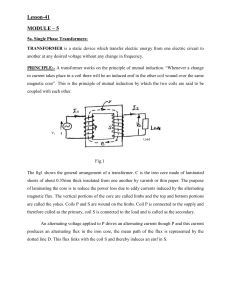

Anand Jain, Hod EE Govt. Polytechnic College, Hanumangarh Transformer Construction Transformer Construction Core-Shell Transformer Construction Core-Shell Anand Jain,Hod EE Govt. Polytechnic College, Hanumangarh A transformer consists of two electrical isolated windings coupled through a magnetic medium. When one of the winding is connected to ac supply of one voltage level, it can produce alternating supply of the same frequency but different voltage depending upon the turns ration. The two major types of construction of transformers (used in transmission and distribution of electrical energy) are core type and shell type. Depending on the application, these transformers can be classified as distribution transformers and power transformers. The most important function performed by transformers are, Changing voltage and current level in an electric system. Matching source and load impedances for maximum power transfer in electronic and control circuitry. Electrical isolation. The standard ratings of oil immersed, naturally cooled 3 phase 11 kV/433 250 V distribution transformers shall be 10, 16, 25, 63, 100, 160, 200, 250, 315, 400, 500, 630, 1000, 1250, 1600, 2000 and 2500 kVA The transformer either single or 3-phase, usually consists of the following elements: a) Magnetic circuit, consisting of limbs (core), yokes and clamping structures The core support the winding and it offers a low reluctance path to the magnetic flux. The core is a stack of cold rolled grain oriented annealed silicon steel insulated lamination. Both sides of 0.3 to 0.5 mm thick laminations are coated with hot oil proof insulation to reduce eddy loss. 3 to 4% Si content in steel increases its resistivity to eddy currents and reduce hysteresis losses. CRGO laminations are cut at an angle and core leg and core yoke laminations are interleaved in mitred joints. This reduces No load losses, No load current & Noise level. The permissible no load current is only 3-5% of full load current. Core is bolted together and to the frames firmly to prevent vibration or noise. b) Electric Circuit: A standard transformer will have two winding sets which are insulated from one another. In the winding construction single HV coil is wound over LV coil. In high voltage winding, large number of turns of thinner cross section is used. Low voltage winding has thicker conductors and has fewer turns than its high voltage counterpart. HV and LV windings are wound from Super Enamel covered /Double Paper covered, aluminium /copper conductor/ foil 100 kVA and below and only copper conductor/foil above 100KVA. Current density for HV and LV winding should not be more than 2.8 Ampere per sq mm for copper and 1.6 Ampere per sq mm for Aluminium Conductor. LV winding shall be such that neutral formation will be at top. c) dielectric circuit, consisting of insulation in different form and used at different places in the transformer, namely: core to LV, LV to HV, etc. Transformers normally use cardboard and insulating paper as a means of isolating both primary and secondary winding from each other as well as the transformer core. Inter layer insulation is epoxy dotted Kraft Paper/Nomex and pressboard. All spacers, axial wedges / runners used in windings are made of precompressed Pressboard-solid. In cross-over coil winding of HV all spacers and all axial wedges / runners are dovetail in shape. Heavy cellulose sheets are used as insulation between two phases. Another insulating material comes in the form of transformer oil. Axial & Radial cooling ducts in and between sections of the windings allow the free flow of oil around the conductors. In addition to dissipate heat due to losses in a transformer, insulating oil provides a medium with high dielectric strength in which the coils and core are submerged. This allows the transformers to be more compact, which reduces costs. Oil cannot retain high dielectric strength when exposed to air or moisture. Dielectric strength declines with absorption of moisture and oxygen. These contaminants also deteriorate the paper insulation. For this reason, insulating oil is prevented from contacting air. A conservator with breather is used to pressure variations resulting from thermal expansion and contraction of insulating oil. The two major construction of transformers are core type and shell type. CORE TYPE TRANSFORMER In core type transformer, the magnetic core is built of laminations to form a rectangular frame and the windings are arranged concentrically with each other around the legs or limbs. The low voltage winding is wound near the core and high voltage winding is wound over low voltage winding away from core in order to reduce the amount of insulation and increase life of it. SHELL TYPE TRANSFORMER In shell type transformers the windings are put around the central limb and the flux path is completed through two side limbs. The central limb carries total mutual flux while the side limbs forming a part of a parallel magnetic circuit carry half flux. CORE TYPE The top and bottom horizontal portion of the core are called yoke. The yokes connect the two limbs and have a cross sectional area equal to or greater than that of limbs. In a coretype transformer, half of the primary winding and half of the secondary winding are placed round each limb to reduce the leakage flux. . SHELL TYPE In shell type transformers the cross sectional area of the central limb is twice that of each side limbs. CORE TYPE SHELL TYPE 1. Easy in design and construction. Comparatively complex. 2. Low mechanical strength due to non-bracing of windings. High mechanical strength. 3. Reduction of leakage reactance is not easily possible. Reduction of leakage reactance is possible. 4. The assembly can be easily dismantled for repair work. It cannot be easily dismantled for repair work. 5. Better heat dissipation from windings. Heat is not easily dissipated from windings since it is surrounded by core. 6. Best suited for EHV (Extra High Voltage) requirements. Not suitable for Extra High Voltage requirements. 7. Economic and popular in use. Used in welding or high current transformer where more bracing support to winding is required. Our electric power transmission and distribution systems can deliver generated a.c. energy over long distances economically and efficiently only because of extensive use of transformers. As the transformers are such vital links in the network they must be very reliable especially in conditions of lightning and overload including occasional short circuits and switching surges. Transformer design is optimized to minimize manufacturing and operating cost of losses for utility. The two important design part of transformer are magnetic core frame and windings. Core is built with Cold Rolled Grain Oriented low loss silicon steel laminations. Winding is made up of high conductivity & soft drawn E.C. Grade copper or aluminum. Enamel conductors are double paper insulated. Windings are designed to fulfill mechanical, thermal and electrical requirements. Insulation is required in a transformer, wherever a difference in potential exists between two points. Solid cellulose insulating materials and transformer oil are mostly used in distribution transformers. Main and most important insulation between High and low voltage coils are pressboard, separator or cooling ducts. A Pressboard represents a thick insulation paper made of extremely pure cellulose fiber, suitably treated in the manufacturing process and then compacted at very high pressure. All spacers, axial wedges / runners used in windings are made of pre-compressed Pressboard-solid. Diamond Dotted Press-paper (DDP) with epoxy resin layer being used to insulate adjacent layers of conductors or foils. Heavy cellulose sheets are used as insulation between two phases. d=diameter of circumscribing circle D=distance b/w centers of adjacent limbs H=over all height W=length of yoke =D+a Hw=height of window Ww=width of window a=width of largest stamping Hy=height of yoke D=d+Ww H=Hw+2Hy Width over two limbs = D+ outer dia of hv Width over one limb = outer dia of hv d=diameter of circumscribing circle D=distance b/w centers of adjacent limbs H=over all height W=length of yoke = 2*D + a Hw=height of window Ww=width of window a=width of largest stamping Hy=height of yoke D=d + Ww H=Hw + 2Hy Width over two limbs = 2*D + outer dia of hv Width over one limb = outer dia of hv Width of core = Dy= b height of yoke Hy= a length of yoke = W = 2Ww+ 4a over all height =H = Hw+ 2a