4 6 ( 2 0 2 1 ) 3 3 2 1 8 e3 3 2 4 0 [49] Kumbur EC, Sharp KV, Mench MM. On the effectiveness of Leverett approach for describing the water transport in fuel cell diffusion media. J Power Sources 2007;168(2):356e68. [50] Weber AZ. Improved modeling and understanding of diffusion-media wettability on polymer-electrolyte-fuel-cell performance. J Power Sources 2010;195(16):5292e304. [51] Kumbur EC, Sharp KV, Mench MM. Validated Leverett approach for multiphase flow in PEFC diffusion media. J Electrochem Soc 2007;154(12):B1295. [52] Vargaftik NB, Volkov BN, Voljak LD. International tables of the surface tension of water. J Phys Chem Ref Data 1983;12(3):817e20. [53] Gostick JT, Ioannidis MA, Fowler MW, Pritzker MD. Wettability and capillary behavior of fibrous gas diffusion media for polymer electrolyte membrane fuel cells. J Power Sources 2009;194(1):433e44. [54] Pasaogullari U, Wang CY. Liquid water transport in gas diffusion layer of polymer electrolyte fuel cells. J Electrochem Soc 2004;151(3):A399. [55] Weber AZ. Effective diffusion-medium thickness for simplified polymer-electrolyte-fuel-cell modeling. Electrochim Acta 2008;54(2):311e5. [56] Zohuri B. Heat exchanger types and classifications. In: Compact heat exchangers. Cham: Springer; 2017. [57] Zawodzinski TA, Davey J, Valerio J, Gottesfeld S. The water content dependence of electro-osmotic drag in protonconducting polymer electrolytes. Electrochim Acta 1995;40(3):297e302. [58] Powercell Sweden AB. Datasheet PowerCellution P stack. Available: https://www.datocms-assets.com/36080/ 1611437833-p-stack.pdf. [Accessed 3 March 2021]. [59] ElringKlinger AG. Datasheet PEMFC stacks NM12. Available: https://www.elringklinger.de/sites/default/files/brochures/ downloads/ek_factsheets_pemfc_stack_nm12_en_a4.pdf. [Accessed 3 March 2021]. [60] Montaner Rı́os G, Schirmer J, Gentner C, Kallo J. Efficient thermal management strategies for cold starts of a proton exchange membrane fuel cell system. Appl Energy 2020;279:115813. [61] Becker F, Pillath F, Kallo J. Cathode exhaust gas recirculation for polymer electrolyte fuel cell stack. Fuel Cell 2018;18(5):568e75. [62] Becker F, Gentner C, Rı́os GM, Sokolov I, Kallo J. Steigerung € higkeit von Brennstoffzellensystemen für der Leistungsfa Luftfahrttechnische Anwendungen. In: Presented at the deutscher luft-und raumfahrt kongress. Germany: Friedrichshafen; 2018. [63] Fischer AG. Datasheet EMTCT-120k air. Available: https:// shop.fischerspindle.com/WebRoot/Store/Shops/fp/5813/ D763/DDD2/25F2/C853/B2FA/1909/C010/137901_data_map_ sheet_EMTCT_120k_Air.pdf. [Accessed 3 March 2021]. [64] Fumatech Bwt GmbH. Membrane humidifiers. Available: https://www.fumatech.com/NR/rdonlyres/0B9A1C7F-5BA64409-A003-5C4E79CD61AB/0/FUMATECH_BWT_ GmbHMembrane_Humidifiers.pdf. [Accessed 3 March 2021]. [65] Zanger J, Krummrein T, Siebel T, Roth J. Characterization of an aircraft auxiliary power unit test rig for cycle optimization studies. J Eng Gas Turbines Power 2018;141(1). [66] Giannakakis P, Laskaridis P, Pilidis P. Effects of off-takes for aircraft secondary-power systems on jet engine efficiency. J Propul Power 2011;27(5):1024e31. [67] Dollmayer J, Bundschuh N, Carl UB. Fuel mass penalty due to generators and fuel cells as energy source of the all-electric aircraft. Aero Sci Technol 2006;10(8):686e94. w. Our products/APS 5000 [68] Pratt&Whitney AreoPower Rzeszo for boeing 787 dreamliner. Available: http://pwaeropower. com/en/apu-engine-center/our-products. [Accessed 3 March 2021]. [69] Powercell Sweden Ab. Datasheet PowerCellution power generation system 100. Available: https://www.datocmsassets.com/36080/1611437574-power-generation-system100.pdf. [Accessed 3 March 2021]. [70] German Aerospace Center (Dlr). Conceptual study for environment-friendly flight. Available: https://www.dlr.de/ content/en/articles/news/2020/02/20200504_conceptualstudy-for-environment-friendly-flight.html. [Accessed 3 March 2021]. [71] Struchtrup H. Thermodynamics and energy conversion. 1st ed. Berlin Heidelberg: Springer-Verlag; 2014. [72] Lombardi A, Ferrari D, Santos L. Aircraft air inlet design optimization via surrogate-assisted evolutionary computation. In: Gaspar-Cunha A, Henggeler Antunes C, Coello C, editors. Evolutionary multi-criterion optimization. EMO 2015. Lecture notes in computer science, vol. 9019. Cham: Springer; 2015. [73] Ji SW, Myung NS, Kim TS. Analysis of operating characteristics of a polymer electrolyte membrane fuel cell coupled with an air supply system. J Mech Sci Technol 2011;25(4):945e55. [74] Zhao H, Hou Y, Zhu Y, Chen L, Chen S. Experimental study on the performance of an aircraft environmental control system. Appl Therm Eng 2009;29(16):3284e8. [75] Freudenberg Filtration Technologies Se & Co Kg. Datasheet fuel cell filter type FC F-0630-N. Available: https://www. freudenberg-filter.com/en/world-of-automotive/products/ fuel-cell-solutions/. [Accessed 6 April 2021]. [76] Carlucci AP, Ficarella A, Laforgia D, Renna A. Supercharging system behavior for high altitude operation of an aircraft 2stroke Diesel engine. Energy Convers Manag 2015;101:470e80. [77] Mecrow BC, Jack AG. Efficiency trends in electric machines and drives. Energy Pol 2008;36(12):4336e41.