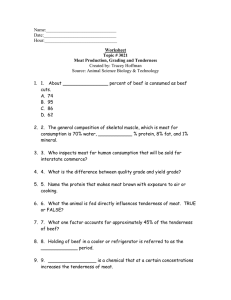

ORIGINAL ARTICLE Full Access Physicochemical properties and tenderness analysis of bovine meat using proteolytic enzymes extracted from pineapple (Ananas comosus) and jackfruit (Artocarpus heterophyllus) by-products Aizi Nor Mazila Ramli , Hazrulrizawati Abd Hamid, Farah Hanani Zulki"i, Normaiza Zamri, Prakash Bhuyar, Nor Hasmaliana Abdul Manas First published: 09 September 2021 https://doi.org/10.1111/jfpp.15939 Citations: 1 Abstract Present research investigation aimed to explore the pineapple and jackfruit by-products, the core and the seed, respectively, as a meat tenderizer. The e#ects of beef samples treated with bromelain and Artocarpus heterophyllus protease in four di#erent concentrations (0, 1%, 2%, 3% and 4%) and combination (4% bromelain and 4% A. heterophyllus protease) were studied. The physicochemical treated beef samples showed a 13.30 ± 0.30 decrease in the water holding capacity (WHC), pH 5.47 ± 0.03, moisture content 63.86 ± 0.16 and cooking yield 75.78 ± 0.16 with the increased addition of crude enzyme extract (p < .05). The cooking loss increased signi$cantly with the concentration of extracted proteolytic enzymes (p < .05). Microstructural analysis of the treated beef samples demonstrated the degradation of muscle $bers and the generation of numerous gaps or space. The sensory evaluation analysis also revealed the acceptance of the treated beef sample compared to the untreated sample. The results showed that the bromelain and A. heterophyllus protease extract from by-products could be used as an e#ective natural meat tenderizer. The core and seed as (pineapple and jackfruit) waste by-product could e#ectively improve the tenderization of tough muscle in beef without disturbing quality parameters, signi$cantly contributing to the agricultural processing industry. Practical applications Pineapple and jackfruit are popular fruits in south-east Asian countries. Pineapple and jackfruit are good for preserving meats and for helping to $ght bacterial spoilage. Some plant-based and food-derived ingredients are more e#ective than others when maintaining the freshness of a product as long as the meat is not harmed. Proteolytic enzymes boost the fragmentation of myo$brils in meat and aid in the degradation of the intramuscular connective tissue structure. Combining pineapple and jackfruit by-products can be a most e#ective tenderizer for the meat as an actual preservative without impeding the natural quality or freshness. 1 INTRODUCTION Meat, which is animal "esh or tissue eaten as food, is considered an essential product in some countries with high consumption rates (Guerrero et al., 2013). Besides being an essential source of dietary protein, meat provides other biological values such as vitamins, minerals, and other bioactive compounds. In addition, it also supplies fatty acids, including saturated fatty acids (SFA), unsaturated fatty acids (USFA), omega-3, cholesterol, triacylglycerol and phospholipids (Hathwar et al., 2012). Meat tenderness is long known as the highest quality feature for the acceptability of fresh consumer meat (Mennecke et al., 2007). The tenderness of meat has a signi$cant impact on customer satisfaction and, as a result, enhances consecutive purchases (Grunert et al., 2004). The quality of meat can be contributed by several properties, including tenderness, color quality, water-holding capacity, cooking losses, and texture. Other critical factors that can in"uence meat value are eating quality, tenderness, "avor, and juiciness (Istrati et al., 2012). A previous study reported that tenderness is the most determinant of palatability characteristics among consumers (Shackelford et al., 2001). Thus, to improve customer satisfaction and increase the market potential for meat products, the industry needs to supply high-quality meat with consistent tenderness. However, the inconsistency in beef tenderness continues to be a challenge faced by the industry due to the di#erent tenderness properties among bovine muscles from various anatomical locations and the dissimilarities in the structural components which can in"uence tenderness (Von Seggern et al., 2005). Several strategies have been implemented to improve meat tenderness, thus making it more palatable. Conventional methods such as modi$ed online carcass suspension method (Aalhus et al., 2000), prerigor skeletal separations (Shanks et al., 2002), pressure treatments (Palka, 1999), electrical stimulation (Claus et al., 2001), blade tenderization (Pietrasik et al., 2010) and chilling improvement (Janz et al., 2004) have been used to improve the meat tenderization. There have also been attempts to tenderize meat by calcium chloride injection chemically (DeYonge-Freeman et al., 2000), phosphates, salts (Pietrasik et al., 2010) as well as enzymes treatment (Ashie et al., 2002; Gerelt et al., 2000). Each of these strategies has been shown to have varying degrees of activity against a di#erent type of meat. Meat tenderization by proteolytic enzymes originating from plants, bacterial, and fungal sources are gaining popularity. However, plant proteolytic enzymes, such as papain, bromelain, and $cin, are superior to bacterial-derived enzymes, which are primarily due to microbial enzymes’ safety problems, including pathogenicity or other unfavorable e#ects (Bhuyar, Rahim, Maniam, et al., 2020; Naveena et al., 2006). The fruit waste accumulates over the year; using it to make essential compounds helps to reduce the total amount of waste produced. Fruit waste is produced in signi$cant numbers as a result of agricultural operations. Pineapple, jackfruit, citrus, banana, apple, and pear residues leftover from industrial processing are examples of such litter (Bhuyar, Maniam, et al., 2021; Ramli, Badrulzaman, et al., 2021; Ramli, Binti Muhammad Sukri, et al., 2021; Ramli et al., 2020). Bananas, apples, and pears produce around 107.1, 75.5, and 24.0 million tons per year, respectively, and 25%–40% of this mass is wasted after processing. Fruit waste is used as cow feed, but it is not a high-value feedstock due to its low protein content; thus, much of it is in land$lls or the ocean. These disposal methods may generate environmental issues because fruit waste is high in sugars, antioxidants, and other nutrients. The fruits also contain many enzymes that can be used for food preservation and meat tenderizer (Bhuyar, Rahim, Sundararaju, Ramaraj, et al., 2020; Choi et al., 2015; Gupta et al., 2019). Proteolytic enzymes were reported to increase the fragmentation of myo$brils in meat and aid in the degradation of the intramuscular connective tissue structure. Bromelain is found naturally in di#erent parts of the pineapple plant, including fruit, core, stem, pulp, peels and leaves (Ramli et al., 2017). Bromelain is a proteolytic enzyme from the pineapple plant, Ananas comosus, that had been used traditionally to tenderize meat, including beef (Ketnawa & Rawdkuen, 2011), mutton (Bille & Taapopi, 2008), chicken (Koide et al., 2010) and pork (Ieowsakulrat et al., 2011). Bromelain, which is categorized in the sulfhydryl proteolytic enzymes group, works on myo$brillar proteins by hydrolyzing the structure of myosin and actin $laments. Furthermore, United States federal agencies recognize bromelain together with papain, $cin, as generally recognized as safe (GRAS) to improve meat tenderness (Sullivan & Calkins, 2010). Jackfruit, Artocarpus heterophyllus, is latex and seasonal fruit-producing tree which belongs to the family of Moraceae and genus Artocarpus Lam. Though it was originally from India, this tree grows wild in East Asia’s tropical areas, including Malaysia. As far as we are concerned, lack of prior research studies on the analysis of proteolytic enzymes produced from di#erent part of the Jackfruit. In addition, the tenderization e#ect of the proteolytic enzyme from jackfruit and its combination with bromelain also least explored. Currently, higher demand in fruit-processed-items leads to the escalation of production processes which consequently resulted into huge generation of agricultural waste. This is generally owing to the selection and removal of fruit components unsuitable for human consumption. Typically, agricultural wastes are easily exposed to microbial spoilage thus limiting further exploitation. Therefore, the aim of this study is to explore the added value of the pineapple and jackfruit byproducts; the core and the seed, respectively, to be used as a meat tenderizer. 2 MATERIALS AND METHODS 2.1 Sample preparation 2.1.1 Bromelain extracts preparation from pineapple core The pineapple (A. comosus) samples used throughout this research were obtained from the local variants around Pahang, Malaysia: Josepine, Sarawak, MD2, Philippine and Morris. Initially, 100 g of the pineapple core was cut into small pieces and were weighed using the analytical balance, followed by crushing in a food processor containing 500 ml of 0.05 M of phosphate bu#er (pH 7.5). The extract was $ltered through a double-layered muslin cloth to remove the solid parts. The $ltrate was then collected and centrifuged at 10,000×g at 4℃ for 20 min to remove the remaining residue. The crude supernatant of bromelain was collected and stored at −20℃ until further use. 2.1.2 Proteolytic extracts preparation from ripe and unripe jackfruit The fruit sample of A. heterophyllus that was used in this research was “nangka madu”. The fruits were obtained from the local jackfruit orchard located around Pahang, Malaysia. Both ripe and unripe jackfruit samples (seed, skin, inner part) were used in this research study. Each part was cut into small pieces. A total of 100.0 g was weighed for each part by using an electronic balance. The extraction method was the same for each part of the jackfruits. The sample was crushed in a food processor containing 500 ml of 0.05 M of phosphate bu#er (pH 7.5). The mixture was then $ltered by using a double-layered muslin cloth, and the solid parts were removed. Filtration was carried out to discard the $brous materials, and the $ltrate containing protein was collected. Next, the $ltrate was centrifuged at 10,000×g at 4℃ for 20 min. The supernatant was collected and stored at −20℃ until further use. 2.2 Proteolytic analysis of di#erent pineapple variants and jackfruit samples The incubation temperature in this enzyme assay was 37℃. 5 ml of casein solution (0.65% [wt/vol]) was added to the test tubes, followed by incubation at 37℃ for 5 min. A total volume of 1 ml of bromelain solution was added to the test tube and incubated for 10 min. After that, 5 ml TCA (110 mM) solution was added to the mixture reaction, including control. The tubes were incubated for 30 min and subjected to centrifugation at 6,000×g for 5 min. The supernatant was transferred into new tubes, and 5 ml Na2CO3 (500 mM) was added, followed by 1 ml Folin & Ciocalteu’s Phenol Reagent. After centrifugation at 6,000×g for 5 min, the absorbance value of the supernatant was obtained at 660 nm. This enzymatic assay was obtained in triplicate. The proteolytic activity can be determined in terms of Units/ml activity, indicating the amount of tyrosine in micromole equivalents released from casein per minute (Bhuyar, 2017; Bhuyar, Rahim, Sundararaju, Maniam, et al., 2020). 2.3 Marination of meat samples by bromelain extract Fresh boneless meat was purchased from a local store and cut into cubes of the same size and weight before being treated with bromelain solutions of varying concentrations (1%, 2%, 3%, and 4%). The meat sample obtained was identi$ed as beef meat from cattle (Tulang Lembu). The meat samples were labeled as a control (untreated meat: 0%) and bromelain treated samples at di#erent concentrations. All the experimental analysis of treated beef cubes was done in triplicates. 2.4 Physicochemical properties determination 2.4.1 Water-Holding Capacity (WHC) Water-holding capacity (WHC) determination was conducted using a method described by Wardlaw et al. (1973). Beef cubes (6 g) were prepared using di#erent bromelain and A. heterophyllus protease (1%, 2%, 3%, and 4%). Untreated beef cube was used as a control. All the beef samples were mixed with 10 ml of 0.6 M sodium chloride (NaCl) solution in a centrifuge tube and stirred with a glass rod for 1 min. The tubes were then incubated at 4℃ for 15 min and stirred again for 1 min, followed by centrifugation at 10,000×g at 4℃ for 15 min. After centrifugation, the volume of the supernatant was measured, and the waterholding capacity of the treated and untreated beef was calculated using the formula: 2.4.2 Measurement of pH Beef cubes were weighed (2 g) accurately and treated with di#erent bromelain and A. heterophyllus protease solution (1%, 2%, 3%, and 4%) in test tubes. A test tube without bromelain served as a control. The samples were incubated for 10 min at room temperature and homogenized by grinding and then crushing mechanically using a mortar and pestle. The pH of the samples was measured by a pH meter. The pH meter was initially calibrated with pH 7 and pH 4 bu#ers before being used in pH determination (Bhuyar, Sundararaju, et al., 2021). 2.4.3 Moisture content For determination of the moisture content, 5 g of beef cubes (treated with 1%, 2%, 3% and 4% of bromelain and A. heterophyllus protease solution) and control samples (untreated) were suspended in 10 ml of 0.6 M sodium chloride (NaCl) solution for 30 min. The weight of the samples was measured using an analytical balance. The beef cubes were then placed on an aluminum foil and heated (100℃) for 20 min using a hot plate. The weight of the beef cubes (treated and untreated) after removing moisture was determined. Percentage of moisture content in the meat samples were calculated as the following: 2.4.4 Cooking yield The beef cubes were weighed accurately (5 g). The samples were cooked for 1 min at 100℃ and then cooled at room temperature. The cooked sample was reweighed using an analytical balance. The cooking yield was calculated by the di#erence in raw and cooked weights as follows: (Brugiapaglia & Destefanis, 2012): 2.4.5 Cooking loss The beef cubes were prepared and weighed accurately just before cooking (5 g). Immediately after cooking, the samples were cooled and weighed. According to Sultana et al. (2009), the cooking loss was calculated as the following equation: 2.4.6 Textural properties The beef sample texture was analyzed using an electronic universal testing machine (VEW-20, Victor) with a 10 mm/min crosshead speed. Three rectangular samples of bromelain treated and untreated bromelain raw beef with dimensions of 20 × 20 × 25 mm (width × length × height) were prepared. The room conditions were controlled at 25℃ and 34% humidity. The load-displacement values were reordered for further analysis. 2.4.7 Microstructure property using a scanning electron microscope (SEM) In the present study, the samples’ microstructures were observed using a Scanning Electron Microscopy (SEM) (FEI QUANTA 450) at an accelerating voltage of 15 kV. Cross-sections of all samples were $xed with 2.5% (vol/vol) glutaraldehyde in a 0.2 M phosphate bu#er (pH 7.2) for 2 hr. After that, the samples were dehydrated with increasing alcohol concentrations (20%, 40%, 60%, 80%, and 100%) for 10 min each. The samples were air-dried by keeping the samples in a fume hood. Lastly, the samples were sputter-coated with a thin layer of platinum in double 30 s consecutive cycles at 45 mA to reduce charging and produce conductive surfaces (BALTEC SCD 005 Sputter Coater—BALTEC). 2.4.8 Sensory evaluation The sensory evaluation was carried out based on a 5-point hedonic scale method, as proposed by (O’Sullivan, 2016). A survey was conducted among Universiti Malaysia Pahang (UMP) students and sta#. Totally 10 participants were chosen randomly. The survey was performed in an isolated room to minimize external factors such as noise, which might a#ect the sensory evaluation. The survey was carried out to check the tenderness and toughness of the meat after being treated with the best enzyme extracts. The meat samples were marinated with the enzyme extracts for 30 min and then cooked for 8 min. The ten participants were given two di#erent samples of meat (treated and untreated meat samples). A form of the survey was given to each of them, and they had to evaluate these meat samples regarding appearance, taste, texture, aroma and acceptance, with $ve taste scales, starting from score 1 indicate like signi$cantly to score 5, which indicate dislike highly. At the end of the sensory evaluation, the panelists need to choose which meat samples were better between the two provided. 2.4.9 Statistical analysis The resulting data were statistically analyzed using the SPSS analysis of variance (SPSS version 12.0 for Windows, SPSS Inc., Chicago, IL, USA). Duncan’s multiple range test was used to analyze the di#erence between means. The signi$cance for all comparisons was determined at the p < .05 level. Experiments were conducted in triplicate. 3 RESULTS AND DISCUSSION 3.1 Bromelain analysis from di#erent variants of A. comosus A di#erent A. comosus: Josepine, Sarawak, MD2, Philippine and Morris were collected from di#erent places in Malaysia. Each variant is di#erent: skin color, size and shape, and the amount and size of spines. These di#erences could contribute to the dissimilarity in the amount of protein content for each sample. Josepine’s skin is much darker than other varieties, almost black with more prominent and lesser spines. Its body size is smaller than other variants of pineapple. MD2 has bright yellow skin and smaller and lesser spines, and it has the most robust smell among the other varieties. This type of pineapple also produces smaller fruit sizes. Sarawak variety has the most signi$cant size with brighter orange skin color and more spines. Morris’s size is considered signi$cant, but it is usually much smaller than Sarawak, usually known as Queen Pineapple (Yuris & Siow, 2014). Morris variant usually produces yellowish-brown fruit with more prominent spines. Philippine’s body contains greenish-yellow skin, which is smoother than others and in moderate size. Extracting crude bromelain from the core part is more di&cult than the "esh part due to the husk content in the core that is higher than the "esh part with lower moisture content. All $ve varieties of A. comosus have a core diameter range from 1.5 to 2.3 cm. Sarawak species has the biggest core diameter, while Josephine and Morris have the smallest comparatively. Determination of enzyme activity is essential for $nding out the actual proteolytic activity and any application purpose. The activity of an enzyme can be assayed either by substrate utilization method or product formation method. A protease activity assay was done to determine bromelain activity from di#erent varieties of A. comosus (Figure 1a). From the enzymatic analysis, MD2 gave the highest activity of bromelain, which is 0.5486 units/ml followed by Josepine (0.5008 units/ml), Philippine (0.3813 units/ml), Morris (0.3015 units/ml), and Sarawak (0.2940 units/ml). About Sections FIGURE 1 Open in !gure viewer PowerPoint (a) Protease activity assay to determine the activity of bromelain from di#erent varieties of Ananas comosus. (b) Protease activity assay to determine the proteolytic activity from di#erent parts of Artocarpus heterophyllus fruit 3.2 A. heterophyllus protease analysis from di#erent parts Di#erent parts of ripe and unripe A. heterophyllus, including seed, skin and inner part, were used in the proteolytic analysis. Ripe A. heterophyllus produced pleasant smells compared to unripe A. heterophyllus. The cotyledon of ripe A. heterophyllus seed was enclosed by a thin brown spermoderm; meanwhile, the cotyledon of unripe seed was enclosed by white spermoderm. In addition, the colour of the ripe skin was much brighter (bright yellow skin) than unripe skin. The inner part of ripe A. heterophyllus has appeared in dark yellowish colour. It is edible, and people also consumed ripe inner parts due to its sweet taste. However, the unripe inner part has appeared in white, and it is tasteless. Each part of both ripe and unripe A. heterophyllus contained a certain amount of protease. Thus, a protease activity assay was carried out to determine the proteolytic activity for each di#erent component of the A. heterophyllus fruit. Figure 1b shows that ripe seed exhibited the highest proteolytic activity, 0.2955 units/mL, followed by ripe inner, which is 0.2369 units/ml. The enzymatic activity for unripe skin is 0.1547 units/ml, followed by mature skin with its enzymatic activity of 0.1401 units/ml. Unripe inner and unripe seed shows the lowest protease activity, 0.1188 and 0.0997 units/ml, respectively. Generally, all the ripe parts of A. heterophyllus exhibits higher proteolytic activity compared to the unripe parts. To the best of our knowledge, no studies were reported on the proteolytic analysis of di#erent parts of ripe and unripe jackfruit, A. heterophyllus. Usually, the fruit is consumed due to its delectability; however, the seed is often discarded. Thus, it was interesting to see the potential of the A. heterophyllus by-products as a meat tenderizer. 3.3 Physicochemical properties determination of meat 3.3.1 Assessment of WHC, pH and moisture content Zayas (1997) determined that water holding capacity (WHC) is the food’s ability to hold existing water and the added water during the forces, pressing, centrifugation, or heating processes. In addition, WHC also has been categorized under the physical property and a food structure ability to avoid water losses from its three-dimensional structure (Wallingford & Labuza, 1983). The determination of WHC in meat is essential since several physical properties, including color, texture and $rmness, are partially reliant on the WHC (Ketnawa & Rawdkuen, 2011). In this experiment, a signi$cant reduction of WHC is observed in all treated meat samples, signi$cantly when the concentration of bromelain and A. heterophyllus protease extracts increased, as presented in Table 1 (p < .05). The highest WHC value was found in the untreated sample (control). The highest and the lowest WHC values of treated samples obtained were from the beef cube samples treated with 1% and 4% of both bromelain and A. heterophyllus protease, respectively (Table 1). The lowest WHC values were observed in the beef sample treated with a combination of 4% bromelain and A. heterophyllus protease compared with others. The treated beef sample with 1% bromelain showed the highest WHC value. Compared to the untreated sample, reducing the WHC value in treated samples can be possibly due to proteolytic enzyme action on the myo$brillar proteins, thus leading to protein denaturation. Generally, in the muscle structure, water is entrapped in the intra- and extra- myo$brillar spaces of cells (Hu#-Lonergan & Lonergan, 2005). The increase or decrease in WHC may a#ect vice versa. The decrease in water holding capacity a#ects loss of pro$t for the meat seller, and the increased cooking loss a#ecting the customers to get less meat in their pan. Bromelain is suggested to hydrolyze these myo$brillar proteins in the muscle into simpler components that in"uence the changes in the cell’s intracellular architecture, consequently a#ecting the ability of muscle cells to retain water. TABLE 1. Physicochemical properties of beef samples treated with bromelain and Artocarpus heterophyllus protease extract at di#erent concentrations Sample pH WHC (%) Properties Cooking moisture (%) yield Cooking loss A. comosus Bromelain 0% 6.01 ± 0.04 36.7 ± 0.06 71.17 ± 0.01 96.18 ± 0.06 3.82 ± 0.06 1% 5.32 ± 0.12 26.95 ± 0.01 71.02 ± 0.06 90.88 ± 0.18 9.12 ± 0.18 2% 5.22 ± 0.02 21.19 ± 0.01 69.46 ± 0.07 82.50 ± 0.16 17.5 ± 0.16 3% 5.12 ± 0.05 21.07 ± 0.01 66.57 ± 0.01 79.86 ± 0.04 20.13 ± 0.04 4% 4.83 ± 0.08 20.95 ± 0.01 65.98 ± 0.01 76.35 ± 0.09 23.65 ± 0.09 1% 5.97 ± 0.02 23.30 ± 0.06 70.32 ± 0.04 92.26 ± 0.19 7.74 ± 0.19 2% 5.96 ± 0.02 20.00 ± 0.00 67.97 ± 0.12 90.88 ± 0.11 9.12 ± 0.11 3% 5.91 ± 0.04 16.72 ± 0.12 66.78 ± 0.11 89.28 ± 0.13 10.72 ± 0.13 4% 5.85 ± 0.06 16.70 ± 0.06 64.24 ± 0.11 88.28 ± 0.07 11.72 ± 0.07 Combination 4% A. 5.47 ± 0.03 13.30 ± 0.30 63.86 ± 0.16 75.78 ± 0.16 24.22 ± 0.14 A. heterophyllus protease comosus bromelain and 4% A. heterophyllus protease In addition, the $nal pH value also plays an essential role in the WHC of meat. The reduction in WHC in all treated samples might be due to a lower pH value (Ketnawa & Rawdkuen, 2011). In this study, a signi$cant reduction in pH was observed in all bromelains, and A. heterophyllus protease treated samples compared to the untreated sample (Table 1). The pH was found to be decreased signi$cantly with the increasing concentration of bromelain and A. heterophyllus protease. The decrease in pH of the treated sample with 1%–4% of each bromelain and A. heterophyllus protease ranges are between 5.32 to 4.83 and 5.97 to 5.85, respectively, while the beef sample treated with the combination of 4% bromelain and A. heterophyllus protease gave the pH value of 5.47. The lowest pH was found in the sample treated with 4% bromelain (pH4.83), while the highest was found in the untreated beef sample (pH6.01). Gradual increase in bromelain and A. heterophyllus protease concentration results in a pH decrease, making the treated meat sample more acidic. Previously, the WHC was found to increase markedly with decreasing ultimate pH, reducing the electrostatic repulsion between the $laments (den Hertog-Meischke et al. (1997)). This phenomenon causes the water movement from the myo$lament space into the extracellular space, thus leading to myo$brillar shrinkage. Therefore, the rate of the pH decrease is an essential determinant of WHC (Hu#-Lonergan & Lonergan, 2005). Other than WHC, the pH value in the meat product is also highly important because it has a signi$cant in"uence on other quality and physicochemical properties, including tenderness and juiciness (Goli et al., 2007). It was found that the moisture content of the treated samples of beef with extracted bromelain from the core part decreased considerably compared to the untreated sample, as shown in Table 1 (p < .05). The beef sample treated with the combination of 4% bromelain and A. heterophyllus protease gave the lowest moisture content of 63.86%, followed by 64.24% and 65.98% when treated with 4% bromelain and 4% A. heterophyllus protease, respectively. The control beef sample contains the highest moisture content of 71.17%. A comparable $nding was reported by Sultana et al. (2009), which reported a signi$cant decrease in the moisture content of treated beef from 75.8% to 68.77%. Nadzirah and his coworkers (2016) also reported a similar $nding of reduced moisture content in bromelain treated beef compared to the control. Huang et al. (2011) reported that the water content in meat is primarily located within the structure and cells of muscles. Thus, the degradation of myo$brillar protein muscle by the action of bromelain triggered the muscle structure destruction, leading to the decrease in the percentage of moisture content in treated beef samples. 3.3.2 Cooking yield and cooking loss All the cooking yields of the treated samples were signi$cantly low compared to the untreated sample (p < .05). As shown in Table 1, it was found that with the increase of bromelain and A. heterophyllus protease concentration in the samples, the cooking yield decreased. For bromelain treated sample analysis, the sample treated with 1% bromelain shows the highest cooking yield percentage of 90.88%, followed by the samples treated with 3%, 2%, and 1% bromelain the percentage value of 82.50%, 79.86% and 76.35%, respectively. A similar trend was observed for the beef sample treated with A. heterophyllus protease, where 1% enzyme extract treatment gave the highest cooking yield (92.26%), followed by 2% (90.88%), 3% (89.28%), and 4% (88.28%) enzyme concentration. However, the lowest cooking yield for all treated samples was observed in a beef sample treated with the combination of 4% bromelain and 4% A. heterophyllus protease (75.78%), while the most considerable value of cooking yield was exhibited in an untreated beef sample that served as a control (96.18%). This result implies that thermal treatment removes more water from the treated beef samples than the untreated sample. It is suggested that the protein hydrolysis e#ect is more potent in the sample treated with a higher concentration of bromelain. Compared to the untreated sample, the reduced cooking yield in the treated sample may be caused by the degradation of sarcoplasmic and myo$brillar proteins in the muscle meat. Ketnawa and Rawdkuen (2011) studied the e#ects of bromelain extract from pineapple peels on beef, chicken and squid, and it was found that all marinated meat samples with bromelain extract showed a reduction in cooking yield. On the other hand, the percentage of cooking loss was inversely proportional to cooking yield (p < .05). The cooking loss for treated beef was increased signi$cantly from 9.12% to 23.65% and 7.74% to 11.72% after treatment with 1% to 4% bromelain and 4% A. heterophyllus protease, represented in Table 1. The lowest percentage of cooking loss was detected in untreated beef samples (3.82%), while the highest percentage was observed in the beef sample treated with the combination of 4% bromelain and 4% A. heterophyllus protease (24.22%). This $nding was in agreement with Nadzirah et al. (2016), which found that bromelain produced from pineapple crowns increases beef’s cooking loss value which is also supported by Klinhom et al. (2011), which reported an increase of untreated beef from 36.55% to 42.90% after the beef was treated with 0.05 M citric acid followed by the cooking process at 70℃. Temperature rise during the cooking process resulted in the denaturation of myo$brillar proteins, especially the actomyosin complex part, leading to the shrinkage of the muscle $ber. This condition causes water loss from tissue because the myo$brils weaken the ability to hold water (Murphy & Marks, 2000; del Pulgar et al., 2012). Furthermore, the beef with proteolytic enzymes is suggested to cause the denaturation of myo$brillar proteins in muscle, which results in structural changes, thus causing the cooking loss of meat to increase. The resulting data was obtained from the physicochemical properties (pH, WHC, moisture content, cooking yield and cooking loss) of beef samples treated with di#erent bromelain, A. heterophyllus protease, and combination of both extracts textural and microstructure properties were performed, followed by sensory evaluation. 3.3.3 Textural properties The beef sample treated with both extracts (4% bromelain and 4% A. heterophyllus protease) and the untreated beef sample were then selected for textural properties analysis. Figure 2 shows the textural properties such as compress strength and elongation at the break of treated and untreated samples. The mechanical properties, such as the data of load and elongation, are summarized in Table 2. Compared with the bromelain untreated samples, the load and elongation at break are reduced from 101.04 to 46.5 kN and 9.35 to 8.95 mm, respectively. The high force load stress observed in untreated bromelain samples speci$es the toughness of the meat, where more connective tissues are presented. When the applied stress increases, the dislocation of intramuscular connective tissue also increased, as observed in the sample chemically treated by bromelain enzyme due to the reduced amounts of connective detective tissue before the action of proteolytic enzymes on myo$brillar proteins (Kumar et al., 2011; Manohar et al., 2016). This $nding agrees with Ketnawa and Rawdkuen (2011), which con$rmed a signi$cant reduction in roughness values of treated samples with the increased bromelain concentration from 3% to 20% (wt/wt). FIGURE 2 Open in !gure viewer PowerPoint The textural properties of treated and untreated beef samples TABLE 2. Sensory score of combination of bromelain and Artocarpus heterophyllus protease tenderizer on the sensory attributes of beef sample based on a hedonic scale Sample Appearance Taste Texture Aroma Acceptance Control 1.97 ± 0.556 2.03 ± 0.765 1.87 ± 0.730 2.10 ± 0.803 1.77 ± 0.774 Treated 1.80 ± 0.551 1.87 ± 1.252 1.53 ± 0.860 1.73 ± 0.944 1.50 ± 0.572 3.3.4 Microstructure properties Scanning electron micrograph (SEM) of the treated beef combined with 4% bromelain and 4% A. heterophyllus protease and untreated beef (control) provided additional physical evidence for the structure organization changes of the meat before and after treatment. Figure 3(a) shows the microstructure of the untreated beef samples where all the muscle $bers had a well-organized structure and were closely bound to each other. Whereas Figure 3(b) depicts the muscle $bers in the di#erent bundles of the treated sample are broken, not well attached and has a loss of interaction. Furthermore, the inter$brillar space between muscle $bers is more signi$cant in the treated sample, which could be due to the degradation of muscle $bers and connective tissue layers surrounding muscle $bers and the degradation of cell membranes. The microstructure properties of the treated and untreated samples showed a strong correlation with the previous results in terms of textural properties and can become the evidence to improve the meat tenderization process. Similar microstructure properties have been found in the bu#alo muscle treated with the ginger extract (Naveena et al., 2004). SEM analysis revealed that the treatment broke muscle $bers into di#erent bundles and enlarged the bundles’ space. In addition, there was obvious structure deformation and disruption detected in beef, chicken and squid samples treated with bromelain extracted from the pineapple peels, which involve broken tissue $bers, degraded cell membranes, loss of connections between the sarcolemma as well as the myo$brils and the formation of more gaps (Ketnawa & Rawdkuen, 2011). FIGURE 3 Open in !gure viewer PowerPoint Microstructure of the beef samples at magni$cation of 500× (a) untreated (control) and (b) treated with 4% bromelain and 4% Artocarpus heterophyllus protease extract 3.3.5 Sensory evaluation The primary purpose of the sensory evaluation was to give more detailed information on the acceptability of the formulated meat tenderizer to the consumer. This method enables the panelists to evaluate the softness, taste and palatability of the meat. Data on the sensory evaluation of beef containing a combination of 4% bromelain and 4% A. heterophyllus protease as a tenderizer and untreated beef (control) are presented in Table 2. From the analysis, most panelists preferred treated meat samples (a combination of 4% bromelain and 4% A. heterophyllus protease) compared to the untreated sample. All the attributes’ scores for the treated sample were higher than the control sample. The texture was the most vital attribute to consider in this sensory evaluation. A combination of bromelain and A. heterophyllus protease had a tenderizing e#ect on the beef samples. The treated beef sample provided the tender meat compared to the untreated sample. The level of tenderness was excessive, leading to a relatively high taste, aroma, and acceptance score. Regarding appearance, the presence of a tenderizer makes a slight di#erence beyond the color contribution. The appearance had a minuscule percentage compared to other criteria as the meat was not marinated with anything other than the combination enzyme extract itself. The score would probably be much better if the meat were cooked well by adding any seasoning to the meat. Except for color, all other organoleptic characteristic’s samples were signi$cantly di#erent (p > .05). 4 CONCLUSION In conclusion, the treatments given in this work were proved to exhibit the e#ective utilization of extracted bromelain and A. heterophyllus protease from pineapple and jackfruit waste byproduct, respectively, in improving the tenderization tough muscle in beef without unfavorably disturbing other quality parameters. The results reveled that physicochemical treated beef samples showed a decrease in the water holding capacity (WHC), pH, moisture content and cooking yield with the increased addition of crude enzyme extract. Results suggested that the extracted proteolytic enzymes from a local variety of A. comosus and A. heterophyllus can be used as a source of meat tenderizer and become a better alternative to chemical tenderizers. All the attributes of sensory evaluation scores for the treated sample were higher than the control sample. In addition, coupled with pineapple and jackfruit processing items, the core and the seed as a waste by-product could signi$cantly contribute to the overall return from the investment in the meat and agricultural processing industry. ACKNOWLEDGEMENTS The authors gratefully acknowledged Universiti Malaysia Pahang for the $nancial assistance through the Internal Research Grant No. UIC190301 and RDU182207-1. CONFLICT OF INTEREST The author declares that there is no con"ict of interest that could be perceived as prejudicing the impartiality of the research reported. AUTHOR CONTRIBUTIONS Aizi Nor Mazila Ramli: Conceptualization; Funding acquisition; Methodology; Project administration; Software; Supervision; Visualization; Writing-original draft; Writing-review & editing. Hazrulrizawati Abd Hamid: Writing-review & editing. Farah Hanani Zulki"i: Writingreview & editing. Normaiza Zamri: Writing-review & editing. Prakash Bhuyar: Conceptualization; Formal analysis; Software; Writing-original draft; Writing-review & editing. Nor Hasmaliana Abdul Manas: Writing-review & editing. REFERENCES