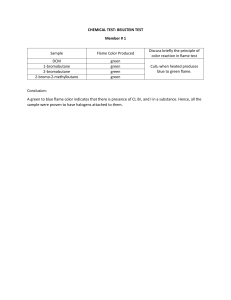

Safety and Reliability ISSN: 0961-7353 (Print) 2469-4126 (Online) Journal homepage: www.tandfonline.com/journals/tsar20 Louvered jet fire deflector – concept and concept validation for flame length reduction, flame deflection and explosion overpressure reduction Nagoor Monnapillai Ahamed To cite this article: Nagoor Monnapillai Ahamed (2017) Louvered jet fire deflector – concept and concept validation for flame length reduction, flame deflection and explosion overpressure reduction, Safety and Reliability, 37:4, 248-258, DOI: 10.1080/09617353.2018.1490486 To link to this article: https://doi.org/10.1080/09617353.2018.1490486 Published online: 11 Oct 2018. Submit your article to this journal Article views: 45 View related articles View Crossmark data Full Terms & Conditions of access and use can be found at https://www.tandfonline.com/action/journalInformation?journalCode=tsar20 SAFETY AND RELIABILITY 2017, VOL. 37, NO. 4, 248–258 https://doi.org/10.1080/09617353.2018.1490486 Louvered jet fire deflector – concept and concept validation for flame length reduction, flame deflection and explosion overpressure reduction Nagoor Monnapillai Ahamed Albain Group Inc, Dubai, UAE ABSTRACT In hydrocarbon processing industries, the standard approach to prevent jet fire escalation to adjacent facilities is to provide a solid fire wall. However, a solid firewall impedes the air flow through the plant, decreasing ventilation and increasing the potential flammable gas cloud size resulting in the generation of higher explosion overpressures if the gas cloud finds an ignition source. The conflicting impact of solid fire walls in preventing jet fire escalates but conversely increasing the potential explosion overpressures is a perennial design issue faced by safety engineers. This paper presents an alternate louvered jet fire deflector design concept; along with the validation work undertaken to demonstrate the explosion overpressure reduction benefits of the louvered wall application. This louvered jet fire deflector concept was subsequently engineered, fabricated, tested and has been incorporated into the plant design. This paper is written to increase the knowledge and awareness of safety engineers of an alternate option to optimise and balance the fire and explosion risk management. Abbreviations: CFD: computational fluid dynamics; FLACS: flame acceleration simulator; ISO: the international organization for standardization; m: meter; DAL: design accident load ARTICLE HISTORY Received 13 February 2018; Accepted 6 June 2018 KEYWORDS Deflector; explosion; fire; firewall; jet fire; Louver; overpressure Introduction In hydrocarbon exploration or processing facilities, fire and explosion events are considered as major accident hazard, and mitigation measures are provided as a part of a plant wide barrier approach to eliminate or minimise the escalation potential to adjacent parts of the facilities. CONTACT Nagoor Monnapillai Ahamed Nagoor.Monnapillai@albaingroup.com; managoor@yahoo.com Albain Group Inc., 4106/4107, Level 41, Tower AA1, Mazaya Business Avenue, Jumeirah Lakes Towers, Dubai, UAE ß 2018 Safety and Reliability Society SAFETY AND RELIABILITY 249 After implementing inherently safer design measures and other practical mitigation measures to reduce the frequency of the events; and the extent and severity of the resultant fire events, one of the recognised industry solution to prevent jet fire impingement of adjacent facilities is to provide a solid jet fire-rated fire wall of suitable construction and testing to resist a set duration in mitigating a jet fire impingement. These solid fire walls provide a physical barrier between the source of fire and the adjacent section of the facility where escalation events could occur. This standard approach of providing a solid fire wall solution impedes the air flow through the plant, thereby decreasing ventilation and increasing the potential gas cloud size within the plant following a hydrocarbon leak, which subsequently results in the generation of higher explosion overpressure, should the leak reach an ignition source. The solid fire wall also provides confinement and additional congestion around the plant which exacerbates the explosion overpressures generated. Although the solid fire wall would prevent jet fire escalation to adjacent facilities, due to the potentially increased overpressures generated, the civil; structural; piping and piping support design would need to be robust enough to resist higher design overpressures, as a result of the solid fire wall, thereby increasing the cost and complexity of the overall plant design. The conflicting impact of solid fire walls in preventing jet fire escalation but conversely increasing the explosion overpressures is a perennial design issue faced by engineers. Project-specific issues A project to replace a hydrocarbon gas processing plant was undertaken as the existing plant was becoming obsolete. Due to limited space availability within the existing facility footprint, the new plant was proposed to be located adjacent to the existing plant which it is replacing. The hydrocarbon storage tank farm is located on one side of the new plant, with the closest storage tank located 60 m from the new plant. Fire consequence assessment undertaken by the project using industry recognised commercially available consequence modelling tool indicated a jet fire from the new plant could potentially impact on the nearest hydrocarbon storage tank. In time, this would lead to catastrophic failure of the tank which would be a major accident escalation scenario. Failure of one storage tank is most likely to lead to adjacent tanks being impacted as they are in close proximity to each other. The standard solution of providing a solid fire wall between the plant and the storage tanks to prevent jet fire reaching the tanks was initially considered for implementation. The project undertook an initial coarse computational fluid dynamics (CFD) explosion analysis which indicated that 250 N. MONNAPILLAI AHAMED the anticipated design overpressures are high for a solid wall solution. The use of a solid wall would require the civil; structural; piping and piping support to be designed to a higher design overpressure with the associated increase in the cost and complexity of the new plant. As a result of this review, the project evaluated alternative solutions which may prevent jet fire escalation to the storage tank but at the same time reduce the potential design explosion overpressures within the plant. Functional requirement of measures to prevent jet fire escalation The critical functional requirement for any mitigation measure is to prevent the jet flame from reaching the storage tanks and to retain its own structural integrity for the duration of the fire to prevent any further escalation within the plant. As the storage tanks are located at a distance from the plant, any measure employed that reduces the flame length or deflects the flame away from the tanks would fulfil the escalation prevention function. Therefore, it was established that the mitigation measures considered should fulfil the following functionality: Provide line of sight obstruction between the new plant and storage tanks to prevent jet flame from directly impinging the tanks. The line of sight obstruction should be maintained under jet fire conditions for a prescribed duration. This prescribed duration was estimated as 30 min, based on depressurisation of the largest isolatable section inventory in the plant. This is to ensure that the structural integrity of the mitigation measure is maintained for the duration of the fire to prevent any further escalation within the plant. Deflection of jet flame away from storage tanks. The angle of deflection required for the flame to clear the top of the storage tank was estimated to be 45˚ (Figure 1). Louvered jet fire deflector concept The project evaluated a concept of a louvered jet fire deflector wall which would enable air to flow in and out of the plant; and allow the jet flame to pass through but partially reduce and deflect the jet flame momentum away from the storage tanks in the event of fire. The ventilation around the plant is provided through the gaps between the louvers which allow air to pass through the louvered wall and dilute any gas release prior to any potential delayed ignition (explosion) event. This louvered jet fire SAFETY AND RELIABILITY Louvered Jet Flame Deflector Deflected Flame Direction Hydrocarbon Storage Tank Plant Initial Flame Direction 251 Angle of Flame Deflection to o 45 Avoid Tank Figure 1. Louvered jet flame deflector and storage tank. deflector wall was perceived to provide the following benefits over a solid fire wall: Increased dilution and dispersion of any hydrocarbon gas leak by allowing increased air flow leading to reduced explosion overpressures. Reducing confinement leading to reduced explosion overpressures generated within the plant. Increase in explosion vent path (through louvers) leading to reduced explosion overpressures within the plant. Reduction of the effective jet flame length by disrupting the jet fire momentum direction and magnitude. Changing the direction of the jet flame towards a preferred safer direction away from the storage tanks. Concept validation The feasibility of designing and fabricating such a louvered jet fire deflector and the expected size of opening between the louvers that could be fabricated was discussed with vendors specialising in designing and manufacturing blast and fire walls. Based on their input, a louvered jet flame deflector with about 65% open space was considered feasible to manufacture. The resultant design was taken forward to assess the following perceived benefits through computational fluid dynamics (CFD) analysis using FLACS software: Increased ventilation and subsequent dispersion of releases. Reduced confinement. Overall reduction in assessed explosion overpressures. The louvered wall panels were modelled as porous walls within the FLACS software for the CFD assessment. A comparative review of the CFD 252 N. MONNAPILLAI AHAMED results was undertaken to ascertain the relative benefits between the following options: Option 1: Solid wall on the one side of the plant (facing the storage tanks). Option 2: No wall. Option 3: Louvered wall modelled with about 65% porosity. Ventilation analysis The results of CFD ventilation analysis concluded that The louvered firewall configuration (when compared with solid wall) results in better ventilation for the whole plant, for all wind directions assessed. The highest difference in the level of ventilation is from the direction of wind on the side obstructed by the solid wall. The increased ventilation could have a significant (positive) impact on the leak dispersion and resulting in smaller flammable cloud. Explosion analysis Further explosion CFD modelling demonstrated that the ‘no wall’ option (no confinement) does result in significantly reduced overpressures generated within the plant when compared with solid wall option, as would be expected. However, when assessed, the louvered fire wall option does not increase overpressures significantly above those from the ‘no wall’ option. The result of the explosion analysis is graphically presented in Figures 2 and 3. The summary of the CFD explosion analysis are The no wall and louvered wall options show a significant reduction in maximum and average overpressures when compared with the solid fire wall option. For the louvered wall option, the peak explosion overpressure reduction is significant (60–75%) for larger gas cloud volume while at smaller gas cloud volumes there is little difference between the three options as the wall has minimal influence on the volume filled for the smaller clouds. For the louvered wall option, the average explosion overpressure reduction is considerable (27–39%) for larger gas cloud volume, while at smaller gas cloud volumes, there is little difference between the three options. SAFETY AND RELIABILITY 253 Figure 2. Peak overpressure. Figure 3. Average overpressure. The reduction in the overpressure values for louvered wall option when compared with the solid wall option are significant enough to positively impact on the civil, structural and piping design criteria. The solid wall option will increase the overall cost and complexity of the design. There is minimal difference in overpressures between the no wall and the louvered fire wall option which was deemed not significant enough to impact the design cost and complexity. Based on the above findings, the project opted for the louvered jet fire deflector wall design which maximises ventilation and minimises the resultant explosion overpressures. The design, engineering and construction of the louvered fire wall were undertaken through a specialist vendor. 254 N. MONNAPILLAI AHAMED Fire endurance and flame deflection testing The functional requirement to provide line of sight obstruction between the new plant and the storage tank was incorporated in the design. The functions to maintain line of sight obstruction under jet fire condition for 30-min period and deflection of flame by 45˚ (or more) from horizontal was tested by undertaking a full-scale jet fire testing of the deflector panel at a Fire and Explosion testing facility. The test arrangement is presented in Figures 4 and 5. The test procedure used is as follows: The louvered jet fire deflector test panel was positioned at 3 m distance from the flame nozzle. This takes into consideration the flame stabilisation distance of approximately 1 m and a further 2 m to the start of the luminous region. This arrangement is based on experience of the Fire and Explosion testing facility. This distance allows the behaviour of flame to be better visualised on impingement of the test panel. Flame nozzle aimed at the centre of the test panel. Introduce jet fire flame to the sample panel, gas flow rate is maintained in accordance with the ISO 22899-1 specification (ISO 22899–1:2007, 2007). The flame was sustained for a period of no less than 30 minutes; Following a sufficient cooling down period, a visual inspection was carried out; and Success/failure criteria defined, as a minimum, the panel should resist the jet fire without degenerating or significant distortion of the louvre blades whilst line of sight obstruction of the louvre blades being maintained. Figure 4. Side view of test arrangement. SAFETY AND RELIABILITY 255 Figure 5. Front view of test arrangement. The jet flame length reduction in the louvered jet fire deflector panel was compared with the experimental free field jet flame length. The angle of deflection due to the louvered fire deflector was also measured to compare with the minimum 45˚ angle requirement. The observed free field flame length and the flame length reduction as a result of the jet fire deflector during the test are presented in Figures 6 and 7, respectively. The free field jet flame distance extends to approximately 7–8m while the flame distance through the louvered panel is about 4–4.5m from the point of flame origin (1–1.5 m beyond the panel). The flame length reduction from the jet flame deflector is, therefore, about 60% for this test arrangement. The angle of actual flame deflection was observed to be more than the required flame deflection angle, which is primarily due to the configuration of the louvers. It is observed that loss of momentum is dependent on the angle of impingement of the flame on the louvers. As would be expected, the jet flame momentum loss is minimal when the flame impingement angle is parallel to the surface of the louvers and the momentum loss is maximised when the flame impingement angle is perpendicular to the surface of the louvers. This can be seen in Figure 7, where the flame above the centre line passes through the louvered wall while very little of the flame below the centre line passes through the louvers. Conclusions As a result of the CFD modelling and the physical tests carried out on the designed and manufactured full scale louvered wall, the following conclusions can be made: A porous/louvered wall reduces the confinement and gas cloud size with the associated reduction in explosion overpressure generated when compared with solid wall. 256 N. MONNAPILLAI AHAMED Figure 6. Free field jet flame profile. Figure 7. Flame profile through louvered jet flame deflector panel. The reduction in overpressures is significant at large gas cloud volume and to lesser extent at smaller gas cloud volume. The louvered configuration reduces the momentum of the jet fire leading to reduced flame length after impacting the louvered wall. The reduction in flame length is dependent on the angle of jet fire impingement and configuration of the louvers. Depending on the angle and configuration of the louvers the jet flame can be deflected at any required angle. SAFETY AND RELIABILITY 257 Design benefits to project An explosion exceedance analysis undertaken using a similar process plant as a basis to compare the changes in the explosion design criteria between solid and louvered wall indicated that the maximum and mean design accident load (a 10 4/year frequency of occurrence) for a louvered wall configuration is reduced by 86% and 60%, respectively, when compared with solid wall configuration (Table 1). From this, it is evident that a significant (60%) reduction in explosion overpressure can be expected when using a suitably designed louvered wall instead of solid wall. From the CFD assessment results, it is noted that there is significant explosion overpressure reduction benefit in using a louvered fire deflector wall which leads to design and cost benefits, whilst providing adequate jet fire escalation mitigation for this application, equivalent to a solid fire wall. Subsequently exceedance frequency analysis specific for the plant was completed and this design accident load (DAL) was implemented within the plant design. Potential application of the louvered jet fire deflector concept In onshore hydrocarbon processing facilities, where protecting specific targets from jet fire event is required, such a louvered jet fire deflector wall can be considered instead of solid fire walls. The angle and direction of deflection can be varied to suit the specific site requirement. The louvered jet fire deflector wall has the potential to be used in offshore oil and gas platforms where explosion overpressure is high due to potentially significant levels of congestion which can be exacerbated by the confinement introduced by a solid fire wall. Depending on the layout of the platform, a suitably designed louvered fire wall may provide a balanced solution to fire and explosion escalation scenarios into adjacent modules. This has the potential to reduce the explosion design criteria and thereby have a beneficial effect on the platform weight. This paper is written to increase the knowledge and awareness of safety engineers of an alternate option to optimise and balance the fire and explosion risk management and positively influence the overall design of the facility. Table 1. Generic comparison of explosion design criteria. 10–4/year Max. overpressure (barg) Solid wall 4.80 10–4/year Mean overpressure (barg) Louvered wall % Reduction Solid wall Louvered wall % Reduction 0.65 86 0.58 0.23 60 258 N. MONNAPILLAI AHAMED Previous publications 1. 2. “Stress Corrosion Cracking of Nickel Lined Steel Flange in Caustic Service”, Material Performance (MP), Sep 2005, NACE, USA. “Review of International Shipping and Port Security (ISPS) Code”, Euroship, Aug 2006, Co-Author. Notes on contributor Nagoor Monnapillai Ahamed, has 28 years of experience in the oil & gas, petrochemical and chemical industries. He has a B.Eng. degree in Mechanical Engineering, M.Sc in Ecology and Environment, and M.Sc in Safety Engineering, Reliability, and Risk Management. He is a chartered engineer in the UK and in India, is a Fellow of Safety and Reliability Society (SaRS) (UK), member of Institution of Engineers (India); and joint member of Society of Environmental Engineers (SEE) (UK). He is also an affiliate professor in BSA Crescent University (India). He currently works for Albain Group Incorporated, as Consultancy Services Director. References ISO 22899-1:2007. (2007). Determination of the resistance to jet fires of passive fire protection materials – Part 1: General requirements (1st ed.).